Originally posted by 190Evan

View Post

im going boost right off the bat now

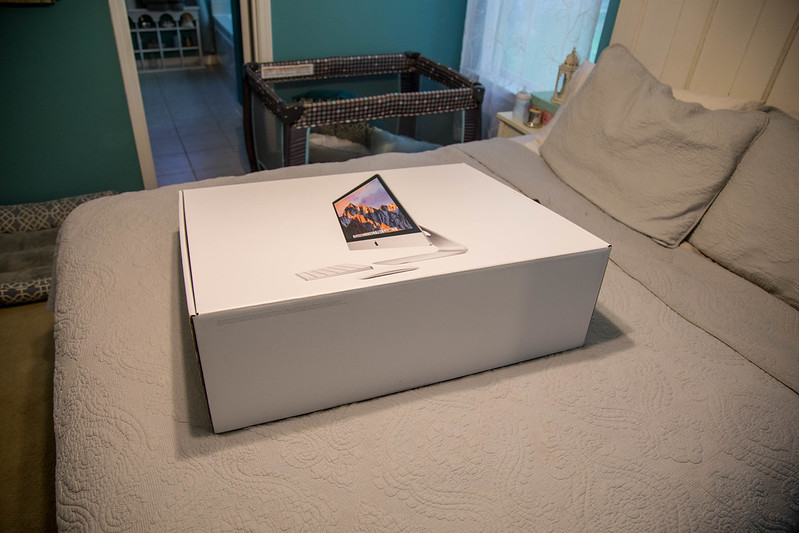

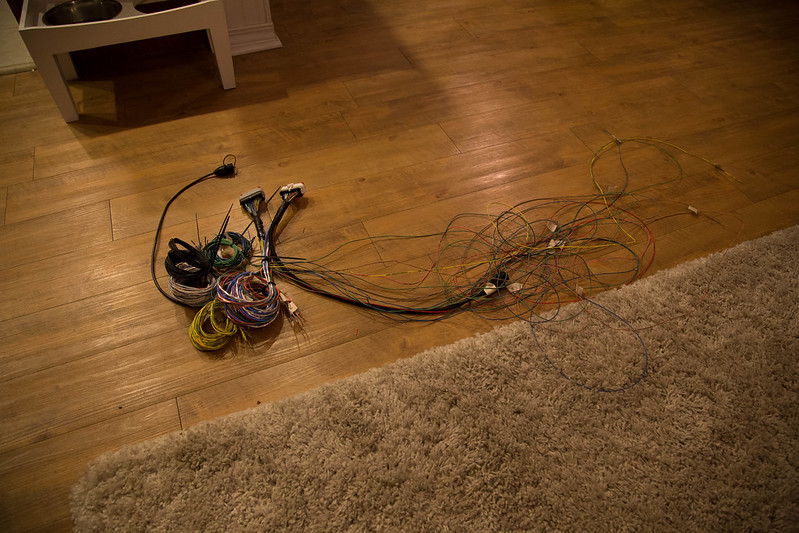

new computer (1 of 7) by lawrx, on Flickr

new computer (1 of 7) by lawrx, on Flickr new computer (2 of 7) by lawrx, on Flickr

new computer (2 of 7) by lawrx, on Flickr new computer (3 of 7) by lawrx, on Flickr

new computer (3 of 7) by lawrx, on Flickr new computer (4 of 7) by lawrx, on Flickr

new computer (4 of 7) by lawrx, on Flickr new computer (5 of 7) by lawrx, on Flickr

new computer (5 of 7) by lawrx, on Flickr new computer (6 of 7) by lawrx, on Flickr

new computer (6 of 7) by lawrx, on Flickr new computer (7 of 7) by lawrx, on Flickr

new computer (7 of 7) by lawrx, on Flickr new computer (1 of 2) by lawrx, on Flickr

new computer (1 of 2) by lawrx, on Flickr new computer (2 of 2) by lawrx, on Flickr

new computer (2 of 2) by lawrx, on Flickr

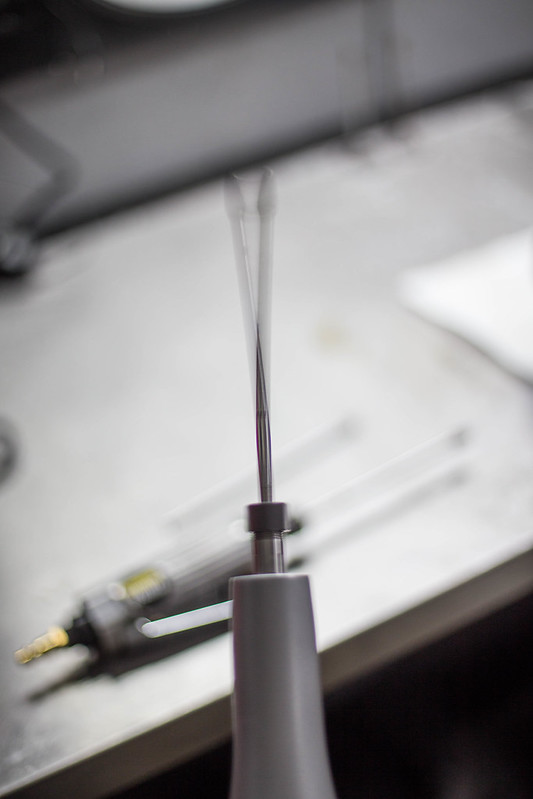

untitled (1 of 1) by lawrx, on Flickr

untitled (1 of 1) by lawrx, on Flickr

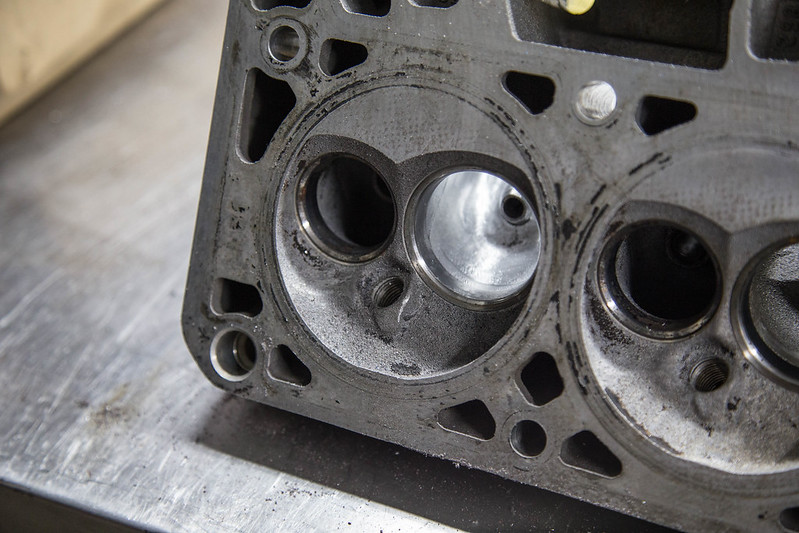

IMG_7991 by lawrx, on Flickr

IMG_7991 by lawrx, on Flickr IMG_7992 by lawrx, on Flickr

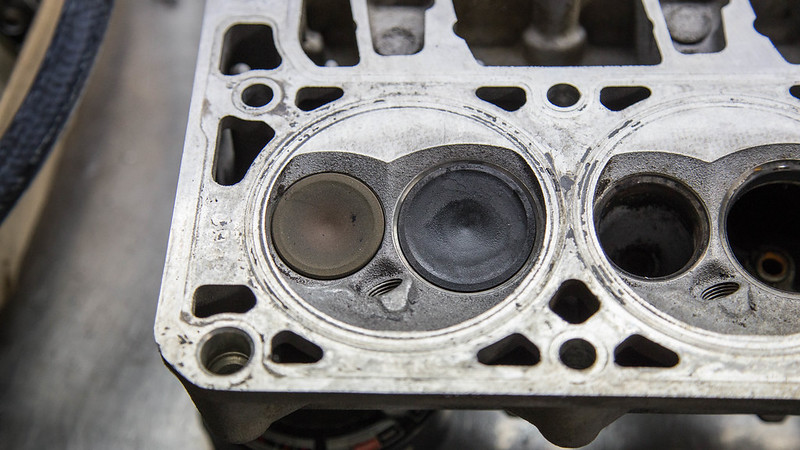

IMG_7992 by lawrx, on Flickr IMG_7993 by lawrx, on Flickr

IMG_7993 by lawrx, on Flickr IMG_7994 by lawrx, on Flickr

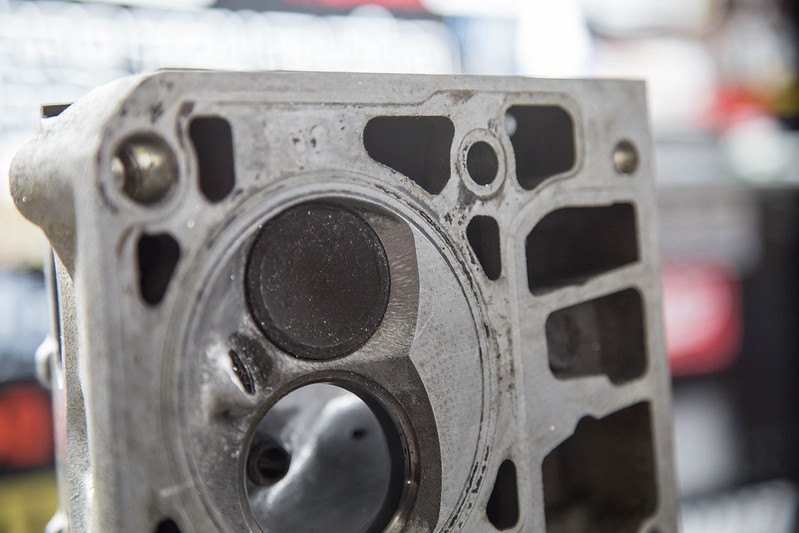

IMG_7994 by lawrx, on Flickr IMG_7995 by lawrx, on Flickr

IMG_7995 by lawrx, on Flickr IMG_7997 by lawrx, on Flickr

IMG_7997 by lawrx, on Flickr IMG_7999 by lawrx, on Flickr

IMG_7999 by lawrx, on Flickr IMG_8000 by lawrx, on Flickr

IMG_8000 by lawrx, on Flickr IMG_8085 by lawrx, on Flickr

IMG_8085 by lawrx, on Flickr IMG_8086 by lawrx, on Flickr

IMG_8086 by lawrx, on Flickr IMG_8088 by lawrx, on Flickr

IMG_8088 by lawrx, on Flickr IMG_8090 by lawrx, on Flickr

IMG_8090 by lawrx, on Flickr IMG_8091 by lawrx, on Flickr

IMG_8091 by lawrx, on Flickr IMG_8092 by lawrx, on Flickr

IMG_8092 by lawrx, on Flickr IMG_8094 by lawrx, on Flickr

IMG_8094 by lawrx, on Flickr IMG_8095 by lawrx, on Flickr

IMG_8095 by lawrx, on Flickr IMG_8096 by lawrx, on Flickr

IMG_8096 by lawrx, on Flickr IMG_8098 by lawrx, on Flickr

IMG_8098 by lawrx, on Flickr IMG_8099 by lawrx, on Flickr

IMG_8099 by lawrx, on Flickr IMG_8100 by lawrx, on Flickr

IMG_8100 by lawrx, on Flickr IMG_8101 by lawrx, on Flickr

IMG_8101 by lawrx, on Flickr IMG_8102 by lawrx, on Flickr

IMG_8102 by lawrx, on Flickr IMG_8104 by lawrx, on Flickr

IMG_8104 by lawrx, on Flickr IMG_8107 by lawrx, on Flickr

IMG_8107 by lawrx, on Flickr IMG_8108 by lawrx, on Flickr

IMG_8108 by lawrx, on Flickr IMG_8108 by lawrx, on Flickr

IMG_8108 by lawrx, on Flickr IMG_8111 by lawrx, on Flickr

IMG_8111 by lawrx, on Flickr IMG_8112 by lawrx, on Flickr

IMG_8112 by lawrx, on Flickr

IMG_7950 by lawrx, on Flickr

IMG_7950 by lawrx, on Flickr IMG_7951 by lawrx, on Flickr

IMG_7951 by lawrx, on Flickr IMG_7954 by lawrx, on Flickr

IMG_7954 by lawrx, on Flickr IMG_7955 by lawrx, on Flickr

IMG_7955 by lawrx, on Flickr IMG_7958 by lawrx, on Flickr

IMG_7958 by lawrx, on Flickr IMG_7962 by lawrx, on Flickr

IMG_7962 by lawrx, on Flickr IMG_7964 by lawrx, on Flickr

IMG_7964 by lawrx, on Flickr IMG_7970 by lawrx, on Flickr

IMG_7970 by lawrx, on Flickr IMG_7963 by lawrx, on Flickr

IMG_7963 by lawrx, on Flickr IMG_7971 by lawrx, on Flickr

IMG_7971 by lawrx, on Flickr IMG_7964 by lawrx, on Flickr

IMG_7964 by lawrx, on Flickr IMG_7967 by lawrx, on Flickr

IMG_7967 by lawrx, on Flickr IMG_7968 by lawrx, on Flickr

IMG_7968 by lawrx, on Flickr IMG_7972 by lawrx, on Flickr

IMG_7972 by lawrx, on Flickr IMG_7976 by lawrx, on Flickr

IMG_7976 by lawrx, on Flickr IMG_7978 by lawrx, on Flickr

IMG_7978 by lawrx, on Flickr

IMG_7744 by lawrx, on Flickr

IMG_7744 by lawrx, on Flickr IMG_7749 by lawrx, on Flickr

IMG_7749 by lawrx, on Flickr IMG_7750 by lawrx, on Flickr

IMG_7750 by lawrx, on Flickr IMG_7752 by lawrx, on Flickr

IMG_7752 by lawrx, on Flickr IMG_7753 by lawrx, on Flickr

IMG_7753 by lawrx, on Flickr IMG_7742 by lawrx, on Flickr

IMG_7742 by lawrx, on Flickr IMG_7754 by lawrx, on Flickr

IMG_7754 by lawrx, on Flickr IMG_7756 by lawrx, on Flickr

IMG_7756 by lawrx, on Flickr IMG_7758 by lawrx, on Flickr

IMG_7758 by lawrx, on Flickr IMG_7760 by lawrx, on Flickr

IMG_7760 by lawrx, on Flickr IMG_7761 by lawrx, on Flickr

IMG_7761 by lawrx, on Flickr IMG_7762 by lawrx, on Flickr

IMG_7762 by lawrx, on Flickr IMG_7763 by lawrx, on Flickr

IMG_7763 by lawrx, on Flickr IMG_7764 by lawrx, on Flickr

IMG_7764 by lawrx, on Flickr IMG_7766 by lawrx, on Flickr

IMG_7766 by lawrx, on Flickr IMG_7770 by lawrx, on Flickr

IMG_7770 by lawrx, on Flickr IMG_7772 by lawrx, on Flickr

IMG_7772 by lawrx, on Flickr IMG_7769 by lawrx, on Flickr

IMG_7769 by lawrx, on Flickr IMG_7775 by lawrx, on Flickr

IMG_7775 by lawrx, on Flickr IMG_7777 by lawrx, on Flickr

IMG_7777 by lawrx, on Flickr IMG_7781 by lawrx, on Flickr

IMG_7781 by lawrx, on Flickr IMG_7783 by lawrx, on Flickr

IMG_7783 by lawrx, on Flickr IMG_7784 by lawrx, on Flickr

IMG_7784 by lawrx, on Flickr IMG_7785 by lawrx, on Flickr

IMG_7785 by lawrx, on Flickr IMG_7787 by lawrx, on Flickr

IMG_7787 by lawrx, on Flickr

Leave a comment: