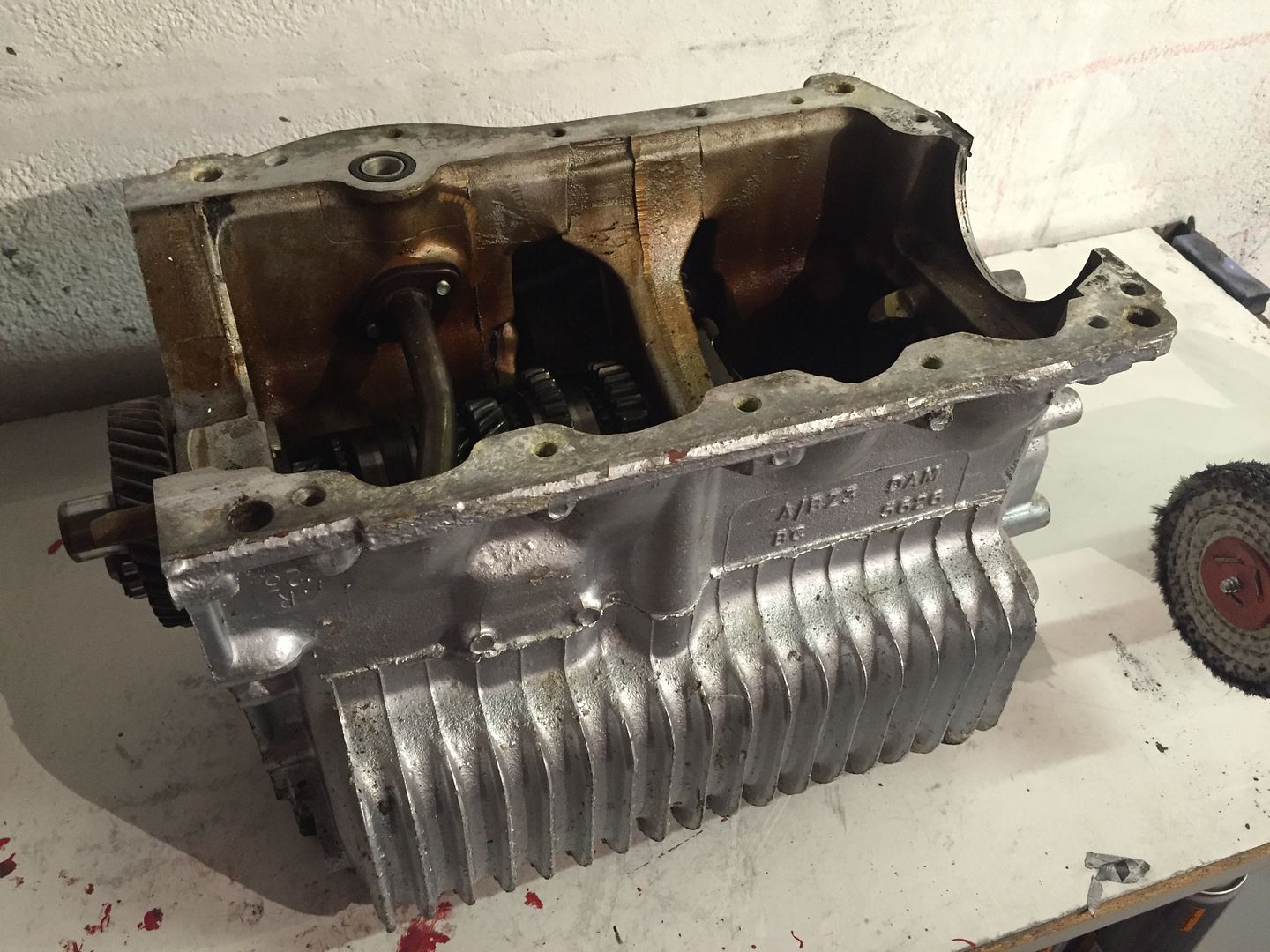

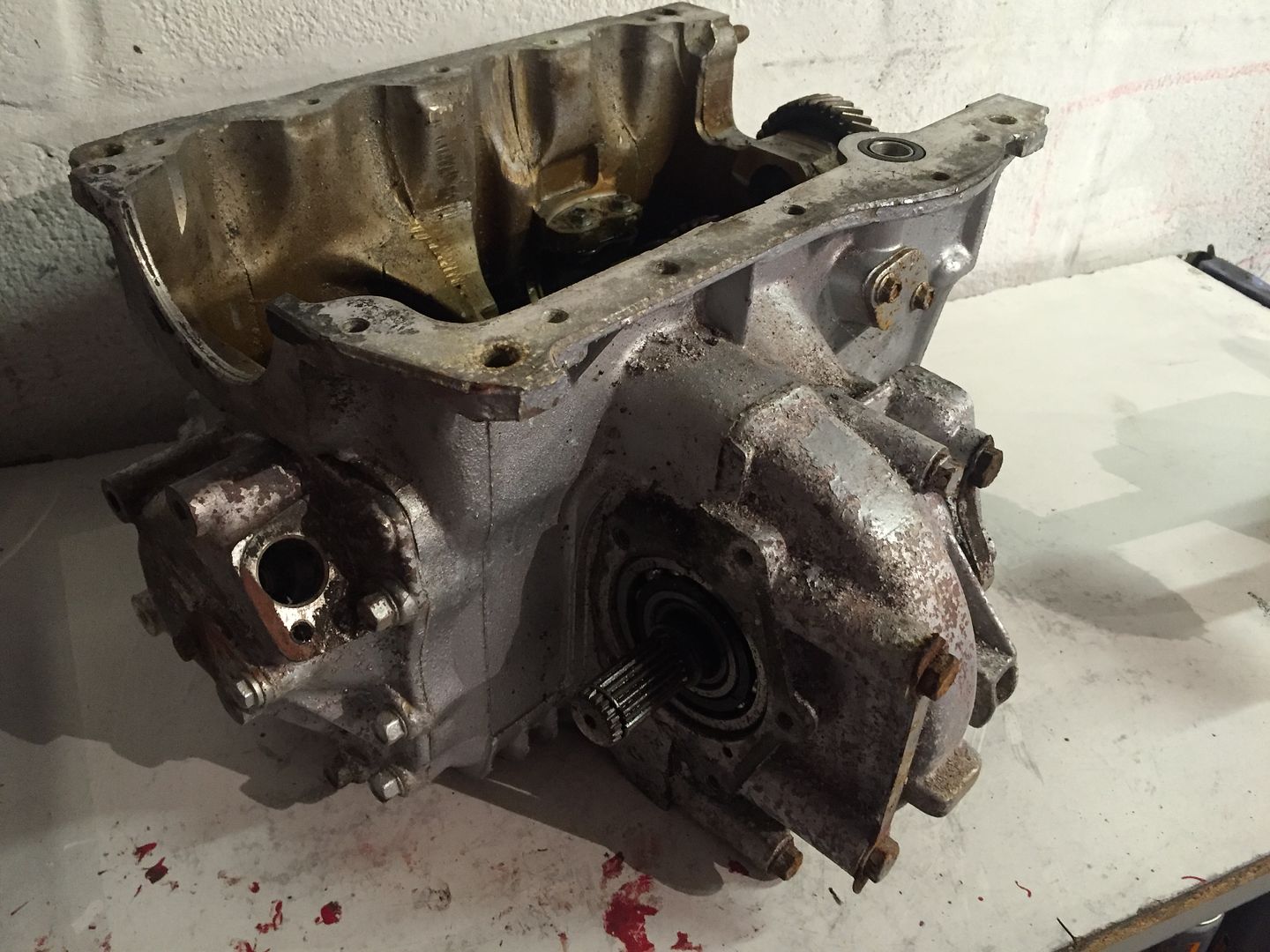

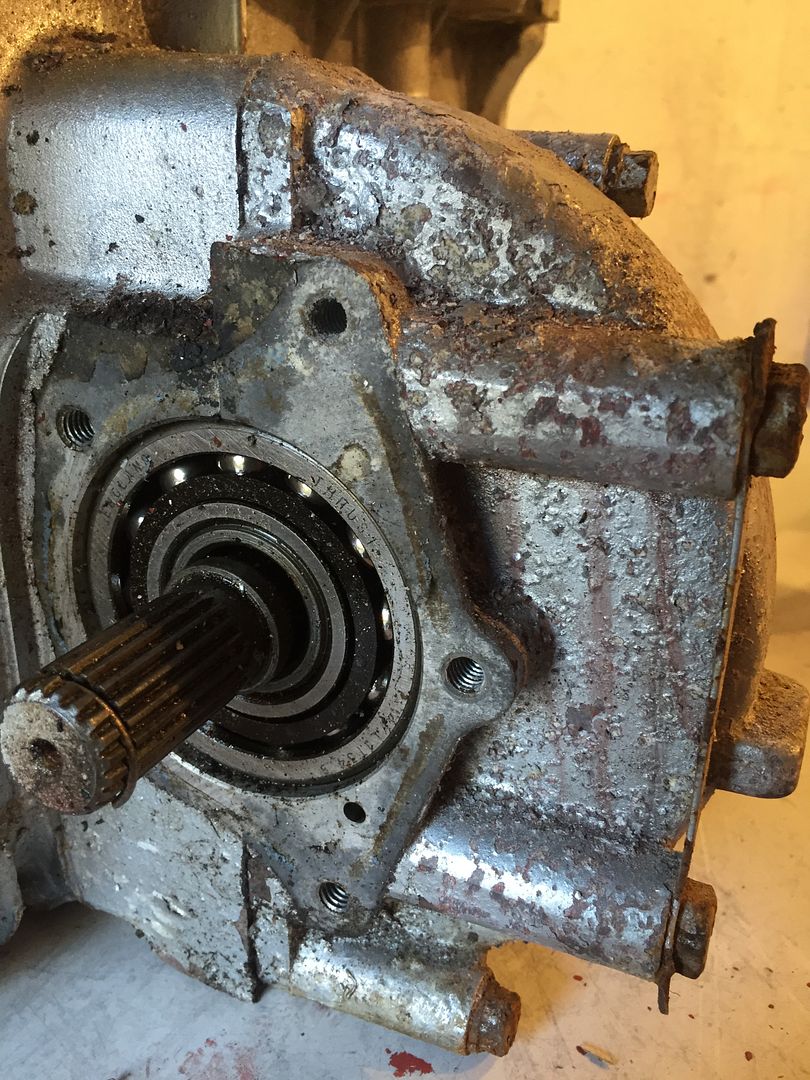

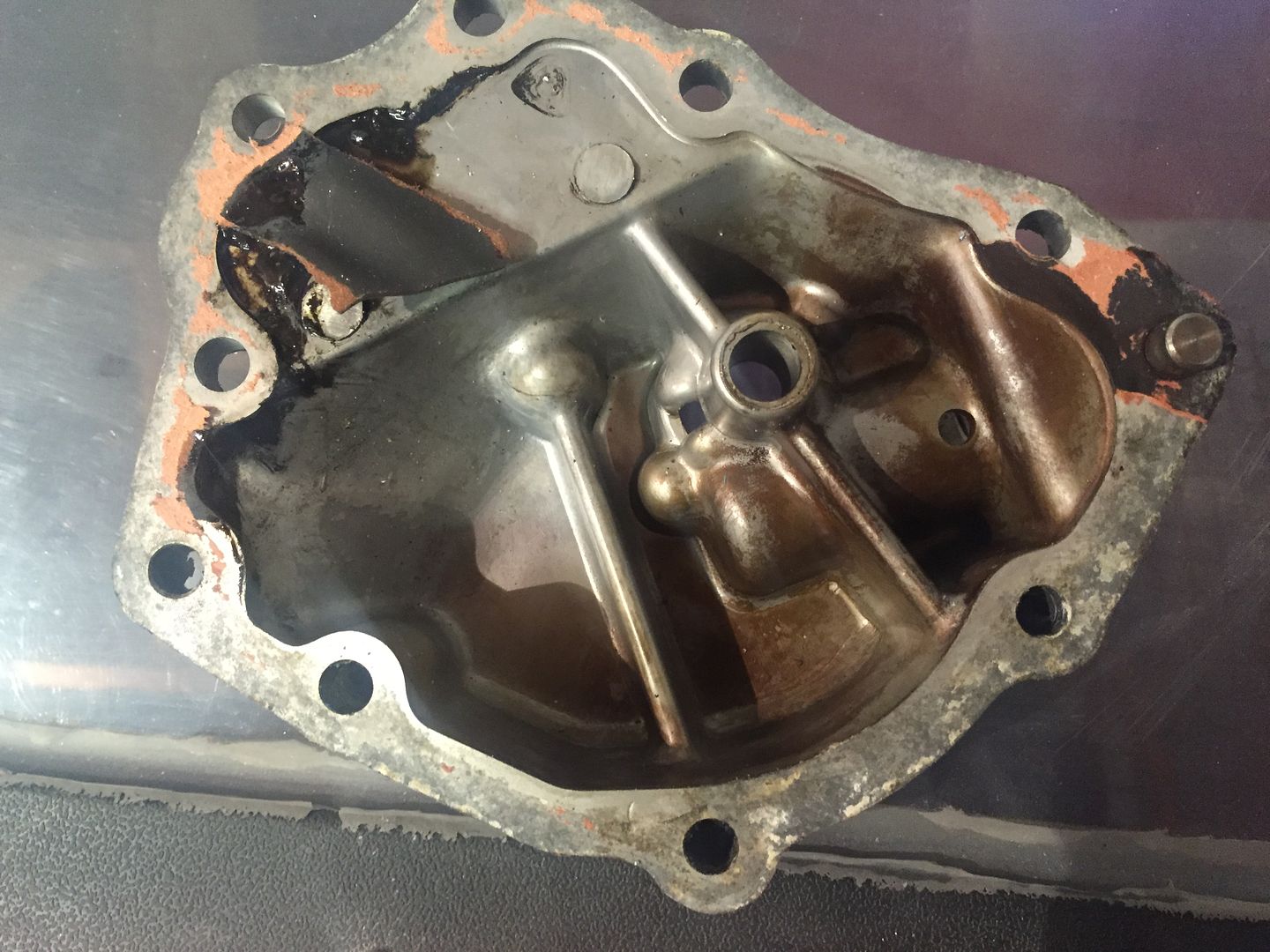

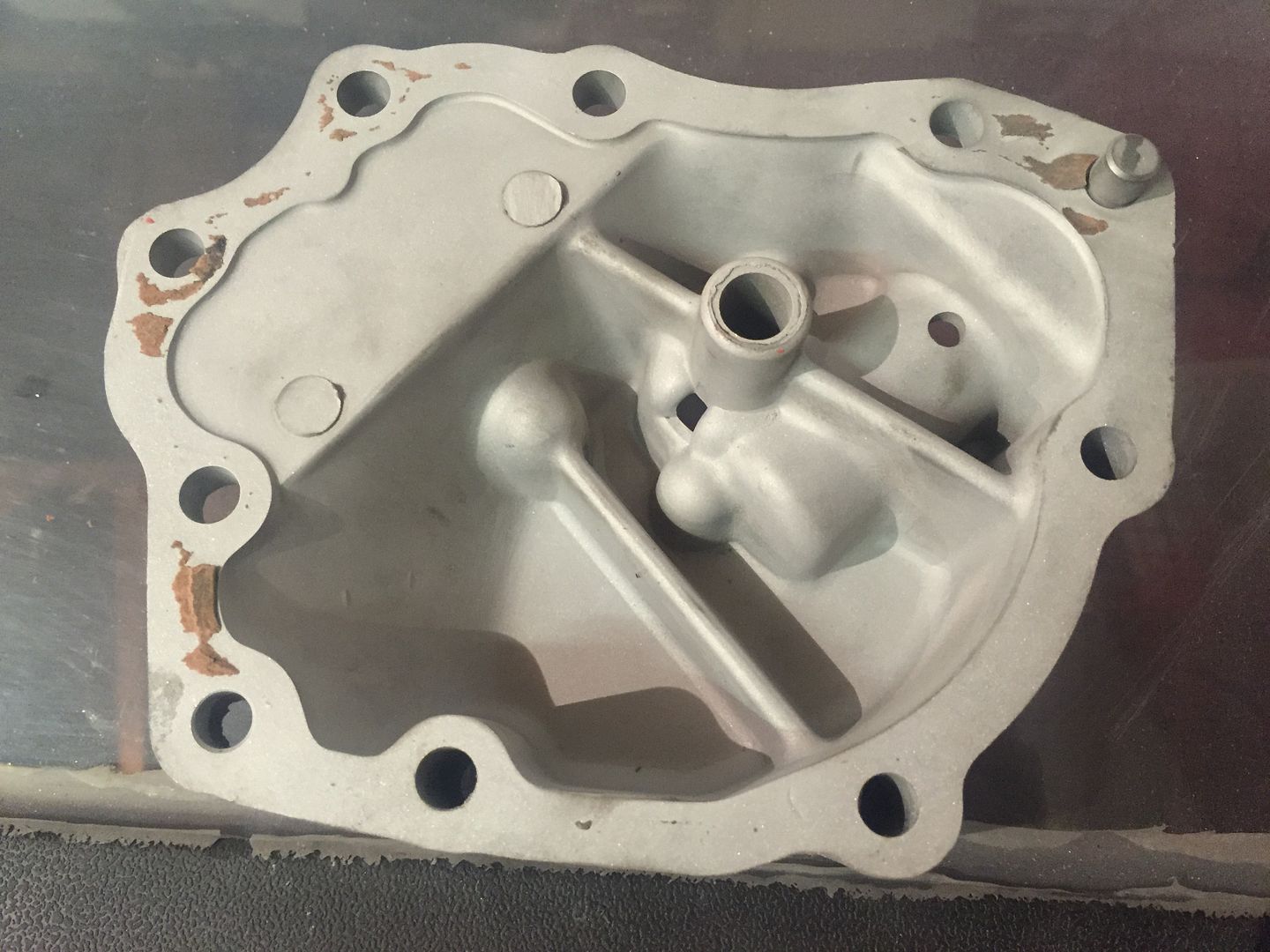

In the meantime I was thinking about why the case had external corrosion on it despite the paint being applied correctly. Looking at a few of the covers and bolts, the bolt heads had corroded, leading the paint to lift around them and then the paint continued to lift and allowed the casings to corrode.

Perhaps overkill but to prevent rusty fasteners, I've just ordered up this kit from Titan Classics...

These won't tarnish or rust as they are full titanium bolts for some of the gearbox. Will order more when I see what quality they are when they arrive. Not cheap but fitting stainless bolts to a gearbox doesn't sound like a good idea to me....

) that truckers hold no respect whatsoever for small cars, so I bailed on the convoy for fear of getting wiped out and arrived an hour ahead of everyone else at our overnight stop at Lancaster. It helps on the motorways to have a relatively powerful and torquey 1275cc engine when compared to the 998cc cars.

) that truckers hold no respect whatsoever for small cars, so I bailed on the convoy for fear of getting wiped out and arrived an hour ahead of everyone else at our overnight stop at Lancaster. It helps on the motorways to have a relatively powerful and torquey 1275cc engine when compared to the 998cc cars.

Leave a comment: