Monster build, this I like.

Announcement

Collapse

No announcement yet.

Blunttech / Classic Daily S85 V10 E30 M3 Swap

Collapse

X

-

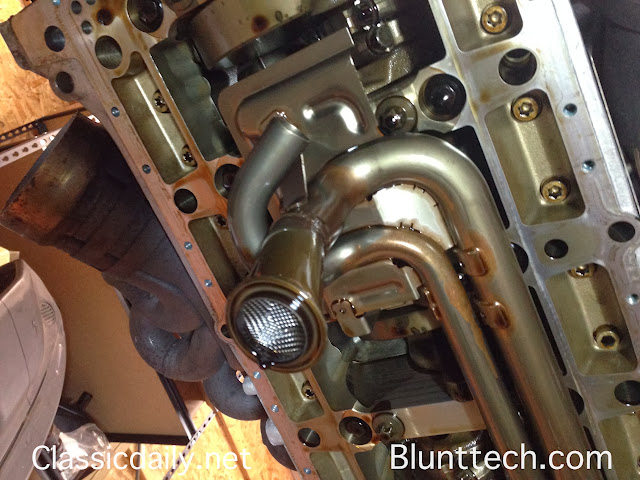

Pulled the pan to cut it apart.

Engine is VERY clean inside.

Time to cut the pan...

To keep it sealed up

This picture is without the trans on. The pan actually sits closer than this to the subframe/rack mounting.

The trans tunnel had to be opened up in one spot to get things to fit better.

A little bit of heat and a hammer did the job.

Getting closer to it's final home

Comment

-

A bit of a slow down with all my projects while I was moving to my new shop. Things are finally moving ahead again so it's time I update some build threads...

First of all the shell was moved from my home shop to a much bigger space. Let me tell you moving this car was nothing sort of scary. I am sure it was well more secure and nothing was going to happen.

Some pics of it's trip.

made it....

Back on a lift..

Working on the toe and camber adjusters on the rear subframe.

I didn't like how much was unsupported so I extended it some.

Freshly powdercoated bits

reinforcing trailing arms

A couple pictures of what has been holding things up...

New shop

and a new toy...

Last edited by jakeb; 03-28-2014, 09:34 PM.

Last edited by jakeb; 03-28-2014, 09:34 PM.

Comment

-

Steve flew in to do some work on the M3 last week....

Got the bottom all re undercoated.

Before

After

Fresh rear subframe and painted diff bolted up.

Subframe in and trailing arms bolted up..new bushings, bearings, etc etc etc

undercoated in the wheel wells too

New brake and fuel lines run

Gas tank ready to go in

Comment

-

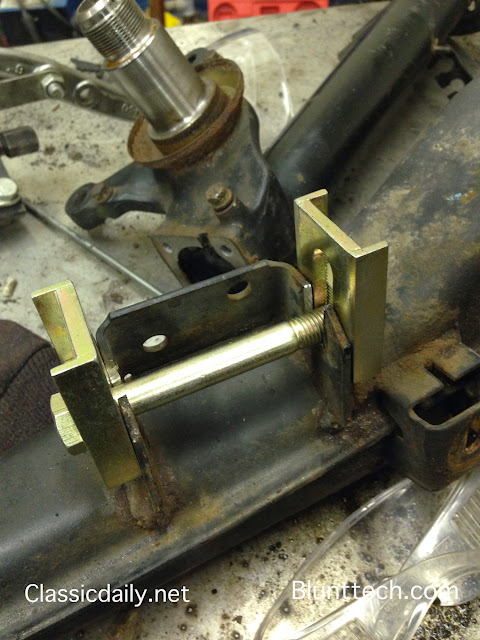

Well the subframe from before was a bust.... The z3 steering rack was wanting to be in the same spot as the header. So we start again.

The engine about in it's final location

This is the e30 m3 rack rotated slightly down to clear the header.

Rack in it's new home in the subframe jig.

Bending a piece to connect the dots

Trimmed down and tacked together

Testing and ears for rack

Boxing it in

You can see a piece of bent plate going under the pan here. This piece was fun to make.

Tacked together

Clearance to the pan...around 1/8-1/4"

Out of the car

I really like how this part came out. Some little open holes still.

Before (opposite side of after pic)

After

Still more cleanup needed.

Entire thing before welding...

Also if you are going to vintage in NC this coming weekend this car will be there. Not done but it will be there to check out.

Comment

-

This update is from a few weeks ago but just finally getting around to uploading all the pics and posting.

Welding the new subframe up.

Starting on mounts

drivers side

These will be fully boxed and also a new set of plates will be drawn and then water jetted. These are the mock ups.

Subframe with mounts welded on

And with both mounts connected. All this will be powder coated

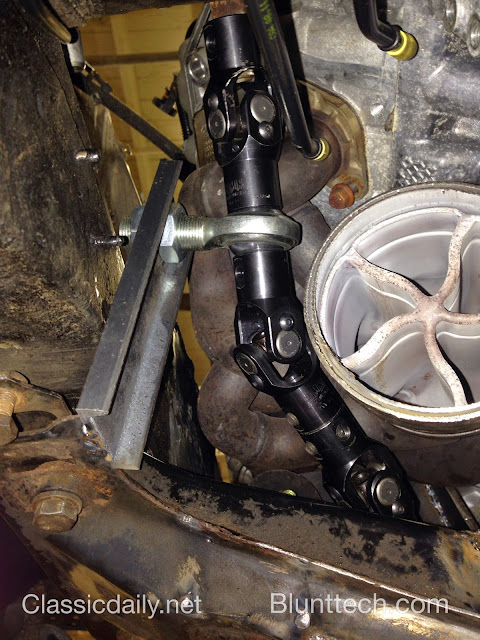

Steering clearance

Adding another joint

And a locator

This is JUST a MOCK up. We needed to have the car movable to take to a show so this locator mount was just tacked on so the car can steer. There will be a stronger more elegant solution once the engine comes back out.

Rebuilt rear axles

A quick shot from the front.

The coilovers are turned all the way down here and there is about 3-3.5" here. Yes it is close but the air boxes are about a 1/4" from the hood.

Here it is at the vintage in NC a couple weeks ago.

Also it is looking VERY good that we will be using the stock DME. nando has been working on cracking it and it's looking like it's gonna happen.

Comment

-

Not a huge update but something none the less.

We had found some rotors that were going to work for the brake setup but they were not ideal. So we got some hats from Ireland and then had some rotors made custom from coleman eng.

Here are the rotors when they showed up.

Fronts

Starting to mock stuff up

These are just sorta stuck in there...if you look to the left of the caliper it looks like they are hitting the wheel. The caliper is nut but there is a washer in there to keep the caliper clamped to the rotor. There is room all around.

clearance between wheel and caliper

rear rotor....nothing that exciting here.

[img[https://lh5.googleusercontent.com/-DqJ97ieM94Y/U77S8FHKt_I/AAAAAAAAMIU/xwqWJID7drY/s640/IMAGE_1830.jpeg[/img]

rear compared to front

Comment

-

Been spending some time on the brakes recently.

Will be running 135 brakes front and rear.

We bought e36 fitment wheels so we could space to fit and clear the brakes.

This is with about 12mm of spacing.

Front brackets were not to bad to make. Piece of 6061 aluminum... Stacked washers just used do to lack of hardware at the time. Brackets will be cleaned up some....edges rounded, etc.

We are using hats from IE with custom rotors from coleman. The hats have been installed INSIDE the rotors to give more clearance at the control arm ball joint.

Kinda hard to tell but nice and centered.

All mounted up.

Now the rears were a MUCH different story. We machined the calipers and removed the mounting ears.

There was VERY little room between the mounting bracket and the backing plate. To keep enough material left in the bracket some was machined out to give clearance at the backing plate.

mounted

The m5 uses a very odd radiator as it is actually two radiators stacked on top of each other. If BMW designed it that way we would love to keep it. But one issue is the m5 radiator is too wide.

Sometimes you have to cut...

The cut part will be completely boxed in.

And there we go...

The engine has been mounted but the trans has had a VERY temp mount. But that needs to change. So...getting going on that.

Just to show how big the e60 guibo is.

Mount will be two parts.

One that bolts to the trans (flat part in picture below) and then the cross brace. There will be a poly bushing in between (update on that when it shows up Tuesday)

Comment

-

this thing is not getting the attention it needs. such an awesome build. love the fabrication and brake setup-FREEDOM- is cruisin at 80, windows down and listening to the perfect song-thinking "this is it"

-The Beauty in the Tragedy-

MECHANIC SMASH!!- (you all know you do it)

Got Drop??

Comment

-

Comment