Announcement

Collapse

No announcement yet.

'00 FRC Hardtop - moar LS/Murica/long distance high speed cruising

Collapse

X

-

Very nice video, always nice to see complex stuff being not that complex when a mortal explains it in mortal language.

Leave a comment:

-

The transmission is back together, 4.10 diff came back from RKT56, torque tube is reassembled with new couplers, LS7 clutch and flywheel installed, drill mod done on new LS6 clutch slave...it was a busy weekend.

Leave a comment:

-

See my last post, I was being sarcastic about the CNC, just a drill press. I wish I had CNC.Originally posted by 190Evan View PostAh I see, cool stuff it's gotta be nice having a CNC in your life haha! I had access to one back in California and it was an amazing machine to have access to.

Leave a comment:

-

Ah I see, cool stuff it's gotta be nice having a CNC in your life haha! I had access to one back in California and it was an amazing machine to have access to.

Leave a comment:

-

Evan the spring is not centering the shift rail properly. The shifter "sticks" in the 5-6 position.

So while I wait for the diff to come back and other parts to come in, I had a friend make me some brass bushings for the C6 lower shift box.

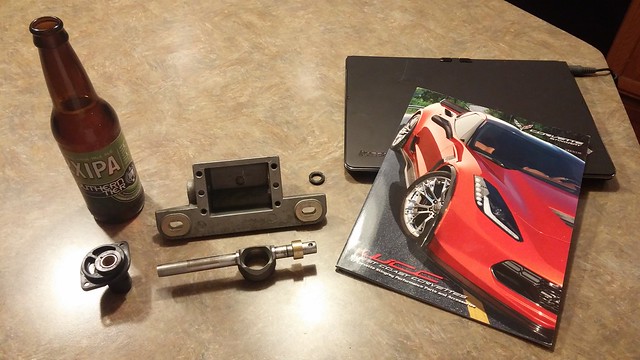

After a long Monday at work followed by some snowmobiling, it was nice to come home to this and relax.

0206172108 by Norbert Ogiba, on Flickr

0206172108 by Norbert Ogiba, on Flickr

Pressed into retaining plastic

0206172109a by Norbert Ogiba, on Flickr

0206172109a by Norbert Ogiba, on Flickr

Great fitment on the larger (rear) bushing, only minor hand sanding needed.

0206172108a by Norbert Ogiba, on Flickr

0206172108a by Norbert Ogiba, on Flickr

The rear bushing needed more work to to fit correctly as it was too tight. It was taking forever to hand sand this stuff so I chucked up the shift rod in the 5 axis CNC lathe and got to it.

Leave a comment:

-

Laextreme manual trans's are pieces of cake. Tearing apart an auto trans can be confusing and intimidating your first time but as long as you remove the clutches in correct order and everything they are pretty straight forward. If you can build and LS you can easily tear apart one of these for basic inspection. Nsogiba what difficulty was that torsion spring giving you or are you just upgrading it?

Leave a comment:

-

isnt there certain clearances and proper gear meshing and such? Thats one thing ive simply never touched. Its a bit overwhelming to think about. Then again so was engine work and yet here i am about to start assembling shortblocks.Originally posted by nsogiba View PostGuys, the trans is not complicated. The only tools I used (besides regular sockets to remove bolts holding housings together) were some big snap ring pliers and a 3 jaw puller with extensions on it.

Leave a comment:

-

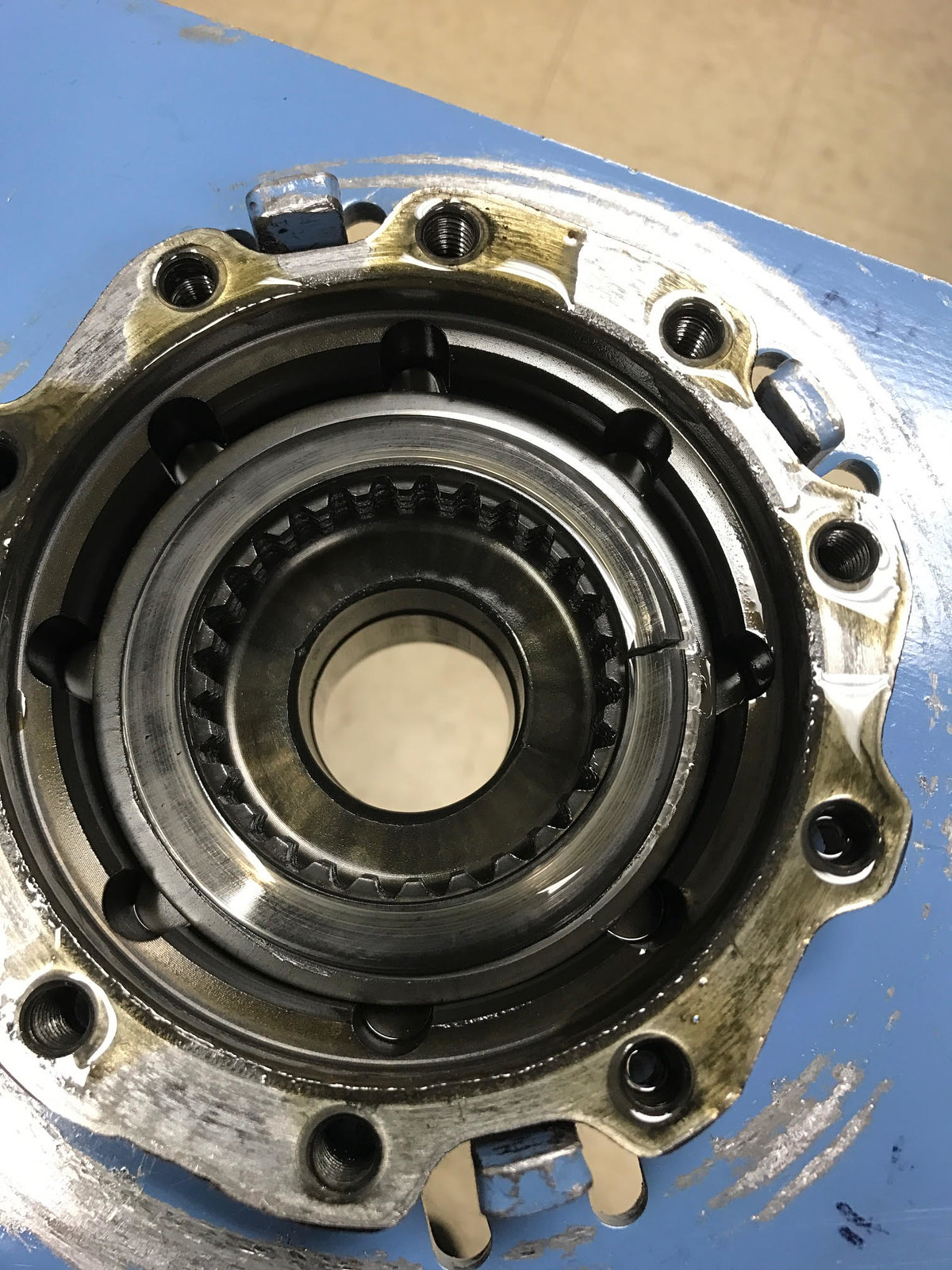

Diff is all torn apart at RKT Performance.

unnamed7 by Norbert Ogiba, on Flickr

unnamed7 by Norbert Ogiba, on Flickr

LS7 clutch, flywheel, pressure plate, pilot bearing on order.

Torque tube guibos on order (stock replacements). Old ones looked generally ok but had some stress cracks starting up.

Polyeurethane rear sway bar bushings on order.

Leave a comment:

-

Guys, the trans is not complicated. The only tools I used (besides regular sockets to remove bolts holding housings together) were some big snap ring pliers and a 3 jaw puller with extensions on it.

Leave a comment:

-

I followed the BMW build... how the hell did I miss this. Anywho I just caught up and love where it's going. I envy your ability to take apart your transmission... my luck works against me in those situations.

Leave a comment:

-

holy shit, I thought I had issues with "whilst its out" mentality :P

love detailed builds like this

Leave a comment:

-

I've yet to dive into learning transmissions. This is intriguing.

Leave a comment:

-

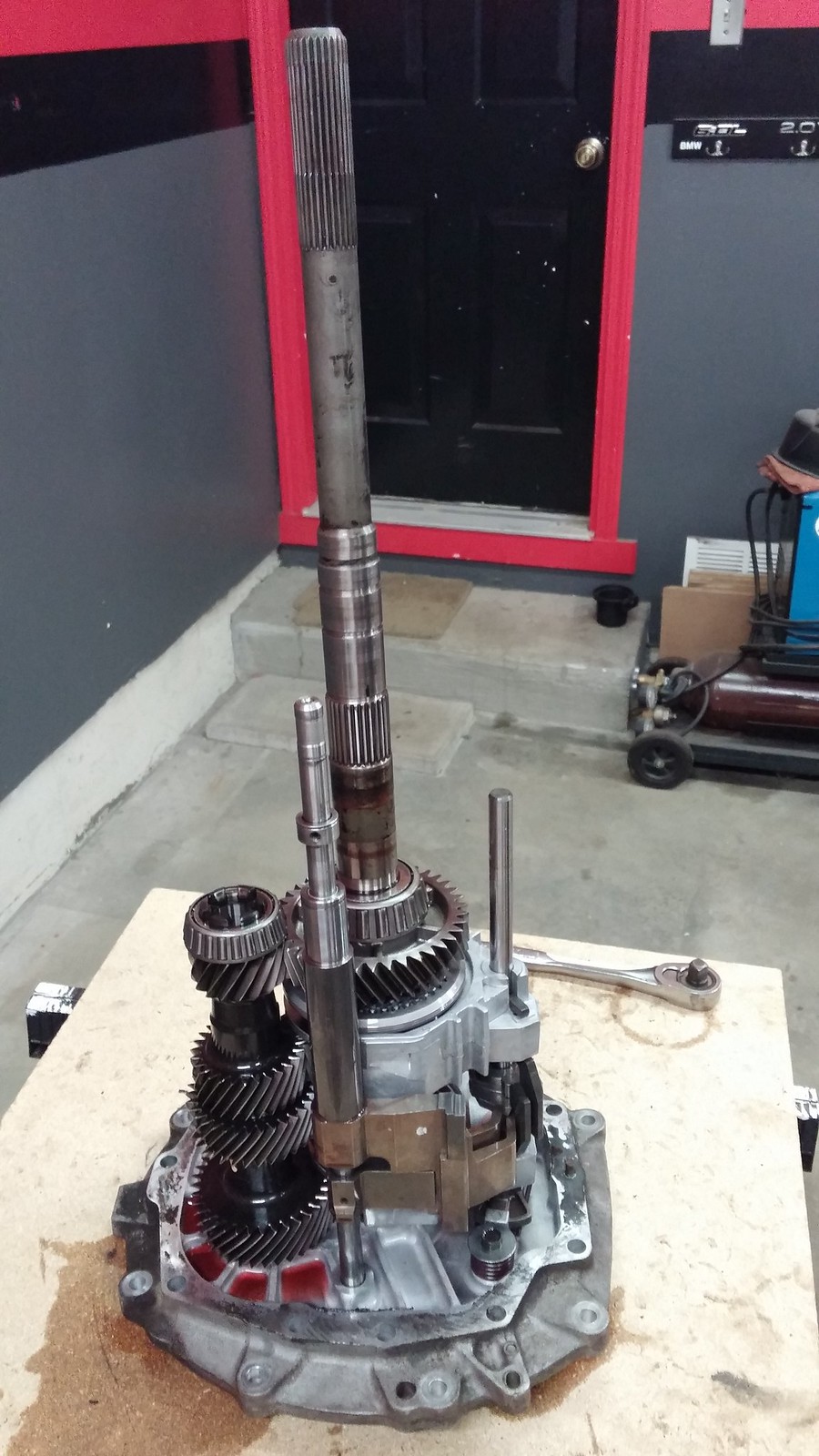

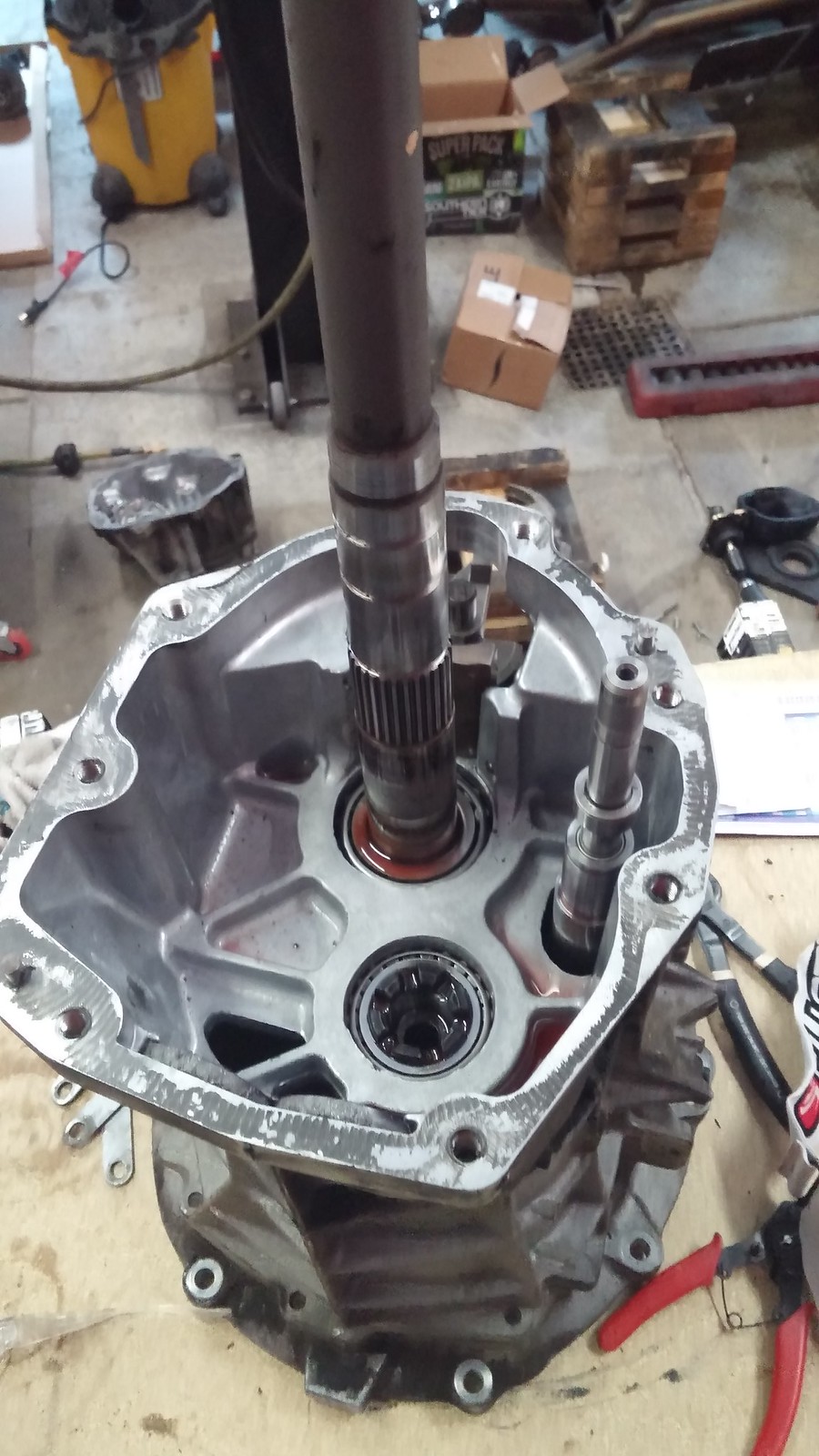

Got some work in last night.

Main case off

0131171903 by Norbert Ogiba, on Flickr

0131171903 by Norbert Ogiba, on Flickr

And it's remarkably light

0131171903b by Norbert Ogiba, on Flickr

0131171903b by Norbert Ogiba, on Flickr

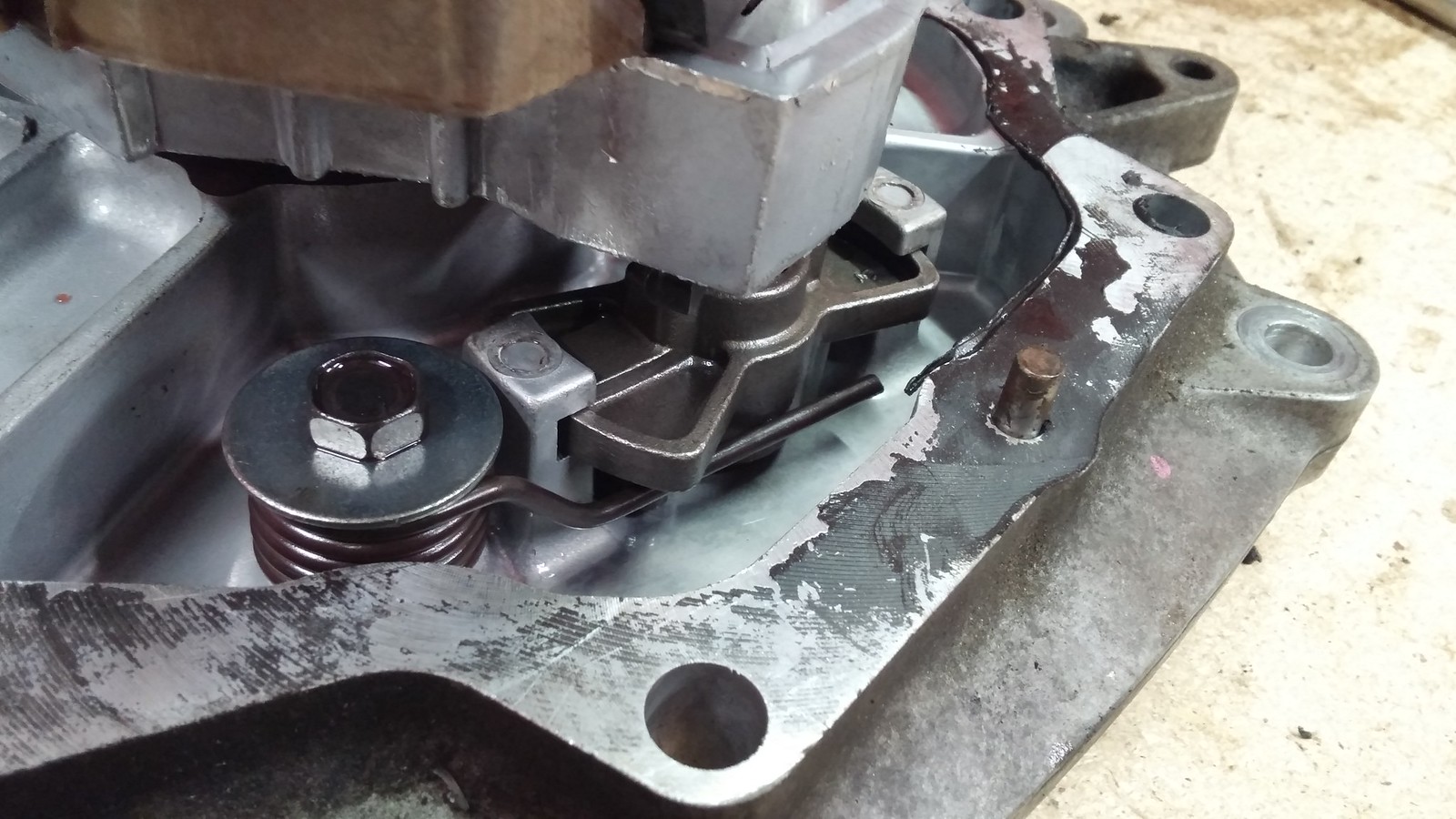

The torsion spring I've been trying to get at.

0131171903a by Norbert Ogiba, on Flickr

0131171903a by Norbert Ogiba, on Flickr

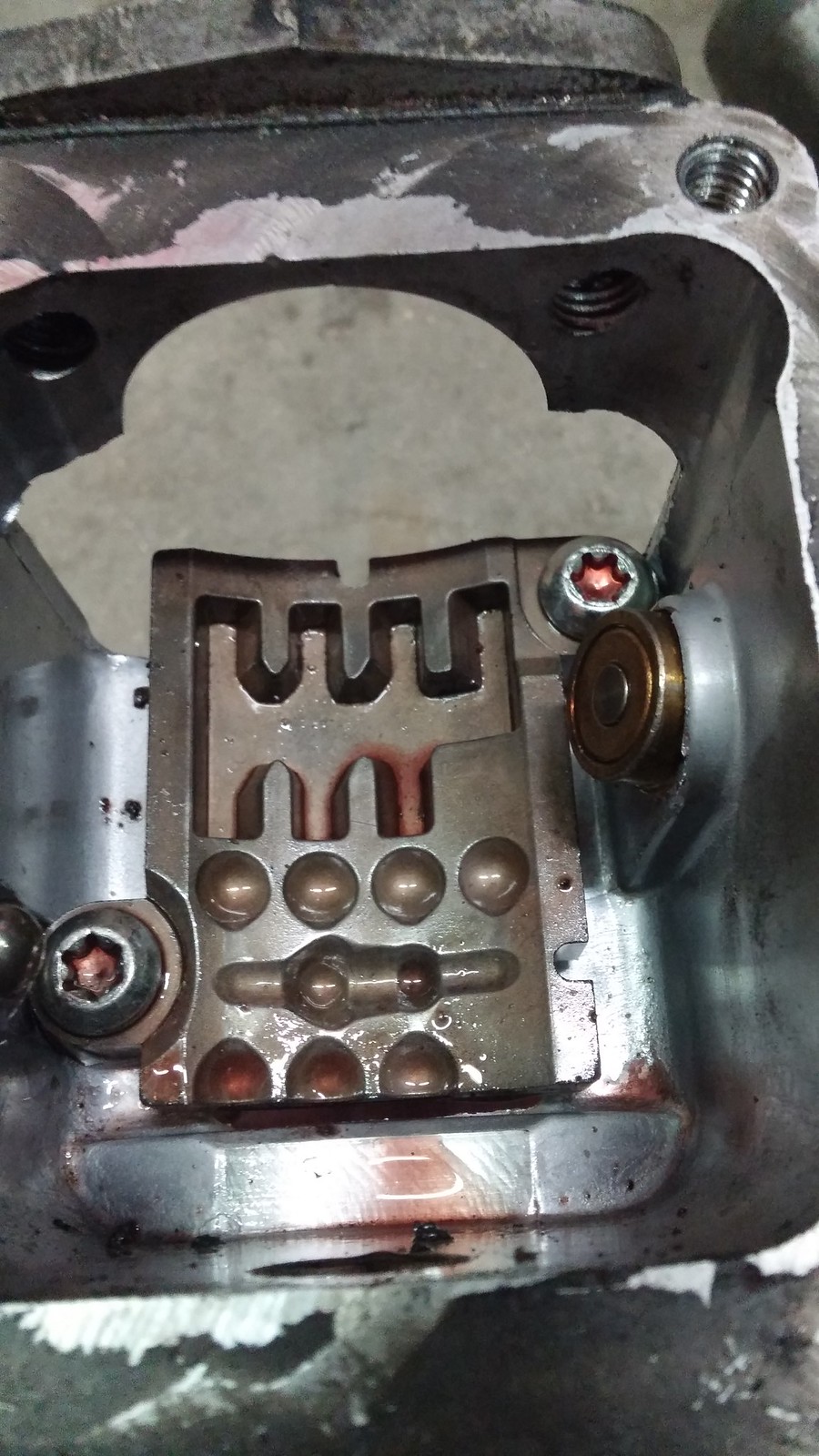

Shift guide plate was in nice shape, so was the detent ball that rides in it

0131171905 by Norbert Ogiba, on Flickr

0131171905 by Norbert Ogiba, on Flickr

Mainshaft off, parts pile grows

0131172025 by Norbert Ogiba, on Flickr

0131172025 by Norbert Ogiba, on Flickr

The stock 3.42 diff arrived today at RKT Performance for a rebuild and Motive 4.10 ring and pinion install. Rick sent over some pictures of the worn clutches and broken Belleville spring.

unnamed1 by Norbert Ogiba, on Flickr

unnamed1 by Norbert Ogiba, on Flickr

unnamed2 by Norbert Ogiba, on Flickr

unnamed2 by Norbert Ogiba, on Flickr

unnamed3 by Norbert Ogiba, on Flickr

unnamed3 by Norbert Ogiba, on Flickr

In addition to the Motive 4.10s it will be getting new C6Z06 clutches, springs, seals, and o-rings.

While I wait on T56 parts and the diff I think I'll start to work on the torque tube. That will consist of inspection of the rubber couplers (guibos), bushings, and bearings. Last of the "must do" items is an LS7 clutch and flywheel. I am starting to get the itch to drive this thing.

Leave a comment:

-

Good news - I was able to pull off the 5-6 driven gear without much difficulty after making up some 3 jaw puller extensions

Not my pic, just an example

Main case nearly empty of parts (all 5-6 and reverse stuff gone)

Everything laid out in order of disassembly

The bad news is that both the 5-6 and reverse shift fork pads showed issues of cracking. Probably to be expected after 115K miles. I will be replacing them for all gears/forks with billet bronze units.

Magnets will need some cleanup but no chunks of anything on them, just that metallic paste

Hoping to have the main case off the front plate this week so I can finally get to the spring that made me take this whole thing apart in the first place.

Leave a comment:

Leave a comment: