Epic build, just epic.

Announcement

Collapse

No announcement yet.

1967 Pro-Touring 122 Amazon (Project Volvo X)540 Horsepower LS6/Tremec TKO600 5-Speed

Collapse

X

-

Got the exhaust finish welded up, minus the O2 sensor bungs, but I will do that when I remove the exhaust for coating. At that time I will do the rest of the finish grinding and final touches before the hot coating, and then it should look alot more respectable. I will be coating the whole exhaust unit (Including the Mufflers) in the same Silver/Chrome color my header kit is in, but that will be minuse the actual woven stainless area of the center flex joint.

The exhaust fits pretty tightly to the body, and there should still be enough room of engine load and torque, but the rear section after the X-Pipe will be very solidly Mounted, so I can avoid exhaut tip/body rattle. With the performance engine mounting setup, the motor will be held fairly tightly, so the stainless mesh flex joints should be able to absorb most of the movement needed. It has been years since I have actually made my own exhaust, but I really think this will be nicer than anything I could have gotten done in my area, because the Mufflers are within an 1/8 in being exact in front/rear postion, side position, and front/rear height and angle, which is something that can really kick your ass trying to get done. I actually had to make the right and left side of the front/center part of the exhaust just a bit off of each other for Starter Clearance and the off center Volvo emergency brake lever, but I tried to make it look like a very similar overall setup anyway.

The front/center section of the exhaust is held in place by the Header/Collector mount, and with pin bolt setup that attaches to the transmission tail housing, so it is very solid.. The motor and tranmission move the same during engine torque, so you can actually attach the exhaust to the transmission with no real issue at all. The rear section right after the X-pipe and flex joints, has a hard rubber mounting that attaches through the drive shaft tunnel, and that offered and easy and rigid attachement point. The mufflers are attached to the rear interior compartment walls by a heavy strap that was welded to the muffler, and it is nut and bolted through the body with a rubber insulator also. The tail pipe section off the muffler, has a rigid bracket welded to it, and that allows that section to be attached to the body structure with a bolt/nut and insulator also. I think there is enough rigidity and flex in the way I have it all setup, but I guess I will have to see if changes need to be made after the car fires up and moves around.

Comment

-

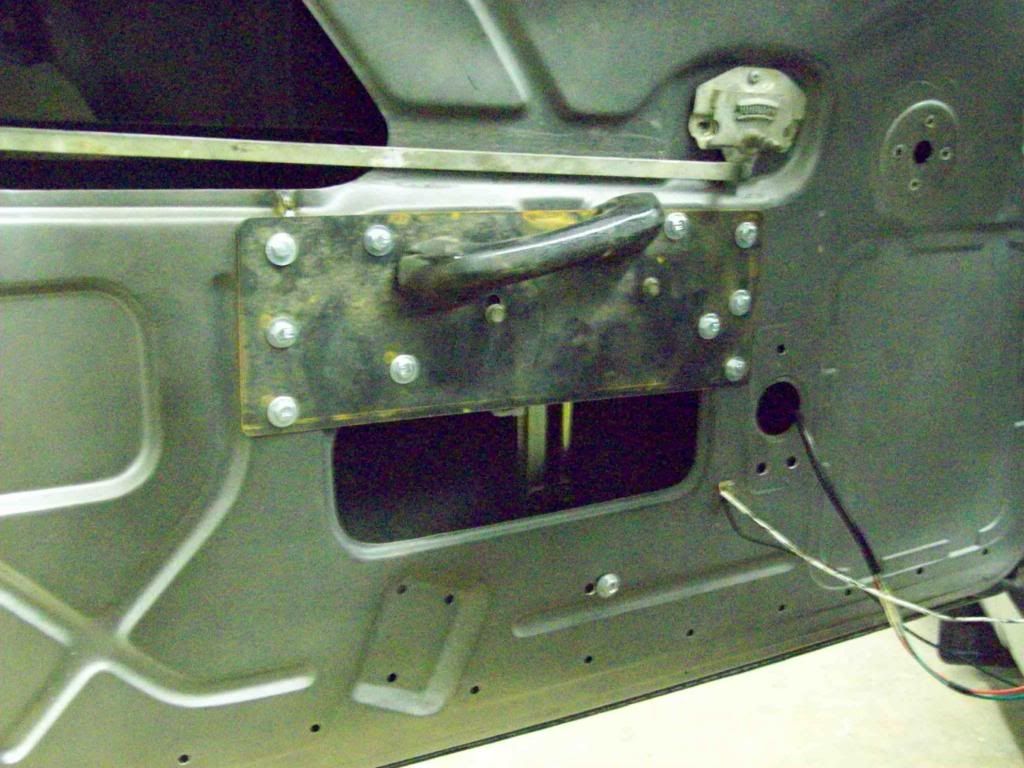

Here are some pics of the One Piece Door Glass and Power Window Conversion kit, and it came out pretty nice.. I went with a very light smoke glass instead of a clear, but you can still clearly see in the car.

Here is a pic of the basic kit that I have come up with for the build cars, and I even have a full replacement window felt and belt line kit to work with the original door and channels. There is a plate in the kit picture, and that plate allows you to install the new regulator assembly, and keep the original arm rest location, without losing any strength.

You can also see the glass I had made to delete the pop out rear quarter window, and make it a fixed glass instead. Some may not like that option, but the pop out window's apprearance really throws out the styling on these cars, because it doesnt match anything.

Here are some basic install pictures, and it really isnt that bad, eventhough there is a bit of cutting. When you remove the factory vent window, there is a mount piece in the window opening that will need to be removed, but it is very easy to do even if the vehicle is painted. You will also have to remove the factory window cable roller brackets from the inner door, but you can drill out the spot welds from the outer(Interior) door shell, and then they will come right out.. The only real cut after that, is the notch cut for the Power Window regulator mount to clear, and it is a very non evasive cut also.

When fitting the plate, I will normally put it in position for drilling while on the door, and the position is dictated by some reference points on the door shell. After you have it in position, you can then drill out all the mount holes, and I like to drop a bolt in each hole after it is drilled, so there isnt any chance of getting out of line with the other holes. I have alot more bolt holes than are necessary, but I wanted to be sure to actually brace the door, rather than make it flimsy with this modification.

After all my holes are drilled, you can then easily mark where the notching cuts need to be done, and those are also determined by the door shell stamping features, so it is very easy not to make a mistake.

After you have that done, the regulator will have room for access, and then you can put it in place.. After it is roughly mounted, you can then mark for the two more drill holes that are used for the window motor support bracket, along with the lower regulator Adjustment bolt.. You need to have the lower adjustment bolt, so you can adjust the pitch of your window, as it moves up and down, so it will be on the same plane as the door frame. That adjustment is just a matter of adjusting a nut on the back side of the door shell, and that will hold the bottom regulator in the correct pitch

Here is the fitment of the new glass, along with the new weatherstripping, and it looks much cleaner than the bulky Oem rubbers and flaps.

OEM Comparison Pic..

Comment

-

Trying to make sure that I make my SEMA Convention deadline for completion, while still having time before that to Test and Abuse the car, with enough time to do all the final fitment and cleaning for the show after the abuse.. LOLOriginally posted by Miroteknik View PostLots of work done!

Comment

-

My glass guy couldnt make it this week to install the quarter windows, and I couldnt wait to see the outcome of the new style glass, so I 2 way taped the glass and my finish rail mouldings in place. You will see that the top rail mouldings are not perfectly in place, because the two way tape holds them out just a bit, so they will actually fit much better when they are glue to the quarter glasses. The black out on the front and bottom edges is just electrical tape, so there is a more satin appearance that will be gone, when the black border is added to the back side of the glass.

I also tried to take some better pics of the window channel kit, but it is pretty flush looking, so it is hard to really capture it.

Comment

-

Here are a couple of YouTube video's of how the power windows work, and you can see they are actually pretty fast actuating, and that is being run off of a small motorcycle batter that has been used for all the adjusting and testing, along with new and tight weatherstripping. Once I get a full sized battery, and the new weatherstrip seats a bit better, the upward motion will smooth out alot better.. You can hear the weatherstripping grabbing onto the new glass in the second video, and that is the reason for that one slow spot.

[ame="http://www.youtube.com/watch?v=IwsXZYZOGvY"]1967 Volvo 122 Amazon Vent Window Delete and Power Window Conversion Kit. - YouTube[/ame]

[ame="http://www.youtube.com/watch?v=OYSize99jJk"]1967 Volvo 122 Amazon Vent Window Delete and Power Window Conversion kit. (Inside View) - YouTube[/ame]

Comment

-

A friend of mine made me this quick YouTube Slide Show Video of some of the Volvo X transformation, and it came out pretty good, so I thought I would post it.. When you are dealing with this stuff everyday, you dont realize how far things have come, because you are bombarded with the here and now.. LOL

[ame="http://www.youtube.com/watch?v=xLjU_S5urDE"]1967 Volvo 122 Amazon (Volvo X) 540 Horsepower Pro-Touring Build - YouTube[/ame]Last edited by Iamtheonlyreal1; 07-27-2013, 11:08 PM.

Comment

-

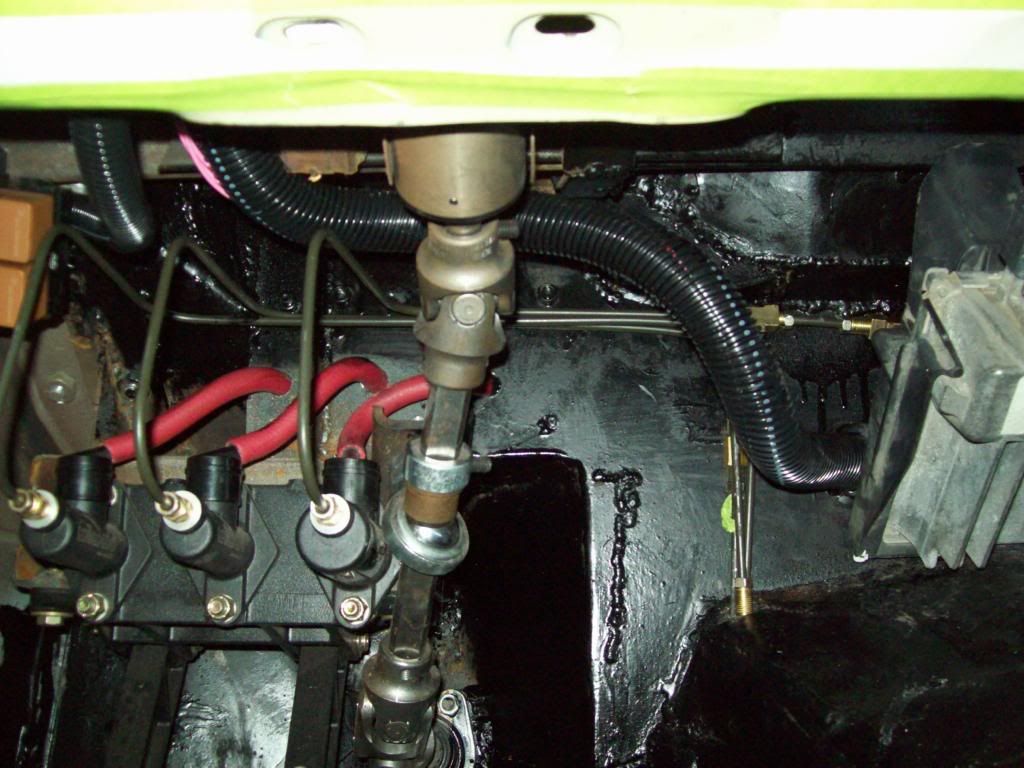

Here are some pics of the brake/clutch mechanism and plumbing, and you can see that I chose and under dash master cylinder setup, which was chosen to keep the engine bay clean. I ran my hydraulic lines on the back side of the firewall, and down through the top corners of the Trans Tunnel, and that allowed me to tuck everything out of the way, along with being able to service something if needed. I have some rubber grommets to seal the holes and secure the brake lines, but I am waiting till I recoat and insulate the firewall before I hard mount the lines. The fitting that is showing sitting on top of the trans hole is my Clutch Line, and I have not sized it yet, so that isnt where that attachment will be at all.

Here are some real world perspective pics of the new Door and Quarter glasses, because it is hard to see the full affect with pictures being taken in a small shop. I dont have the quarter glass trim permanently attached at this point, so they are not as flush to the B-pillar as they will be when installed properly. The rear glass will be removed again, so I can change the tint to something that is a closer match to the side windows, because it is just a couple of shades darker than the side glasses.

Comment

-

I would rather have a modded Odd car, than a modded Cookie Cutter, and that is why I didnt build another 1st Gen Camaro, Mustang, Chevelle, ect... LOLOriginally posted by HooWybrow View PostGreat build of an odd looking car (in my eyes). Love the drivetrain and how everything has been executed. Keep it up.

Comment

-

Yeah.Originally posted by Iamtheonlyreal1 View PostI would rather have a modded Odd car, than a modded Cookie Cutter, and that is why I didnt build another 1st Gen Camaro, Mustang, Chevelle, ect... LOL

Weird cars are cool, I mean look what I did to a Kia. lol

I really look forward to seeing the front splitter on this, I think it'll really pull the look together.

Comment

-

Some of the body trim pieces are suppose to make it back this next week, so I needed to get the Air Cleaner Assembly wrapped up, so I can get my painter started on that. Just a quick catch up on the the Bumper and Trim plating process that I have going on now, because I havent really touched base on what I have decided to change there. I did not send all the trim out for actual Brushed Chroming as I had intended, and that was really due to the shear cost, and the fact that the plater said the bumpers may not come out perfect. I was quoted over 8k for the plating by the time shipping kicked in, and that was with no guaruntee that I would have some perfect pieces, so there was no way I could possibly justify the cost there. I have a very qualified painter that does alot of custom motorcycle work, and he said that he has done a Brushed Aluminun or Brushed Stainlees look in a painted process, so that is the way I am going here. It will actually be a better match to the appearance of my Brushed Aluminum Wheels, and the parts will be perfect, because he can use glazes and primers to block all the imperfections out. These will be done in a Satin/Flat Clear, so all the parts will have the same overall glow of the wheels, and that will also keep all my trim/bumpers uniform in appearance. I will be posting pics of this process, and it is much more economical than the plating, especially if I ever needed future repairs. I have seen sample/test pieces, and they look great, so I think this will be a much better approach.

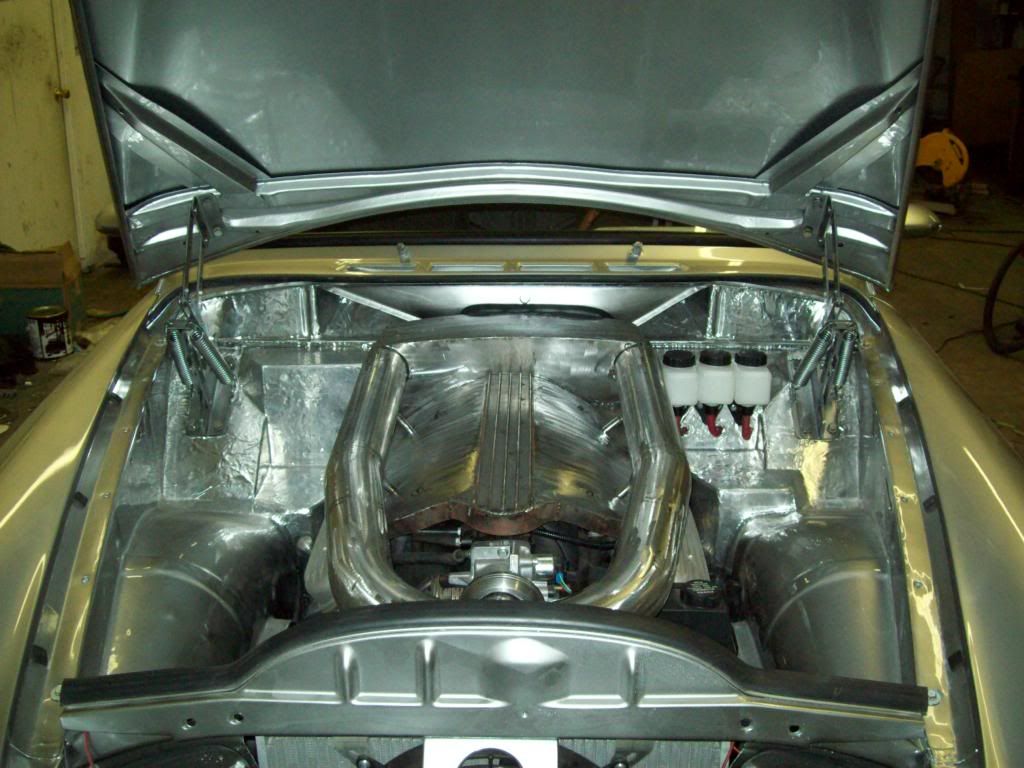

Here are some pictures of how my Air Intake System work, and in these pics, you will see the filter position and how it basically works.. I would do some more finish grinding and welding on it, but my painter likes to do that himself, so I will leave it for him..

Here is how the Seal and Drain system will work, and it is pretty basic, because I used the Original Amazon Heater ring for my seal/drain.. I will be adding a tube and one way baffle for the draining, and it should work just fine.. I will be making the actual drain hole larger, so it will be more than capable of draining the water sump before over flow. The seal is a weatherstrip profile that I have found on another car, but I had to do some removal and triming to remove some of the bulk, and you can see that I have just a bit more finish trimming to make it look nice. I still have to drill the holes for the Mass Air Flow Sensor at the front, and the Intake Air Temp sensor in the rear box somewhere, but they will be hidden on the lower unseen parts of this setup.

Here is how the gasket seals on the original Cowl Vent/Heater Supply fixture, and it is only solid mounted and sealed to the Inake, so it will have the ability to move around on the body during engine torque. I am pretty sure that it will be best to use some sort of grease or lubricant on the seal to body position, and I will have to do a bit of experimenting with that if it is necessary.

I tried to make sure that my intake tubes and filter box wouldnt interrupt the fender contours while the hood is open, because I dont really care of mismatched contours and angles, so this is how it all lays out compared to fender tops. With the filter box, I actually kept the curvature and contour of the cowl sheet metal, so it isnt just a rectangular box stuffed in the hole.. I think features like that really make things look like they are in place, rather than just some items you fabbed or pull off the shelf, especially when you can nothing sticks out as out of place as you walk up.

I am not absolutely sure on how I am going to paint the Intake and Valve Covers yet, but they will be in the same metal theme as the rest of the car, so the Tubes will more than likely be a Brushed Aluminum, while the box and center section will be body colors. I was debating on painting the Valve Covers body color, and then doing something with fin patterns of the valve covers and center intake, but how I need to do it hasnt hit me yet.Last edited by Iamtheonlyreal1; 07-13-2013, 04:32 PM.

Comment

-

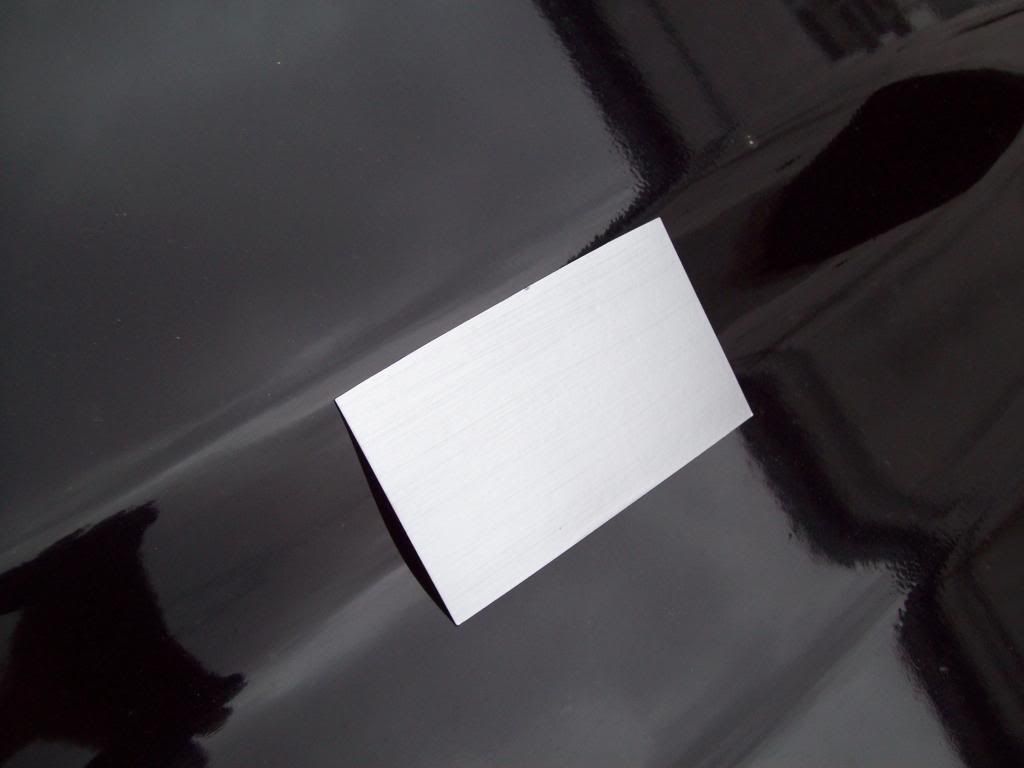

Here are some pictures of the first Test Spray of the Faux brushed aluminum paint work for the bumpers and trim, and I think it is all looking like it is going to work out great, and that is painted on a cardboard test card without any of the satin clear on it yet.. Once the satin clear is applied, there should be just a bit more of a glow/sheen look, and that will really mimic the brushed aluminum look.

Comment

-

While doing some spring cleaning and setup so I can get prepared for the start up of my customer builds, I needed to roll Project Changling outside, and I really forgot how Sleek that car is.. And it even looks pretty damn good in all its Masking Tape glory.. lol I am at the back door of having all the final production components completed and in, so then it will be customer build time, and this Project Saint Marie and a Very Nice 1800es build, so the updates should resume on those cars very very soon.

Last edited by Iamtheonlyreal1; 07-17-2013, 05:27 PM.

Last edited by Iamtheonlyreal1; 07-17-2013, 05:27 PM.

Comment

Comment