Announcement

Collapse

No announcement yet.

'00 FRC Hardtop - moar LS/Murica/long distance high speed cruising

Collapse

X

-

I actually did a refurb on the C6Z lower box when I bought it used, before even installing it in the car for the first time. It needed a thorough cleaning and lubrication, and that did help the general smoothness of the action, but didn't do anything for the sloppiness.

Here is my train of thought and plan of attack:

The plastic bushings that hold the "yoke" shaft have a 1/16" of slop in them which translates to play in the shift knob when in neutral, or any gear really. They will be replaced with either delrin or bronze bushings that will provide a much more solid "hold" on the shaft.

The C6 Upper box looked to be fine. I found that the black "cup" that rides in the lower "receiver" has no slop and moves very freely.

With the entire drivetrain removed from the car (minus engine), the shift linkage (with no shifter attached) still does not spring back from 5-6 to center. This rules out the shifter as causing my centering issue, although the shifter still contributes to the slop.

I bolted the shifter assembly back onto the torque tube to visualize what the shift linkage was doing, and chase down the slop. This video shows the bushing wear in the lower box. The left to right wiggling of the shift knob/lever at the end of the video has no effect on movement of components in the trans - it's all slop in the joint at the rear bellhousing! Any similar front/rear movement of the shift knob/lever has equal slop that is a result of the worn bushings inside the lower box.

There is also lots of play evident in the joint assembly right before the shift linkage enters the transmission. It looks to be held together with roll pins, I have not yet disassembled that area.

Of course I COULD purchase a (relatively) expensive aftermarket shifter such as MGW, Hinson, Kirban that has internal centering springs, but I feel that they are somewhat of a band aid to the pre-existing condition inside the transmission. They also tend to be very stiff and the throw is excessively short, which makes the effort go way up. I drive my car 99% on the street with a couple track days a year so an easy, low effort throw is important.

So the final list of suspects, working towards the back of the car:

C6 Lower box mount bushings (that mount the box to the torque tube) - non issue. These are solid on my C6Z shifter. No movement.

C6 Lower box shaft bushings - cause shifter sloppiness. Plan to install new bronze bushings custom sized to my yoke, press fit into box. Not too bad of a job, will require some machining.

T56 Shift linkage to trans - cause shifter sloppiness. Need to investigate, there looks to be a brass bushing inside a mini u-joint that is worn.

C5 T56 internal centering spring - causes shifter not to snap back to neutral from the 5-6 gate (in my case). Again, an aftermarket shifter might help, but I want to get to the root cause. I initially thought this might be caused by the fore-aft detent ball that rides on top of the shift gate (NOT the detent ball that is altered by the anti-venom mod)

So I mounted up my T56 on the worktable.

0125171925 by Norbert Ogiba, on Flickr

0125171925 by Norbert Ogiba, on Flickr

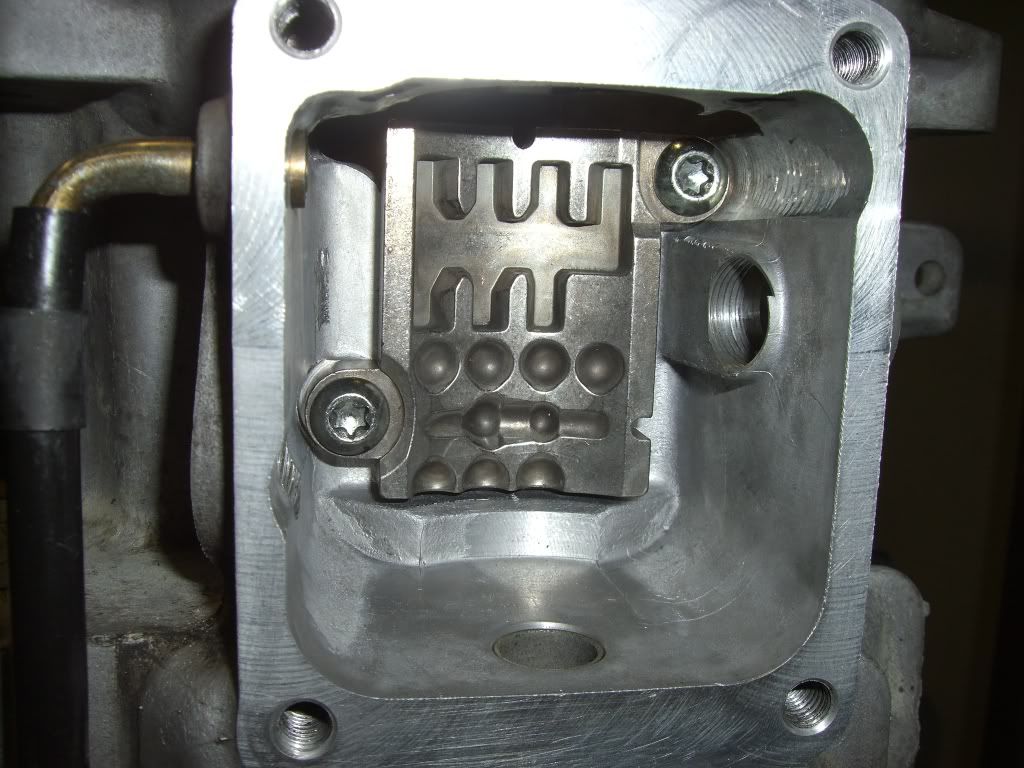

After pulling the rear tail housing case I visually verified that the shift detent ball wasn't binding up. This is not my picture, just an example of the guide plate that the lower detent ball rides in. I can't get the shift rail block off yet to verify if the ball is physically free, but that will come later.

According to Bill Curlee: "There is a U shaped spring on the bottom plate that returns the shifter back to the center: " Through the process of elimination, this must be what is causing my shifter not to return back to center.

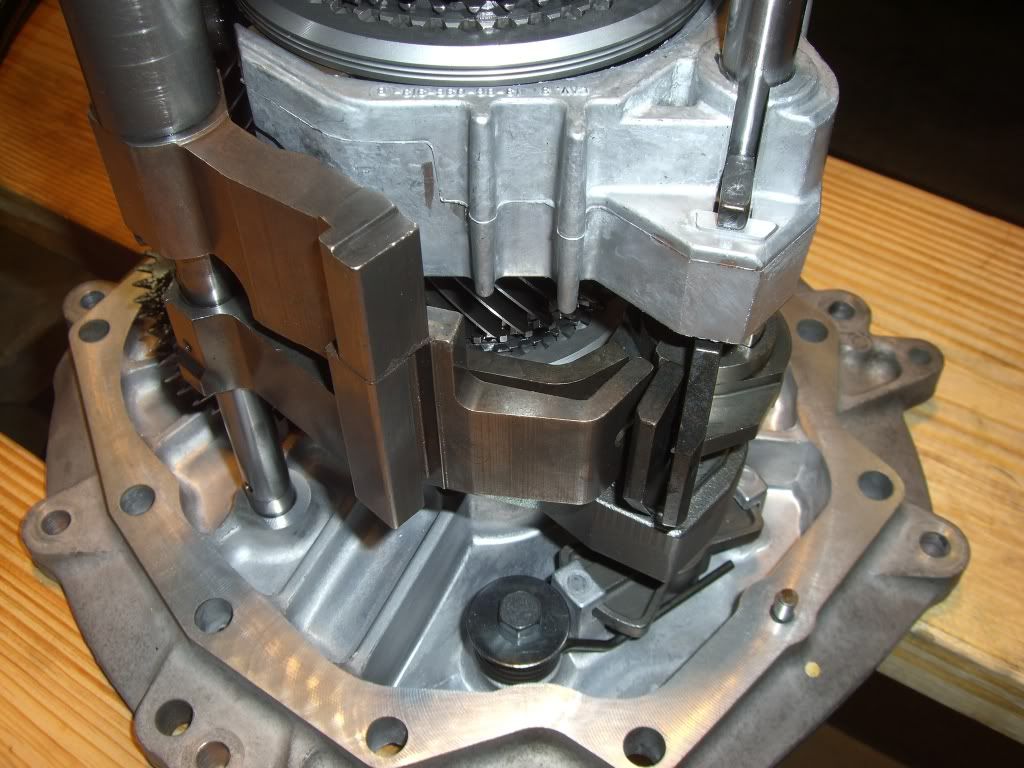

Tailhousing off.

0125171930 by Norbert Ogiba, on Flickr

0125171930 by Norbert Ogiba, on Flickr

I don't know if someone has gone through this trans in its life, but the buildup on the magnets didn't look TOO bad for 115k. I will be removing and cleaning these prior to reassembly. For what it's worth, I did replace the trans fluid with Dexron III ATF 1 year and 10K miles ago, and it looked brand new while draining.

That's where I left off for the night, my snap ring pliers were not big enough to handle the rings on the reverse shaft. More to come tonight.

Leave a comment:

-

I literally stood in front of the transmission last night and willed myself not to pull it apart.Originally posted by LCG View PostSeems like you are really good at keeping yourself controlled on the once we are here bug

I think he's got a bunch of automated replies he has sent out once in a while to keep up the facade that he does car stuff.Originally posted by 190Evan View PostYou're alive LCG?

"Me: Stay outta my goddamn garage"Originally posted by C2_mad View Posti wonder what the wife has to say about taking a perfectly working car apart?lol

ps: man i wish i had a garage like yours...

"Wife: Stay outta my goddamn kitchen"

Marriage is fun.

You'd be surprised at how well some drywall and paint can spiff things up.

Leave a comment:

-

i wonder what the wife has to say about taking a perfectly working car apart?lol

ps: man i wish i had a garage like yours...

Leave a comment:

-

Started my annual winter project of "take a perfectly good running vehicle and take it apart"

0114171752 by Norbert Ogiba, on Flickr

0114171752 by Norbert Ogiba, on Flickr

Midpipes and exhaust removed. Now on to 36 of these little bastards. Thank god for power tools. Stiffening plate was not as stiff as I imagined it would be.

0115171250a by Norbert Ogiba, on Flickr

0115171250a by Norbert Ogiba, on Flickr

Begin the parts pile.

0115171808 by Norbert Ogiba, on Flickr

0115171808 by Norbert Ogiba, on Flickr

No pictures of the physical removal of the drivetrain, but it came out pretty easily.

0115171808a by Norbert Ogiba, on Flickr

0115171808a by Norbert Ogiba, on Flickr

Note the generous amounts of kitty litter on the ground. Gotta drain diff fluid before dropping assy next time. When the axles get pulled out of the trans, and you wiggle the whole thing side to side, she tends to puke out the oil.

0115171808b by Norbert Ogiba, on Flickr

0115171808b by Norbert Ogiba, on Flickr

It's beyond me how some of this junk ended up on top of the diff, short of being deposited by a critter. All components will get scrubbed before going back in the car.

0115171808c by Norbert Ogiba, on Flickr

0115171808c by Norbert Ogiba, on Flickr

Separated the diff/torque tube/trans from the subframe - it's only held together with 2 bolts. The centrally located diff mount does a very poor job of holding a rigid connection between the subframe and drivetrain.

0115171814 by Norbert Ogiba, on Flickr

0115171814 by Norbert Ogiba, on Flickr

I don't want solid mounts in this car so one of these is definitely in my future

So we finally have all this junk

0115171814a by Norbert Ogiba, on Flickr

0115171814a by Norbert Ogiba, on Flickr

0117171935 by Norbert Ogiba, on Flickr

0117171935 by Norbert Ogiba, on Flickr

Tucked away so wife can have her spot back until parts start coming in.

0117172003 by Norbert Ogiba, on Flickr

0117172003 by Norbert Ogiba, on Flickr

The plan right now is an LS7 clutch combo, torque tube rebuild (guibos, bearings), and a 4.10 diff (either send my stocker out or get my hands on a DTE built unit). Anything that doesn't look ok will get replaced with OEM or better parts. I'll probably end up modifying the C6Z06 shifter to have no slop as well - the lower box bushings wear out over time. Already have the Tick clutch MC but I'll replace the slave with a new OEM and throw in a remote bleeder too.

If I really get bored I can investigate the T56 internal centering detents - the 1-2 position snaps back to neutral just fine, but the 5-6 stays put in between those gates unless you snap back to 3-4. The external linkage to the T56 also has some tiny amount of slop in it, but that translates to much more when you multiply by the length of the shifter. I guess I was just spoiled by BMW shifters in the past.

Leave a comment:

-

Usually find a trailer hitch on a car that is not a truck awful, but somehow it looks really cool on your Corvette.

Leave a comment:

-

I'm on the fence. I plan on keeping the car for a while and the paint really bothers me (somewhat sandblasted front end) but I have not yet attempted a full blown paint correction aside from a quick clay bar job and the usual 2 bucket method washes. I want to really hit it with the Porter Cable before pulling the trigger on what will inevitably be an expensive and very time consuming job.Originally posted by C2_mad View Postwas wondering when there would be an update... whats going on with the wrap idea?

More importantly I realize that I enjoy driving the car more than I like looking at it, so I'm moving in the direction of go rather than show:

-Pull Diff and send out for rebuild + install new 4.10 ring and pinion (to defend freedom and make America great again)

-While diff is out, replace torque tube bearings/etc, inspect trans components, etc.

-Possibly replace clutch/PP/flywheel with LS7 components. I used them on my 6.0 LS BMW and loved the setup.

-Finish painting my track wheels (rare magnesium setup that was an original option for this specific car)

-Buy and install Continental slick take offs for track/HPDE use

-Burnouts

Leave a comment:

-

was wondering when there would be an update... whats going on with the wrap idea?

Leave a comment:

-

There's actually not a lot to them in general. I had one on my Outback XT, now this on my C5 - it's all just angle iron, square stock, flat bar all welded together.

Leave a comment:

-

trailer hitch on a vette is so so cool. I've been trying to pick one up for my SC for when I move to the east coast haha.

Leave a comment:

keep it up

keep it up

Leave a comment: