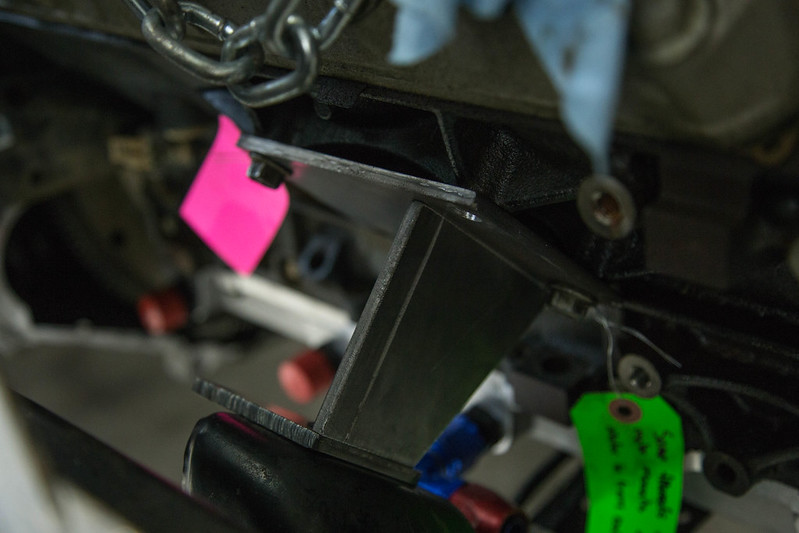

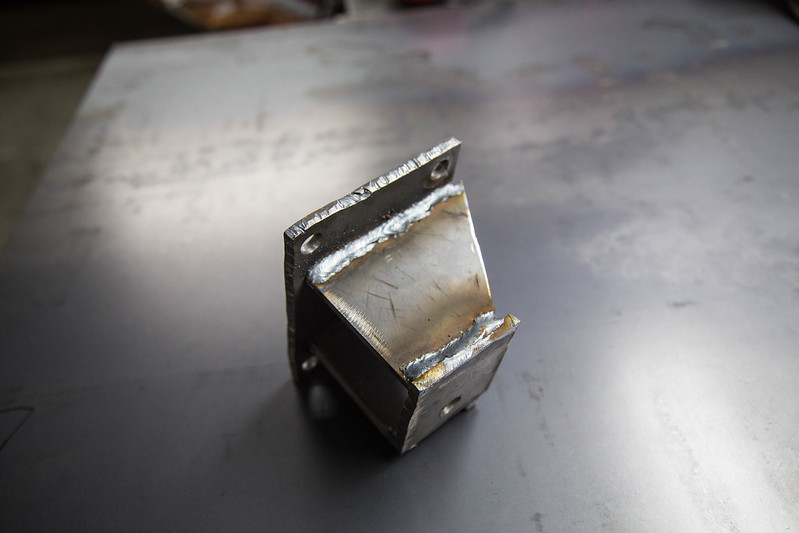

In one of the earlier images, you can see the braces:

untitled (3 of 17)-3 by lawrx, on Flickr

untitled (3 of 17)-3 by lawrx, on Flickr untitled (4 of 17)-3 by lawrx, on Flickr

untitled (4 of 17)-3 by lawrx, on Flickr untitled (6 of 17)-3 by lawrx, on Flickr

untitled (6 of 17)-3 by lawrx, on Flickr untitled (7 of 17)-3 by lawrx, on Flickr

untitled (7 of 17)-3 by lawrx, on Flickr untitled (8 of 17)-3 by lawrx, on Flickr

untitled (8 of 17)-3 by lawrx, on Flickr untitled (9 of 17)-3 by lawrx, on Flickr

untitled (9 of 17)-3 by lawrx, on Flickr untitled (10 of 17)-3 by lawrx, on Flickr

untitled (10 of 17)-3 by lawrx, on Flickr untitled (11 of 17)-3 by lawrx, on Flickr

untitled (11 of 17)-3 by lawrx, on Flickr untitled (12 of 17)-3 by lawrx, on Flickr

untitled (12 of 17)-3 by lawrx, on Flickr untitled (13 of 17)-3 by lawrx, on Flickr

untitled (13 of 17)-3 by lawrx, on Flickr untitled (14 of 17)-3 by lawrx, on Flickr

untitled (14 of 17)-3 by lawrx, on Flickr untitled (15 of 17)-3 by lawrx, on Flickr

untitled (15 of 17)-3 by lawrx, on Flickr untitled (16 of 17)-3 by lawrx, on Flickr

untitled (16 of 17)-3 by lawrx, on Flickr untitled (17 of 17)-3 by lawrx, on Flickr

untitled (17 of 17)-3 by lawrx, on Flickr untitled (1 of 17)-3 by lawrx, on Flickr

untitled (1 of 17)-3 by lawrx, on Flickr untitled (2 of 17)-3 by lawrx, on Flickr

untitled (2 of 17)-3 by lawrx, on Flickr

untitled (1 of 3) by lawrx, on Flickr

untitled (1 of 3) by lawrx, on Flickr untitled (2 of 3) by lawrx, on Flickr

untitled (2 of 3) by lawrx, on Flickr untitled (3 of 3) by lawrx, on Flickr

untitled (3 of 3) by lawrx, on Flickr

untitled (1 of 9)-2 by lawrx, on Flickr

untitled (1 of 9)-2 by lawrx, on Flickr untitled (2 of 9)-2 by lawrx, on Flickr

untitled (2 of 9)-2 by lawrx, on Flickr untitled (3 of 9)-2 by lawrx, on Flickr

untitled (3 of 9)-2 by lawrx, on Flickr untitled (4 of 9)-2 by lawrx, on Flickr

untitled (4 of 9)-2 by lawrx, on Flickr untitled (5 of 9)-2 by lawrx, on Flickr

untitled (5 of 9)-2 by lawrx, on Flickr untitled (6 of 9)-2 by lawrx, on Flickr

untitled (6 of 9)-2 by lawrx, on Flickr untitled (7 of 9)-2 by lawrx, on Flickr

untitled (7 of 9)-2 by lawrx, on Flickr untitled (8 of 9)-2 by lawrx, on Flickr

untitled (8 of 9)-2 by lawrx, on Flickr untitled (9 of 9)-2 by lawrx, on Flickr

untitled (9 of 9)-2 by lawrx, on Flickr

IMG_1386 by lawrx, on Flickr

IMG_1386 by lawrx, on Flickr IMG_1387 by lawrx, on Flickr

IMG_1387 by lawrx, on Flickr IMG_1389 by lawrx, on Flickr

IMG_1389 by lawrx, on Flickr IMG_1390 by lawrx, on Flickr

IMG_1390 by lawrx, on Flickr IMG_1367 by lawrx, on Flickr

IMG_1367 by lawrx, on Flickr IMG_1374 by lawrx, on Flickr

IMG_1374 by lawrx, on Flickr IMG_1352 by lawrx, on Flickr

IMG_1352 by lawrx, on Flickr IMG_1351 by lawrx, on Flickr

IMG_1351 by lawrx, on Flickr

Comment