Bottom end came back from the machine shop on Tuesday June 2nd, so I jumped right in.

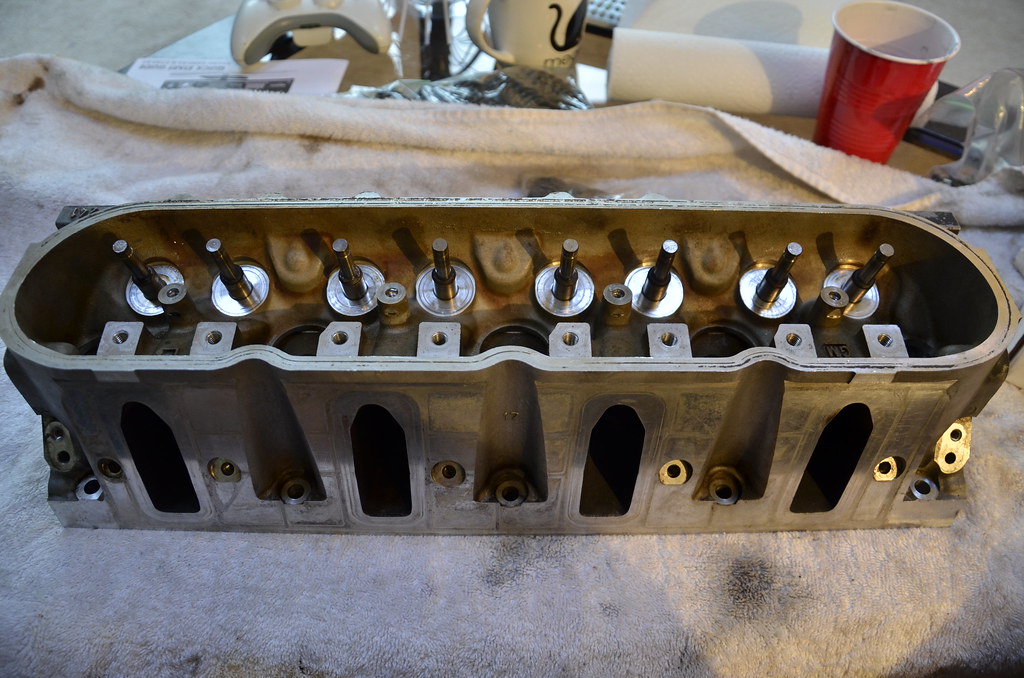

_DSC3854 by Norbert Ogiba, on Flickr

_DSC3854 by Norbert Ogiba, on Flickr _DSC3855 by Norbert Ogiba, on Flickr

_DSC3855 by Norbert Ogiba, on FlickrUnwrapping the goodies

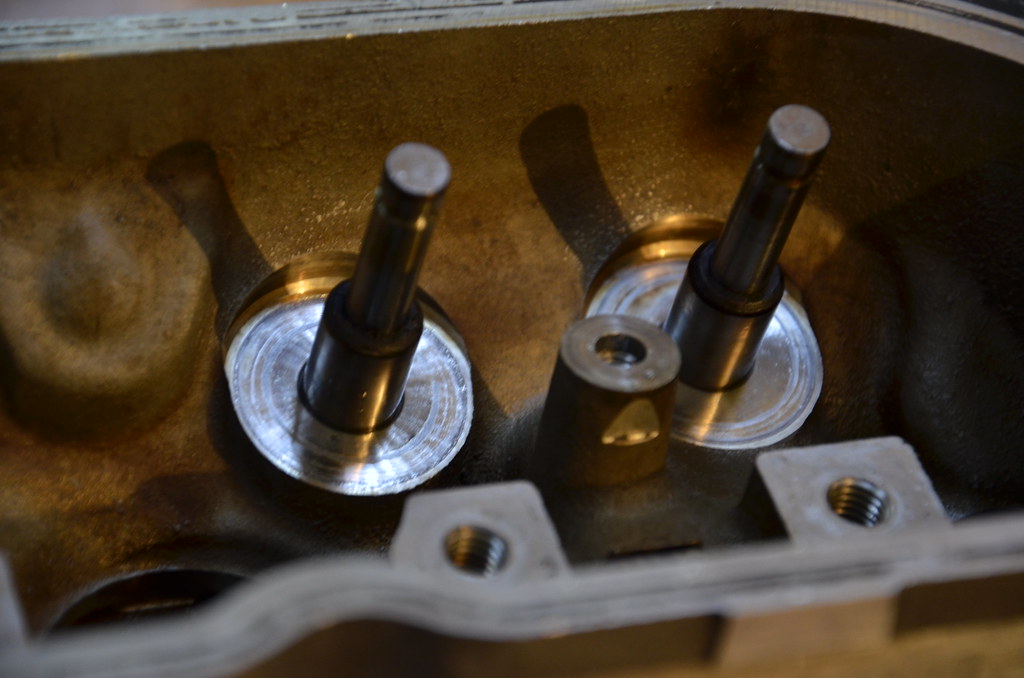

_DSC3856 by Norbert Ogiba, on Flickr

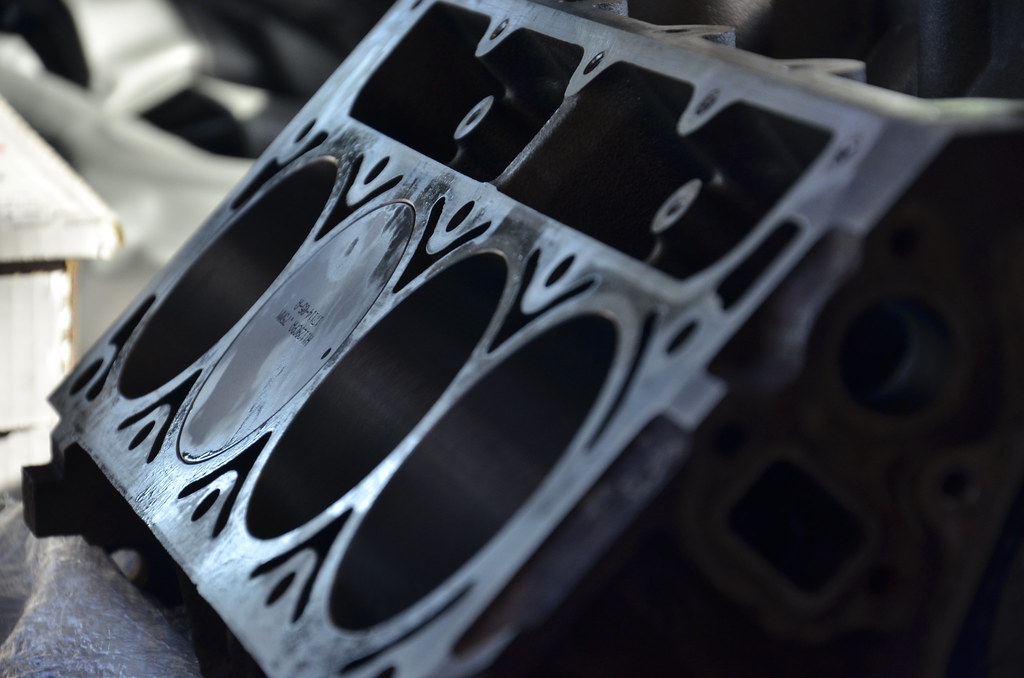

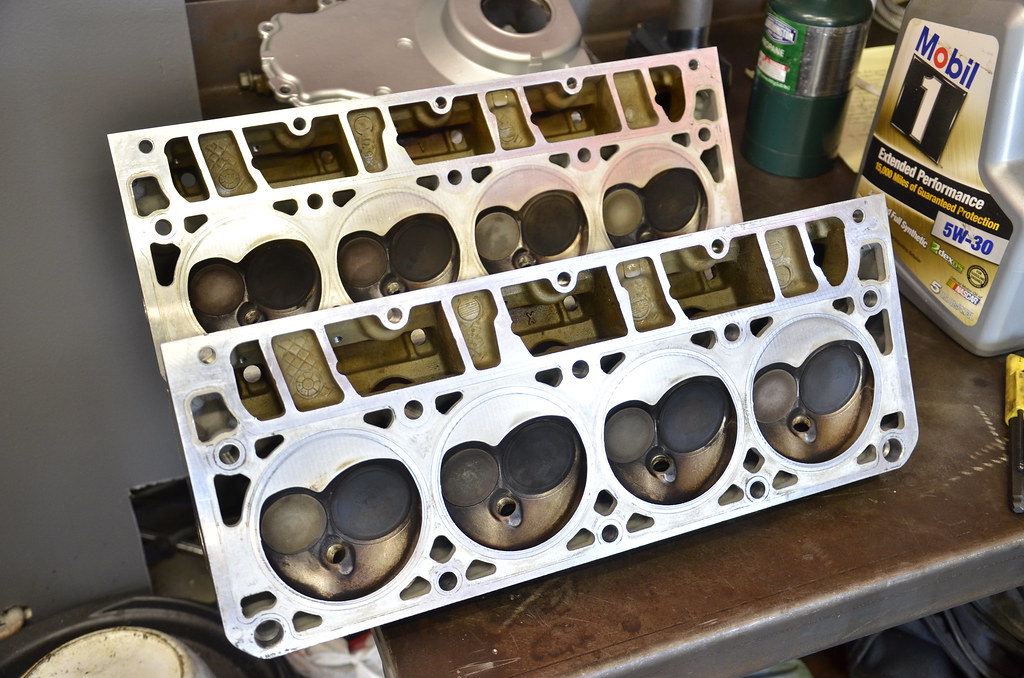

_DSC3856 by Norbert Ogiba, on FlickrFlat-top piston goodness. My builder oiled the motor lightly to prevent flash corrosion on deck surfaces

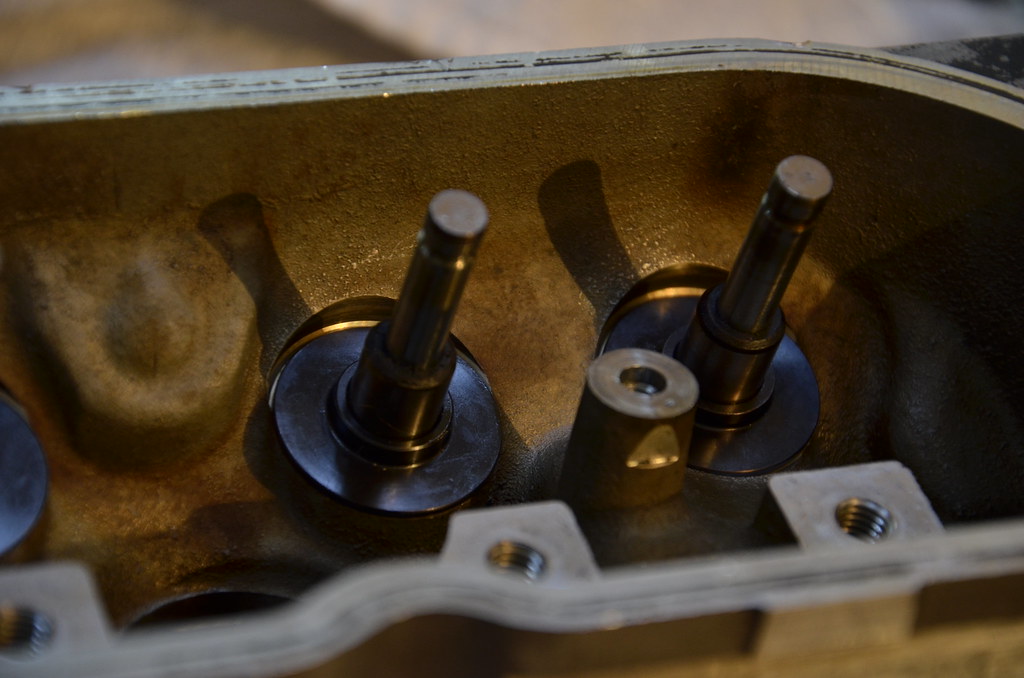

_DSC3857 by Norbert Ogiba, on Flickr

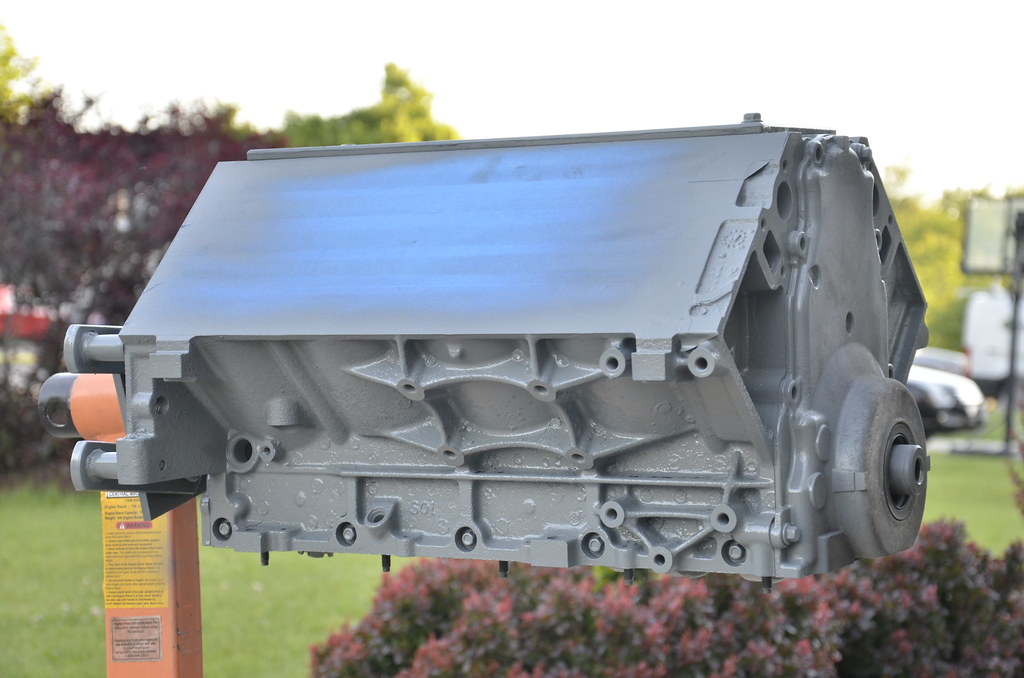

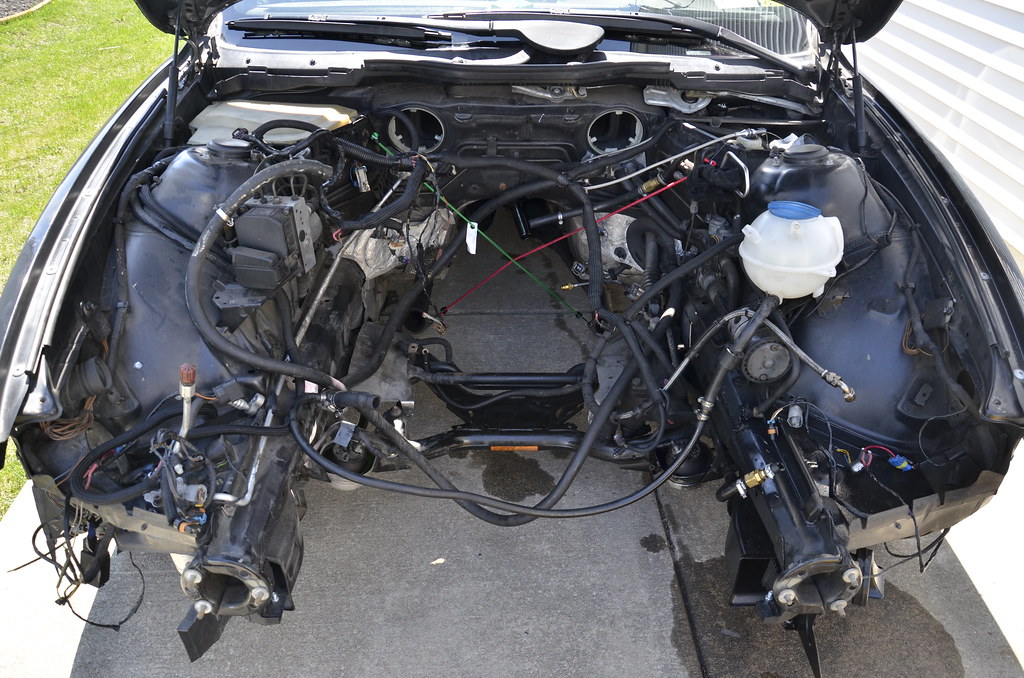

_DSC3857 by Norbert Ogiba, on FlickrUp on the stand, degreased, taped, and ready for paint

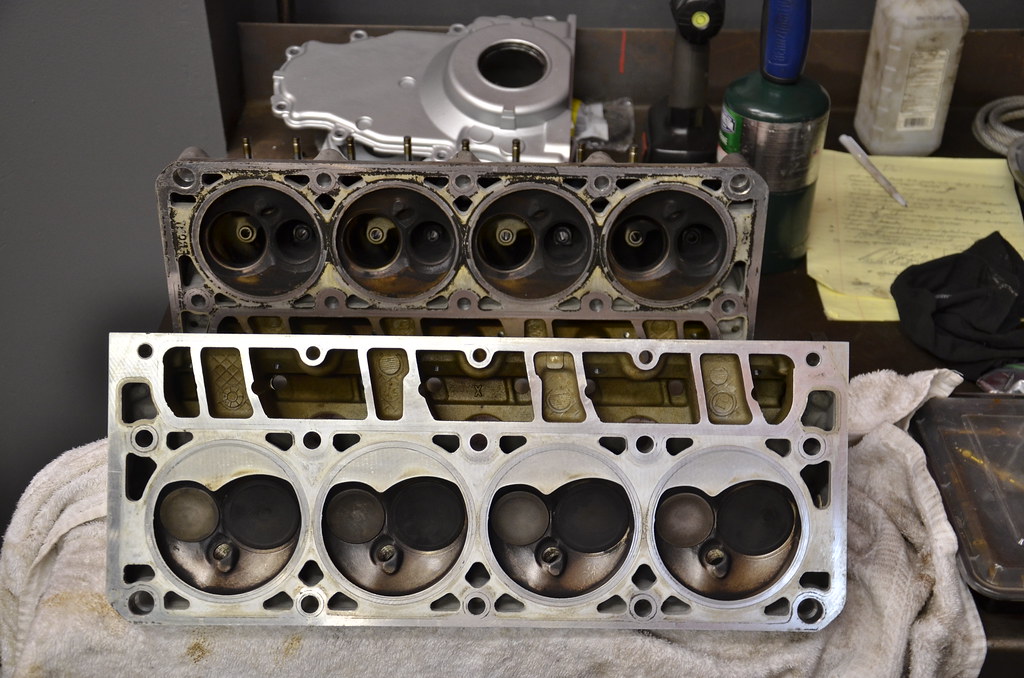

_DSC3858 by Norbert Ogiba, on Flickr

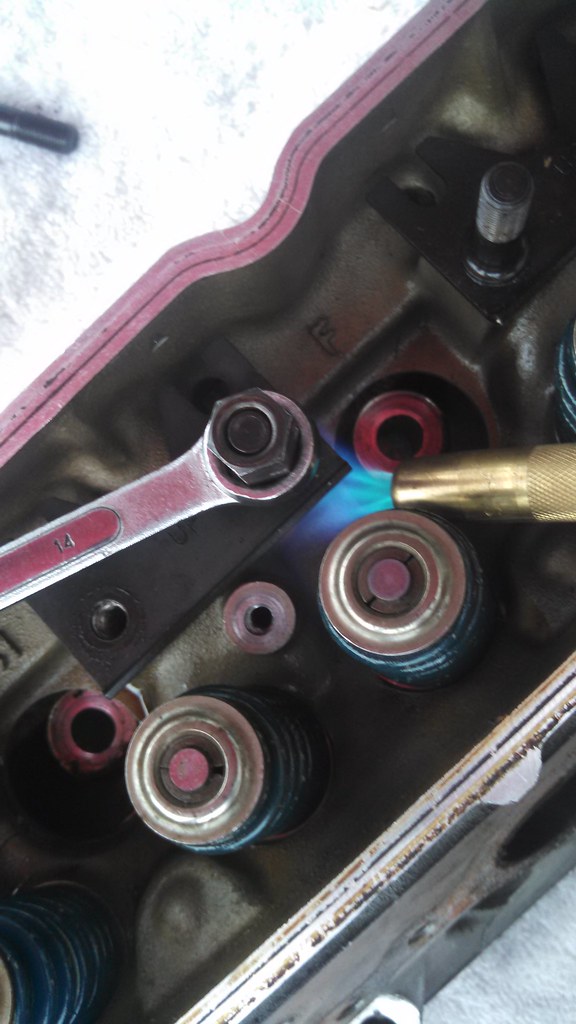

_DSC3858 by Norbert Ogiba, on FlickrI had a set of nasty looking front and rear covers laying around, so rather than tape off those areas, I just snugged them up with 2 bolts to keep the paint out of the internals.

_DSC3859 by Norbert Ogiba, on Flickr

_DSC3859 by Norbert Ogiba, on Flickr _DSC3860 by Norbert Ogiba, on Flickr

_DSC3860 by Norbert Ogiba, on FlickrI chose a high high engine primer to start with, followed by medium gray high heat engine enamel. The idea was a nice "clean" color that would make leaks easy to spot, and not draw too much attention. I was going to go with an aluminum alloy silver, but since this is an iron block, it wouldn't have looked "right" on the porous iron texture.

_DSC3861 by Norbert Ogiba, on Flickr

_DSC3861 by Norbert Ogiba, on Flickr.

Certainly won't win any concourse awards but I like how it came out.

_DSC3862 by Norbert Ogiba, on Flickr

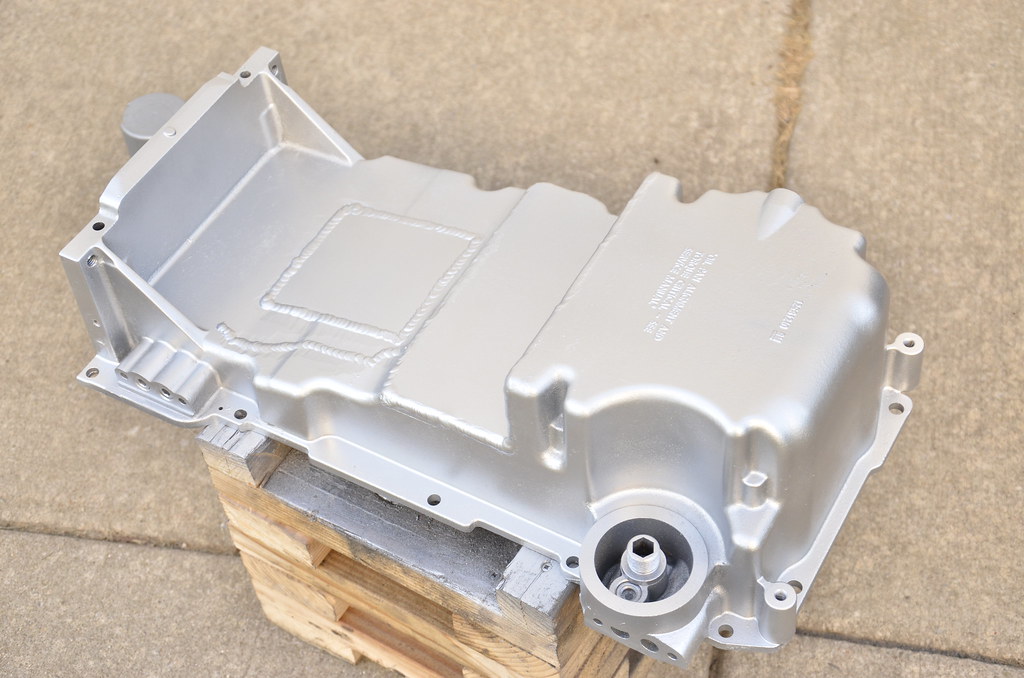

_DSC3862 by Norbert Ogiba, on FlickrOil pan was welded up by a local shop and got a fresh coat of silver aluminum color paint.

_DSC3863 by Norbert Ogiba, on Flickr

_DSC3863 by Norbert Ogiba, on Flickr

Leave a comment: