Originally posted by nellydragracer

View Post

Originally posted by oprahhwinfreyy

View Post

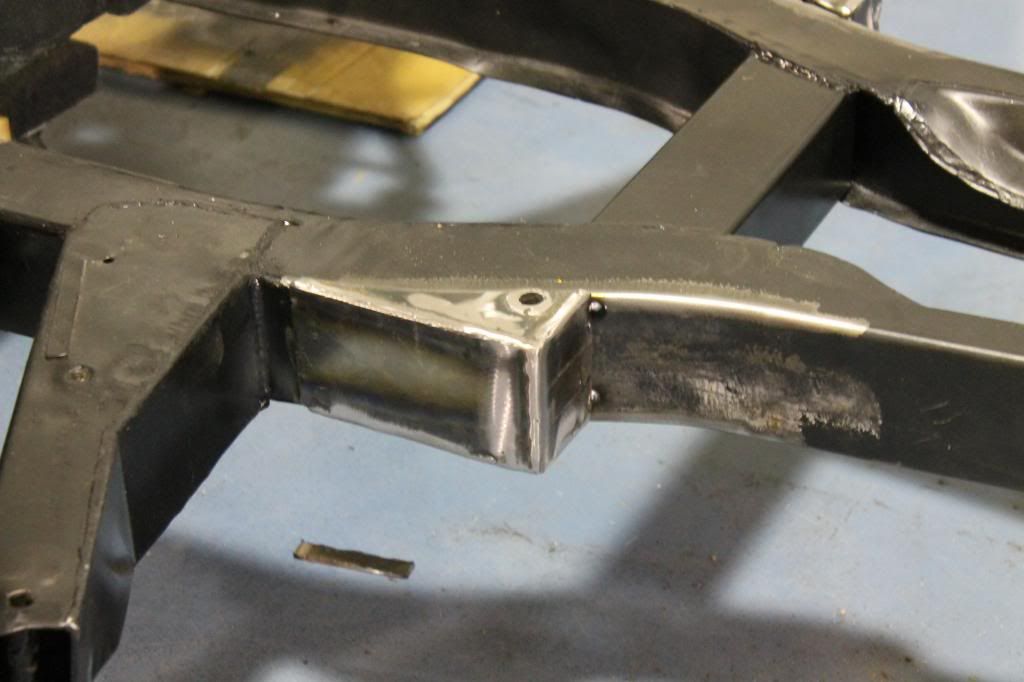

We did a torsion test earlier this week to see how much stiffer we could get the frame to deal with the torque of the turbine. We tested it first, unmodified, then did it again after boxing the center section. We achieved 40% less deflection with the boxing.

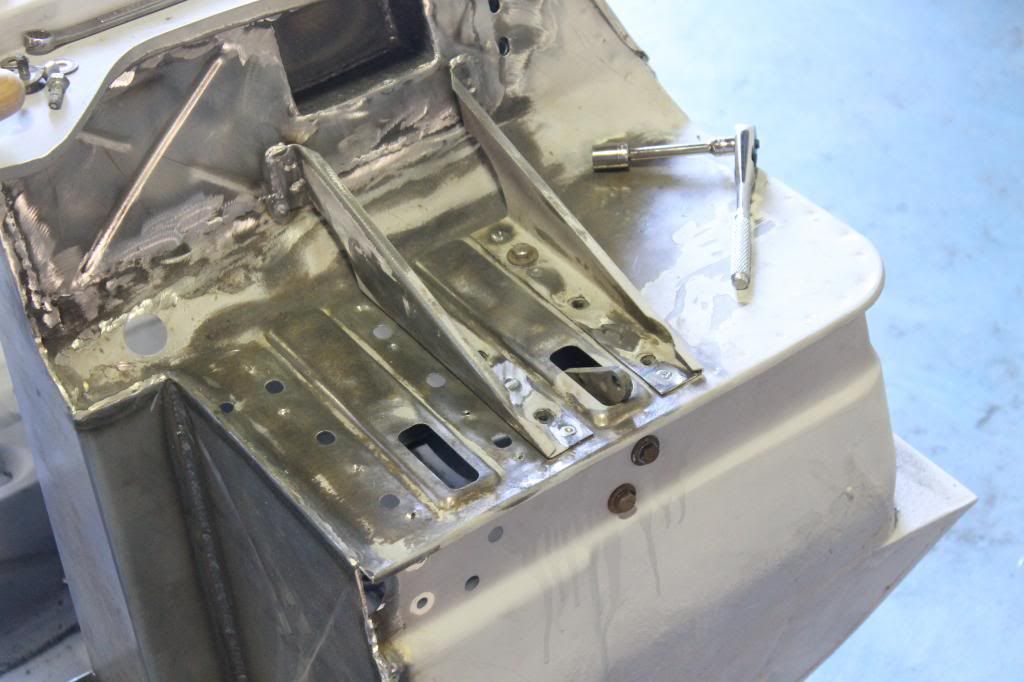

We also clearanced the trunk to fit the 22 gal fuel cell.

Cut some 5052 for the interior paneling

We also had to move the brake to the clutch position to clear the much larger firewall.

Anderson Paint also powder coated our wheels for free which are 13"x6" TR7 wheels that I removed from my car for the project. They blasted and coated them in 1 day, thanks Anderson!

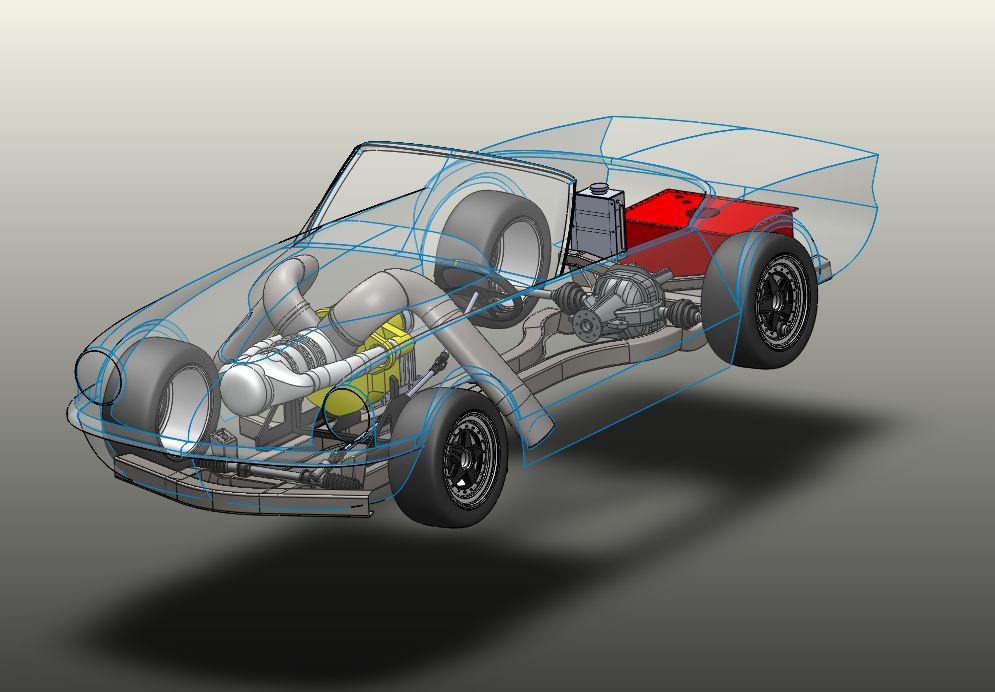

Did a final test fit of the turbine for mounts. The speed holed brace is to take the place of the piston engine, and take some of the load off the strut towers.

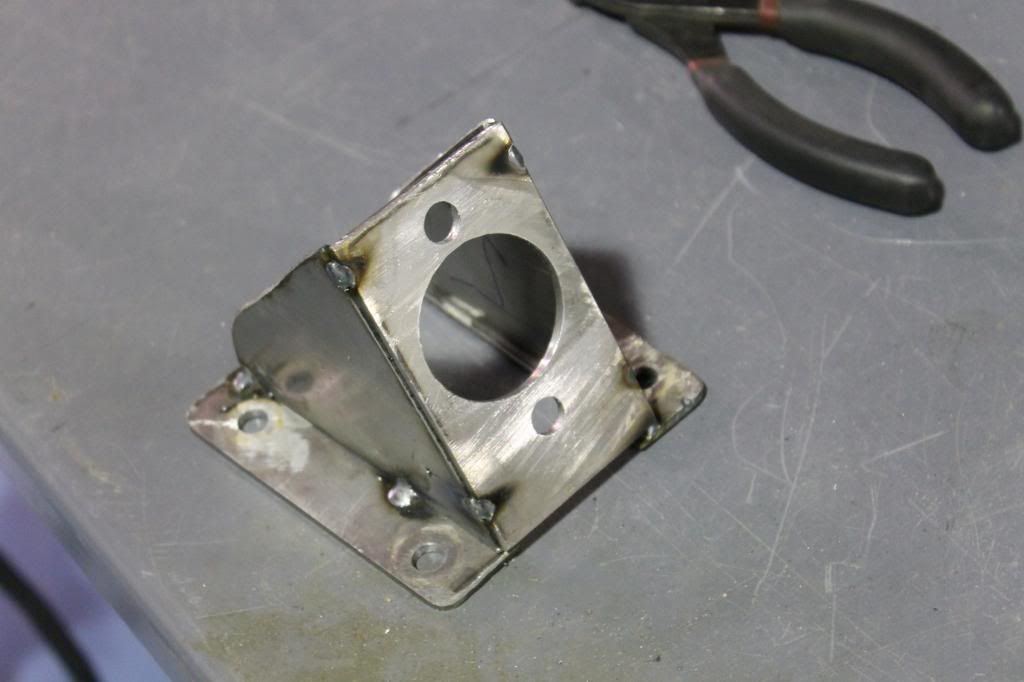

Made some sleeved brackets..

...And tacked them on the frame. we also drilled and welded in sleeves for the front bolts, but you all know what that looks like.

Cleaning up for the day. We'll get more done tomorrow, stay tuned!

Leave a comment: