Originally posted by LQ4-E39

exhaust is done. CTS-V manifolds, stainless 2.25" mandrel piping

oil pan is on. it was warm out so my fiancee decided to help out.

[/QUOTE]

[/QUOTE]Manifolds are finally done, painted with VHT Flameproof header paint

Luckily I didn’t have to trim any of the OEM manifold heat shields to fit the exhaust. Forgot to snap a picture of those bolted onto the manifolds.

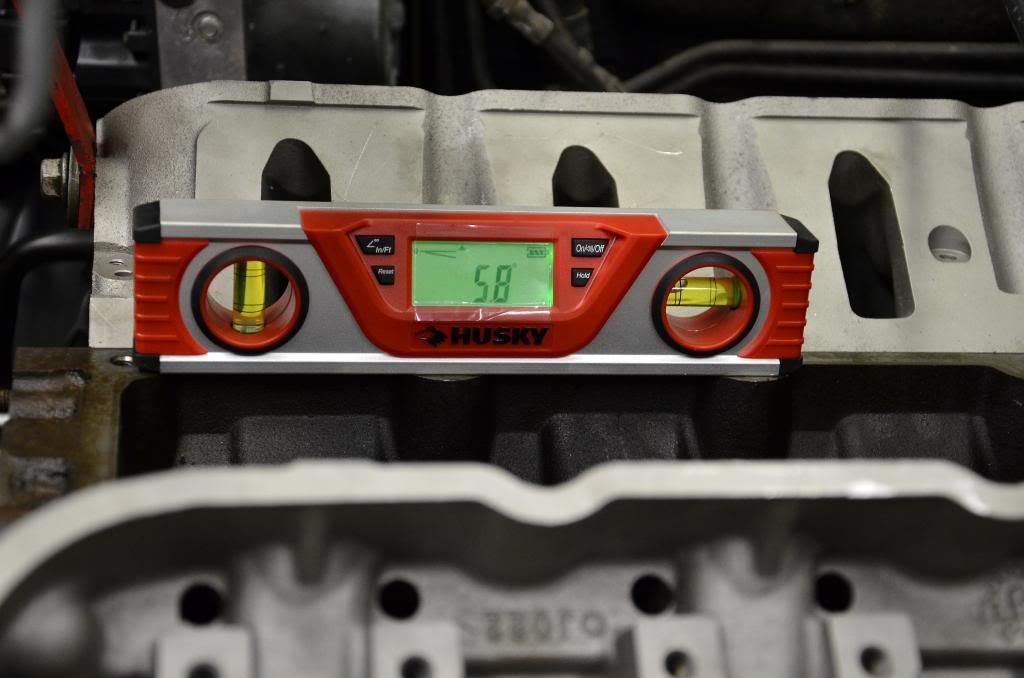

My rebuilt Stage 2 T56 will be here Friday, along with the Diamond lightweight flywheel. I’ll bolt up the flywheel, Diamond Stage 2 clutch/pressure plate, and hopefully install the motor for the last time this weekend.

Also ordered a Tick speed bleeder to bleed the new system quickly and easily. I still need to figure out whether the new 4th gen F-Body clutch line can be modified the way the E36 guys do, since the E39 master may be different.

Ordered a 1330 slip yoke locally, it came in yesterday, test fit it today, and of course it's the wrong one and doesn't fit. I am going to return it and go to another, more competent shop locally (Denny's Driveshaft).

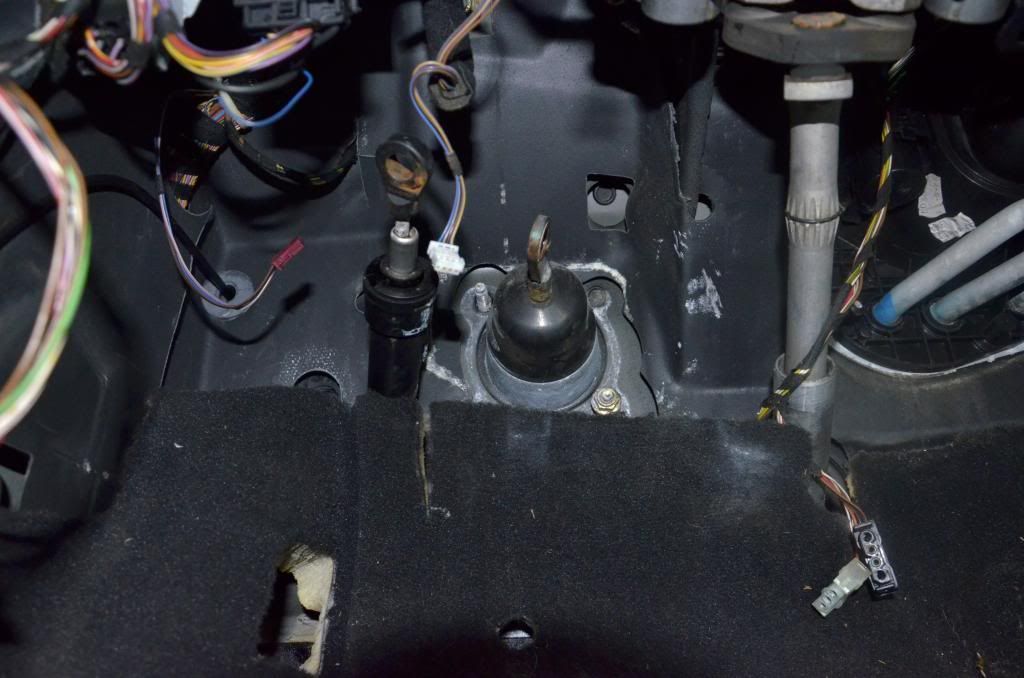

Also wrapped up the clutch line. Rather than modify the camaro master cylinder fitting to match the BMW, i just had a local hydraulic shop mate the 2 lines. Installed and fits perfectly. I also installed the Lokar throttle cable; the outer sleeve was the perfect length, but the inner line was just a tad too short, so $5 later, a bicycle brake line trimmed to fit finished the job. I finished up the pedals, put them all back together, and we're good to go. I would have bled the clutch but didn't have any spare fluid on hand.

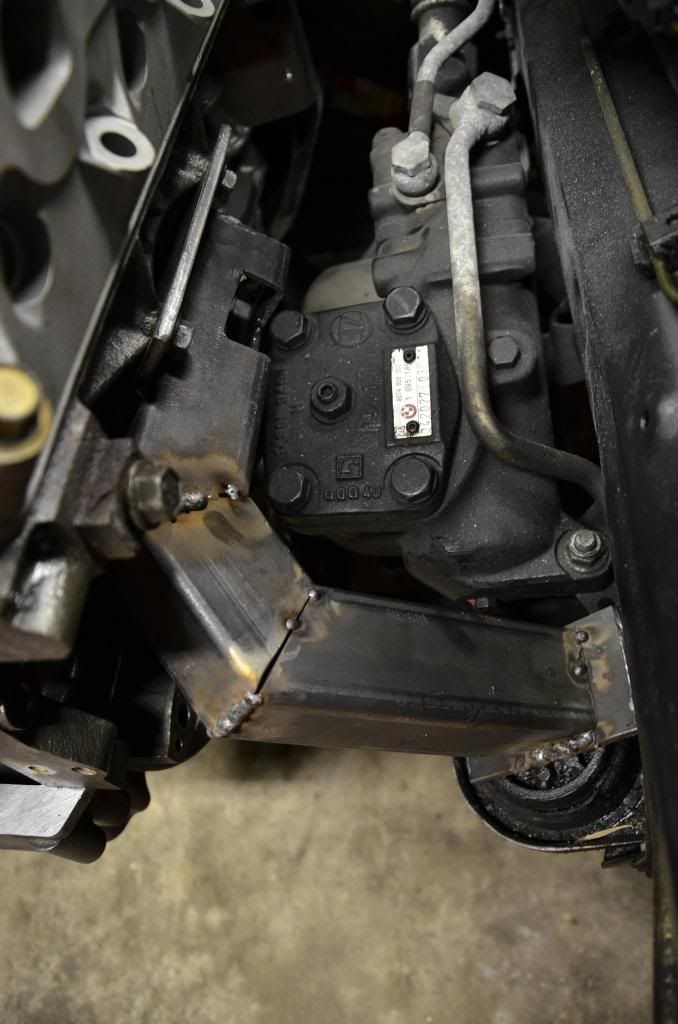

I rebuilt the driver's side engine mount to clear the alternator, and was inspired to get creative with the sharpie...i think it was the brake cleaner fumes

These also came in. I need to buy one of those 45* filler necks so the oil filler cap lines up with the cover.

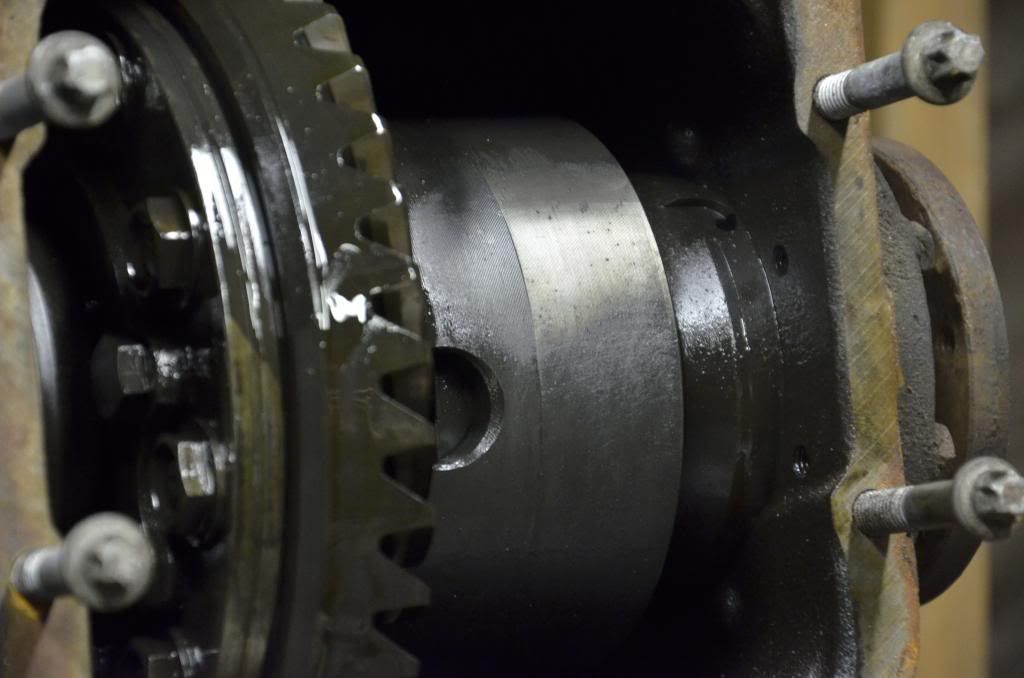

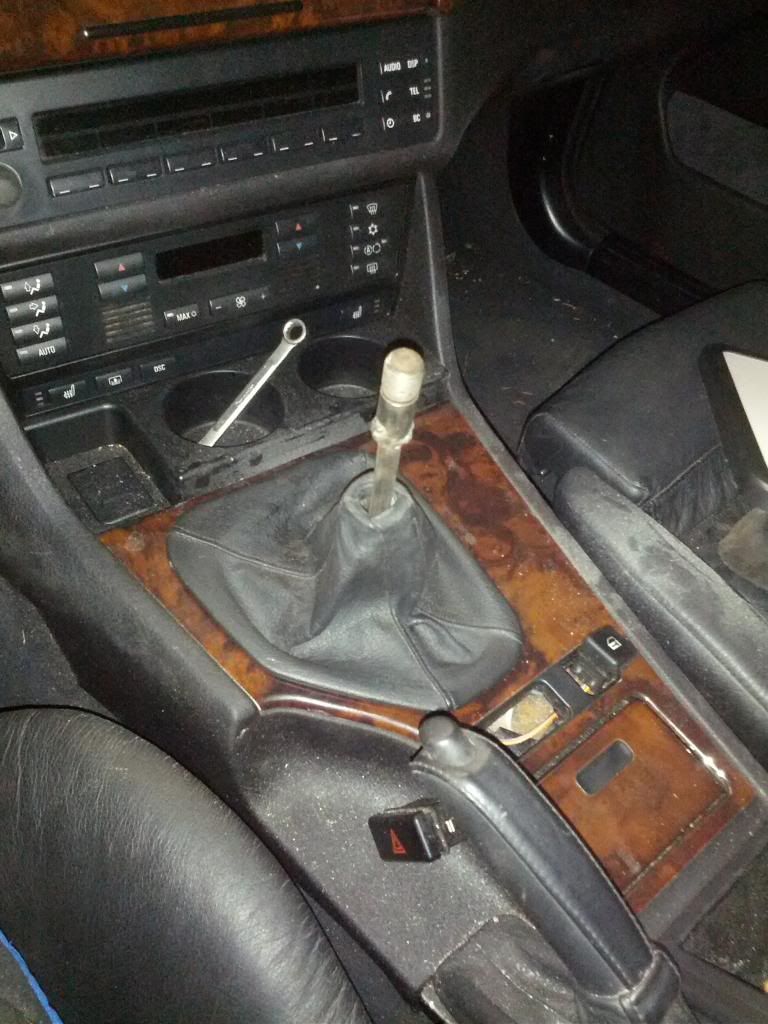

T56 came back from Texas Drivetrain

and it all went together smoothly.

Then, my daily driver decided to surprise me on Thursday morning

It was broken into 5 pieces, and shredded that tire. I grabbed a replacement spring from a junkyard and had it on the road again later that day.

getting closer. I took a week off from work to make progress on the car and blow off some steam overall.

Corvette FPR and filter installed

Cooling system done. No leaks, but it'll really be put to the test once we I fire it up. Here is the final routing I went with.

I also replaced the front sway bar end links as they had been clunking since I bought the car.

Received the last reducing coupler I needed for the intake, so that's all set. I'll be using a section of 3" SS exhaust pipe I have laying around to extend the filter as close as I can to the factory cold air intake ducting in the bumper/fender. Probably going to paint it wrinkle black.

The biggest task of the week was working on wiring. I had to add a few pins/wires to the BMW cluster to be able to accept analog GM tach and coolant temp signals, since the cluster originally got those signals from the DME (now gone) in CAN-BUS. The pins are unlike any other small cluster pins I have seen, but a trip to the yard found me a fistful of these crown shaped connectors out of a white E36. Oddly enough, all the other BMWs there had the common L-shaped pin, both older and newer. I must have spent 2 hours looking for them, but finally got them. I also need a BMW coolant sensor pigtail, but I couldn't find one of those at the yard either, unfortunately.

I went through the GM harness again and removed a handful of circuits I missed the first time around. It's unbelievable how many useless wires and connectors are included in every harness, but I suppose it's easier/cheaper to build them that way as an OEM rather than customizing each harness to each vehicle. Even after thinning it out, the whole mess was still just a huge ball of wires, so there was no chance of laying it on the motor in a clean manner. I spent a day or two on the living room floor disassembling the harness wire by wire, labeling, and separating all the wires. It still needs a bit of cleanup, but it's 90% there. Now it's just a matter of sitting the fuse panel and PCM connectors in their places in the engine bay, and routing/shortening the wires exactly as I like. Time consuming, but much neater and more efficient than trying to untangle on the spot.

Once the GM harness is in and hooked up to all the usual crap, I can make the BMW/GM connections, and once the PCM comes in, I can hopefully fire it up for the first time.

Still need to finish the rear diff and have a driveshaft made before it's driveable.

[/QUOTE]

[/QUOTE]

Leave a comment: