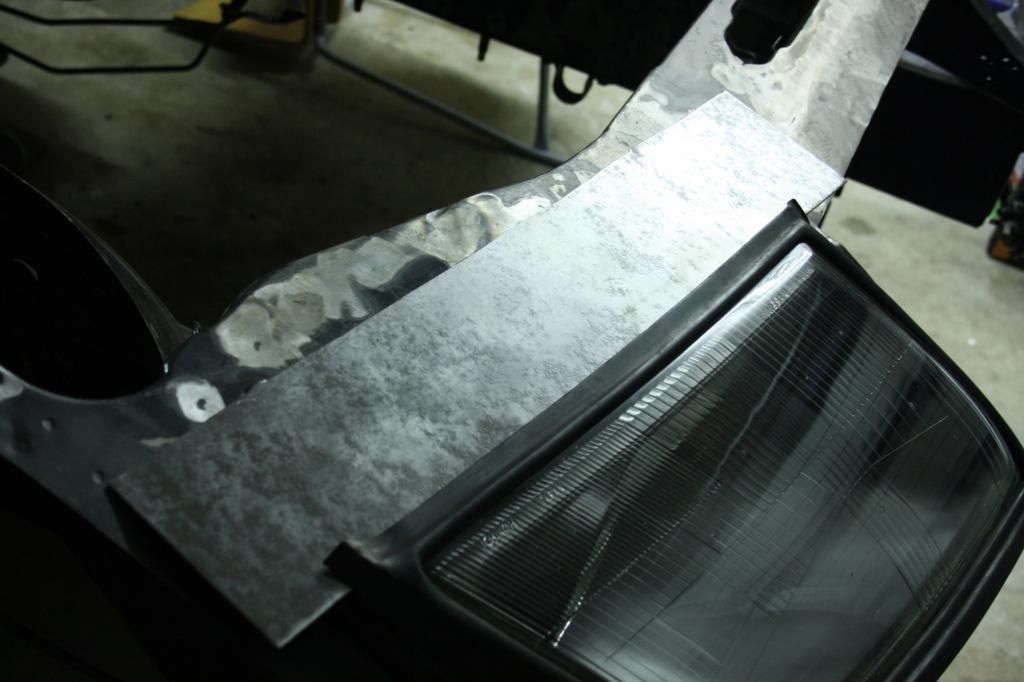

As you can see there's a big gaping hole behind the nose panel. A few people have closed this off before but I wanted to take it a step further and extend the support over the backs of the headlight housings too.

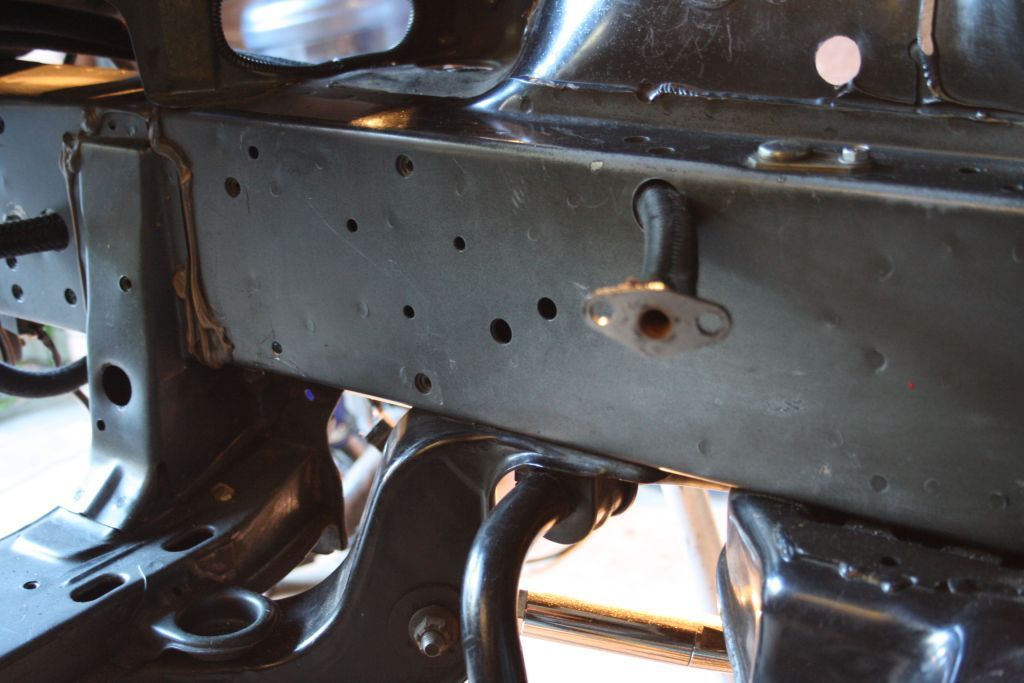

part 1, cut up a wreck.

The hood latch is staying and I wanted to mirror its cut out while closing off the surrounding area. like a permanent, welded in air guide. I'm really not into hood pins from an exterior aesthetics standpoint and there's no way I'd put them in so I could clean up the looks of the bay.

What better way to do that then with the exact same OEM shape... the doner car's front end was bent up, amazingly only the centre of the rad support coming out unscathed. Getting better with the MIG, but still room for improvement.

continuing from the last piece, the centre rad support extension was bent up. It covers up to just under the nose panel, so there're no gaps visible once the car is assembled.

simple bends and simple weld makes for a happy anti

before the piece permanently attached I fully welded the underside so the bend could be smoothed down later on.

plenty of "measure twice, cut once" went into final positioning of the panel

aaaand fully ground down ready for a touch of lead, filler and primer. next bit was extensions for the upper rad support to cover the backs of the headlights.

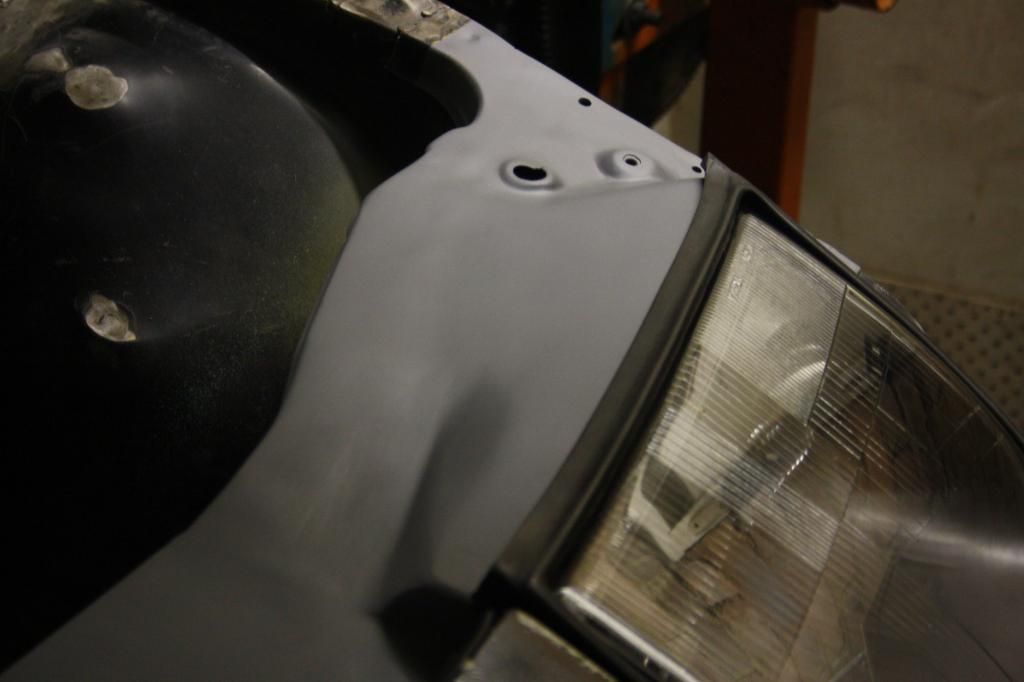

this will mean the entire upper rad support is the same width as the new centre section and some uglyness behind the light will be covered up.

in terms of the actual process I started with a rectangular piece of 15 gauge (1.8mm) mild steel and slowly bent it to suit. this was actually a much more complex shape than I initially thought and by the end of it there were a good 25 or so bends.

also not to plan was my inability to bend this stuff by hand, haha. to overcome this I traced out a straight line on the back of the panel where I wanted to bend it, then ran a cutting disk back and forth along said line a few times to thin the metal. it then bent exactly where I wanted with ease

at first the plan was to work from the rad support towards the headlight, until I realised it would be ten fold easier to work back from the only straight edge (underneath the headlight weatherstrip) rather than to create one.

the back of the headlight had have as much height taken off as possible. this including removal of the top weatherstrip retaining bracket with workaround devised, cutting down some a sizeable amount of glass below it and converting the underside mounting brackets from studs to nuts. the latter means the headlights can be slid straight in without having to lift the front section to slot through the pair of studs. every little bit helps, it's a tight fit.

with one side completed the plan was to flatten out the piece and use it as a mirror template for the other side. then reform, back weld for strength and additional thickness then grind down topside to hide the obvious fold lines. it can of course finally be welded into the car.

So I went and did just that.

Back cut, bent up, trimmed to suit. Unfortunately in the end despite my best efforts I was unable to make the covers from one piece of material. After I was finally happy with the positioning the two innermost sections were made separately as the original pieces turned out too small

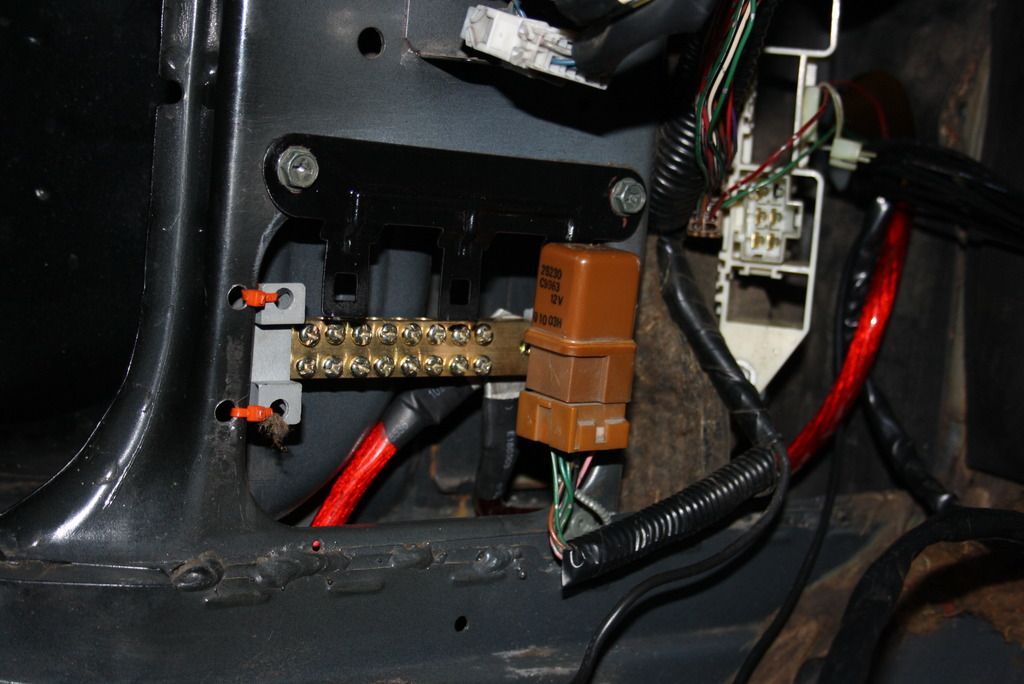

You can see the new portion tack welded in place. funny talking point in my garage is the gold plated magnets I use to hold metalwork in place. they are disconcertingly strong, left over from a home made rail gun project of mine when I was a kid, haha.

Back welded (and top where necessary) and ground down

The passenger side headlight was welded in first. hugely satisfying after all the work to actually start the final welding!

getting better with the mig

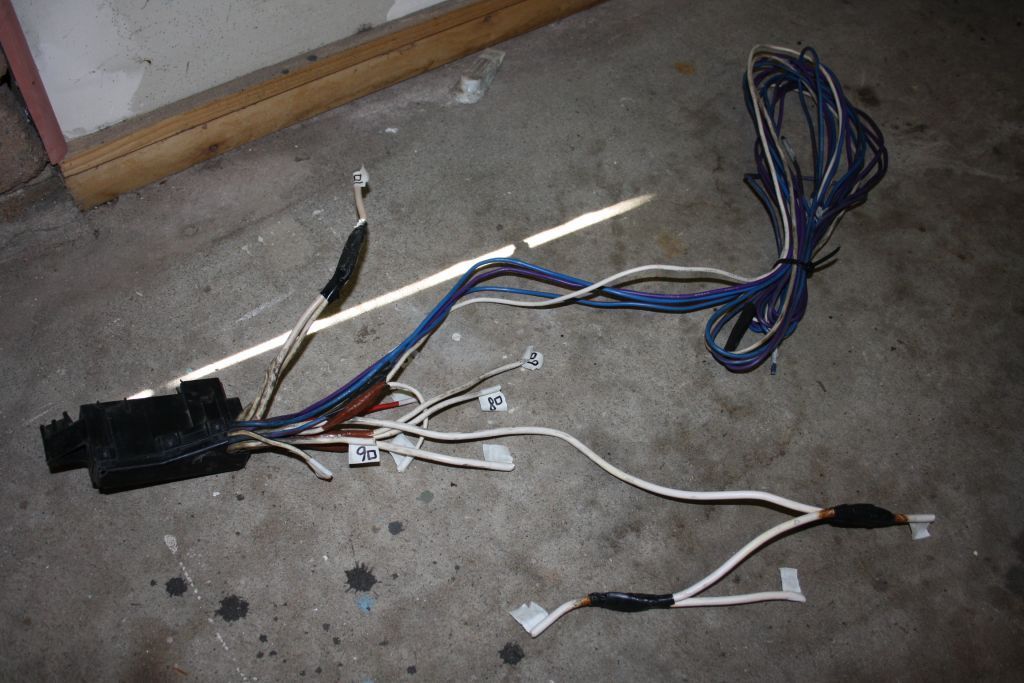

One of the parts of the front end seal up project was that I had to make a custom hood latch lever as the original unfortunately fouled on the new metalwork. Things you never could have called yourself doing when you buy a car...

Chop chop, had to redrill the locating spring for said lever and mount it further inboard too.

New lever was cut from the same box section steel that I made the front tower supports from.

welded up, clears now and is reachable. not sure what to do about final shaping at this point. suggestions are welcome?

as you can see, once the covers were welded in and ground back I back welded the underside for some extra strength.

So next up... digging out the lead work. I'm sort of getting the hang of it - it's all about heat modulation. There's a small window between the lead filler being not hot enough and crumbling under force and too hot and simply running. workable temperature is reportedly between 180 and 250*C.

When working the filler down, filing 100% is the go. Cuts through more material faster and the chunks coming off are too large to be airborne which is a plus (poisonous and such). sharp eyes can see where the transition between filler lead and steel below.

Finally, after a final skim coat with regular body filler to make it 100%, PRIMER. P-R-I-M-E-RRRRR. This was a really satisfying thing for my bomb-hit-it-bay.

With the outer sides left the driver's side was tackled first. Body soldered, filed, soldered, filed, filed, filed, filler skim coat, sand, skim coat, sand, sand, sand, high fill. with all that said and done I wasn't entirely happy with the outcome first time around;

sorry for the shitty photo. as you can see, there was a very visible dip present through the transition from OEM to aftermarket metalwork.

after looking at it from many angles (none of which left me any more satisfied) I cracked on with the passenger side, determined to go at it a different way.

Layering on the lead here. after a bit of practise this is how the raw filler looks, being applied by blowtorch and roughly shaped with wooden paddles. the excess is then filed down and finally smoothed with high grit sand paper. Hard work but if in 1000 years the remains of my car are found, these leaded components will likely be all that's discernible.

much better

a wire wheel made short work of the high fill and bog and I redid the driver's side shortly after.

and there you have it, custom upper front end finished.

I am very happy with it. Some time down the track as a cherry on top I want to close off the ridge in the underside of the nose panel (visible in the last photo) and have it flush with the metalwork. Silly to have that little detail off after all that work.

-A

Leave a comment: