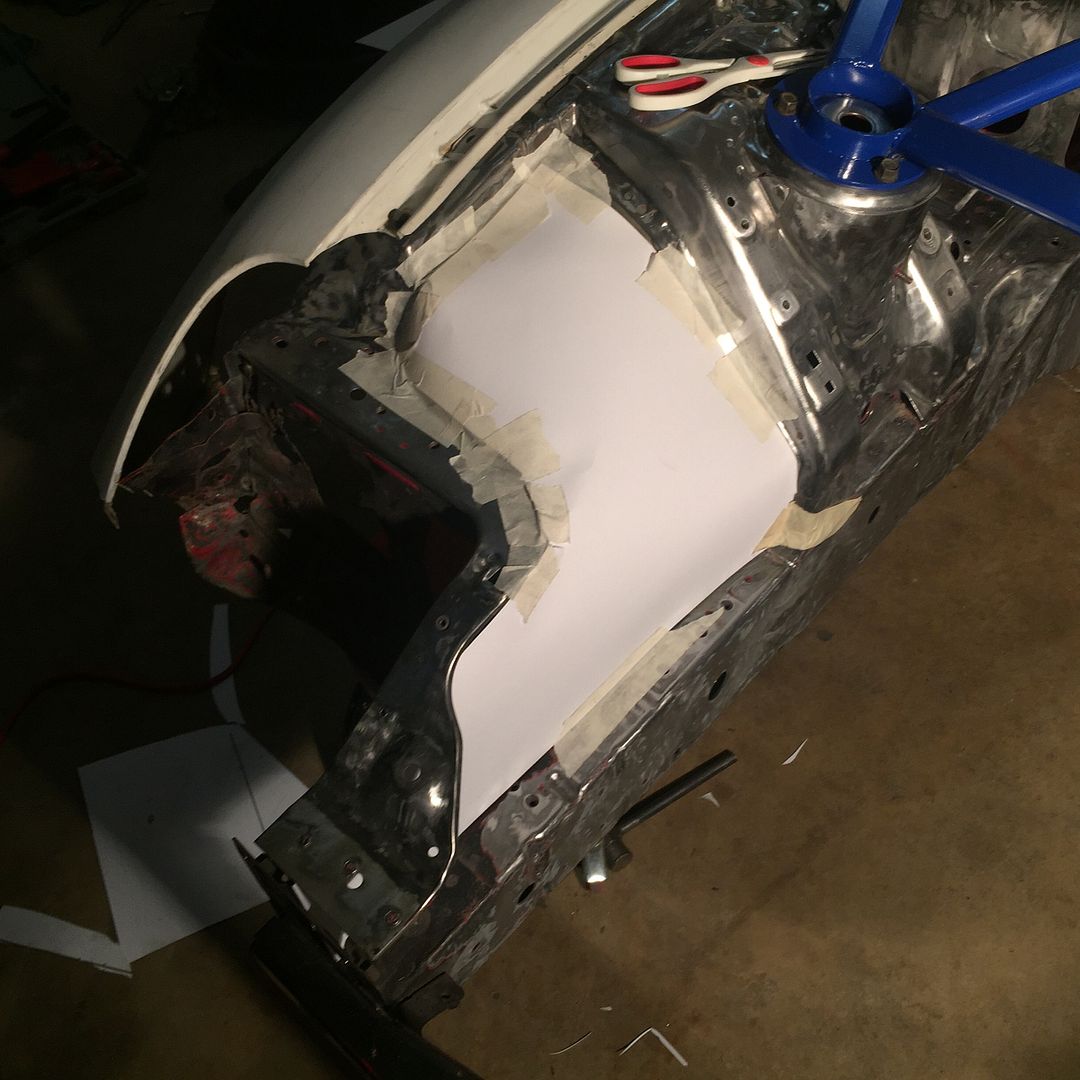

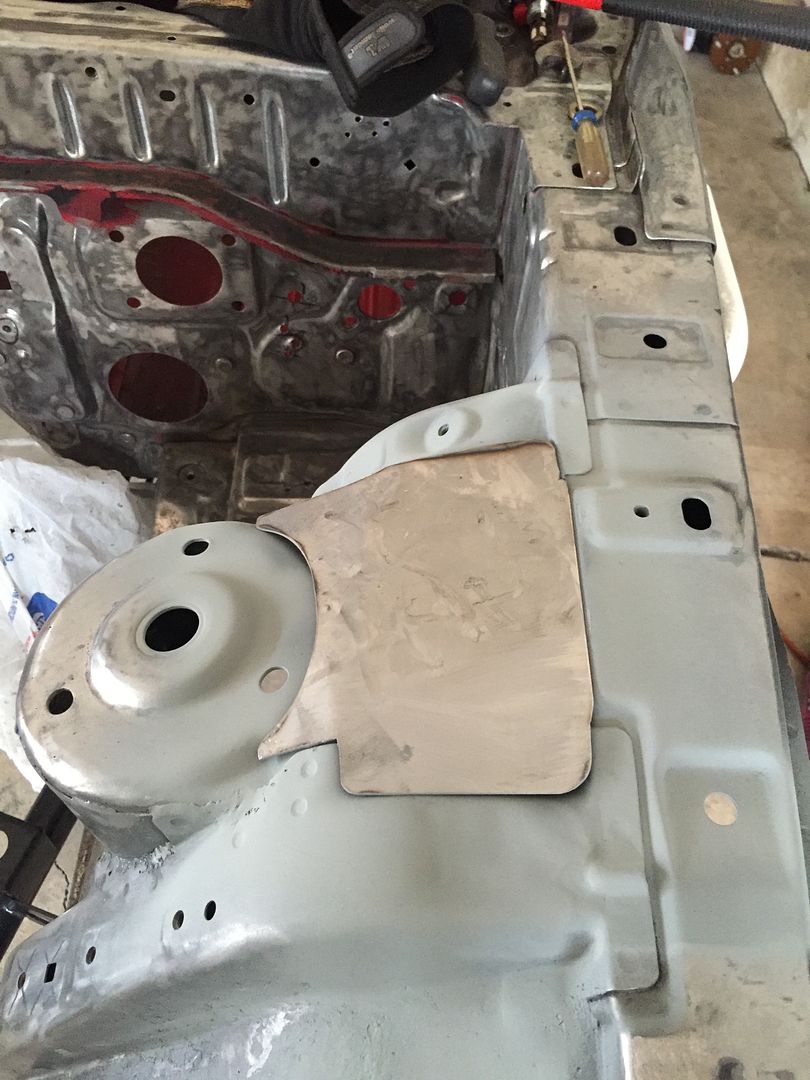

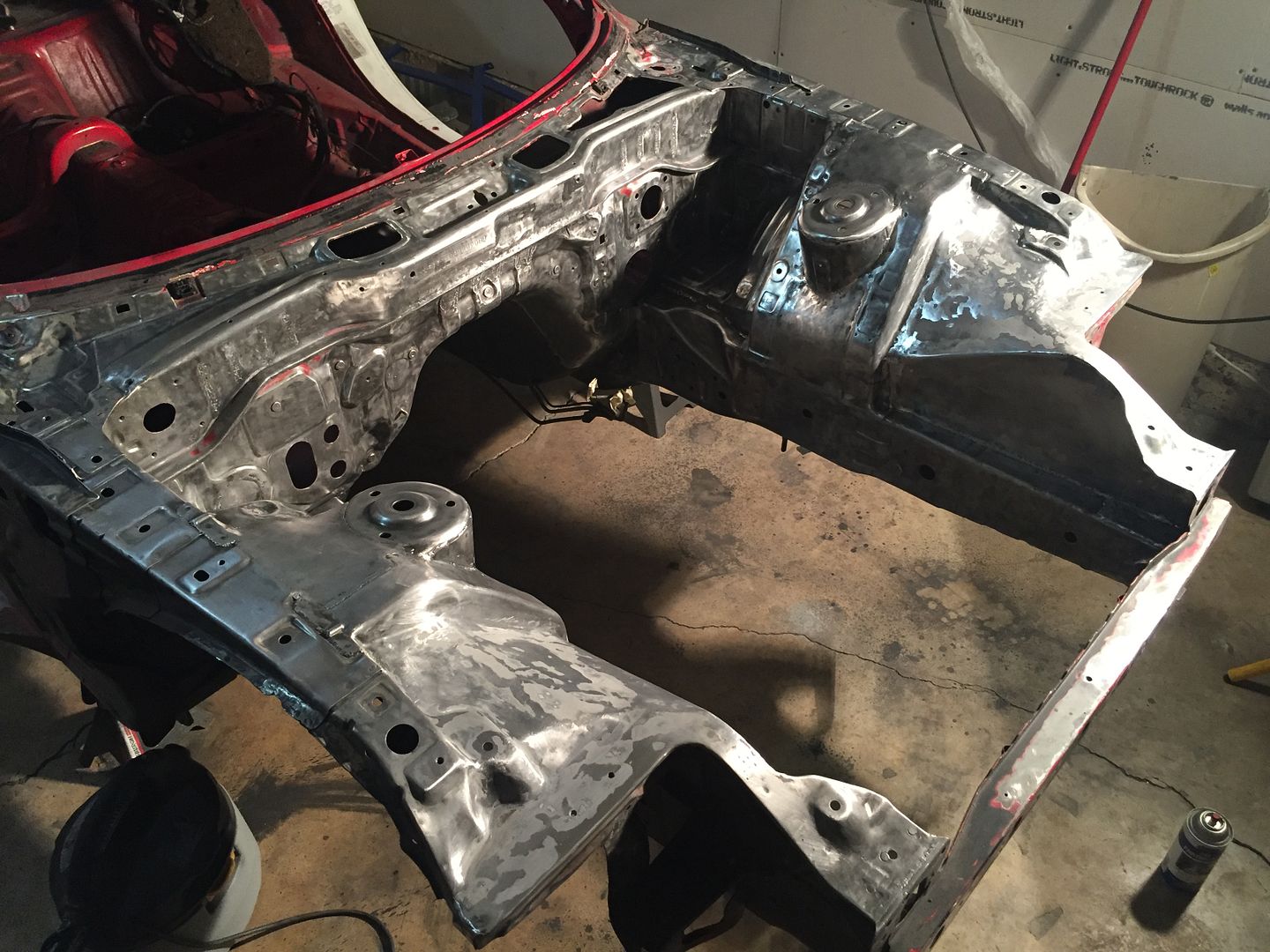

Started mocking up and working on one of the wheel well holes.

Mock up one

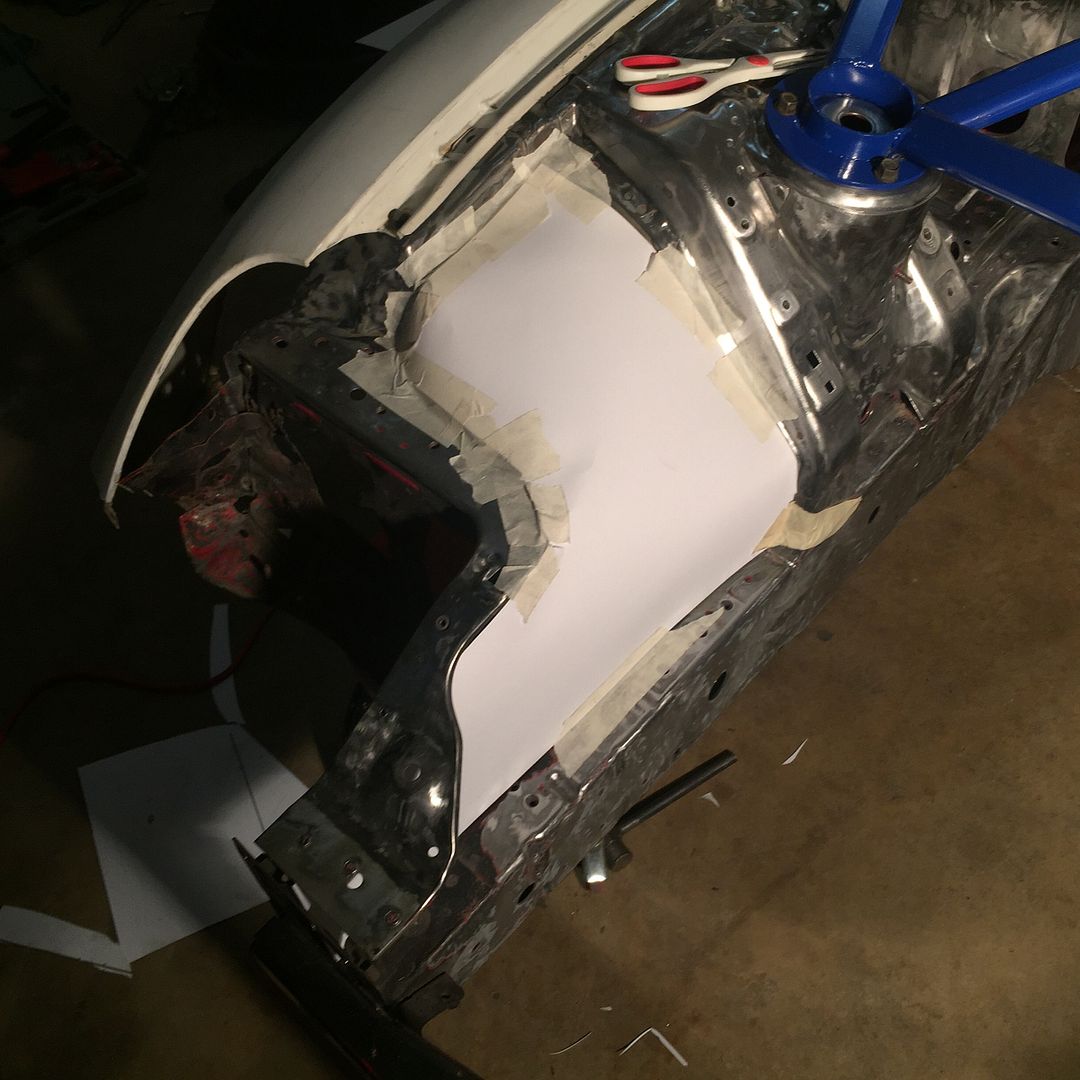

Mock up two

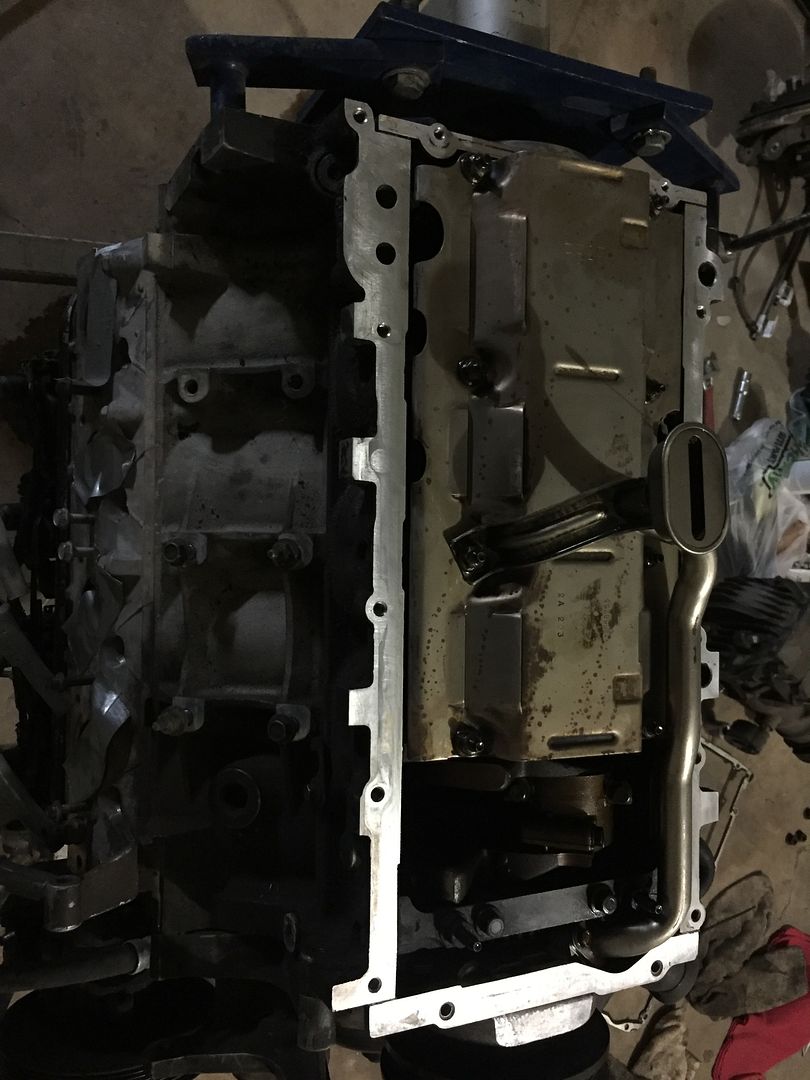

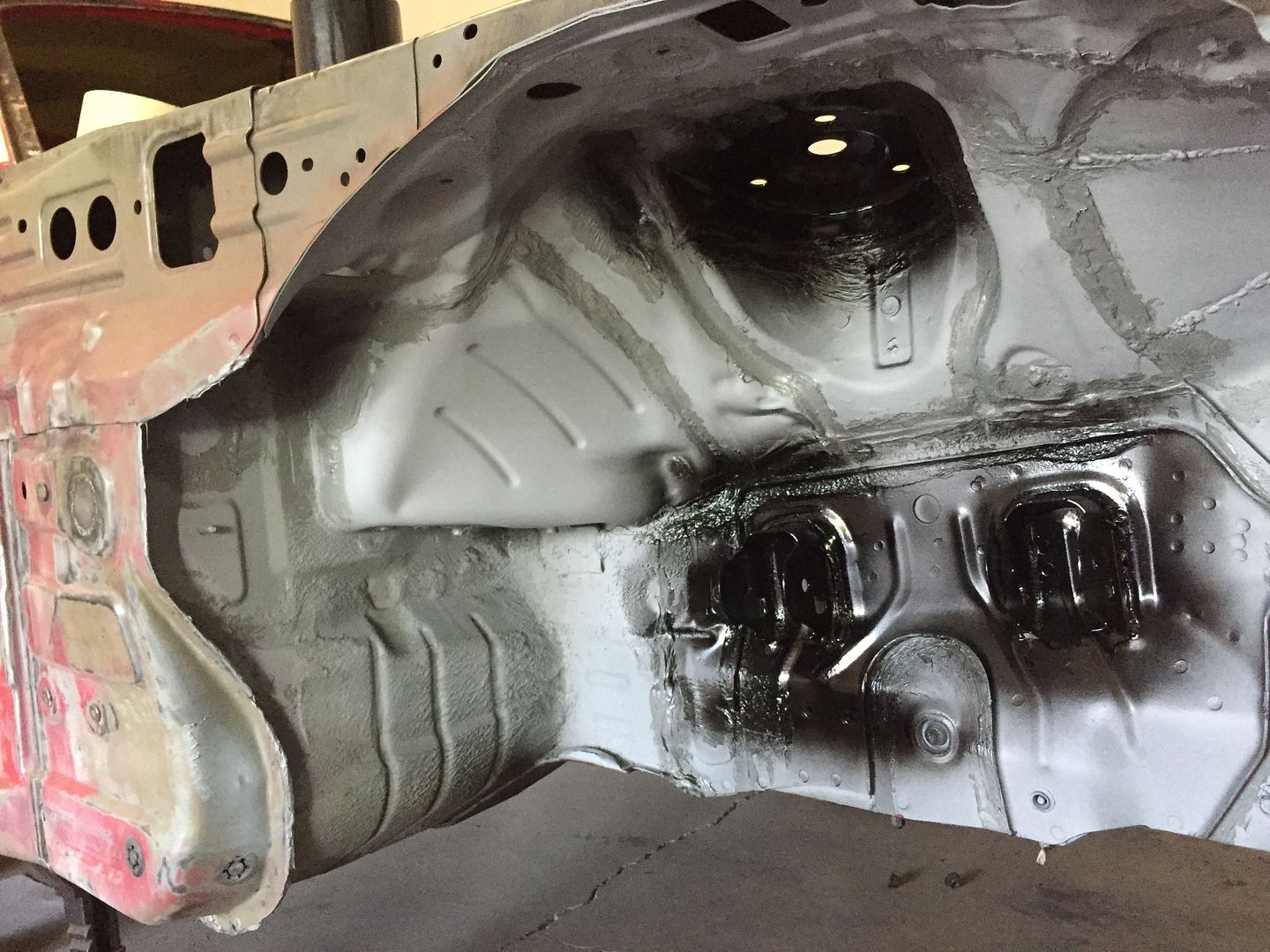

Made up three shapes after the third revision. Transferred pattern to metal and cut it all out. Sprayed self etching primer on to help prevent rust

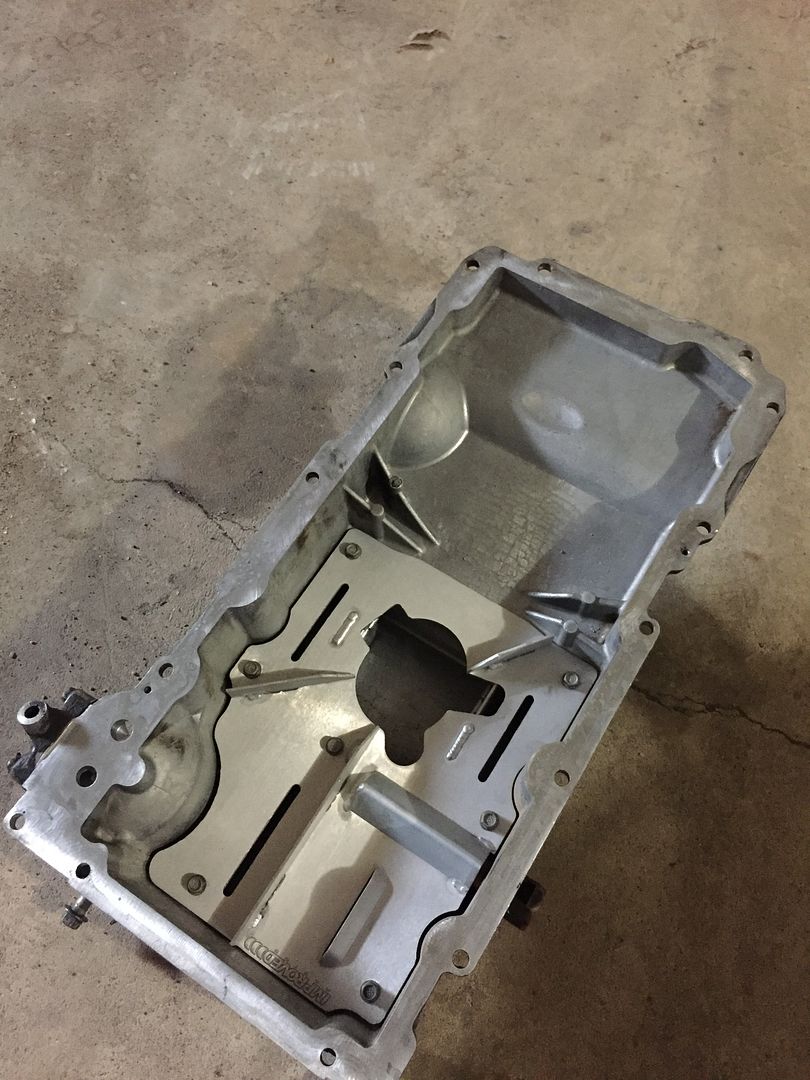

And this is where I stopped today. Have them all tacked in, just need to make another pass and grind down the crappy welds. Also need to weld together the three pieces in the middle. Hopefully I'll get that done tomorrow

Mock up one

Mock up two

Made up three shapes after the third revision. Transferred pattern to metal and cut it all out. Sprayed self etching primer on to help prevent rust

And this is where I stopped today. Have them all tacked in, just need to make another pass and grind down the crappy welds. Also need to weld together the three pieces in the middle. Hopefully I'll get that done tomorrow

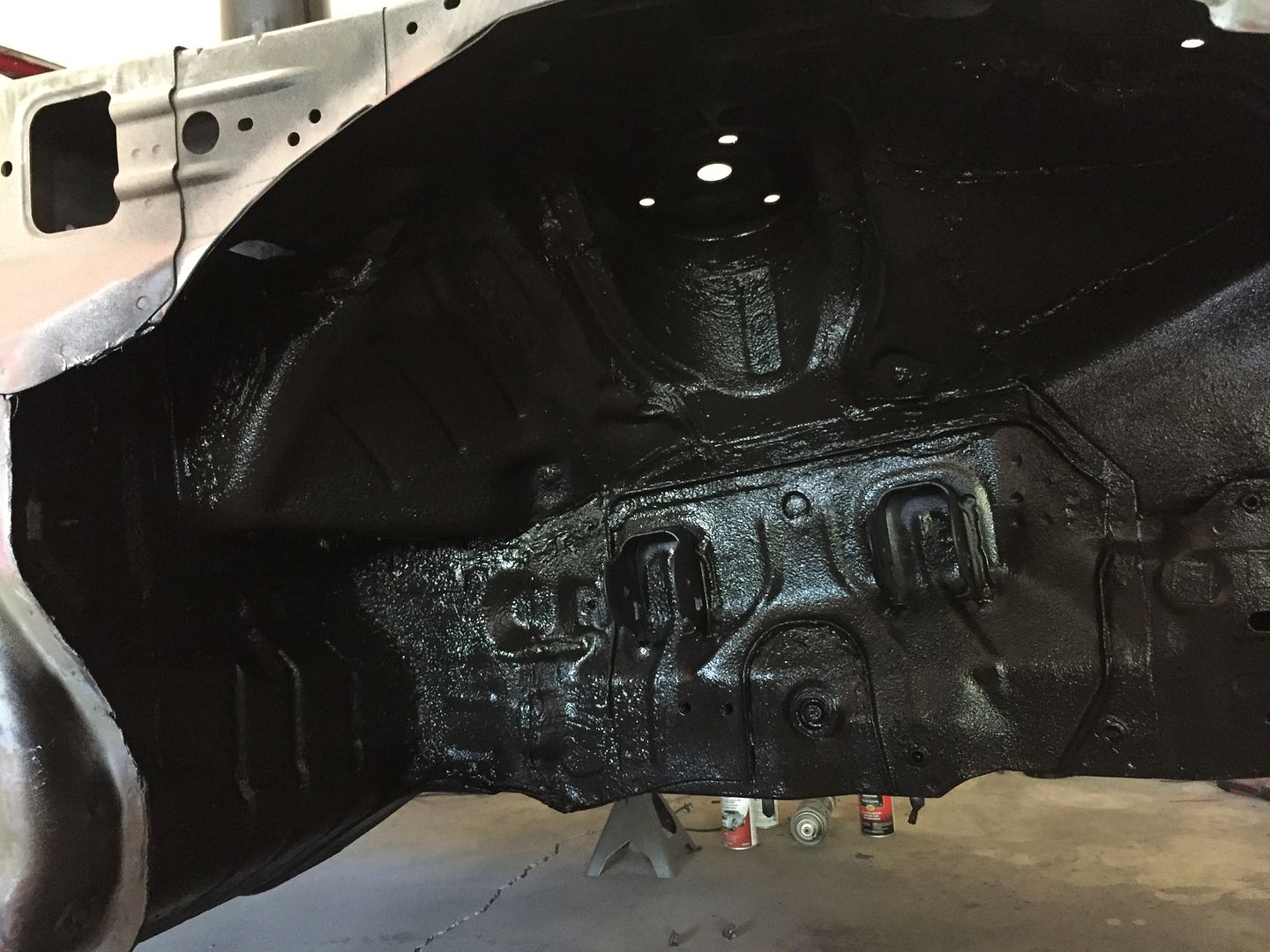

Finished up the bottom cover on one side

Finished up the bottom cover on one side

Comment