I've mostly been tidying up small bits here and there before I refit the subframes again. Plan is to also use Bilthmaber underseal in the arches and possibly a few other places under the car, it's a nasty looking black coating though.

I've only so far fitted the front subframe and rack and the rear end can be bolted up once I have brake lines made and do up the clamps on the new cv boots.

Anyone with BC Coils notice the rear rubber above the top mount perishing? I've had them maybe 2 years and 0 miles and the rubber is full of cracks.

I've only so far fitted the front subframe and rack and the rear end can be bolted up once I have brake lines made and do up the clamps on the new cv boots.

Anyone with BC Coils notice the rear rubber above the top mount perishing? I've had them maybe 2 years and 0 miles and the rubber is full of cracks.

:

:

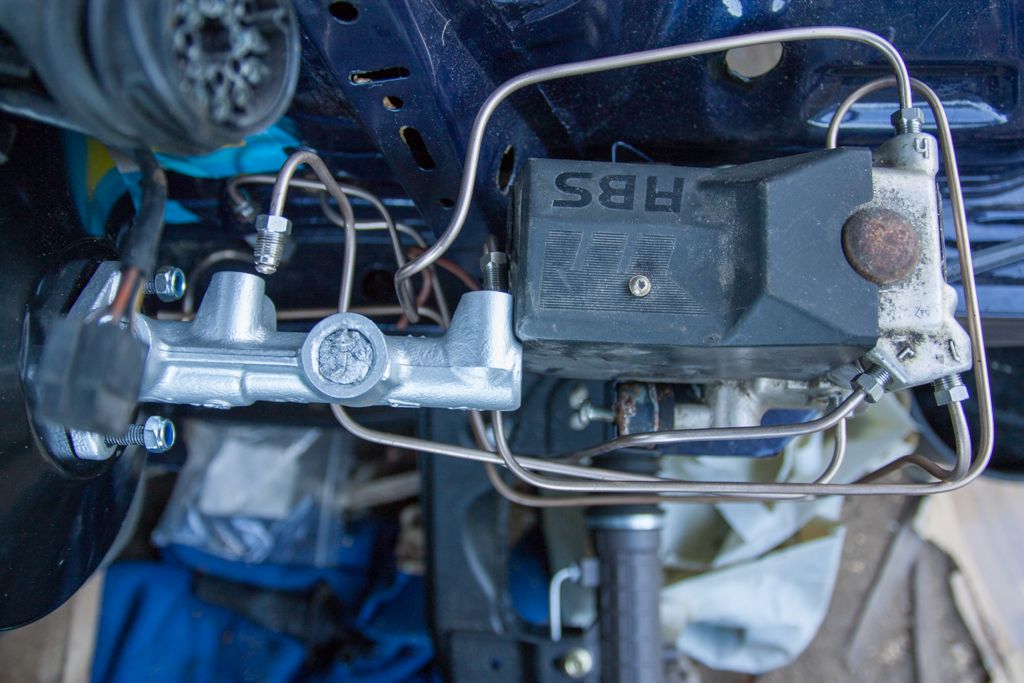

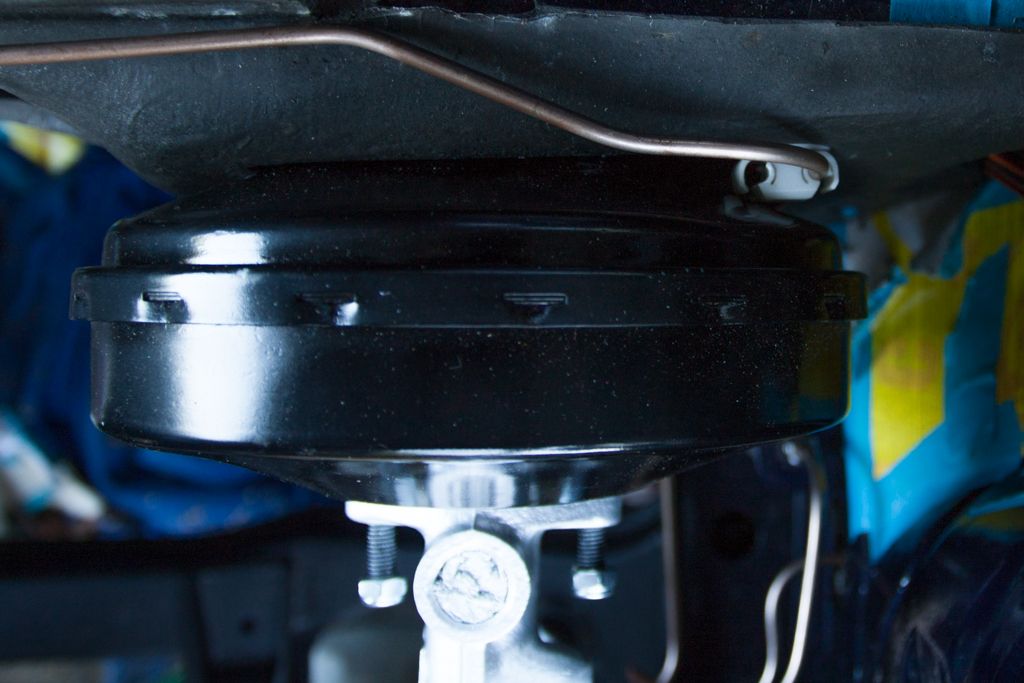

When I mocked up my ABS relocation I must have used the E30 servo, which I think isn't as deep as the Clio one

When I mocked up my ABS relocation I must have used the E30 servo, which I think isn't as deep as the Clio one

:

:

Comment