But today my dad began his weeks holiday from work so we got stuck in (after a break for the epic grand prix of course)

But today my dad began his weeks holiday from work so we got stuck in (after a break for the epic grand prix of course)So the helper getting stuck in with the cleaning up of parts!

I had tried to shim up my hub ball joints before but the kit didn't have enough shims. So I contacted Simon at MiniSpares and got some sent out FOC straight away. More great service but postage is still really slow. Could be because Im in Aberdeen but its the mainland so no reason why it takes so long.

However we got both hubs completed and now we are just waiting wheel bearings to go in.

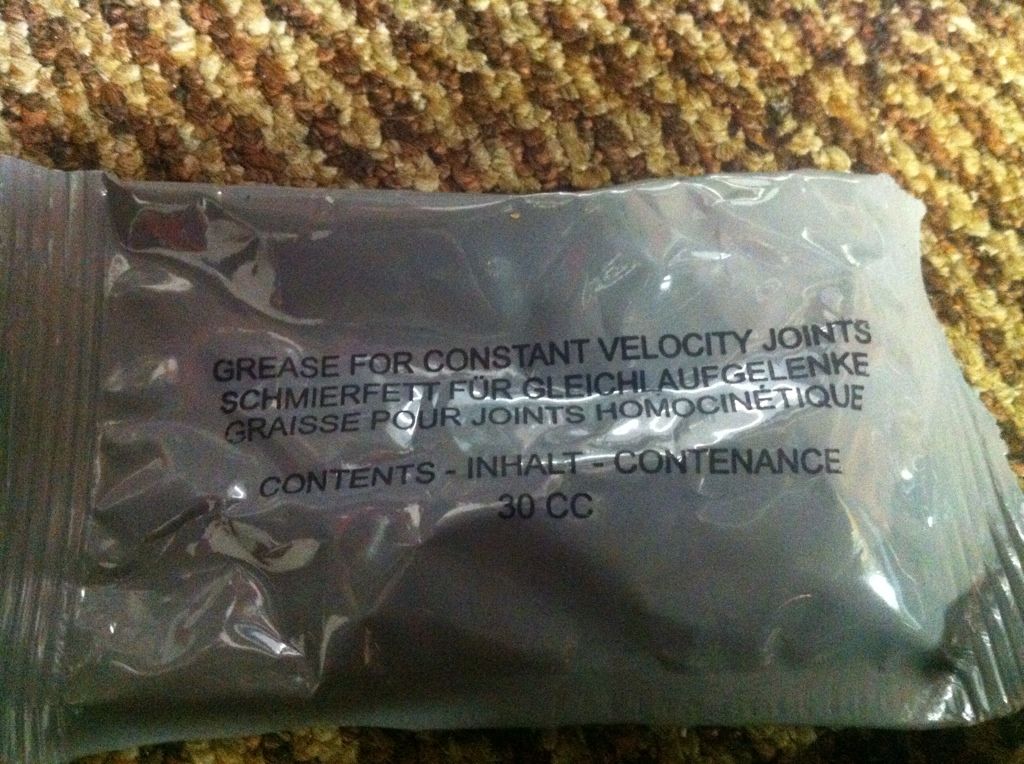

Also you may remember my CV joint ball bearing issues. Well after my 7th attempt we got it all assembled. Not a fun job! But this meant we could get the driveshafts fully reassembled ready to go back in. Just need to buy proper clips to seal them all up.

And with that dad cleaned up one of the pot joints and gave it a lick of primer and then paint.

Also got my thermostat cover stripped cleaned and primed. Waiting for it to dry to give it the top coat of silver.

Took a look at my old brake pipes for a bit of reference for refitting. This was the rear section that sits on the rear frame. Pretty horrible and rusty....

however after a clean up.......

it looks awesome again!

I also got the front subframe rear mounts fitted to the frame ready to go....

and I began to run the brake lines on the front subby too...

Im just awaiting a banjo bolt for this union now.

and then left some more parts to dry overnight.

and this standard intake/exhaust manifold is for sale now its all nice and shiny again

So lots of progress! Plan to have the engine and from subframe in the car by end of the week.

In other news I have just ordered a genuine rear subframe from MiniSpares. Costs a bomb but being genuine it will fit and will last forever with the right protection. Should arrive by end of the week hopefully which means I can finally get the car rolling! Then theres no holding me back

If its not low enough I will just get rid of the adjuster bolt

If its not low enough I will just get rid of the adjuster bolt

Some of it is still soft, the hardened stuff is going to be a paint to remove. I find it great though, certainly better than kurust

Some of it is still soft, the hardened stuff is going to be a paint to remove. I find it great though, certainly better than kurust

Leave a comment: