sounds good man, My mounts will work in an e24.

Announcement

Collapse

No announcement yet.

Blunttech / Classic Daily S85 V10 E30 M3 Swap

Collapse

X

-

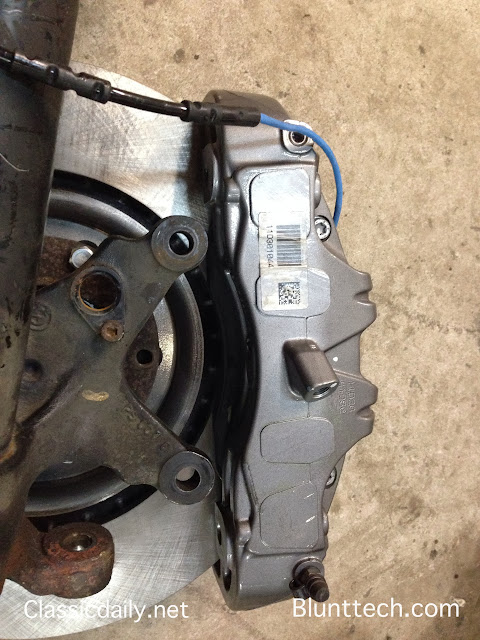

We have been doing lots of research looking for off the shelf rotors that will work with the 135 6 piston calipers on the E30 M3. The biggest issue with the M3 is there is VERY little clearance between the rotor and the tie rod. When you go with a really big rotor. The stock M3 rotor is very shallow, right around 40mm.

So after digging through lots and lots of different rotor specs for all different cars we think we have found something that will work. This rotor is 330mm by 28mm and NOT off a BMW. Once we know everything will work we will say what it is off of. We don't want misinformation out there. It is only 39mm deep so there is around 7mm of clearance at the tie rod.

Now this rotor will need some machining but it is close. The center bore will have to be opened up a little bit and the wheel studs will need to be ob-longed inward.

Ultra flat rotor.

Bolt holes are close...

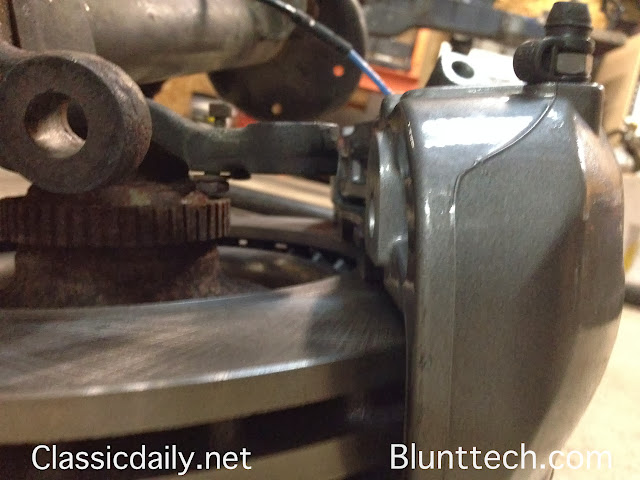

Ground down the rub of the m3 bearing (will be replaced anyway) to be able to set the rotor flat against the hub.

Tie rod clearance

Need to make a bracket...

Mocking up in a 17" wheel

Now this wheel will not clear the caliper. If you look there is some wood stacked to get it to clear. So we will need a different wheel setup. There is around 22mm of "spacer" right now.

Comment

-

-

Started fitting the s85 into the e30.

It is sitting a little high in these pictures.

This is a WIDE engine.

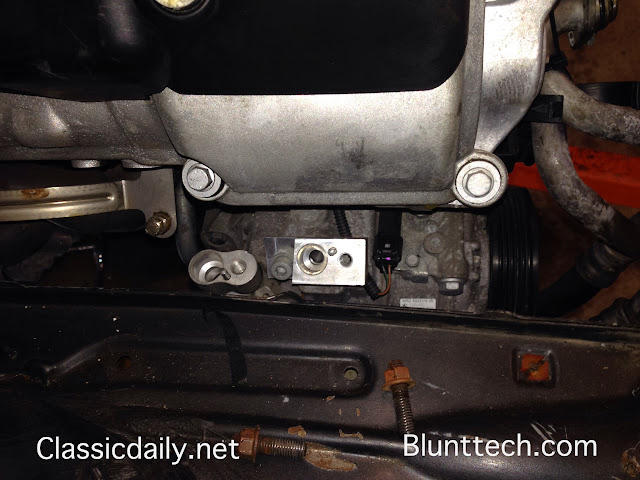

Looks like we will be able to keep AC. This is a street car afterall and will be driven.

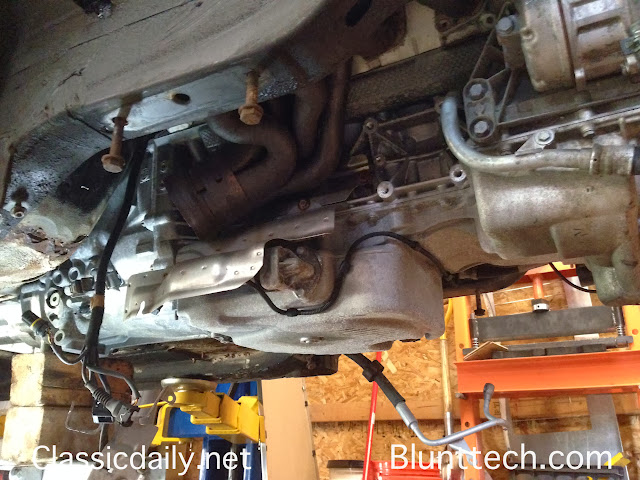

The trans is tight in the tunnel but it fits so far without any adjustments. It might need a little opening up in a couple spots just to give good clearance but so far so good.

Might do something different with the heater hose connection to be able to push it back a little further and give a little more room here.

But it is pretty close to the firewall already.

The cat is built into the header and was hitting the bottom of the car. The plan was to cut them off anyway so off they go now.

These headers are equal length.

Inside the collector.

They dump in a nice location.

The main issue now is building a new subframe and/or modifing the oil pan to get everything to work.

You can also see the catless header here.

Steering shaft actually has a fairly direct shot. Might go to a smaller ujoint/shaft. Also something without the rubber flex disc.

Comment

-

So the subframe and oil pan want to live in the same spot. So what do we do....cut the oil pan? Move the subframe? Or a little of both? The plan is to go with modified subframe and cut oil pan.

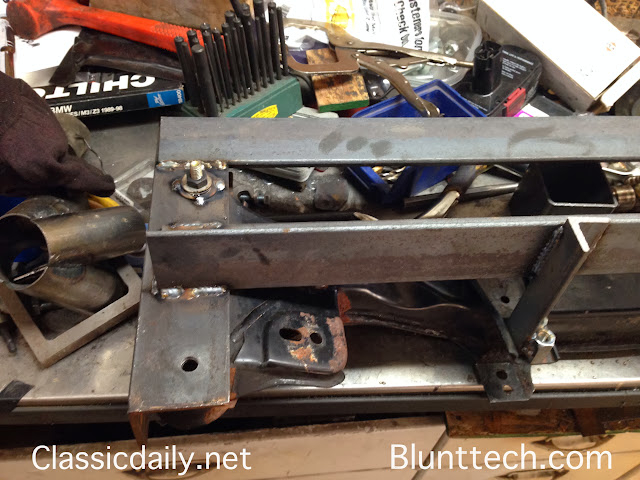

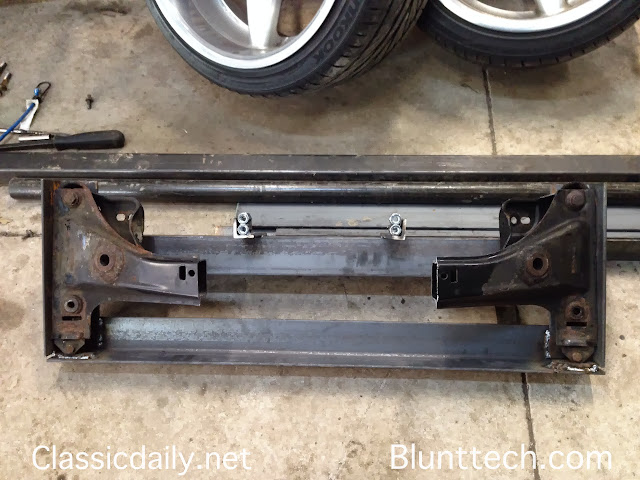

First step is to build a jig to hold the subframe so once it's cut up it will still be in the same spot.

Made with 2.5" angle (might be a little over kill but I don't want anything to move)

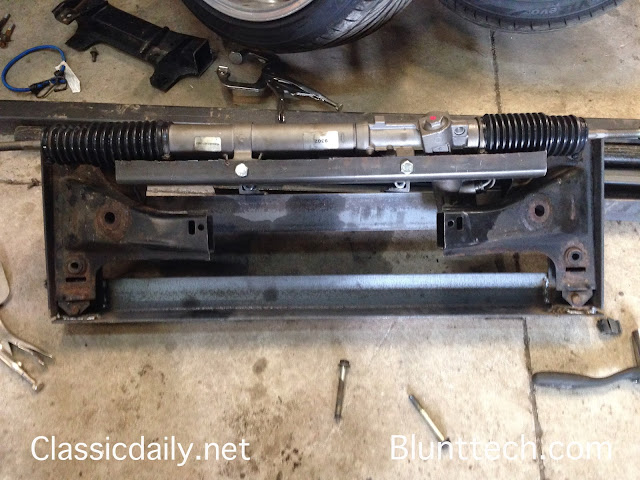

Locating the steering rack. The rack MIGHT get moved forward slightly to allow for less cutting of the oil pan. That is why there are two locations. One about 3/4" forward.

Just random jig pics

Time to cut the subframe apart.

Back in the jig...

Next step is to bolt the subframe to the car and see where things start lining up. Also need to find some fittings for the steering rack as I want to move some of the lines to the front to give more room.

Comment

-

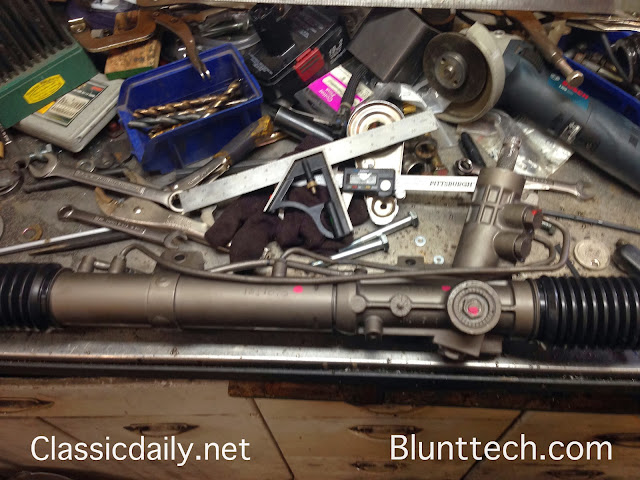

So to limit the amount of oil pan that has to be cut we are going to mount the steering rack as tight as possible. We are using a 2.7 turn Z3 rack and moved the lines to the top/front of the rack rather than the front. As seen here.

To mount the rack tight as possible the subframe is also the mounting spot. This started as 2" - 0.25 wall box and was cut down into a C. A few spots had to be notched out to make it all fit around the rack. This was cut witha plasma and still needs to be cleaned up a little.

Bolted to the jig

Starting to connect the dots

Trimmed down and more pieces tacked in.

Out of the jig

In the car

About how much will need to be trimmed from the pan.

Now this subframe is FAR from done. It will get a lot more reinforcements but we are still at the, "lets make it all fit" stage.

Comment

Comment