I go through cars too fast, The last car I posted ended up having a lot of rust that I didn't see originally, I guess I should have looked at it better. Also while working on it I noticed that the drivers floor was buckled a bit and came to a conclusion that it was probably hit in the door which is why the door doesn't fit 100% and the rocker was rusted. I begin my hunt for another shell and ended up calling about a car that was posted on craigslist. It ended up being about 10 minutes about on Edgewood avenue and the guy just wanted it out of his yard so I went and looked at it really quick.

Heres the photos of how it sat when I went to look at it.

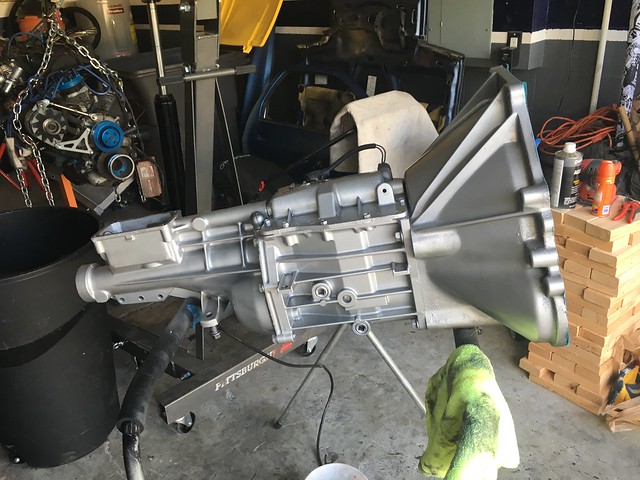

I didn't jump on it right away because it was a automatic and I knew the transmission mount was different from manual trans cars to automatic. IDK why mazda would do this but whatever thats life lol. I come home and call up Grannys speedshop and get a price for a new mount, it was way cheaper then I expected so I ordered and it drove back down to look at the car more thoroughly. It was really clean and had everything I needed for my current car. Needs a windshield but that will come later on I suppose.

Well I picked the car up Tuesday 24FEB15 and had it towed to my house.

Then wednesday 25FEB15, less then 24 hours later I had my suspension and wheels on the car just so I could get an idea of how they would look. In my opinion the tires are way too stretched for my taste so they will be changed out but overall I'm really happy with it. I can't wait to get my motor in this car and finally be able to drive it again.

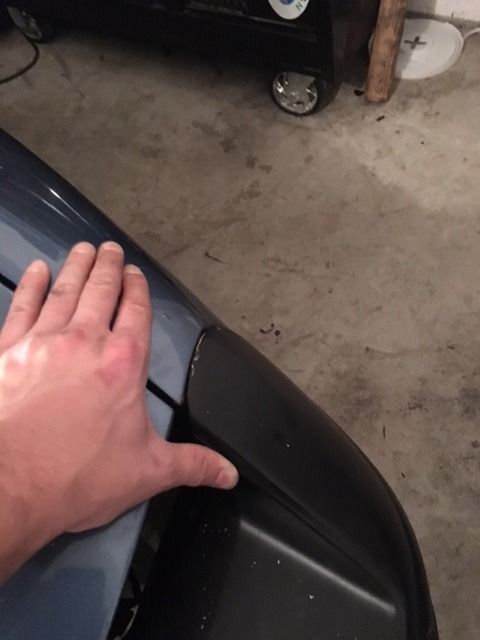

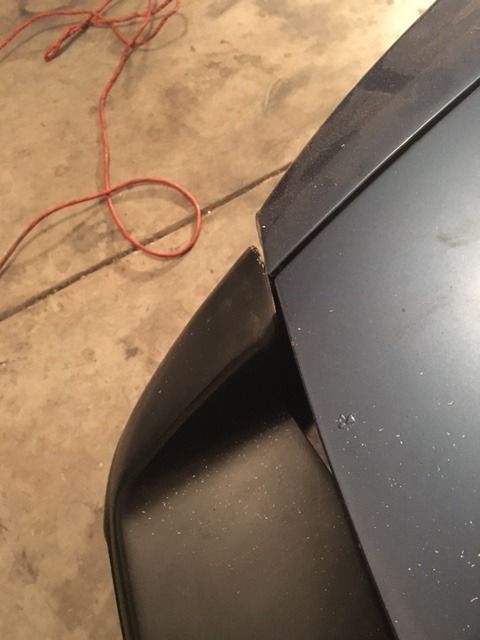

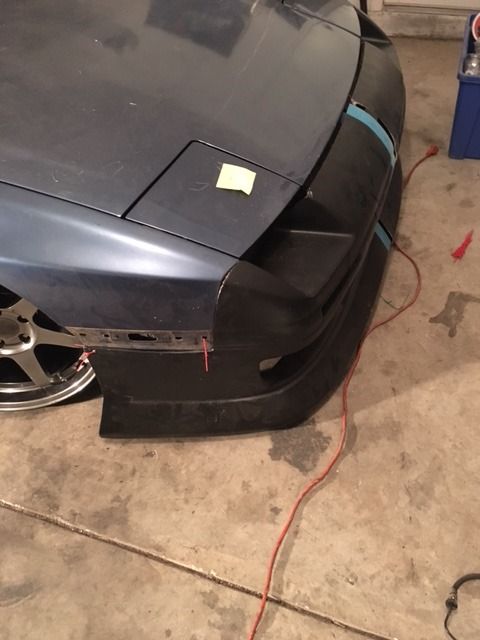

Then today when I got home I wanted to get an idea of how low it would be with the skirts on. so I threw the drivers side on.. I really can't wait now.

Thats all for now, but as soon as I can get the bay painted I will be putting the motor in and sending it off to have an exhaust made for it.

Heres the photos of how it sat when I went to look at it.

I didn't jump on it right away because it was a automatic and I knew the transmission mount was different from manual trans cars to automatic. IDK why mazda would do this but whatever thats life lol. I come home and call up Grannys speedshop and get a price for a new mount, it was way cheaper then I expected so I ordered and it drove back down to look at the car more thoroughly. It was really clean and had everything I needed for my current car. Needs a windshield but that will come later on I suppose.

Well I picked the car up Tuesday 24FEB15 and had it towed to my house.

Then wednesday 25FEB15, less then 24 hours later I had my suspension and wheels on the car just so I could get an idea of how they would look. In my opinion the tires are way too stretched for my taste so they will be changed out but overall I'm really happy with it. I can't wait to get my motor in this car and finally be able to drive it again.

Then today when I got home I wanted to get an idea of how low it would be with the skirts on. so I threw the drivers side on.. I really can't wait now.

Thats all for now, but as soon as I can get the bay painted I will be putting the motor in and sending it off to have an exhaust made for it.

Comment