Not really made much progress, been working to much and not spending time at the touring since the summer.

At some point last year I started extending all the wires running around the engine bay, I wanted to hide them as much as possible but not go to crazy.

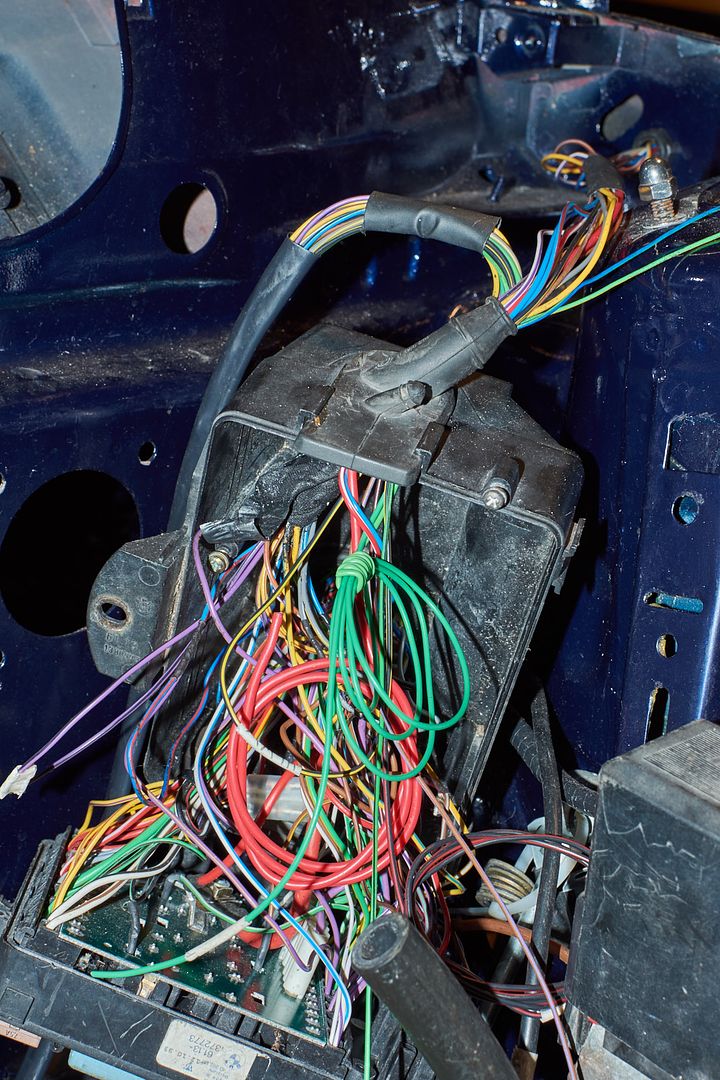

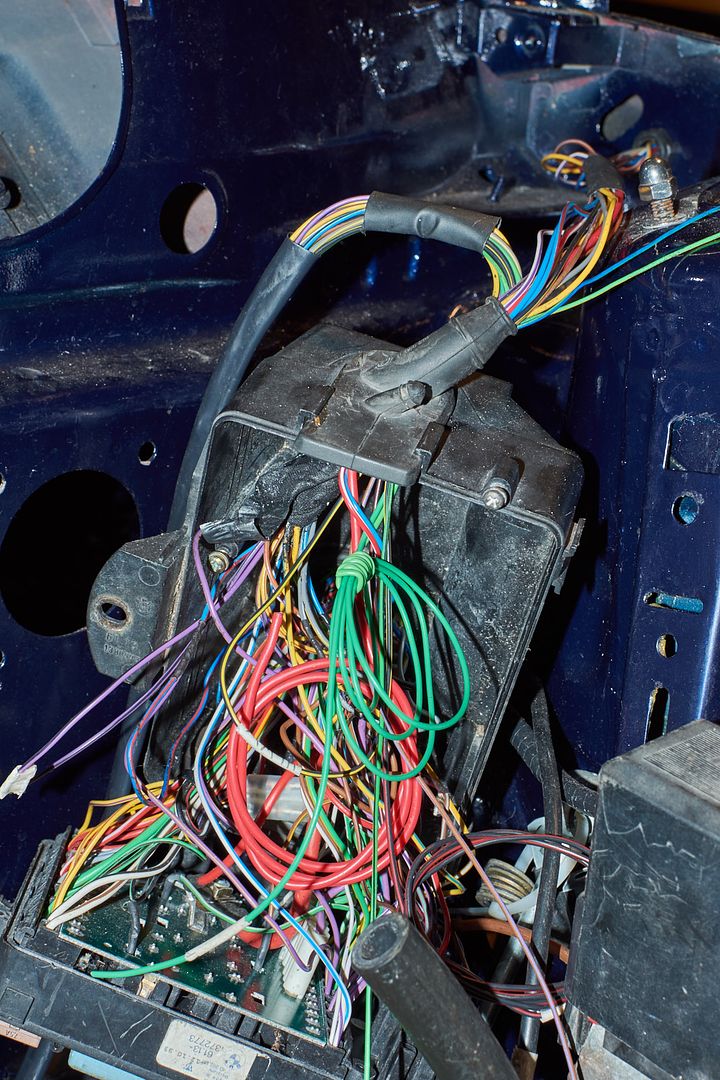

Using an old loom I extended all the wiring with the same color cable. Then came to my senses after realizing I potentially had up to 3x solder joins that could fail and went ahead and ordered a load of cables and various crimps so I could tack this mess:

In the end I pulled all the original cables going to fuses and replaced them with extra long new cables with the right ends crimped on and sloted back in place. A few cables ran into the car and those were solder joined inside the fusebox and had some heatshrink applied.

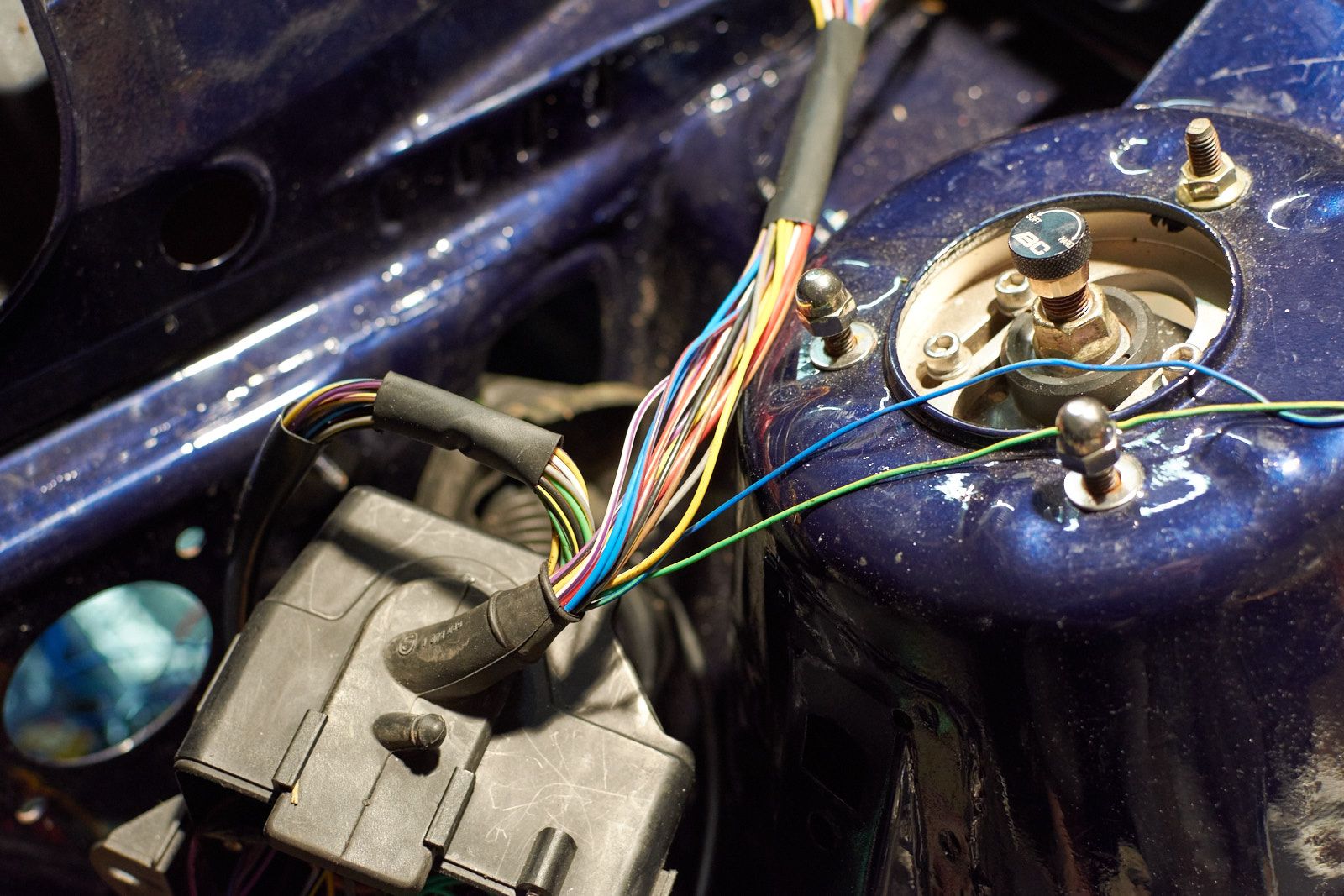

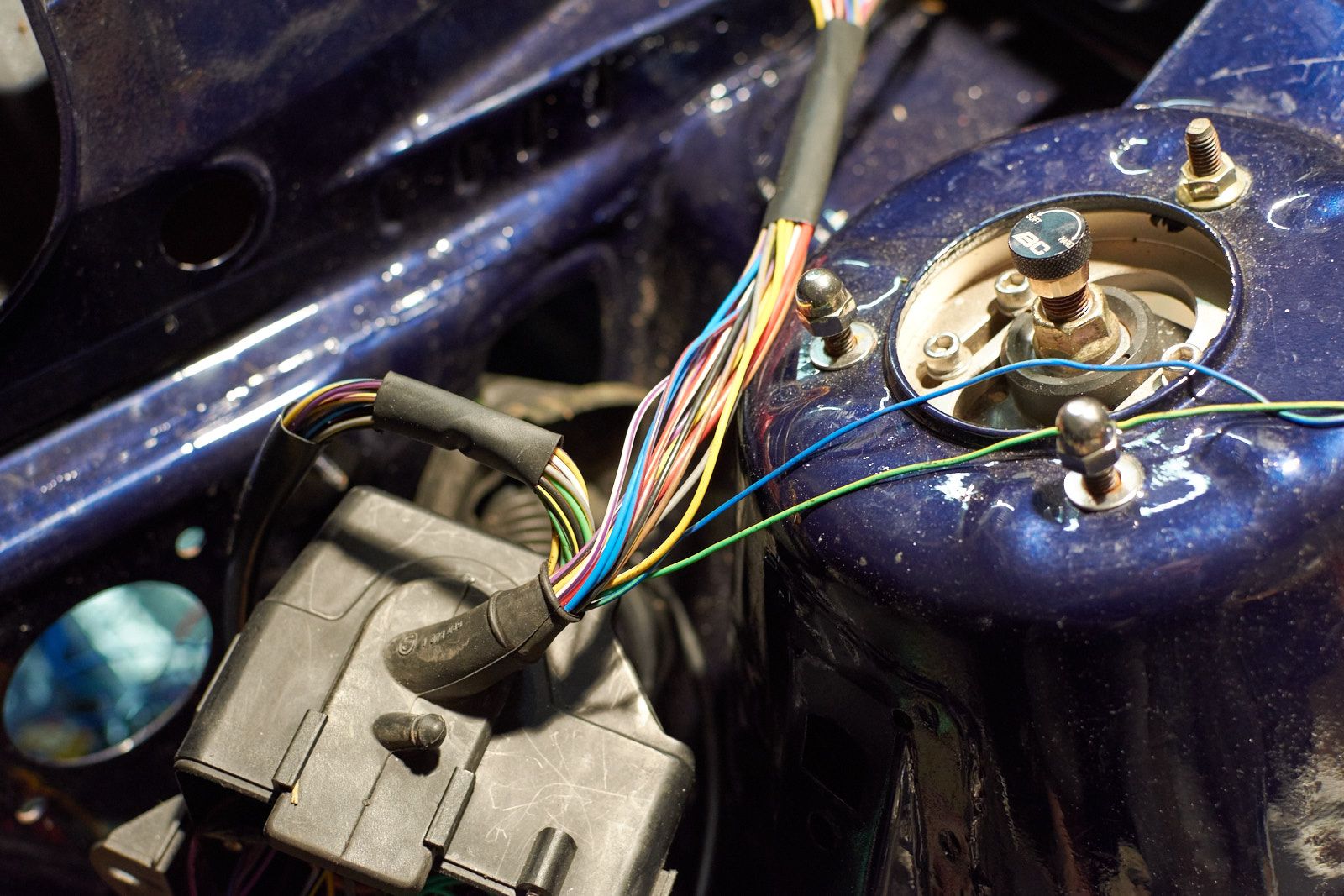

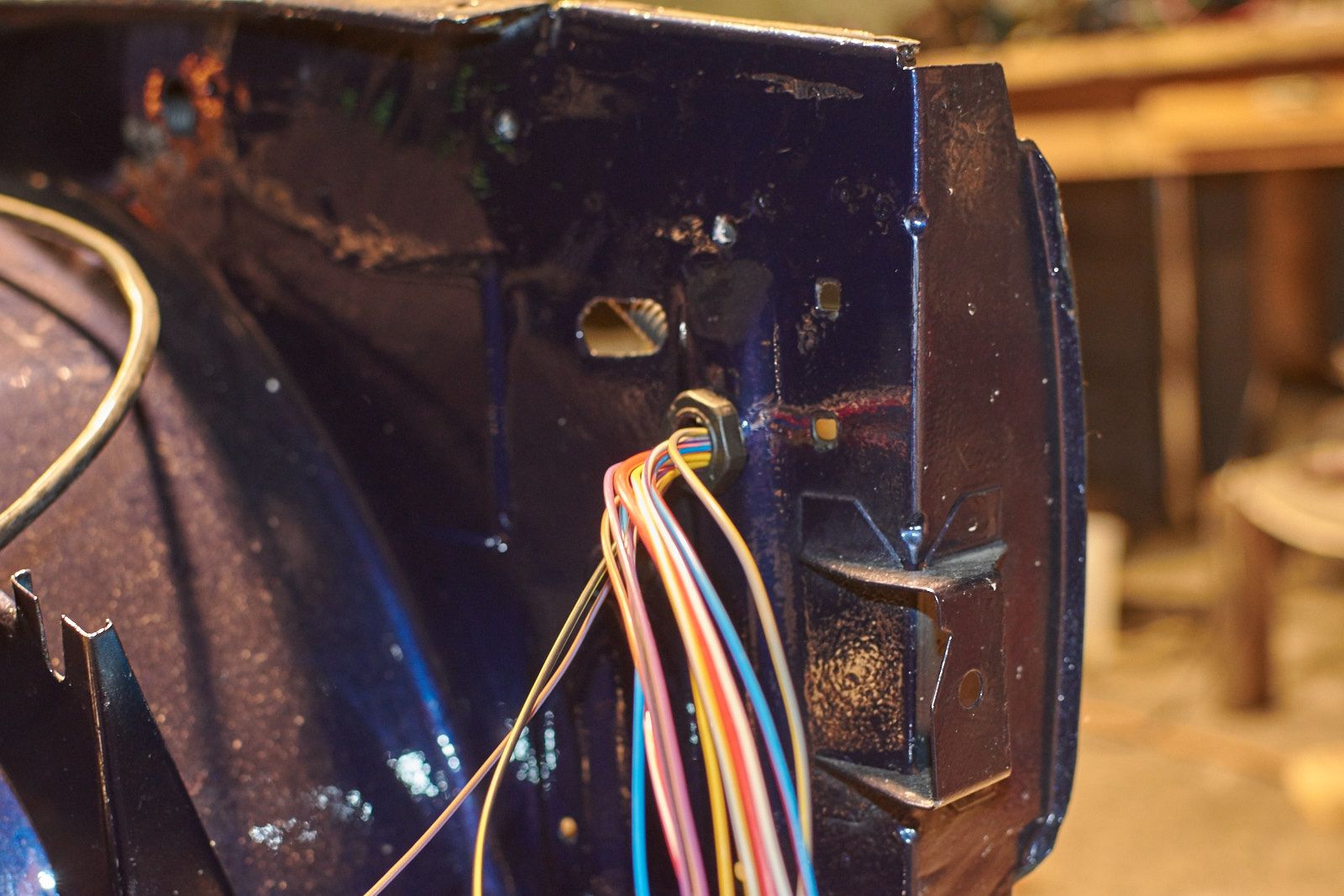

The plan was to separate all the wiring going to the passenger and driver side and route them both separately as can be seen below:

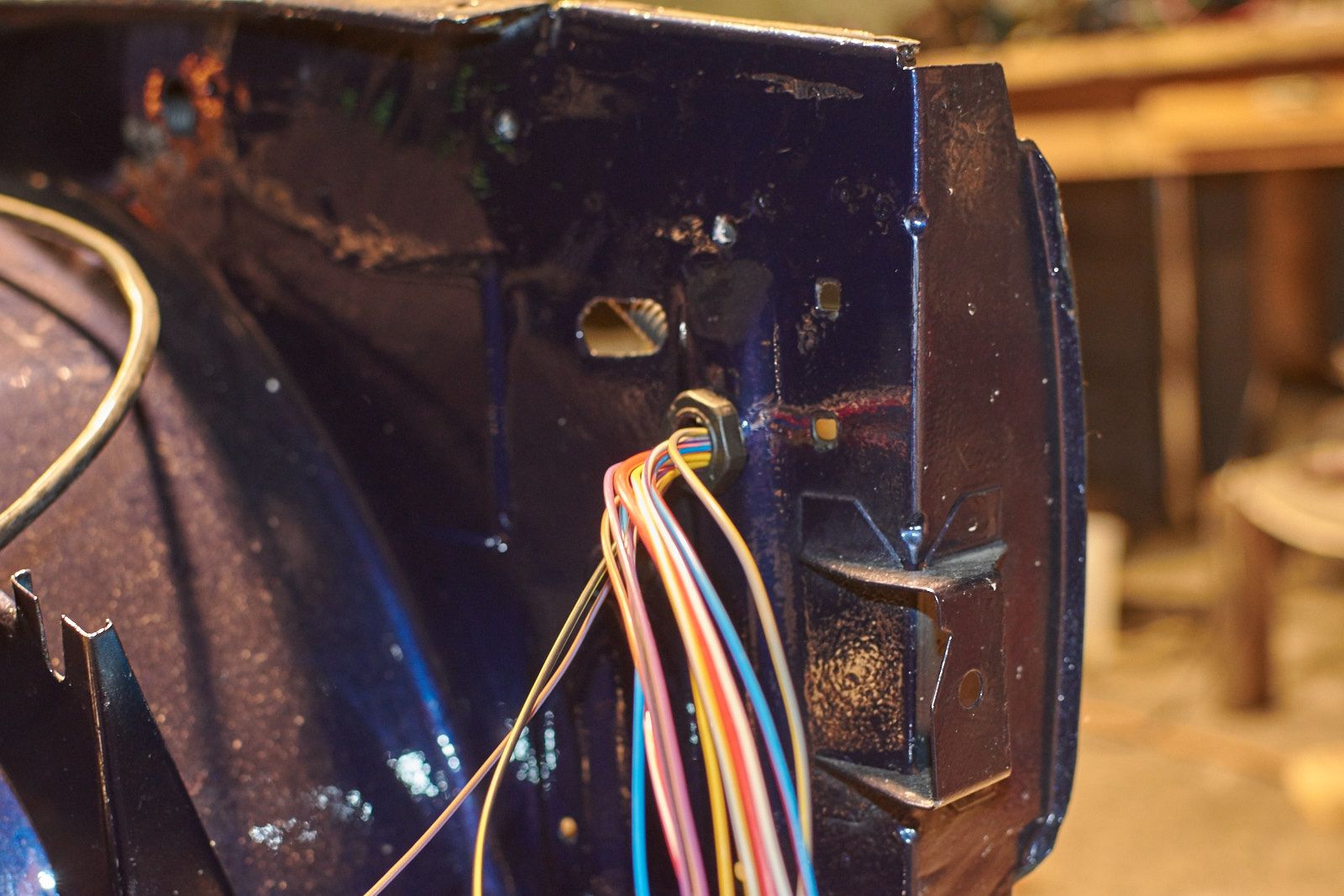

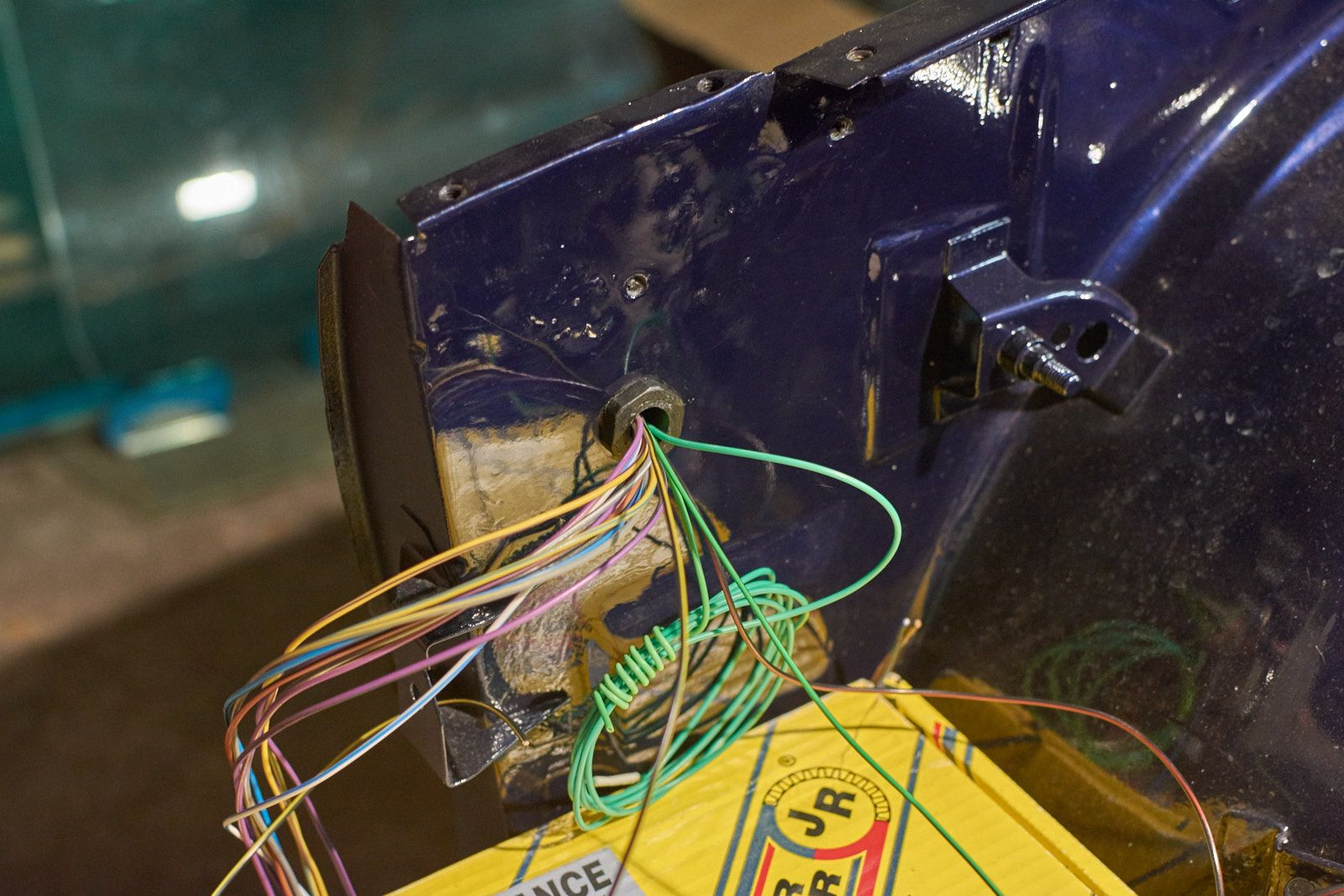

That was then stuffed through a pair of holes into conduit on the inner wings and routed to the front of the car where it exits under the front slam panel on either side

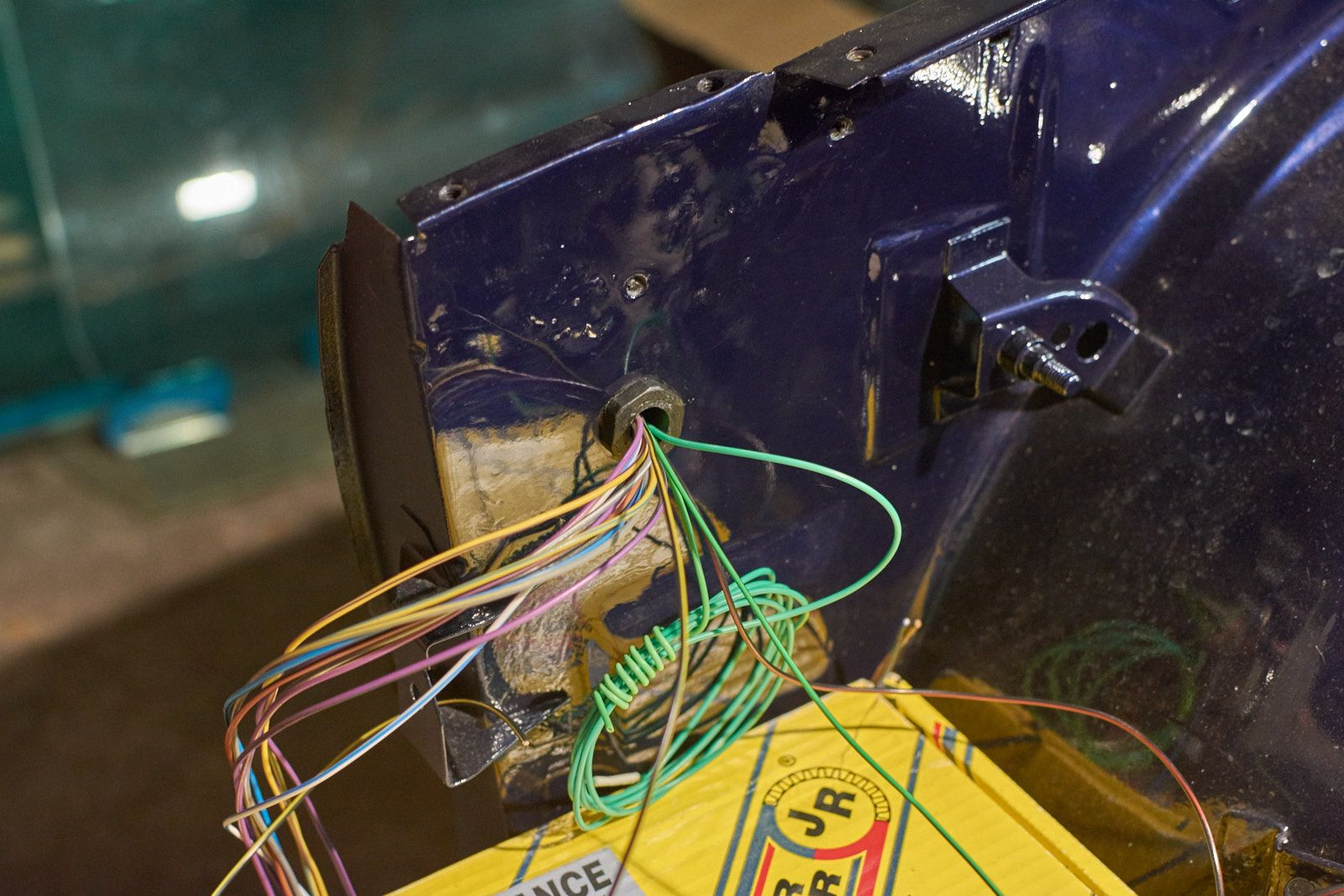

Conduit and 90deg elbow I used on both ends to protect it from the elements as much as possible (apparently the elbows are water proof)

This all took me months and many weekends, everytime I spent a couple hours at it most of the time was spent re-tracing my steps and making sure I didn't miss any cables or got things mixed up. Eventually I pulled it all through the conduit which turned out to quite difficult! I pulled out all the wires and after speakign to a friend he recomended I use wire pulling lube : That took a bit to arrive but it made everything about 100x easier. In the event I missed a wire I left one long redundant wire in the loom which runs to/from the fuse box so I could tape wire to this and pull it through if I have to (which I have with a few cables since).

: That took a bit to arrive but it made everything about 100x easier. In the event I missed a wire I left one long redundant wire in the loom which runs to/from the fuse box so I could tape wire to this and pull it through if I have to (which I have with a few cables since).

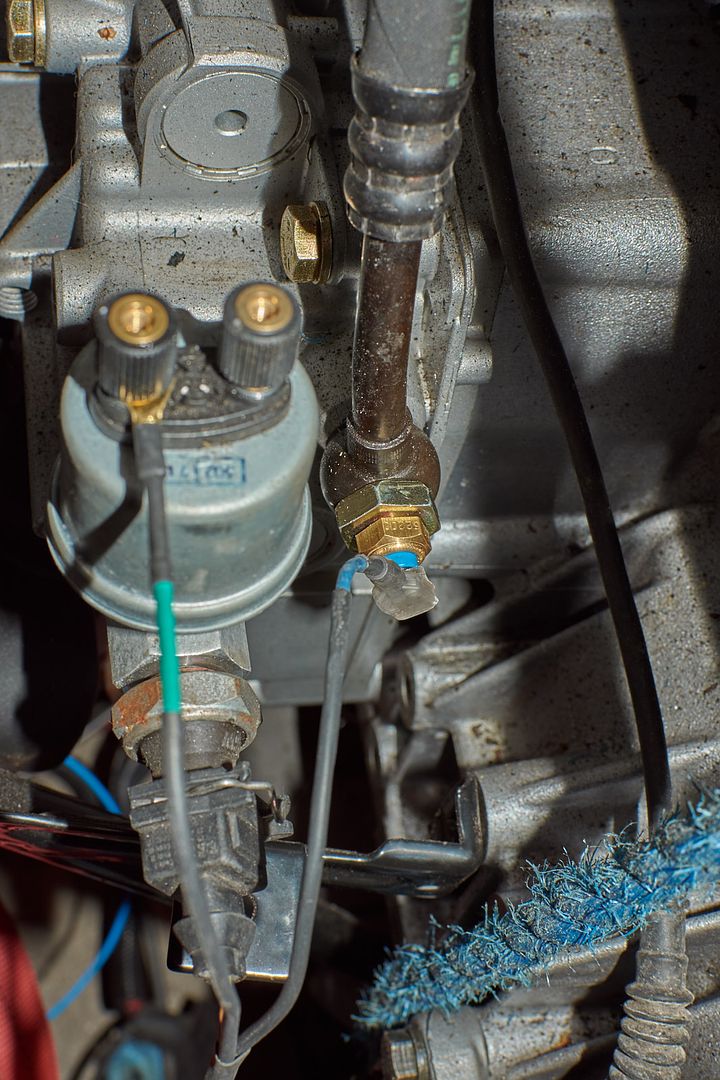

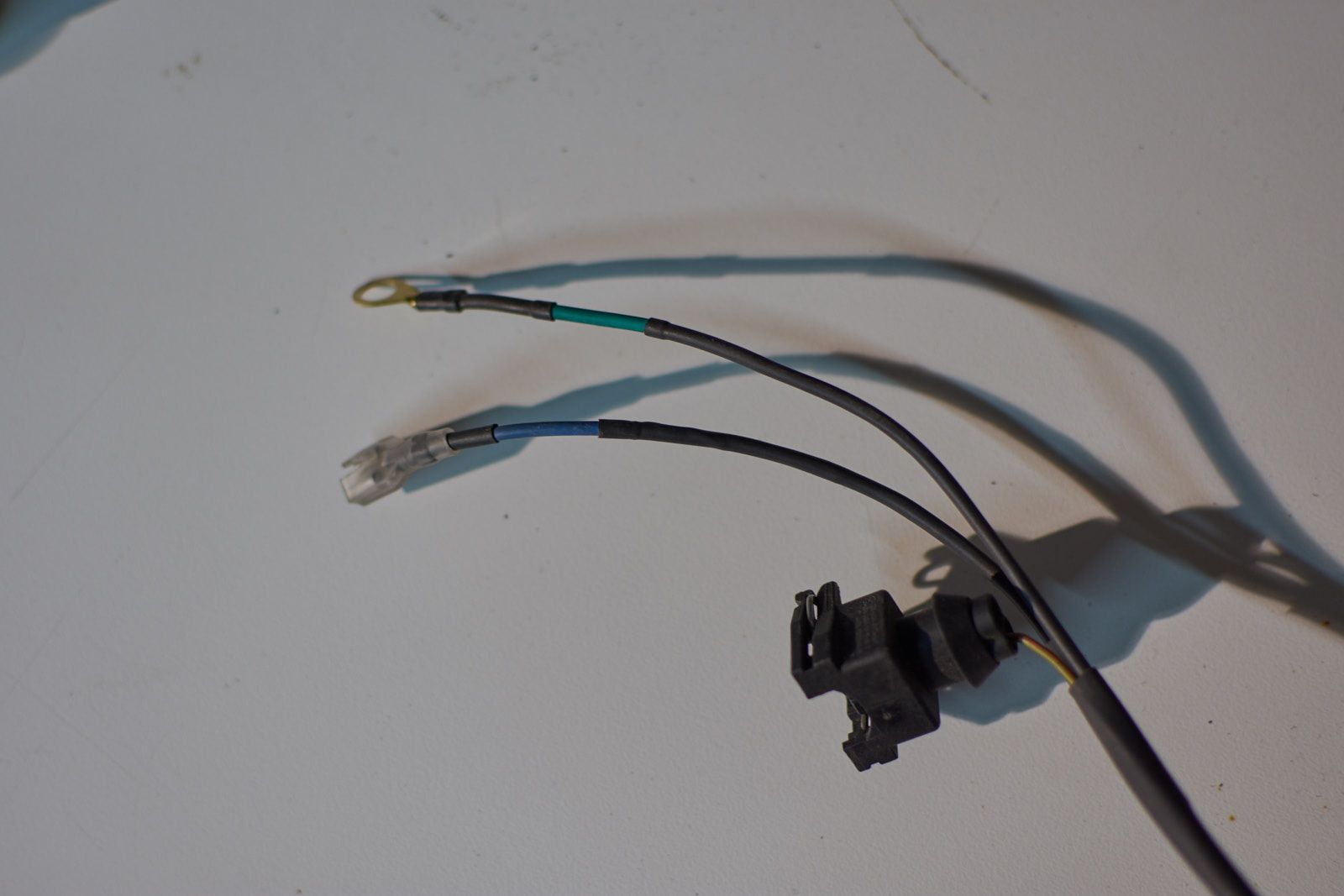

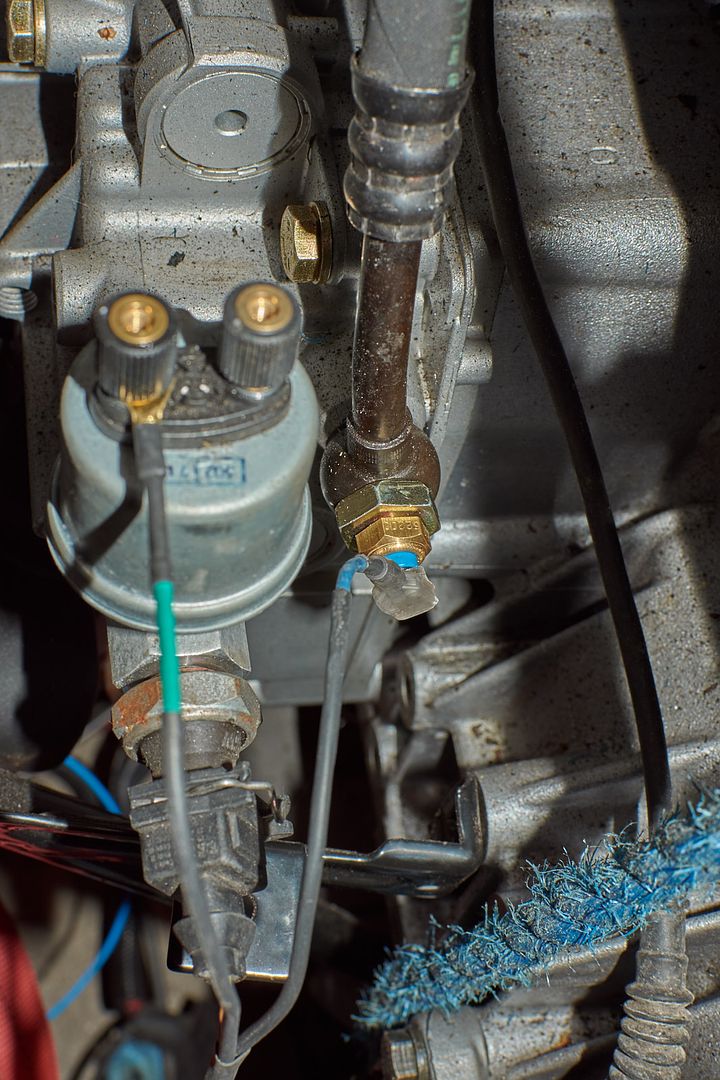

I'm also fitting VDO gauges which needed wiring up neatly. Not liking many of the t-pieces and adapters and what not available I ended up drilling a hole in one of the vanos banjo bolts and threading it for the temp sender. The pressure sender is still on an extension/adapter but at least I now don't have another adapter on this for temp. Both wires were fed through the engine loom, crimped and I used some heatshrink to color code the wires, pics below of it in place:

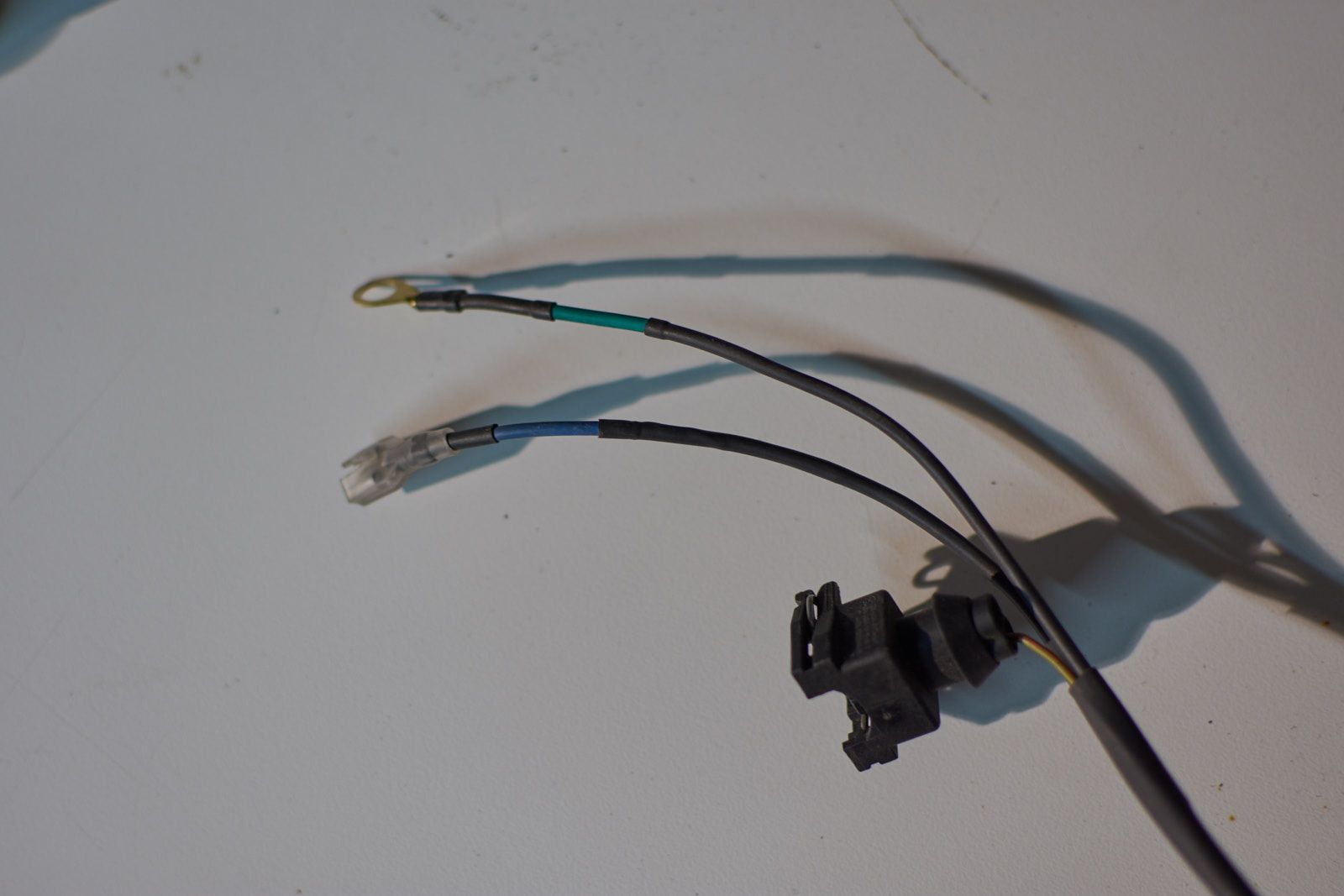

And the bit of engine loom I fed both wires through:

Over the weekend I'll probably undo all the above after realizing the second terminal on the pressure sender is for a warining light, which I might as well also make use of.

Thats all for slow progress :thumb:

At some point last year I started extending all the wires running around the engine bay, I wanted to hide them as much as possible but not go to crazy.

Using an old loom I extended all the wiring with the same color cable. Then came to my senses after realizing I potentially had up to 3x solder joins that could fail and went ahead and ordered a load of cables and various crimps so I could tack this mess:

In the end I pulled all the original cables going to fuses and replaced them with extra long new cables with the right ends crimped on and sloted back in place. A few cables ran into the car and those were solder joined inside the fusebox and had some heatshrink applied.

The plan was to separate all the wiring going to the passenger and driver side and route them both separately as can be seen below:

That was then stuffed through a pair of holes into conduit on the inner wings and routed to the front of the car where it exits under the front slam panel on either side

Conduit and 90deg elbow I used on both ends to protect it from the elements as much as possible (apparently the elbows are water proof)

This all took me months and many weekends, everytime I spent a couple hours at it most of the time was spent re-tracing my steps and making sure I didn't miss any cables or got things mixed up. Eventually I pulled it all through the conduit which turned out to quite difficult! I pulled out all the wires and after speakign to a friend he recomended I use wire pulling lube

: That took a bit to arrive but it made everything about 100x easier. In the event I missed a wire I left one long redundant wire in the loom which runs to/from the fuse box so I could tape wire to this and pull it through if I have to (which I have with a few cables since).

: That took a bit to arrive but it made everything about 100x easier. In the event I missed a wire I left one long redundant wire in the loom which runs to/from the fuse box so I could tape wire to this and pull it through if I have to (which I have with a few cables since).I'm also fitting VDO gauges which needed wiring up neatly. Not liking many of the t-pieces and adapters and what not available I ended up drilling a hole in one of the vanos banjo bolts and threading it for the temp sender. The pressure sender is still on an extension/adapter but at least I now don't have another adapter on this for temp. Both wires were fed through the engine loom, crimped and I used some heatshrink to color code the wires, pics below of it in place:

And the bit of engine loom I fed both wires through:

Over the weekend I'll probably undo all the above after realizing the second terminal on the pressure sender is for a warining light, which I might as well also make use of.

Thats all for slow progress :thumb:

Comment