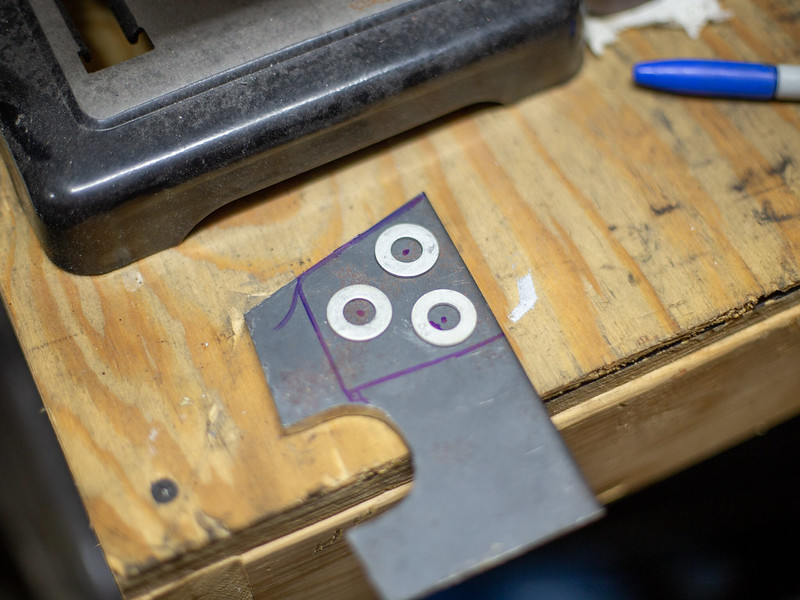

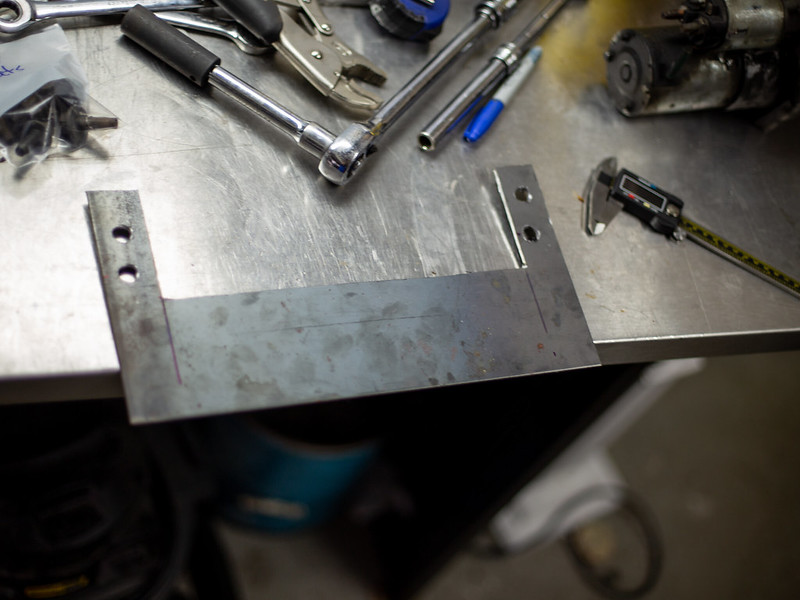

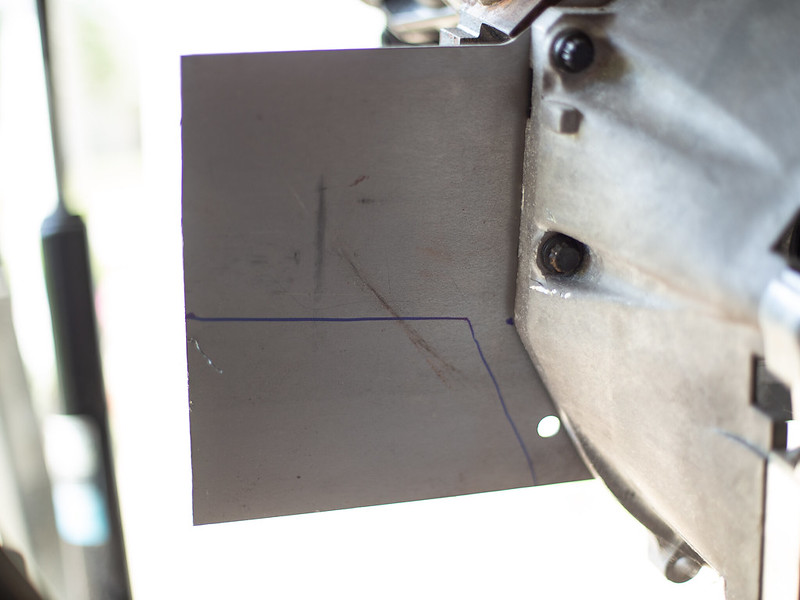

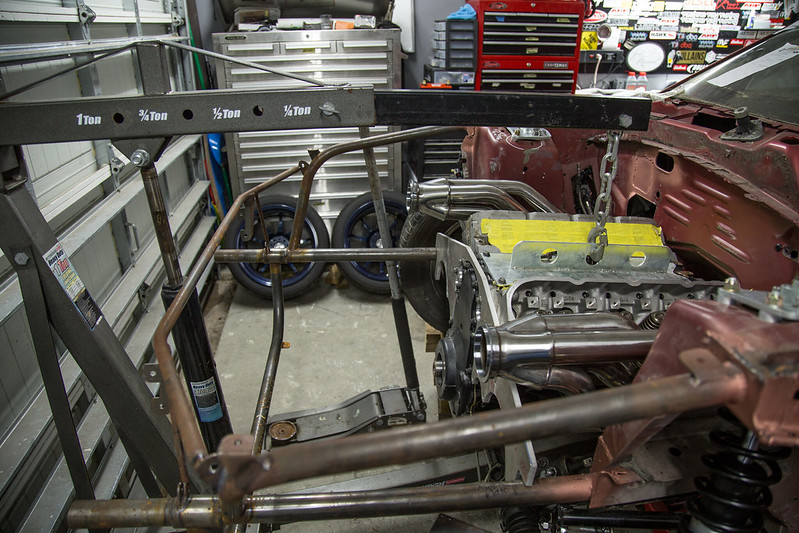

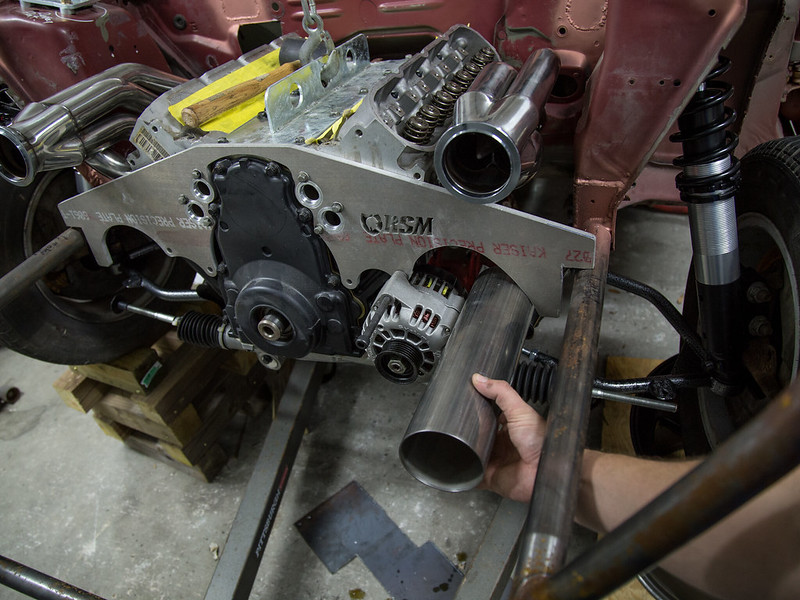

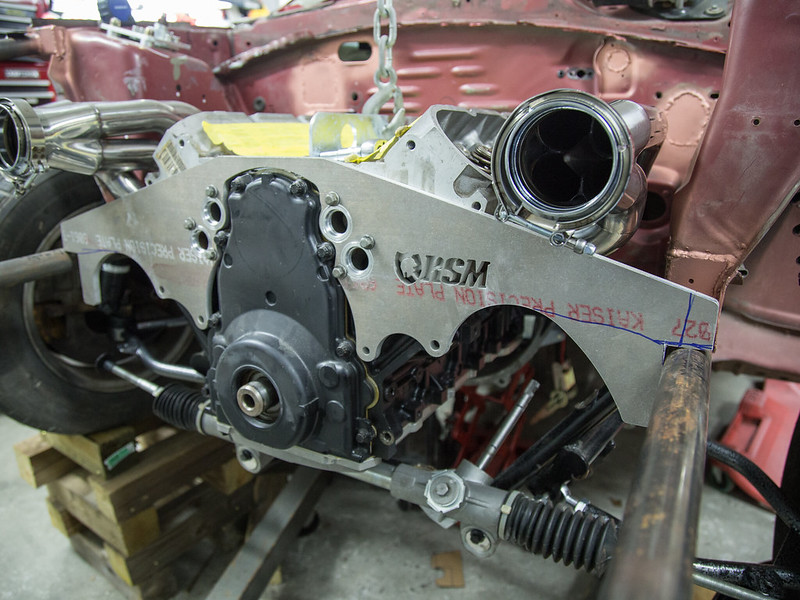

Next step was to finalize mount tabs placement and drill all the holes on the tabs and the motor plate itself.

IMG_0724 by lawrx, on Flickr

IMG_0724 by lawrx, on Flickr IMG_0725 by lawrx, on Flickr

IMG_0725 by lawrx, on Flickr IMG_0726 by lawrx, on Flickr

IMG_0726 by lawrx, on Flickr IMG_0728 by lawrx, on Flickr

IMG_0728 by lawrx, on Flickr IMG_0729 by lawrx, on Flickr

IMG_0729 by lawrx, on Flickr IMG_0730 by lawrx, on Flickr

IMG_0730 by lawrx, on Flickr IMG_0733 by lawrx, on Flickr

IMG_0733 by lawrx, on Flickr IMG_0735 by lawrx, on Flickr

IMG_0735 by lawrx, on FlickrOne night I wasn't able to make much noise as my son was sleep and wife was already in bed and I was itching to do something on the car. I pulled out the seats to sell and the nasty carpet to throw out. I had a mouse/rat something that pissed and shit on it and it smelled. On top of ill be converting to a black interior regardless. This also gives me access to wire the car.

IMG_0882 by lawrx, on Flickr

IMG_0882 by lawrx, on Flickr IMG_0884 by lawrx, on Flickr

IMG_0884 by lawrx, on Flickr IMG_0887 by lawrx, on Flickr

IMG_0887 by lawrx, on Flickr IMG_0887 by lawrx, on Flickr

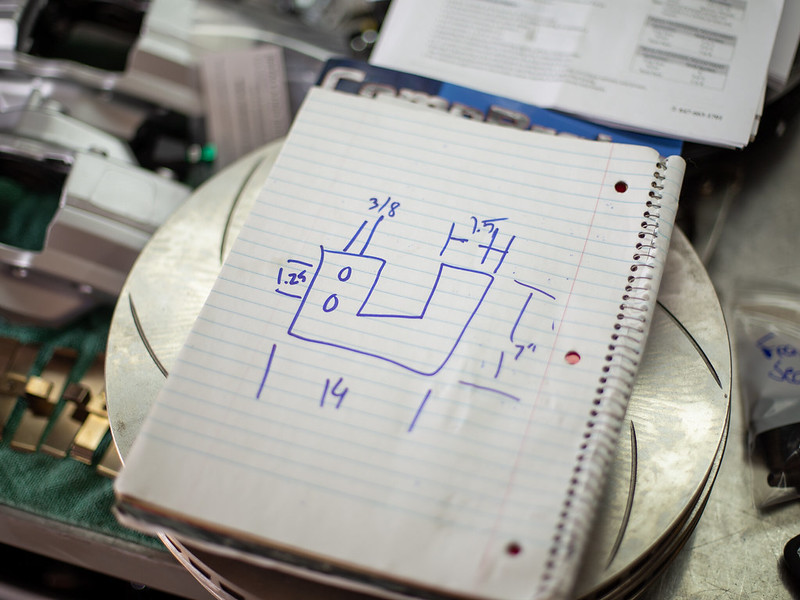

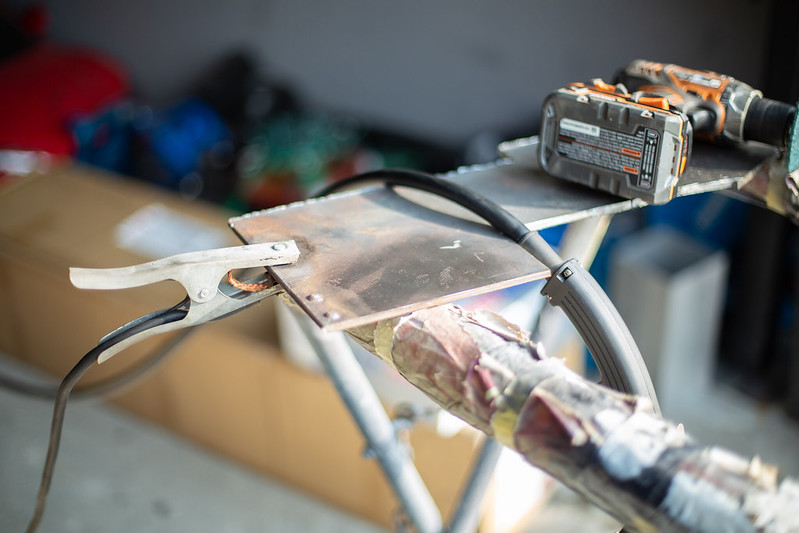

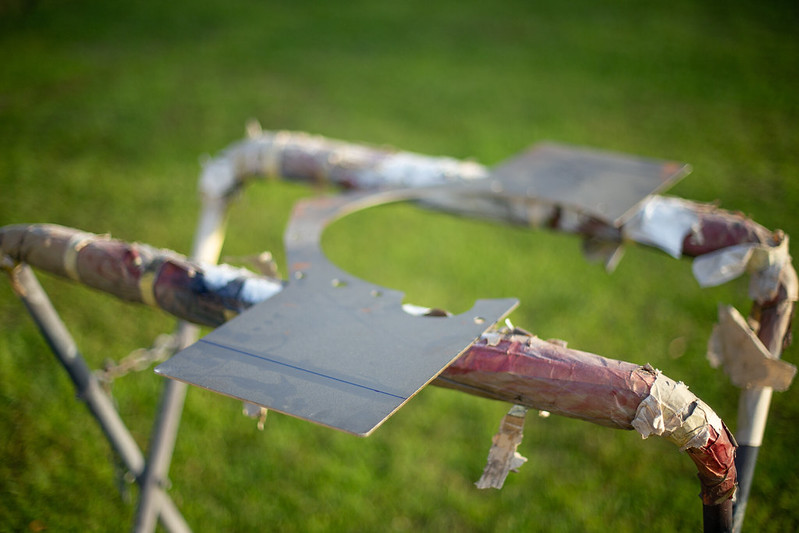

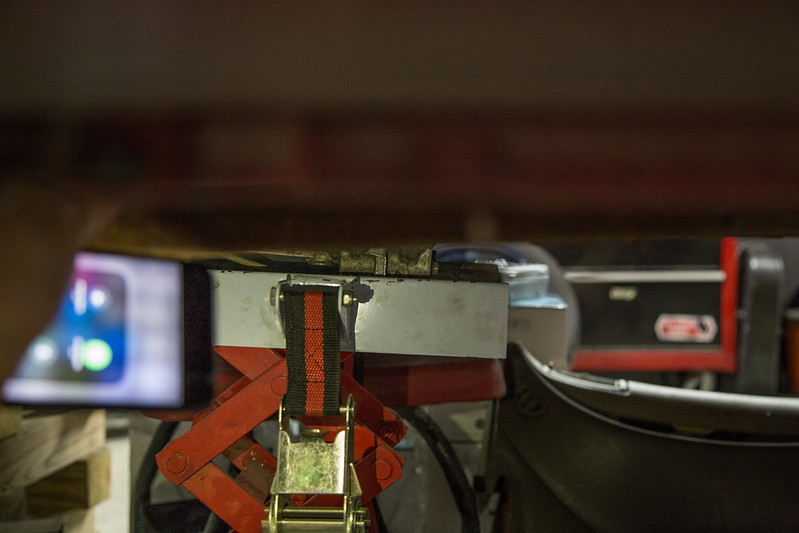

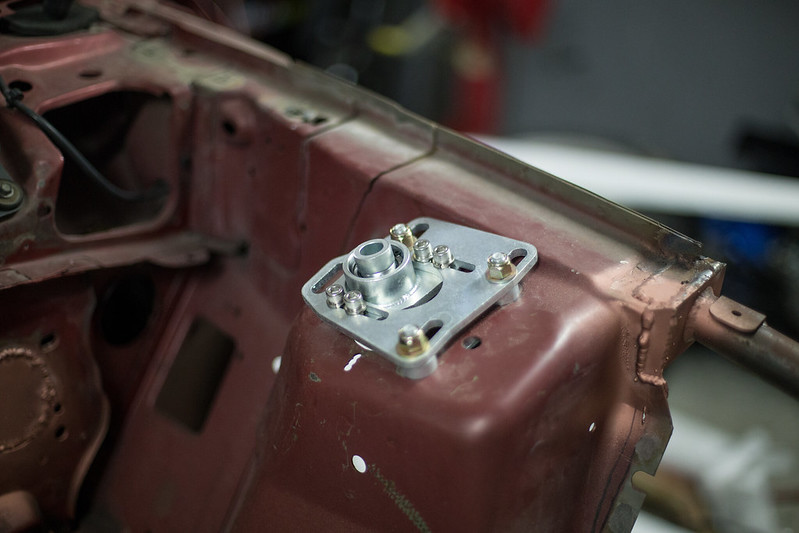

IMG_0887 by lawrx, on FlickrBefore welding in the front motor plate tabs I had to create a trans mount. Took some measurements and transferred them to some thick sheetmetal I had. This is only temporary, ill be getting a buddy of mine to whip one up in some billet t6b aluminum as the final product. For now this will do to place the motor and hold the trans up under its own weight.

IMG_0888 by lawrx, on Flickr

IMG_0888 by lawrx, on Flickr IMG_0893 by lawrx, on Flickr

IMG_0893 by lawrx, on Flickr IMG_0895 by lawrx, on Flickr

IMG_0895 by lawrx, on Flickr IMG_0897 by lawrx, on Flickr

IMG_0897 by lawrx, on Flickr IMG_0899 by lawrx, on Flickr

IMG_0899 by lawrx, on Flickr IMG_0901 by lawrx, on Flickr

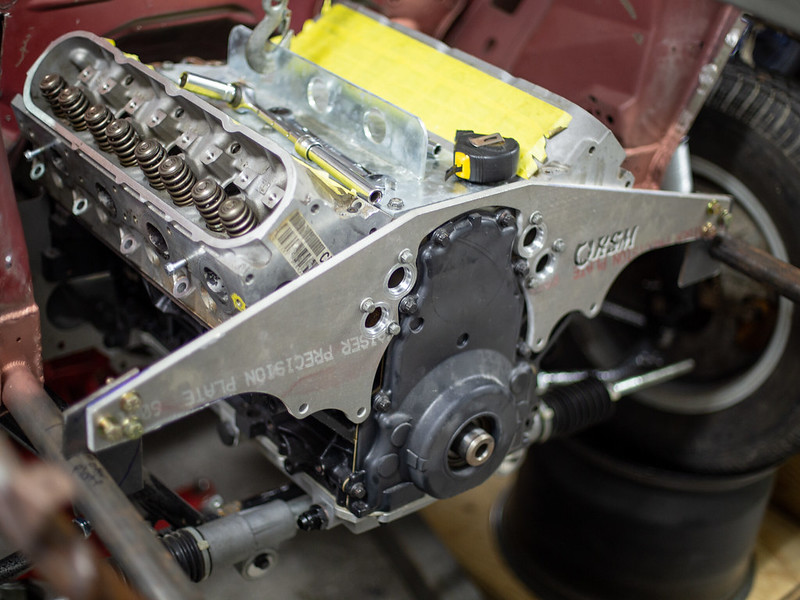

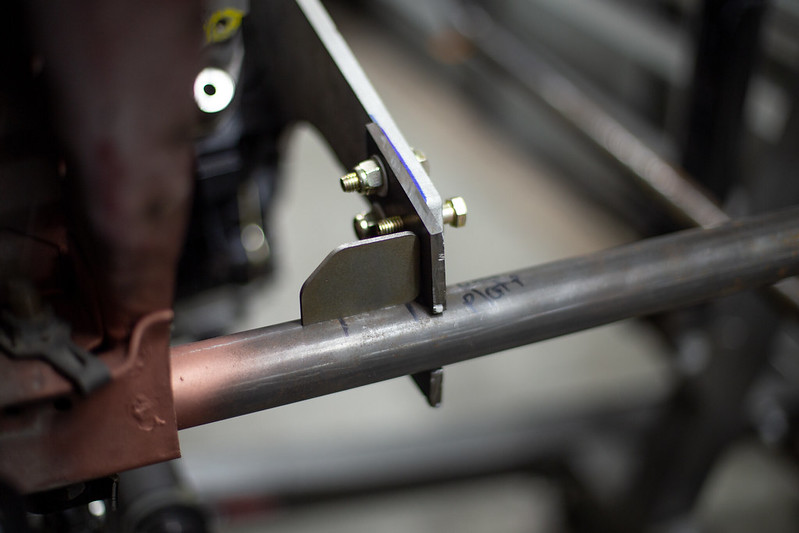

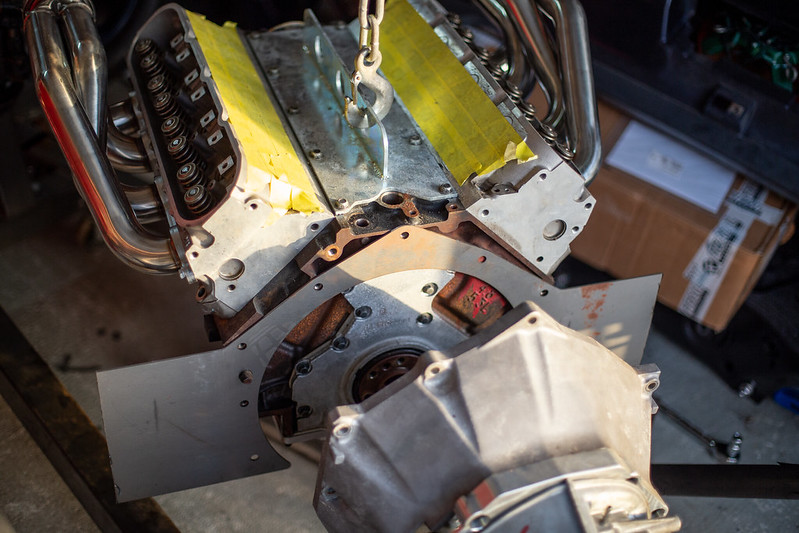

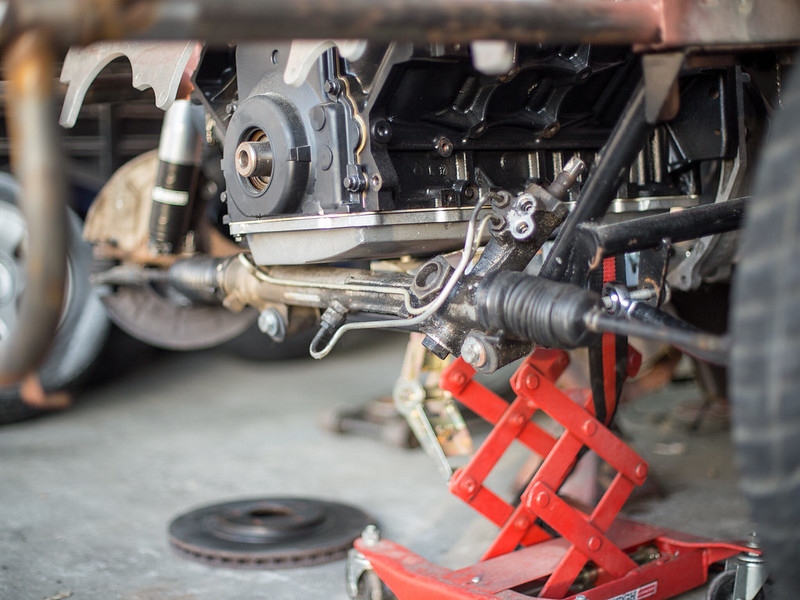

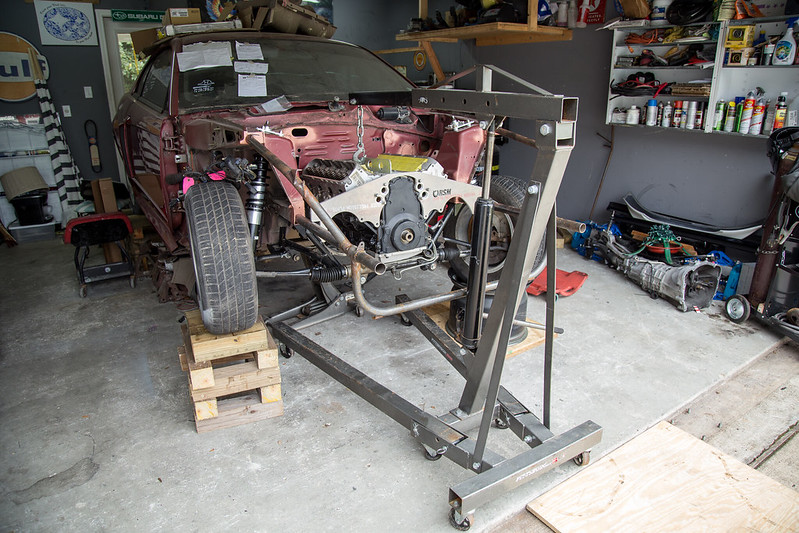

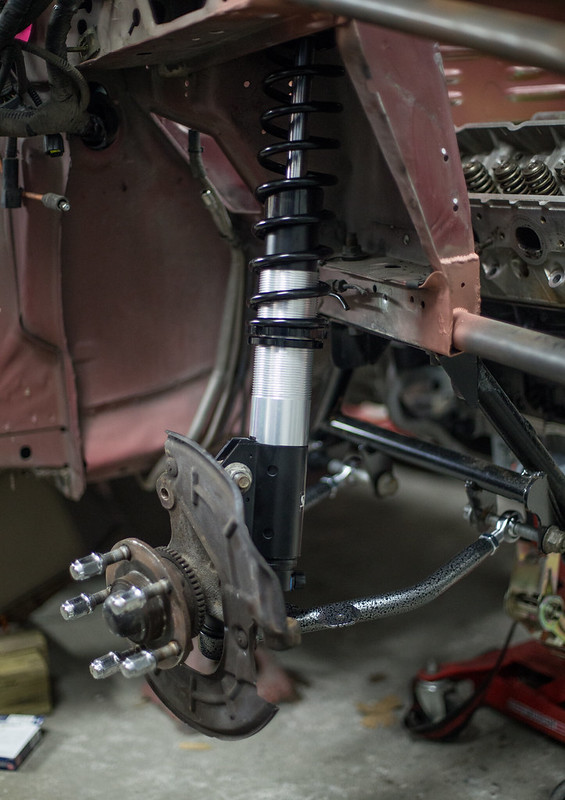

IMG_0901 by lawrx, on FlickrWith the trans mounted the last step was welding the mount tabs to the chassis.Through some test welds on my base material I used for the mounts and the welded the tabs up. With the motor fully suspending itself under its own weight I could set the car down on the chassis and off the stands. Had to clear out a bunch of stuff from underneath as over the last 6-8 months things had accumulated. Now that I had the motor mounted I also tested the front end to see clearance and space for the various objects that would take up space in the engine bay. Lots of room but there will also be lots of components.

IMG_0902 by lawrx, on Flickr

IMG_0902 by lawrx, on Flickr IMG_0904 by lawrx, on Flickr

IMG_0904 by lawrx, on Flickr IMG_0905 by lawrx, on Flickr

IMG_0905 by lawrx, on Flickr IMG_0907 by lawrx, on Flickr

IMG_0907 by lawrx, on Flickr IMG_0909 by lawrx, on Flickr

IMG_0909 by lawrx, on Flickr IMG_0911 by lawrx, on Flickr

IMG_0911 by lawrx, on Flickr IMG_0913 by lawrx, on Flickr

IMG_0913 by lawrx, on Flickr IMG_0915 by lawrx, on Flickr

IMG_0915 by lawrx, on Flickr IMG_0916 by lawrx, on Flickr

IMG_0916 by lawrx, on Flickr IMG_0917 by lawrx, on Flickr

IMG_0917 by lawrx, on Flickr IMG_0918 by lawrx, on Flickr

IMG_0918 by lawrx, on Flickr

Leave a comment: