Originally posted by sdistc

View Post

Announcement

Collapse

No announcement yet.

Project Crowdmower : Ford Chassis, Chevy Motor, and Nissan Transmission

Collapse

X

-

Ive yet to actually need it. Although im sure i will, as to why i bought it. For as cheap as it was it was a no brainer since i saw already ordering things.

-

Its been a big week over at my house this week.

Ill start off with the big news of my daughter being born this past Monday 9/3 on Labor Day. All is good Momma and baby are healthy. My 2yr is exact over her. Wants to hold her, help feed her, worries when she cries etc. Needless to say thats taken up much of my time overall the past two weeks with multiple trips for contractions etc. Just before all that was set into motion I was able to snag my dads Miller tig welder to bring to the house to start practicing. Obviously this was put on hold for a bit with the pending arrival of my daughter.

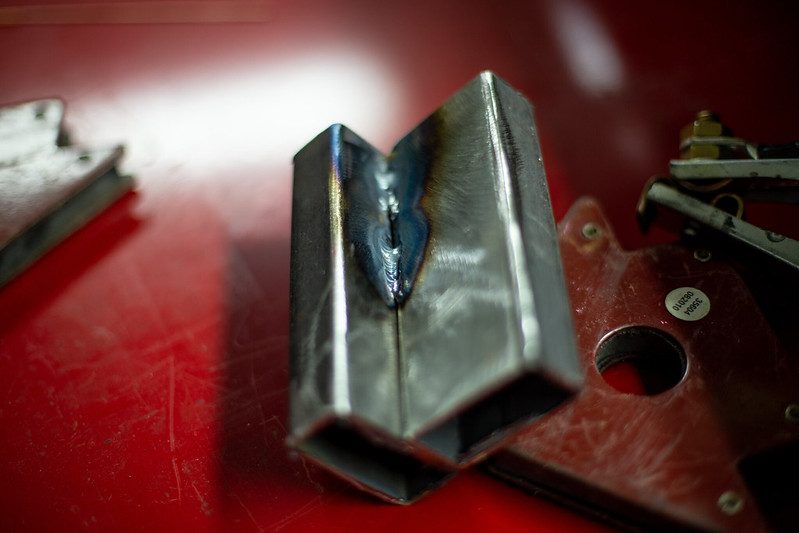

But late this week I got in the last few tools and such I was missing to start melting some metal. Needed a carbon blade for my chopsaw, some filler rod as dad was out, I wanted a new set of gloves etc. Got it all in and went to town! This is my first time TIG welding so was a bit of a learning curve. As soon as I was getting the hang of it I touched the tungsten with my filler rod, with no more spares left to use. Couldn't grind them as it was late and would have woken the kiddos. I made a lot of mistakes but I learned what they were and how to improve on them. Excited to get more hood time this weekend.

I also FINALLY picked up a bench vice and bolted it to the bench. Only been putting it off since we moved in....

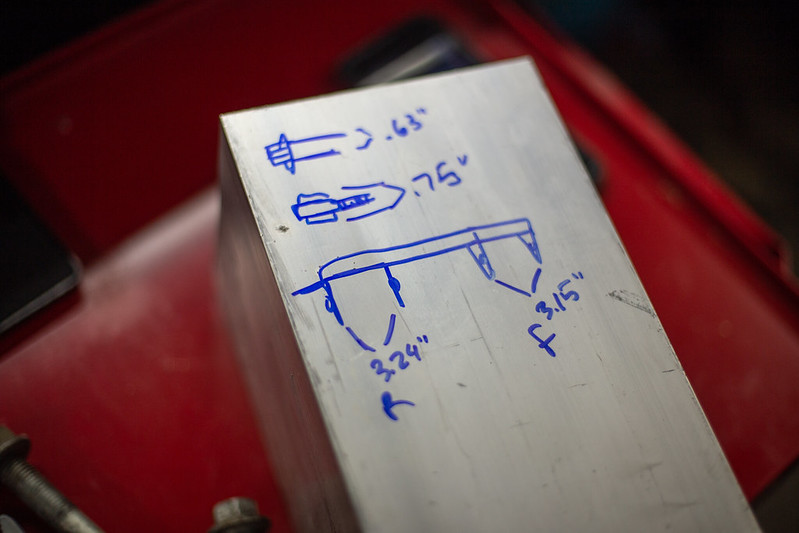

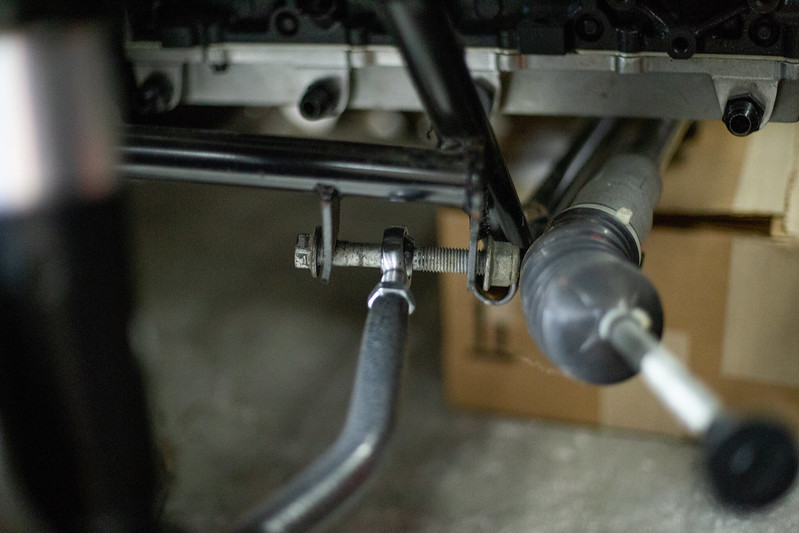

And lastly my front and control armsstruts. I don't recall if I mentioned it but the coiler sleeve kit seized up, the adjustment rings are locked up in the aluminum threads, so I pulled them off, going to contact the manufacture and say what gives. All I did to them wasset a ride height it sat that way for a few months, not sure what caused them to seize up. As for the control arms, the spacers between the rod ends and k member were poorly built, not the right ID size etc. SO ill be making my own for them.

IMG_0053 by lawrx, on Flickr

IMG_0053 by lawrx, on Flickr

IMG_9882 by lawrx, on Flickr

IMG_9882 by lawrx, on Flickr

IMG_0071 by lawrx, on Flickr

IMG_0071 by lawrx, on Flickr

IMG_0062 by lawrx, on Flickr

IMG_0062 by lawrx, on Flickr

IMG_0059 by lawrx, on Flickr

IMG_0059 by lawrx, on Flickr

IMG_0060 by lawrx, on Flickr

IMG_0060 by lawrx, on Flickr

IMG_0065 by lawrx, on Flickr

IMG_0065 by lawrx, on Flickr

IMG_0068 by lawrx, on Flickr

IMG_0068 by lawrx, on Flickr

IMG_0077 by lawrx, on Flickr

IMG_0077 by lawrx, on Flickr

IMG_0074 by lawrx, on Flickr

IMG_0074 by lawrx, on Flickr

IMG_0067 by lawrx, on Flickr

IMG_0067 by lawrx, on Flickr

IMG_0082 by lawrx, on Flickr

IMG_0082 by lawrx, on Flickr

IMG_0083 by lawrx, on Flickr

IMG_0083 by lawrx, on Flickr

IMG_0084 by lawrx, on Flickr

IMG_0084 by lawrx, on Flickr

IMG_0085 by lawrx, on Flickr

IMG_0085 by lawrx, on Flickr

IMG_0086 by lawrx, on Flickr

IMG_0086 by lawrx, on Flickr

IMG_0088 by lawrx, on Flickr

IMG_0088 by lawrx, on Flickr

IMG_0091 by lawrx, on Flickr

IMG_0091 by lawrx, on Flickr

IMG_0093 by lawrx, on Flickr

IMG_0093 by lawrx, on Flickr

IMG_0092 by lawrx, on Flickr

IMG_0092 by lawrx, on Flickr

IMG_0094 by lawrx, on Flickr

IMG_0094 by lawrx, on Flickr

Leave a comment:

-

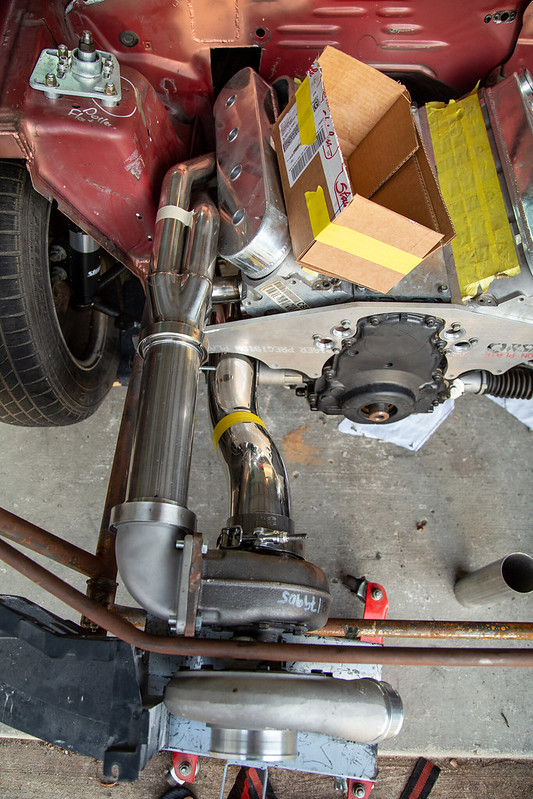

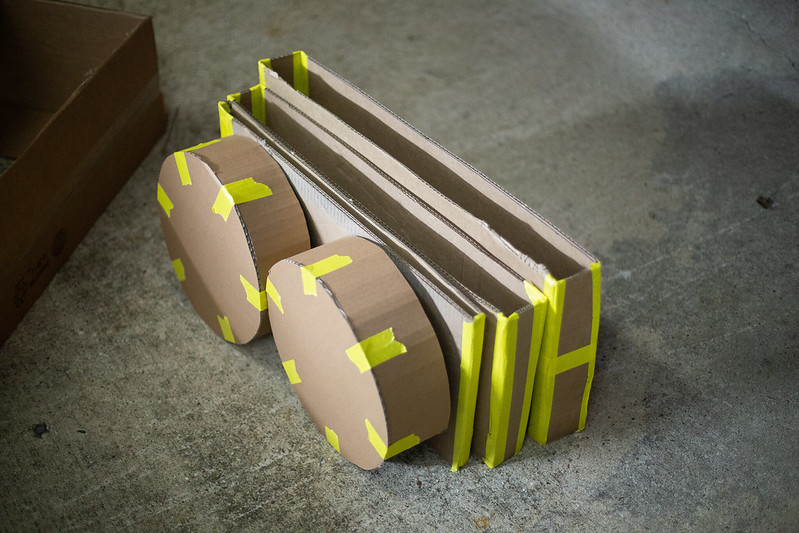

Been a bit since the last update. Been piddling away at various things. Material for downpipes and ewgs tubes came in. Got to work mocking up and cutting the downpipes section to see what sort of real estate they would take up. I still need to purchase the waste gates so ill just hold into that material until then. With the downpipes mocked up I grabbed some charge piping I had sitting around and some cardboard and mocked up a rough intercooler position and charge pipe routing. It snakes a bit but will be clean and symmetrical and a fairly straight shot.

IMG_9600 by lawrx, on Flickr

IMG_9600 by lawrx, on Flickr

IMG_9601 by lawrx, on Flickr

IMG_9601 by lawrx, on Flickr

IMG_9605-2 by lawrx, on Flickr

IMG_9605-2 by lawrx, on Flickr

IMG_9604 by lawrx, on Flickr

IMG_9604 by lawrx, on Flickr

IMG_9602 by lawrx, on Flickr

IMG_9602 by lawrx, on Flickr

IMG_9607-2 by lawrx, on Flickr

IMG_9607-2 by lawrx, on Flickr

IMG_9609-2 by lawrx, on Flickr

IMG_9609-2 by lawrx, on Flickr

IMG_9610-2 by lawrx, on Flickr

IMG_9610-2 by lawrx, on Flickr

IMG_9617 by lawrx, on Flickr

IMG_9617 by lawrx, on Flickr

IMG_9613 by lawrx, on Flickr

IMG_9613 by lawrx, on Flickr

Ive also piddled with the suspension some. With the car back to the garage by itself I wanted to set the suspension height level side to side. Well the adjusters are seized on the aluminum threaded bodies. They were tightened down and it sat, so pretty upset about it. Going to have to contact Strange and see what they can do about it. Also went to install the lower control arm spacers and the ID isn't big enough for the bolt to go through, and they are also not the right length. SO that overall work sucked.

IMG_9785 by lawrx, on Flickr

IMG_9785 by lawrx, on Flickr

IMG_9786 by lawrx, on Flickr

IMG_9786 by lawrx, on Flickr

IMG_9788 by lawrx, on Flickr

IMG_9788 by lawrx, on Flickr

IMG_9784 by lawrx, on Flickr

IMG_9784 by lawrx, on Flickr

IMG_9790 by lawrx, on Flickr

IMG_9790 by lawrx, on Flickr

Leave a comment:

-

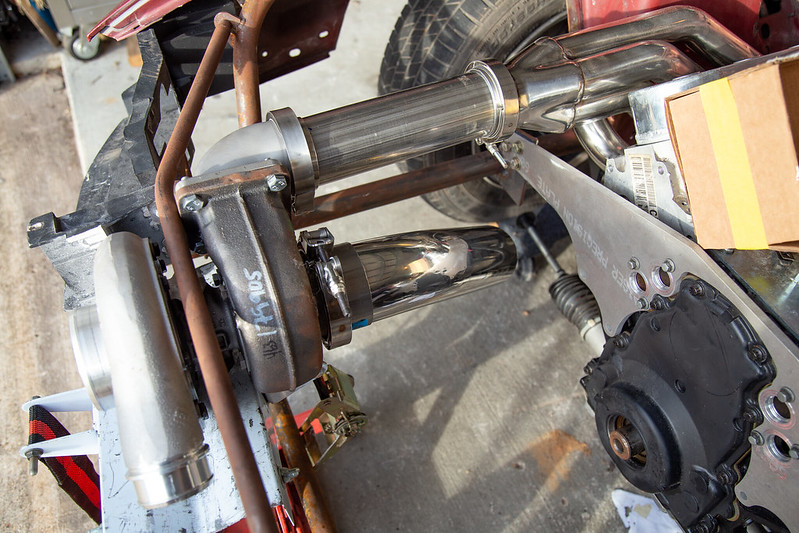

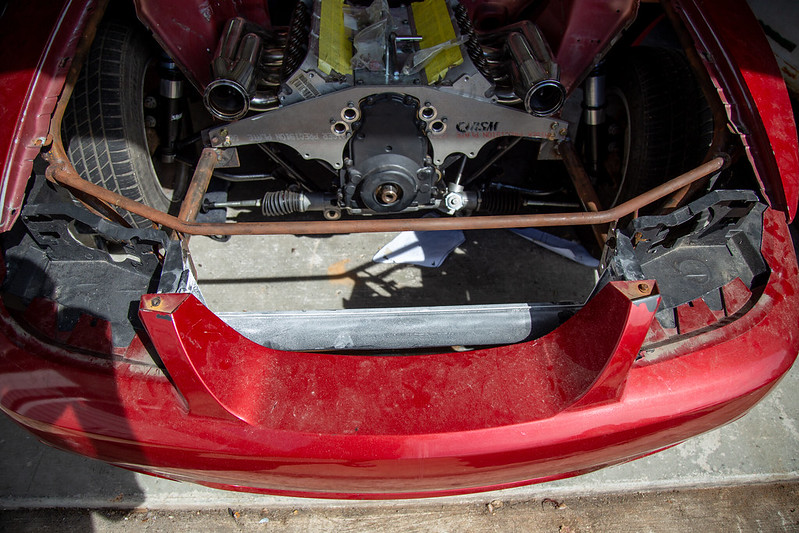

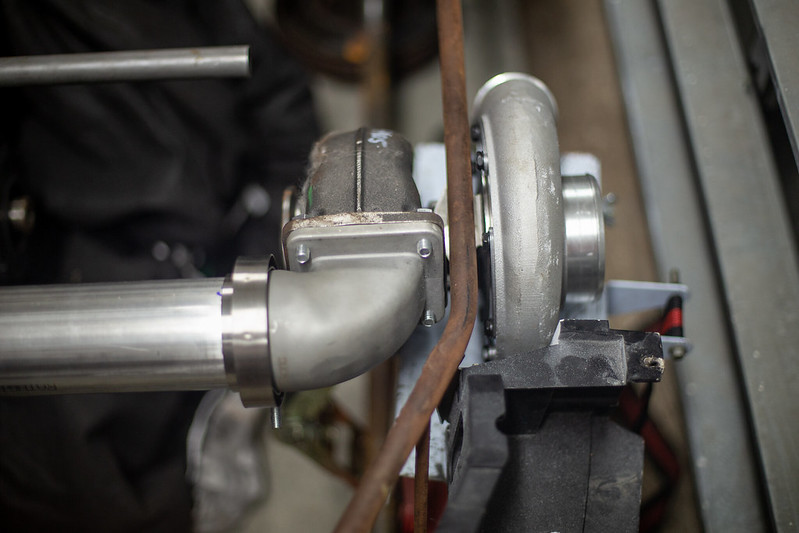

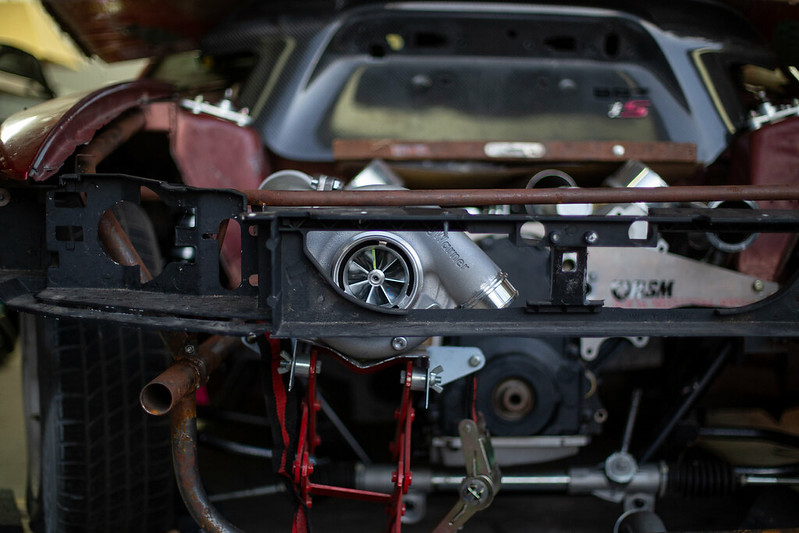

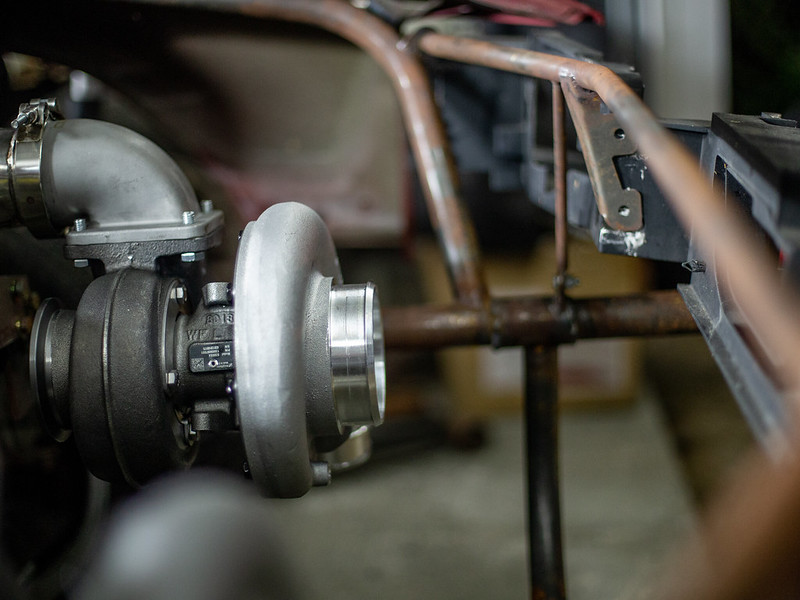

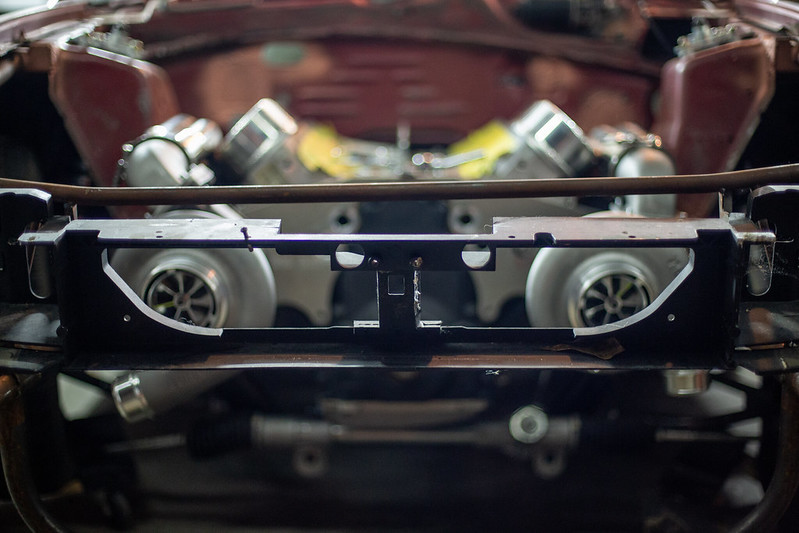

Over the weekend I performed some more mock up and test fitting. Slowly the turbos have been pushed farther and farther forward. I don't think I can push them much farther forward from this point lol

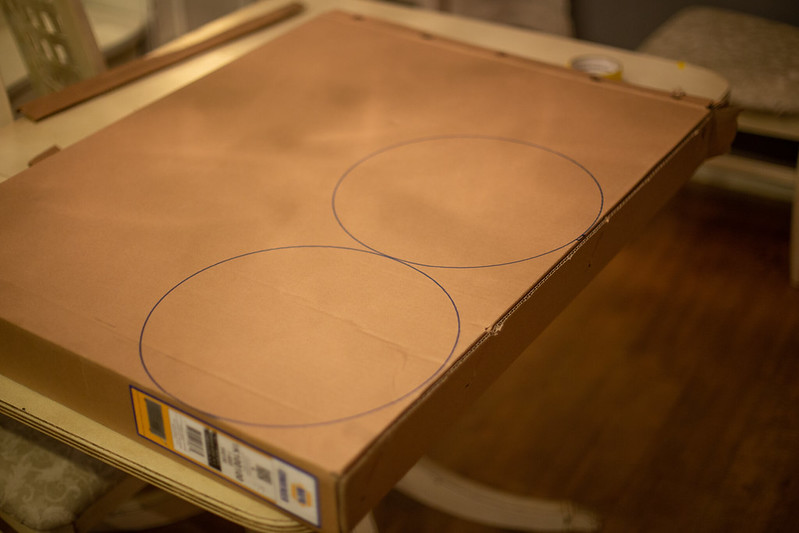

I ended up cutting out the center portion of the header/headlight pane, as one it wasn't needed for support and two was in the way of ALL UP IN YOUR FACE turbo mounting. I also made some cardboard mockups of the cooling components that also need to be upfront. 1.Radaitor 2. Air to water heat exchanger and 3. Condensor for ac system.

Needless to say, its all going to be a tight fit. However with everything will work out. The cooling module (all the cooling componets will be bolted together for most efficient flow from fans) will have a large degree of slant rearwards, towards the engine. A popular mod is to have them lean forward in mustang swaps but due to depth issues that wouldn't wok for me with the turbo location. My hot side material also came in early this week and I was able to get the lengths cut and mock it up to see how it looks. Ill be getting my dads Miller TIG machine likely this week over the house to get some practice in before I weld on the car.

IMG_9542 by lawrx, on Flickr

IMG_9542 by lawrx, on Flickr

IMG_9543 by lawrx, on Flickr

IMG_9543 by lawrx, on Flickr

IMG_9544 by lawrx, on Flickr

IMG_9544 by lawrx, on Flickr

IMG_9546 by lawrx, on Flickr

IMG_9546 by lawrx, on Flickr

IMG_9547 by lawrx, on Flickr

IMG_9547 by lawrx, on Flickr

IMG_9549 by lawrx, on Flickr

IMG_9549 by lawrx, on Flickr

IMG_9555 by lawrx, on Flickr

IMG_9555 by lawrx, on Flickr

IMG_9556 by lawrx, on Flickr

IMG_9556 by lawrx, on Flickr

IMG_9557 by lawrx, on Flickr

IMG_9557 by lawrx, on Flickr

IMG_9558 by lawrx, on Flickr

IMG_9558 by lawrx, on Flickr

IMG_9559 by lawrx, on Flickr

IMG_9559 by lawrx, on Flickr

IMG_9561 by lawrx, on Flickr

IMG_9561 by lawrx, on Flickr

IMG_9563 by lawrx, on Flickr

IMG_9563 by lawrx, on Flickr

IMG_9564 by lawrx, on Flickr

IMG_9564 by lawrx, on Flickr

IMG_9565 by lawrx, on Flickr

IMG_9565 by lawrx, on Flickr

IMG_9566 by lawrx, on Flickr

IMG_9566 by lawrx, on Flickr

IMG_9567 by lawrx, on Flickr

IMG_9567 by lawrx, on Flickr

IMG_9570 by lawrx, on Flickr

IMG_9570 by lawrx, on Flickr

IMG_9571 by lawrx, on Flickr

IMG_9571 by lawrx, on Flickr

IMG_9572 by lawrx, on Flickr

IMG_9572 by lawrx, on Flickr

IMG_9575 by lawrx, on Flickr

IMG_9575 by lawrx, on Flickr

IMG_9576 by lawrx, on Flickr

IMG_9576 by lawrx, on Flickr

Leave a comment:

-

I have a mount that bolts to the center cartrige which has provisions to weld 1'' tube as a support rod. It will run across the engine bay similar to the top of the rad support. Will be able to be unbolted so as to make engine work easy and out of the way.Originally posted by MikeyRa View PostHow do you plan on supporting the weight of the turbos?

Leave a comment:

-

Thanks man! and yeah, its a little excessive haha. It is all carbon thoOriginally posted by MikeyRa View PostEverything looks great! I love seeing updates from you on any of your threads!

The new cowl hood looks pretty extreme! haha

Leave a comment:

-

Soooooo long overdue update.

Been very busy as of late.

Had a clients car in my car I was doing some repairs on (actually still there but im done with it), so I've had little to know room or time to work on the mustang. On top of that I've purchased some parts for my daily BRZ, and being my garage has two cars in it, and my car is STILL at the dealer, the parts have ended up in and on the mustang due to constricted storage.

SO, now that clients car is done and my brz should HOPEFULLY be coming home soon, I can get back on the mustang.

Since my last update in my rare spare time id come out into the garage....stare....think....stare...think....rub my head to make it stop hurting from thinking so much.... then id mock the turbo up in a position id think is better than where I had last sorted out. I prolly did this 5-7 times with actual realistic useable locations for the turbo. Tonight I had some time to really put some thought into it and move somethings around and I've pretty much come full circle with placement. aka my original plan of straight forward of the manifold exit right in the grill opening.

Also made a cardboard mock-up of my newly selected radiator. It will be forward slanted in conjunction with the a2w heat exchanger and ac condenser. Its going to get tight in the front.

Enough talk from me, heres a few shots from tonight. Hotside material is on the way. Hoping in the next few weeks ill get my dads tig welder over to the house and get some practice and weld this bad boy up.

IMG_9535 by lawrx, on Flickr

IMG_9535 by lawrx, on Flickr

IMG_9541 by lawrx, on Flickr

IMG_9541 by lawrx, on Flickr

IMG_9536 by lawrx, on Flickr

IMG_9536 by lawrx, on Flickr

IMG_9537 by lawrx, on Flickr

IMG_9537 by lawrx, on Flickr

IMG_9538 by lawrx, on Flickr

IMG_9538 by lawrx, on Flickr

IMG_9539 by lawrx, on Flickr

IMG_9539 by lawrx, on Flickr

IMG_9540 by lawrx, on Flickr

IMG_9540 by lawrx, on Flickr

Leave a comment:

-

congrats on the twins.. a picture with baby blankets hugging them is a must...

Leave a comment:

-

So im just now realizing I've been sitting on these images for a week now and I apologize for that.

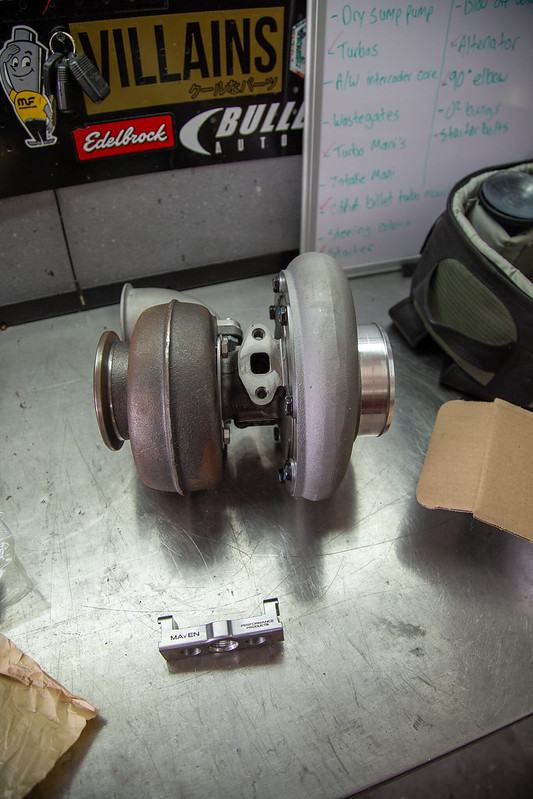

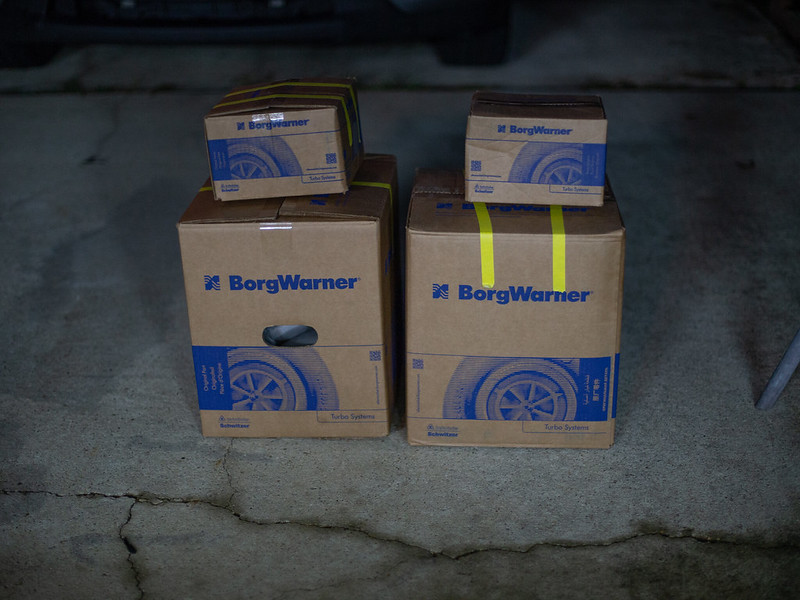

As a happy birthday to me I ordered my turbos. Wallets a bit (decent bit LOL) lighter, but moral is up, so ill take it. Got home after work and putting the little one to bed and got stuck in assembling them and fitting them to the car. Ever since I purchased the car I have been undecided on layout. Spoiler alert. Im still not decided on what route I will go. Up until yesterday actually, the planned orientation was as you see it in these pictures, albeit turbos sitting few inches forward and up slightly.

The largest influencer on layout is airflow. Being that top speed is one of my main objectives, airflow holds the most weight in deciding factor. IF I think of a better way to manage layout I will make sacrifices in other areas to an extent to improve it. This layout still may be in, however im leaning towards a foglight location for the turbos. Gives adequate space for rad/heat exchanger mounting and more importantly ducting.

IMG_1083 by lawrx, on Flickr

IMG_1083 by lawrx, on Flickr

IMG_1085 by lawrx, on Flickr

IMG_1085 by lawrx, on Flickr

IMG_1086 by lawrx, on Flickr

IMG_1086 by lawrx, on Flickr

IMG_1088 by lawrx, on Flickr

IMG_1088 by lawrx, on Flickr

IMG_1089 by lawrx, on Flickr

IMG_1089 by lawrx, on Flickr

IMG_1091 by lawrx, on Flickr

IMG_1091 by lawrx, on Flickr

IMG_1092 by lawrx, on Flickr

IMG_1092 by lawrx, on Flickr

IMG_1093 by lawrx, on Flickr

IMG_1093 by lawrx, on Flickr

IMG_1095 by lawrx, on Flickr

IMG_1095 by lawrx, on Flickr

IMG_1098 by lawrx, on Flickr

IMG_1098 by lawrx, on Flickr

IMG_1100 by lawrx, on Flickr

IMG_1100 by lawrx, on Flickr

IMG_1102 by lawrx, on Flickr

IMG_1102 by lawrx, on Flickr

Leave a comment:

-

Originally posted by toddzilla View PostDamn, that short block sits low! Looks proper race-y.

Was one of the purposes of running the motor plates vs the standard motor mounts. Wanted to keep a stock height hood. The dry sump pan played a factor in getting it to sit this low as well.

Itís unreal.Originally posted by LCG View Postdude.. apart from the work...

watching the pictures of your kid just shows how quickly time goes by and how less we work on cars...

Itís also very depressing.

ďSo what have you accomplished in the last 1.5 years of owing your project car?Ē

ďIíve mounted the motor.....Ē

I mean Iíve done a lot more than that. But thatís pretty much what it boils down to. Luckily Iím getting to the point where itís less fabrication aka less noise. So Iíll be able to get more work one even if my son (oh, also have a daughter being born in late August!) is sleeping. That was the biggest factor on how long itís taken to get to this point. Wouldnít change it for the world tho. Rather barely get anything done and have them around vs the alternative.

Leave a comment:

-

dude.. apart from the work...

watching the pictures of your kid just shows how quickly time goes by and how less we work on cars...

Leave a comment:

Leave a comment: