So more work was done today on the manifold process . . .

Pics to explain better . . .

We first made a ring on the TB flange , for the OEM .:R32 rubber gasket to sit in, as it does in oem manifold.

I really loved how it was done - perfect finish and quality overall I think . . .

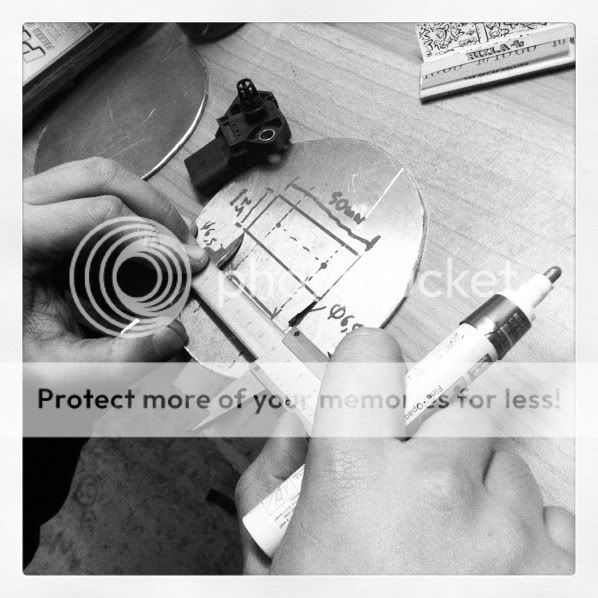

Then, it was time for the plate for the IAT to sit in . . .

And then, a new one for the map sensor - for when the IC pipes are replaced by aluminium ones along with the IM installation .

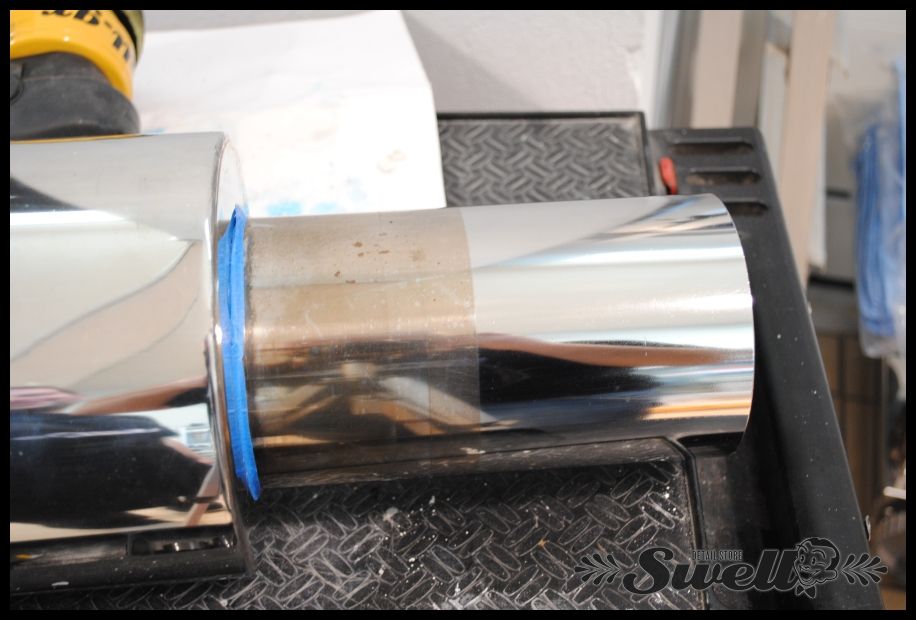

And then - to call it a day - we drilled the hole for the throttle body.

Drill it first . . .

And then . . .

Came out pretty . . . . perfect , thanks Thanos so it so easy to weld now . . .

so it so easy to weld now . . .

we did by the boring- method as shown in the video

[ame="http://www.youtube.com/watch?v=VqW2Ypzmbt8"]Boring-Machining - YouTube[/ame]

Pics to explain better . . .

We first made a ring on the TB flange , for the OEM .:R32 rubber gasket to sit in, as it does in oem manifold.

I really loved how it was done - perfect finish and quality overall I think . . .

Then, it was time for the plate for the IAT to sit in . . .

And then, a new one for the map sensor - for when the IC pipes are replaced by aluminium ones along with the IM installation .

And then - to call it a day - we drilled the hole for the throttle body.

Drill it first . . .

And then . . .

Came out pretty . . . . perfect , thanks Thanos

so it so easy to weld now . . .

so it so easy to weld now . . .

we did by the boring- method as shown in the video

[ame="http://www.youtube.com/watch?v=VqW2Ypzmbt8"]Boring-Machining - YouTube[/ame]

Leave a comment: