I think thats the first time I've been Rick Rolled in over a year.

You bloody hooligan!

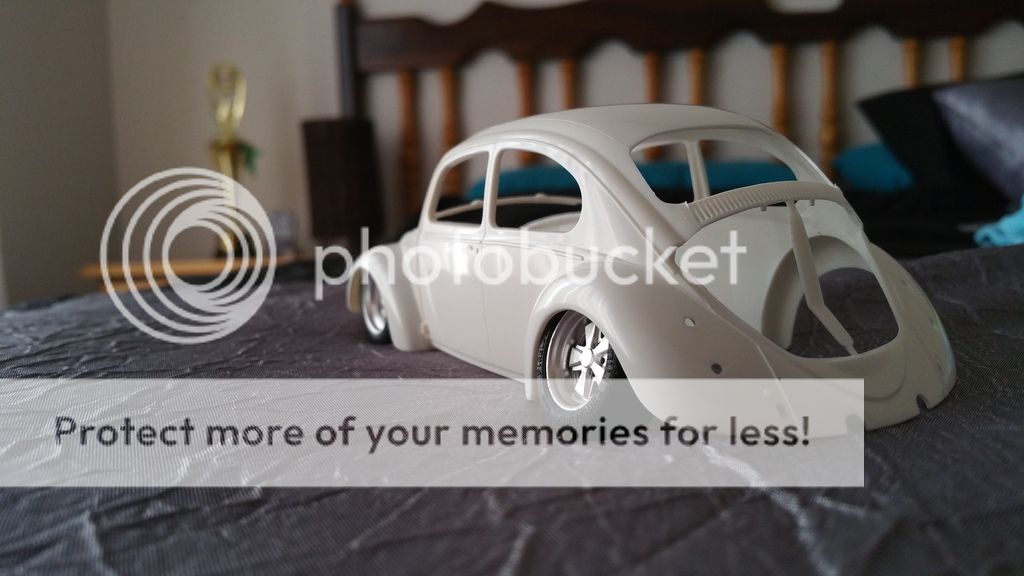

The car is absolutely amazing, the amount of work you put into this is amazing. Looking forward to the updates

You bloody hooligan!

The car is absolutely amazing, the amount of work you put into this is amazing. Looking forward to the updates

Comment