I am not sure if there is alot of difference between the earlier model or 4 door front fenders, but the replacement drivers fender gap was absolutely horrible, so rather intrusive fix had to be done. The original fender that donated the repair fender/door edge was rotted out in the front near the park lamp and facia attachement point, and the replacement white fender had the bad gap and a bit more previous repair and rust than was previously noticed, so we had to work with what we had here.. There isnt a whole lot of panel adjustment with these cars, and the hood/cowl/fender gaps were about perfect, so I would rather just remedy this one area of the drivers fender, rather than do alot more work on several more gaps and panels.

After all the finish welding and gapping is completed, the car will be disassembled, and then all the panels will be stripped and prepped with body work. In the next step involved, the car will be reassembled and then have a sealer primer before the several stages of final blocking and gap checking, which can be very time consuming. After the final blocking and gap tolerances are all worked out, the car will be disassembled again, and then painted. I am going with a Satin Paint, and there isnt any metallic or peal involved, so we dont have to worry about hanging parts back on the car before paint for perfect panel paint blending.

I just want to be clear about the paint and body process with this particular car, and how we are not taking several other steps that are involved with our customer restoration cars. This is not going to be a full routisserie job, because I am not sure what will happen to this car in the several months after it is completed, because it might actually end up in a ditch or against a wall in its immediate future.. This car is going to be used for demonstrations, and will be majorily abused, along with being a daily driver after all the testing/promotions is done, so there isnt any point to put a 12-15k paint process on the car.. The workmanship and materials of what is being done to the exterior will be extremely nice, but I am not going to worry about a trailer queen finish to the bottom of the car.

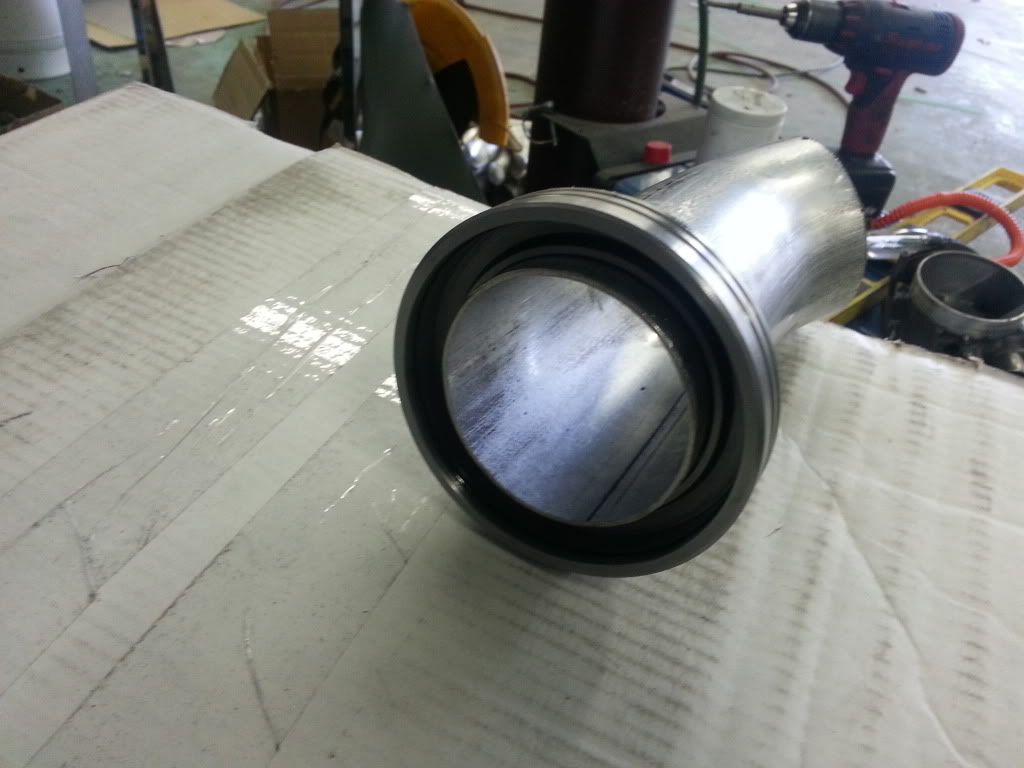

look. I think if the projectors were recessed or if the housing was made darker in color it might eliminate that somewhat. Is there no room to make deeper housings? Other than that this is coming along amazingly and this thread should have far more support and commenter.

look. I think if the projectors were recessed or if the housing was made darker in color it might eliminate that somewhat. Is there no room to make deeper housings? Other than that this is coming along amazingly and this thread should have far more support and commenter.

Leave a comment: