The rear apron parts are still very rough. Just metal with smoothed welds and primer sprayed on for the time being that will get taken off and the weld seams filled over with some duraglass to fill any pinholes etc. Sanded out and finished with a lightweight bodyfiller/glaze/primer/paint etc.

The rear tow hook on the passanger side was cut out because it was in the way of cutting out existing rust and I just closed it off.

Remember this piece of crap? (gas tank support)

That got cut out along with the right side of the gas door

which was rotted around the opening and where the screws for the gas door go. Fail

On a stock mk2 they just use a shitty self tapper to hold the tank up there on the left side. I just ended up using a 8mil flanged nut on the inside.

Did a ton of test fitting with the tank to get it right. Using a mk3 tank in a mk2 makes it sit low in the opening and I wanted to raise it up a little. Happy enough with how it came out.

Gas door obviously still very rough. Had to use a carbide burr to get into the edges and corners to smooth it out as best as I could. Filler will take care of any low spots.

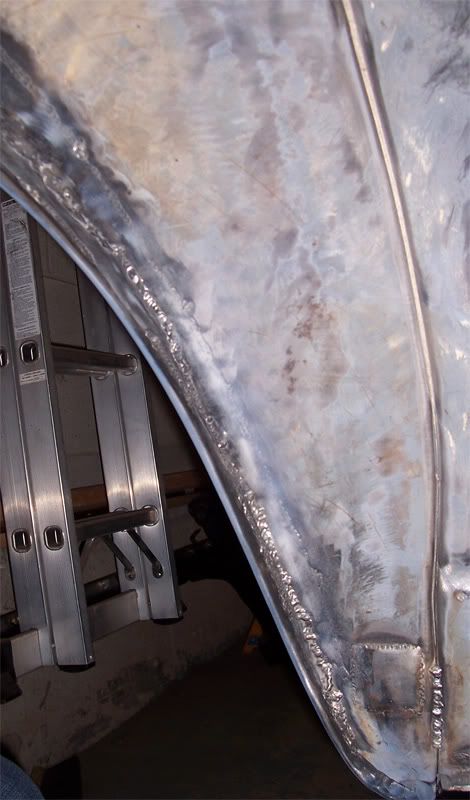

Inside of the arch. Stupidly enough the inner fender is part of the gas opening

Had to seal it up and I couldn't wear a helmet in such a tight spot so I had to keep looking away while welding it up. Doesn't look the greatest but its a complete weld all around that will just get painted and seam sealed so its not too much of a big deal.

After all that I can concentrate on putting the outer back on with extending the inner out first.

Still a long way away from being finished and stanced

thanks for looking.

thanks for looking.

Leave a comment: