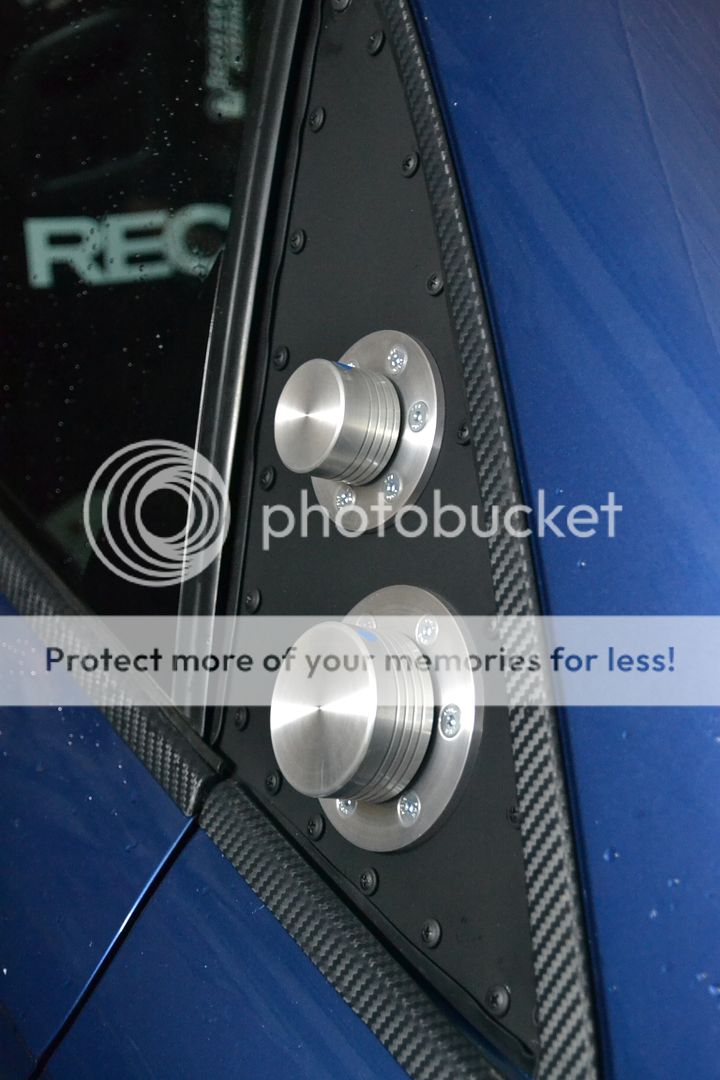

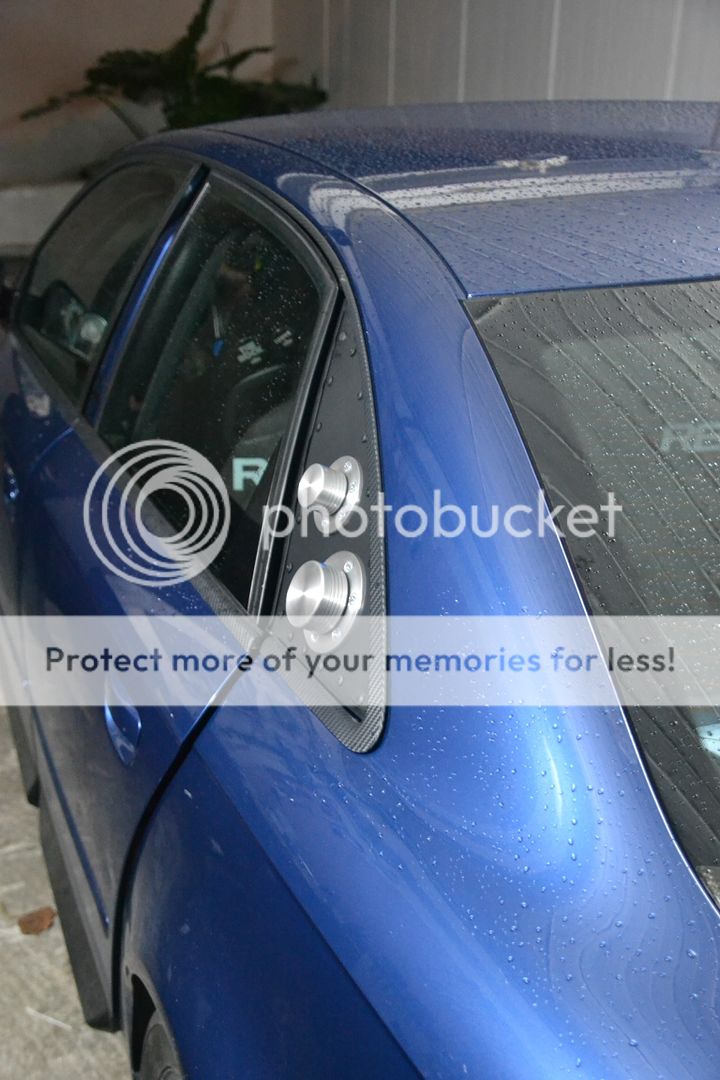

Gave the car a good wash after all the heavy rain these days in Athens

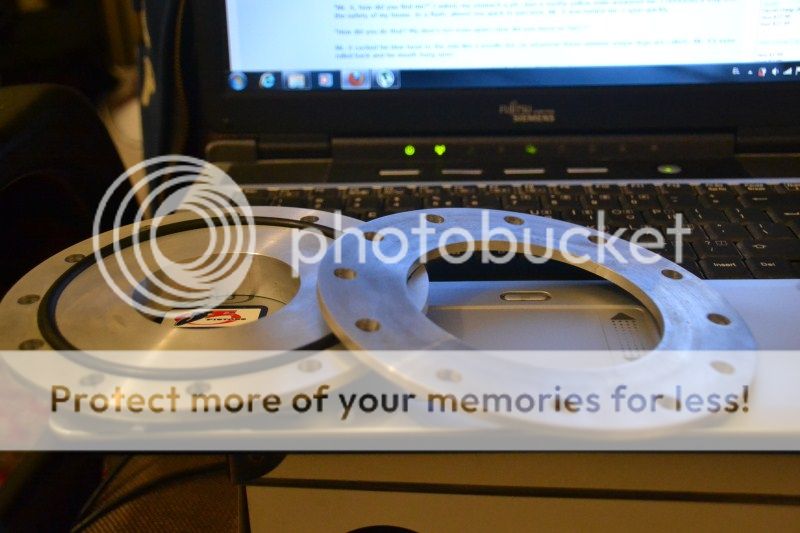

Next on the Fuel list is the fabrication of the Water/Meth Tank by Tom, and then after the installation of these on the Fuel Cell

Welding them pipes from the filler necks to the tanks. Let's see, it will be interesting I think

Cheers

Next on the Fuel list is the fabrication of the Water/Meth Tank by Tom, and then after the installation of these on the Fuel Cell

Welding them pipes from the filler necks to the tanks. Let's see, it will be interesting I think

Cheers

And

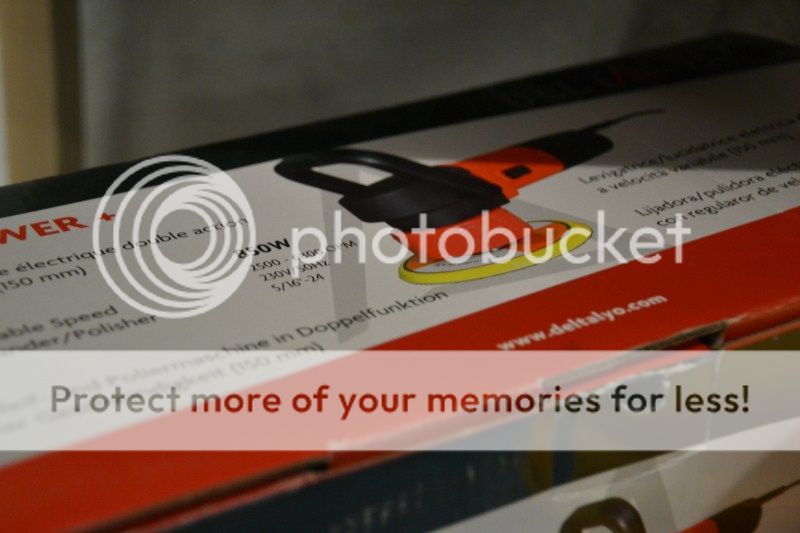

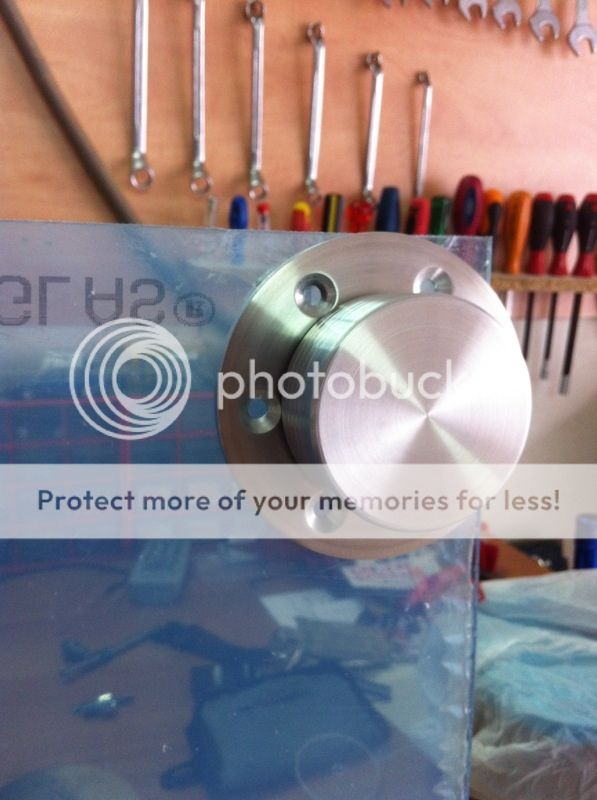

Ordered this . . .

Along with this

Cant wait to get them.

Cheers

Along with this

Cant wait to get them.

Cheers

Leave a comment: