Spring rate, pre-load, progressive rates, tender springs… what does it all mean?! Across the web, there’s a heap of information, some right, and some wrong. Today, we’re taking a dive in on basic spring tech to cover the most common and important aspects of spring technology and vernacular. A few years ago, we took a look at H&R Springs’s manufacturing facility in Lennestadt, Germany, to learn how springs are made, from raw material to finished product. Now it’s time to learn how to choose the right spring for the job, and to dispel the myths that run rampant.

Springs 101: What’s in a spring?

Chances are, you’re familiar with the concept of a spring. From the tiny springs we’ve all found after taking apart a retractable pen, to the dozens springs found around the edge of the trampolines we were lucky to walk away from as children, springs are everywhere. Relevant to StanceWorks, of course, are the springs found under your car. Chances are you’re familiar with those too, and if I were a betting man, I’d wager you’ve swapped them out in one fashion or another already. For the basics though, it’s worth stating anyway: vehicles rely on coil compressions springs — one of the most common types of springs — for their suspension systems.

Spring Rate:

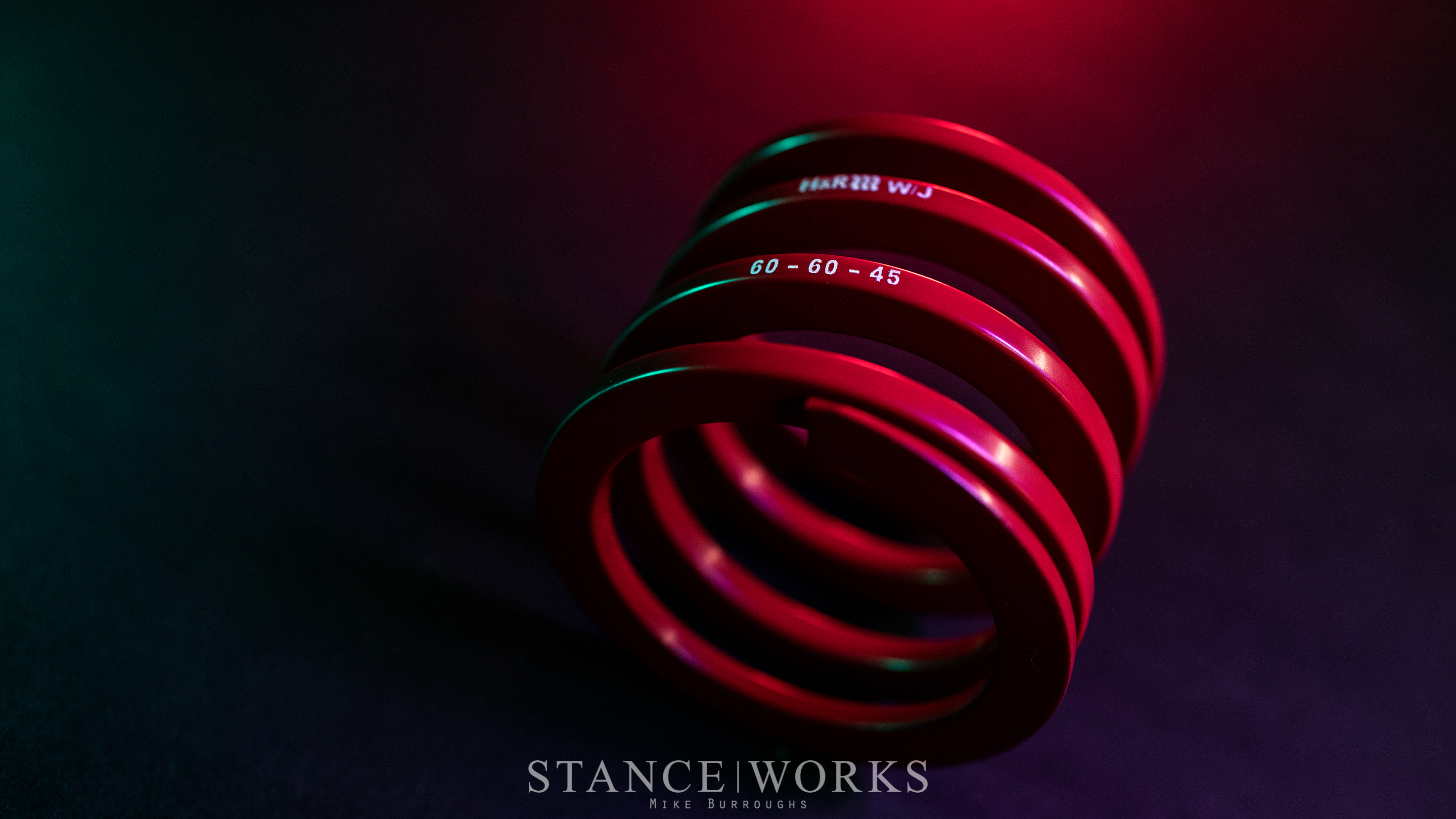

Springs can be measured in lots of ways, such as spring length and spring diameter, but a spring’s most important measurement is its “spring rate.” Spring rate, or spring constant, is a measurement of change in force a spring exerts, divided by a change in deflection of the spring itself. Don’t worry, that’s the complicated way to put it. In laymen’s terms, it’s simply a measure of how stiff a spring is. Spring rate is measured in units of force divided by distance. Most commonly in the world of aftermarket suspensions, that leaves us with pounds-per-inch, newtons-per-millimeter, and kilograms-per-millimeter. For most cars, pounds-per-inch is the standard, although most Japanese cars and tuners prefer kilogam-per-millimeter, often abbreviated simply by “K”. The most technical measurement, which ze Germans at H&R rely on, is in newtons.

Breaking it down:

A spring with a spring rate of 400lb/in is relatively easy to understand. It will take 400 pounds of force to compress the spring one inch. 800 lbs yields a compression of two inches, so on and so forth. It’s as easy as that! That translates to 7.1kg/mm, usually known simply as a “7K spring.” In Newtons-per-millimeter, it’s 70N/mm. Going up in spring rate — increasing the spring’s stiffness — means moving from 400 lb/in, up to 450 lb/in, for example. For softer springs, it’s the other direction.

So what do I do with spring rate?:

For most folks, the answer is simple: nothing at all. Spring rates are handled and solved for your car long before your parts arrive at your door. H&R Springs, for example, outfits each spring and coilover kit they sell with spring rates prescribed specifically for the car they’re intended to go on. H&R’s Volkswagen MK7 Street Performance + kit, for example, is built ready to rock out of the box, meaning no guesswork on your end, and no need to pick and choose spring rates.

Some folks, though, may have the itch to tinker or fine tune, whether it be to account for their aggressive wheel fitment, or their desire to shave seconds on the race track. Changing spring stiffness can alter tire compliance, change handling characteristics, and can keep wheels from colliding with fender arches, if that’s your thing. It’s important to note, though, that with spring rate changes should come changes in damping to your shocks… but that’s for the next article.

Progressive Springs… Upping the Ante:

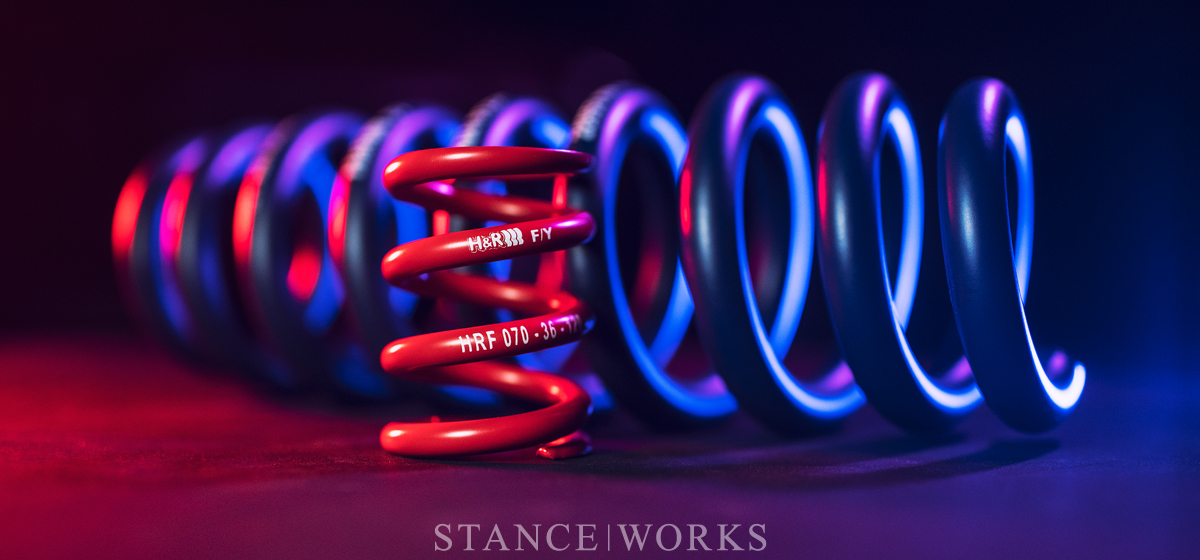

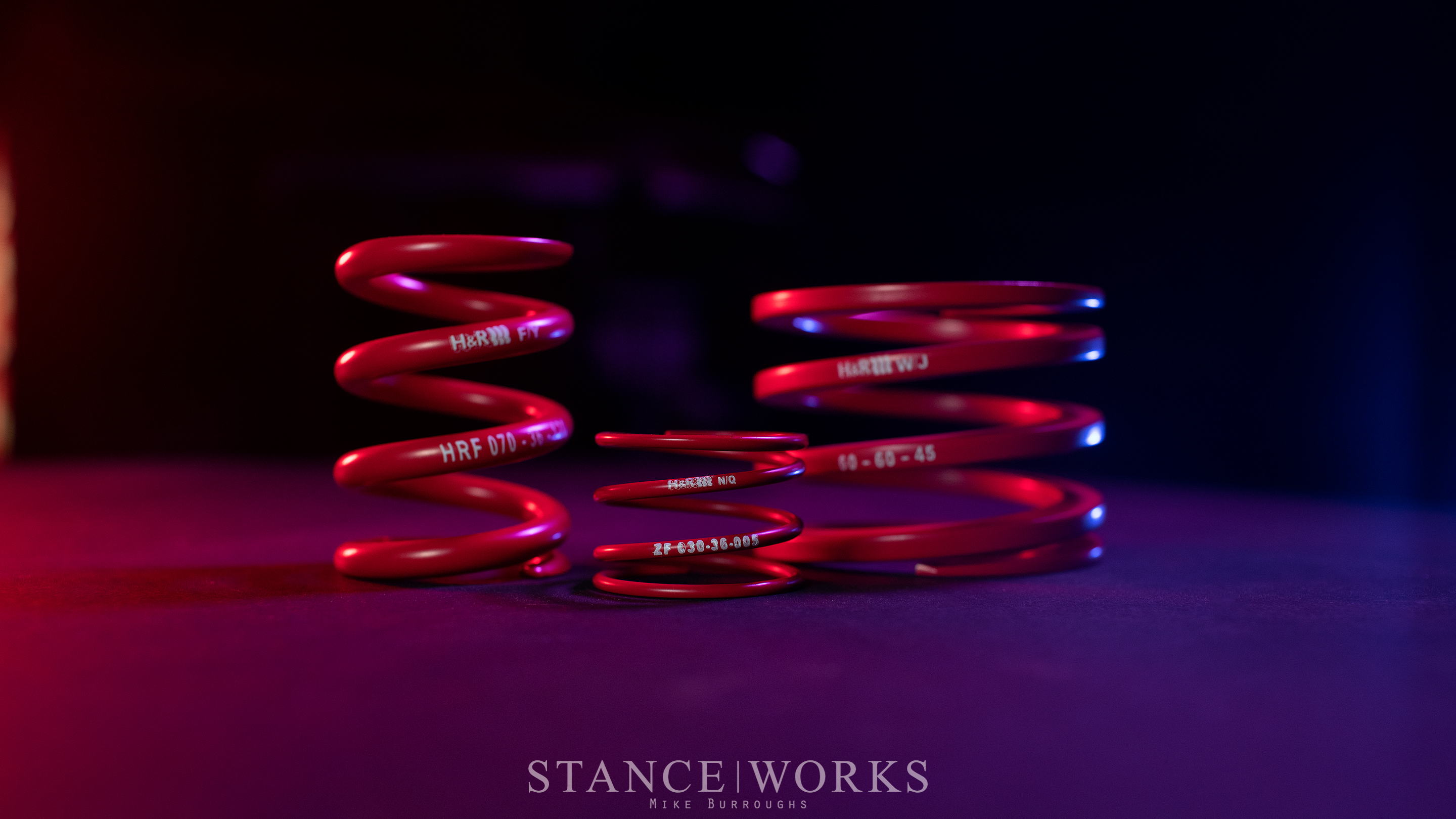

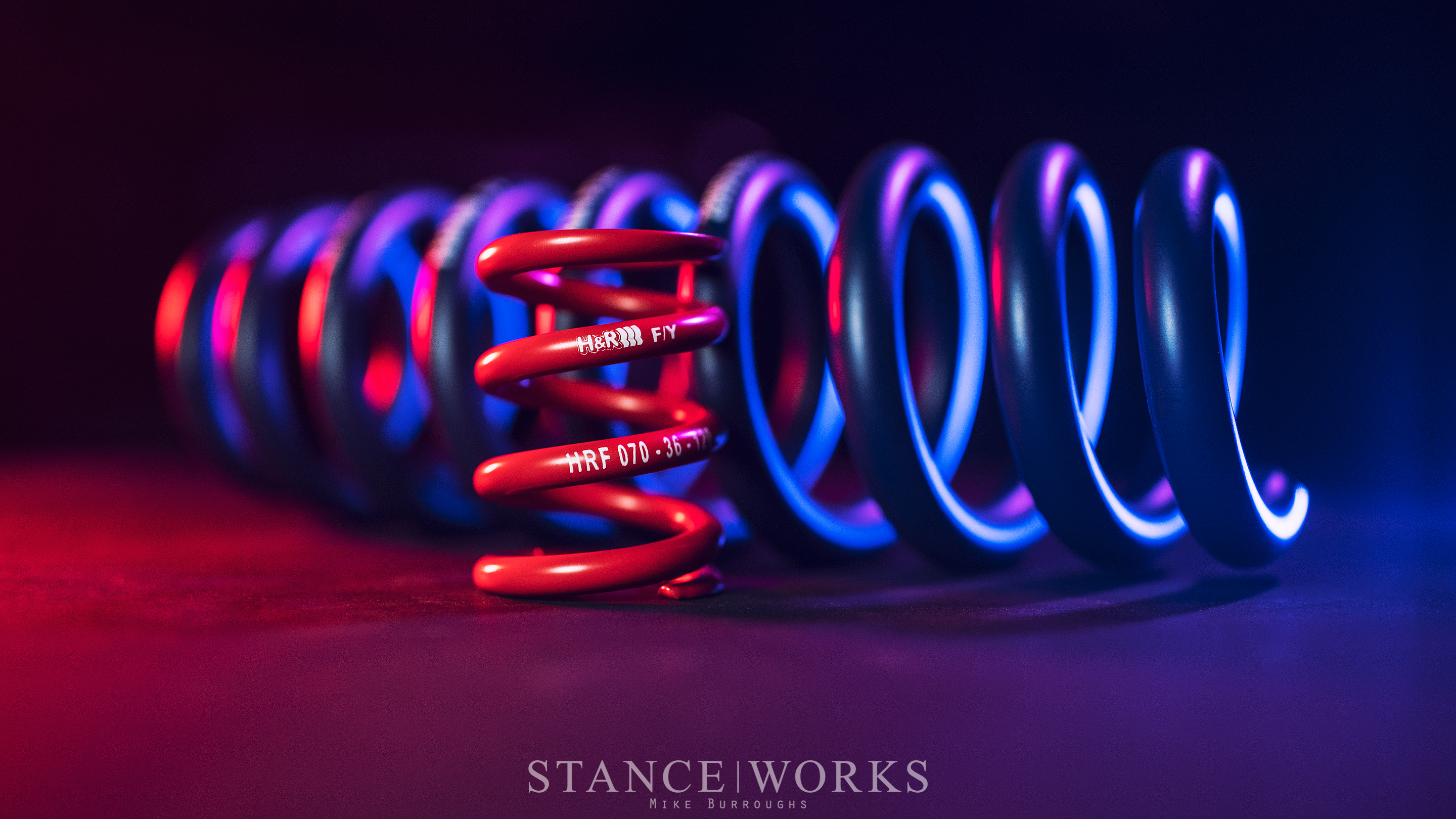

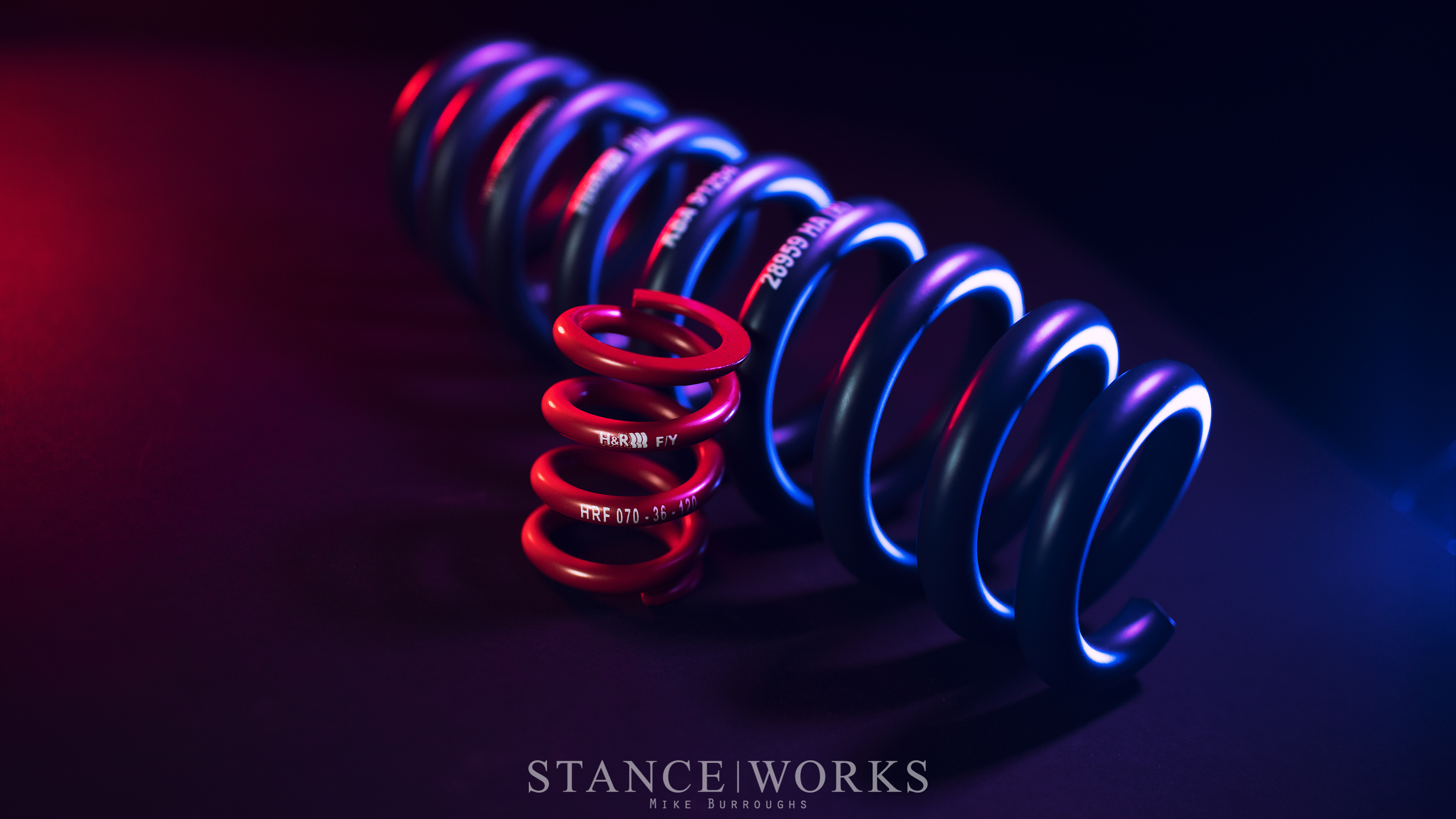

Spring rates are simple on the surface, but can be very complex in execution. Whenever possible, H&R turns to progressive springs for their systems. Progressive springs feature a changing spring rate, made visible by the drastic change in shape. In a sense, a progressive spring allows a spring to act a “multiple springs in one.” A glance at the spring indicates that as the spring compresses, it becomes stiffer, which is ideal when customers want a smooth ride over bumps but stiffness in the corners, for example.

Spring Length & Diameter:

Springs do, of course, have other measurements, with sizing being an important factor alongside spring rate. While any decent spring kit or coilover kit will have the sizing solved for you, it’s sometimes helpful to know what it all means, and should you go modifying things, now you’ll know what you’re looking at.

Spring length is as simple as it sounds: it’s the measurement of a spring from one end to the other in its uncompressed state. An 8″ spring measures 8″ end to end, as one might expect. Remember though: spring length is variable. An 8″ spring with a 400lb/in spring rate, and with 400 pounds atop it, will stand at just 7″ tall.

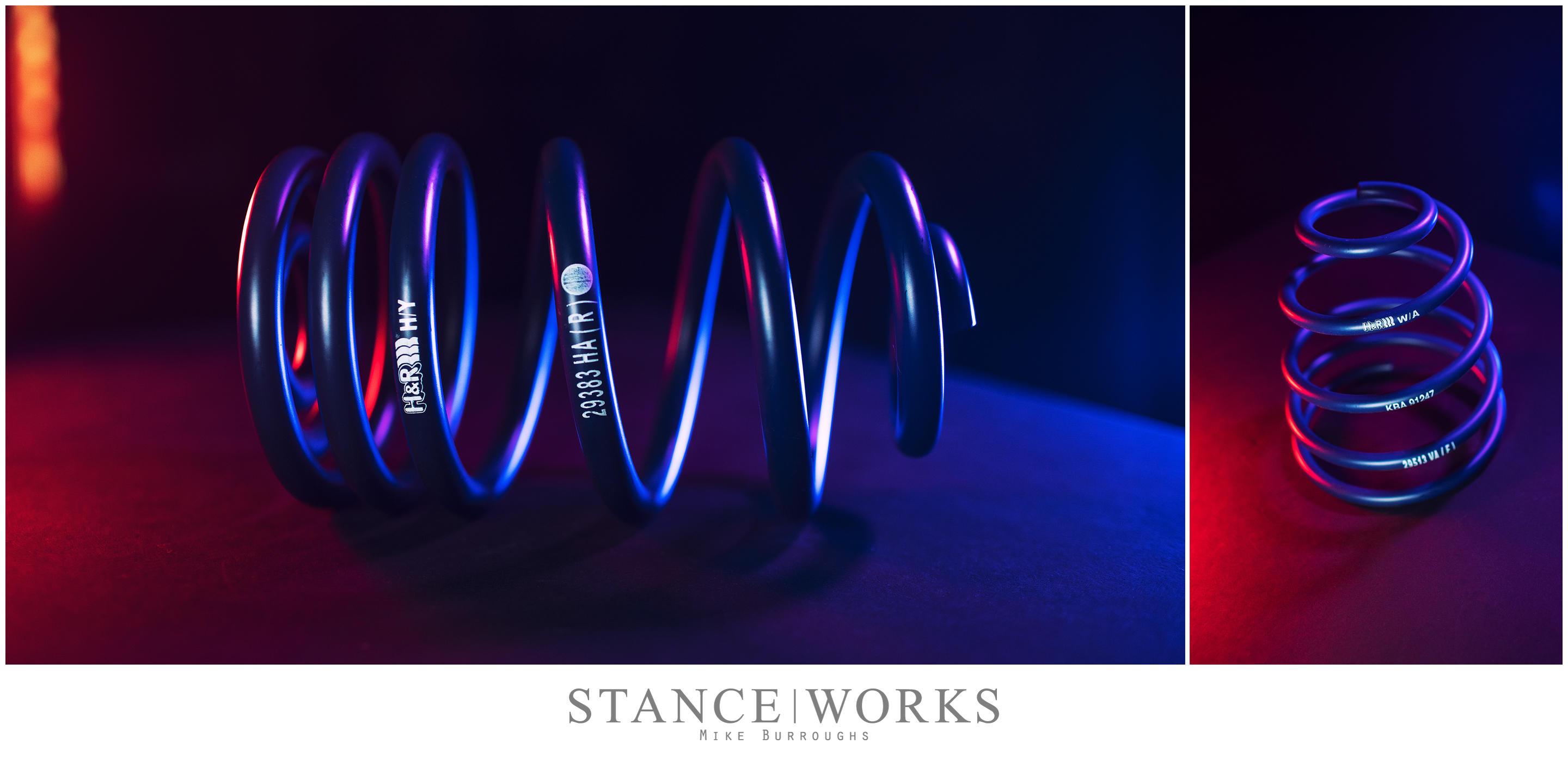

Spring diameter, on the other hand, is constant. Springs are measured in Inside Diamter (ID) and Outside Diameter (OD). ID is useful in establishing what springs will fit on a given coilover or spring perch, or what springs may fit over a given shock body. OD is helpful in finding out if a spring will fit behind a wheel or inside of a strut tower, for example. Many progressive springs, such as “beehive” springs, which are conical in shape, have a changing OD and ID; however, if you’re swapping out springs and customizing aspects like length, diameter, and rate, you’ll be sticking with very simple constant-rate cylindrical springs, like the ones above.

Helper Springs & Tender Springs:

There’s a good chance you’ve seen coilover systems with more than one spring on a single strut. “What’s going on there?” is a totally fair question, and fret not: the answer is relatively simple. The smaller, secondary spring is either a helper spring or a tender spring, and while similar in appearance, they are quite different in function. Helper springs provide no actual spring rate to the suspension system itself. They are only present to help keep the main spring seated on its perches when the system is not compressed, either during down-travel or when the car is jacked up and the suspension droops. Short springs that are not under constant compression on a strut can unseat, and helper springs provide just enough force to prevent that from happening. Under static load (when the car is simply parked, for example), helper springs are fully compressed, essentially neutralizing them.

Tender springs, on the other hand, are part of a dual rate system. Think progressive springs, but with two springs instead of one. While helper springs compress completely and close up before normal load is applied, tender springs remain open, and offer secondary rates to a suspension system. Tender Springs are very complicated to tune, and thus are uncommon in almost any application, save for racing technology. You won’t find tender springs on most consumer coilover applications.

The Myth of Preload:

Last but not least, there’s the myth of spring pre-load. If you’ve spent any time at all researching suspension tuning, you’ve undoubtedly come across the “preload” term, and chances are, the debates surrounding it, too. Well, debate no more, because the hard truth is simple: Spring Preload isn’t a thing. There are no secret advantages, nor handling characteristics to be found by pre-loading springs, as it doesn’t change your spring rates, or anything else for that matter, on standard static-rate springs. No matter how red-faced and angry some may get insisting otherwise, that’s simply not how physics works. Cranking down your coilover perches to compress a 400lb/in spring a half inch does nothing at all but bring you closer to coil bind.

Coil Bind:

We’ve reached the end of our lesson with the last vocabulary term: Coil Bind. When springs are fully compressed, eventually, they reach coil bind: the rings of the spring hit each other, and no further compression happens. When you bottom out your car over a hard bump, “bump stops,” foam or rubber components, are present to prevent bottoming out the shock or binding the springs. They’re an essential part of a properly functioning suspension system, and without them, you’re likely to blow your shocks and bind your springs. You don’t want that, trust us.

And with that, you’ve got the basics: Springs 101 with H&R Springs. There’s a million and one things left to discuss, debate, and calculate, but with the basics at hand, you’re now better equipped than ever to understand what’s happening under your car. Stay tuned for next time, when we dive into shocks. Damping, Compression, Rebound? Oh my.