Today's post is full of spinning metal at a high rate of speed!. Also this will be part 1 of 2, took way more pictures than I realized

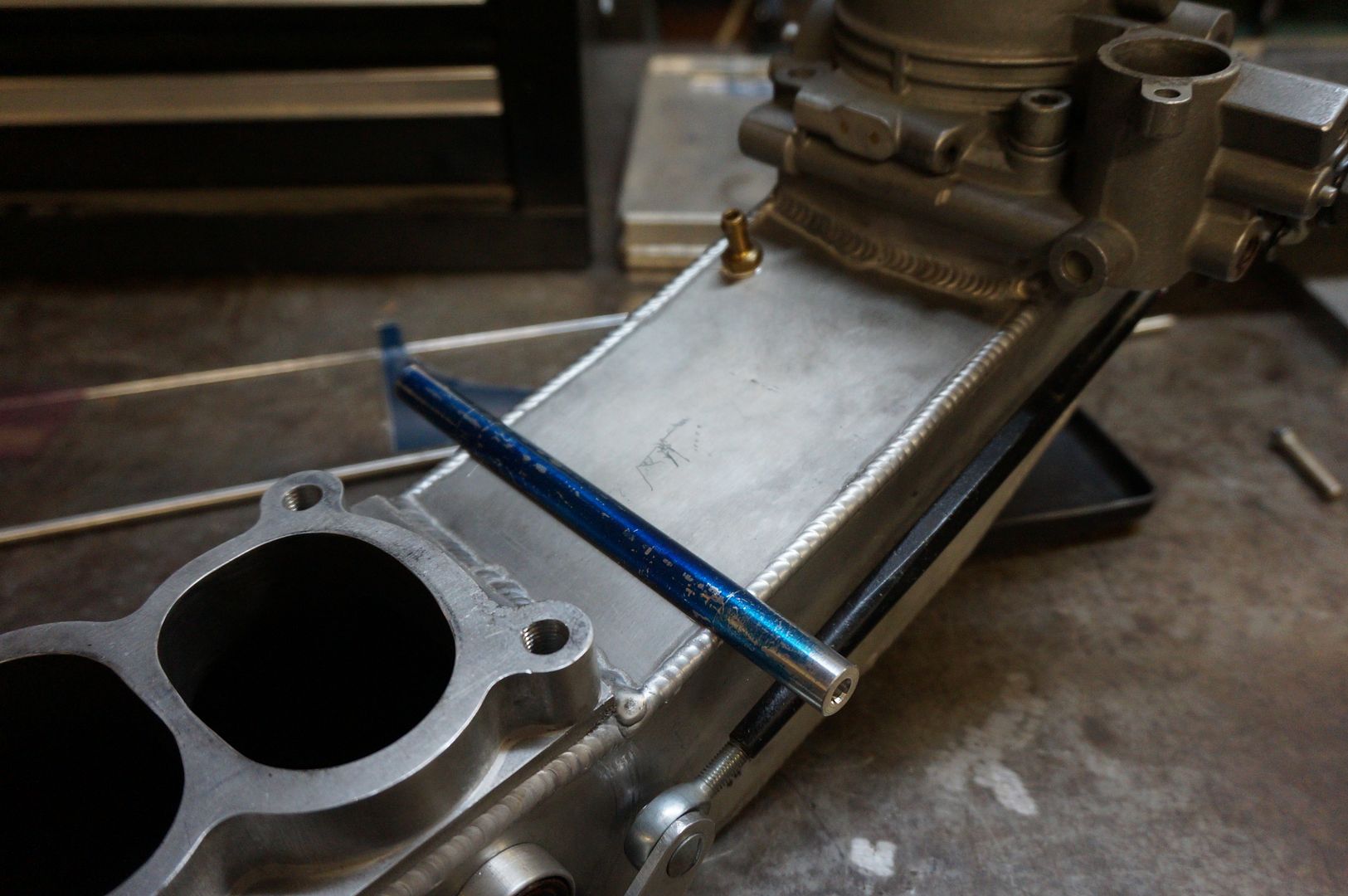

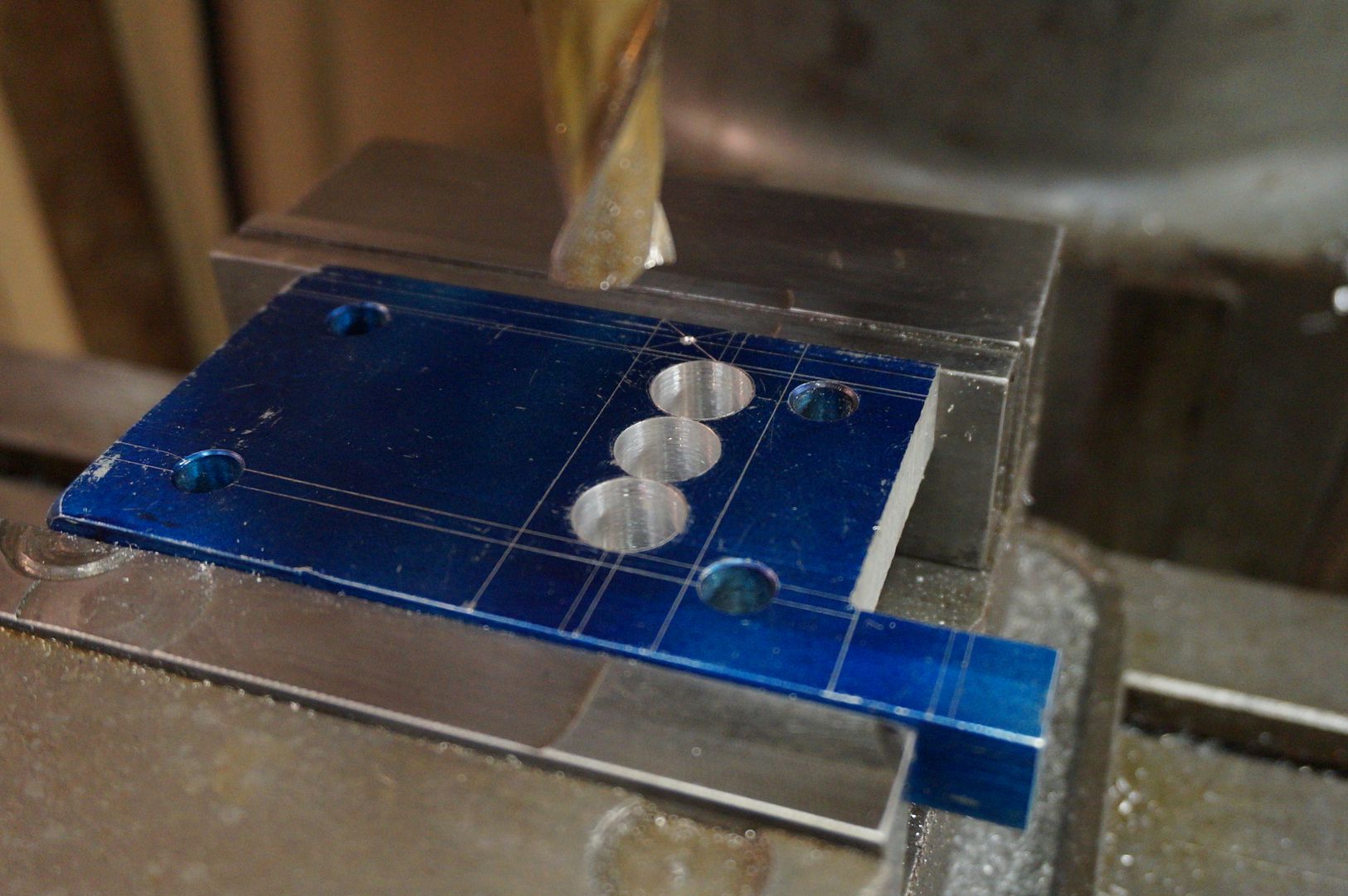

Using v blocks to machine a face on the aluminum bar

V blocks are almost a necessity when milling round materials

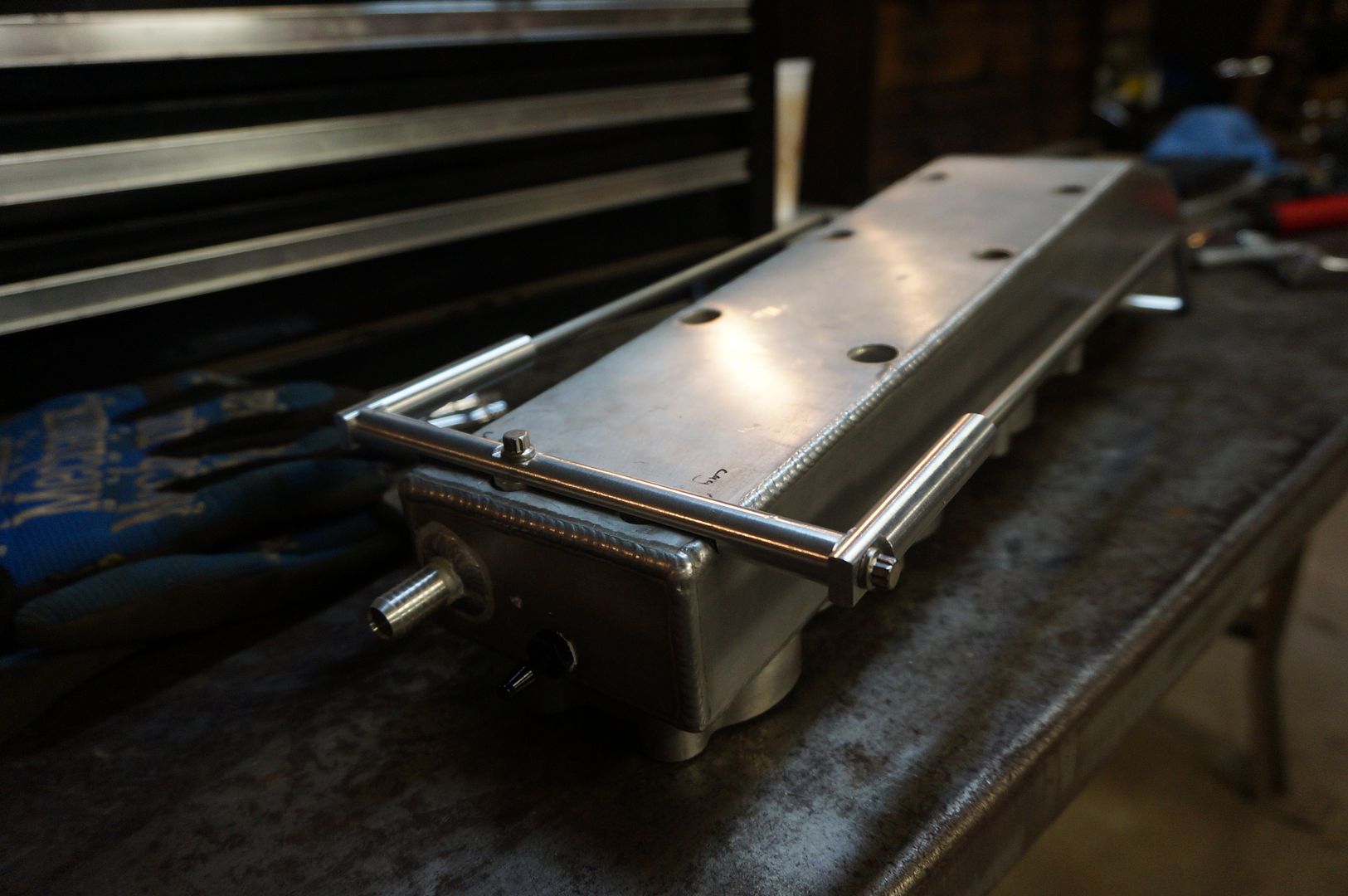

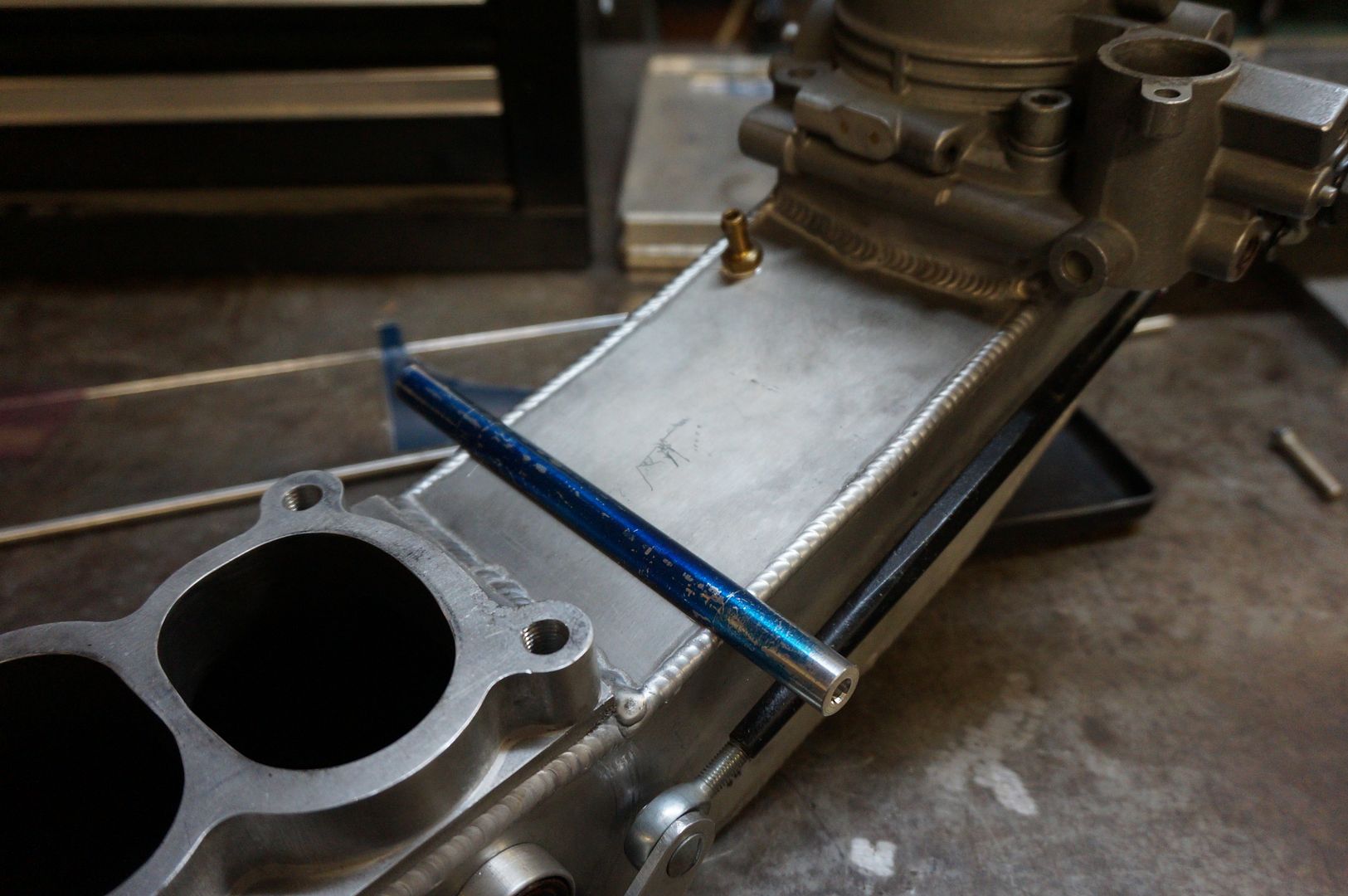

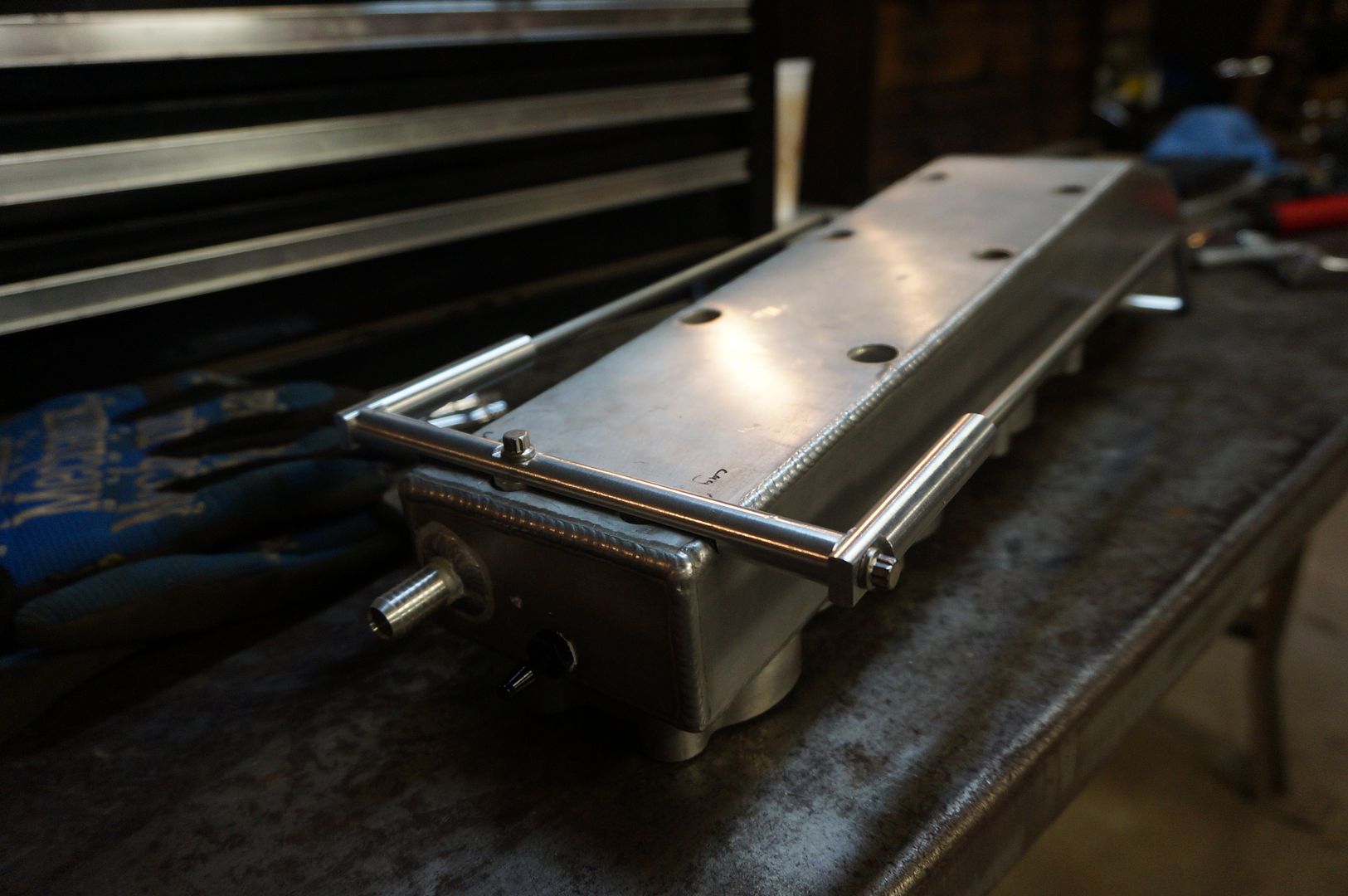

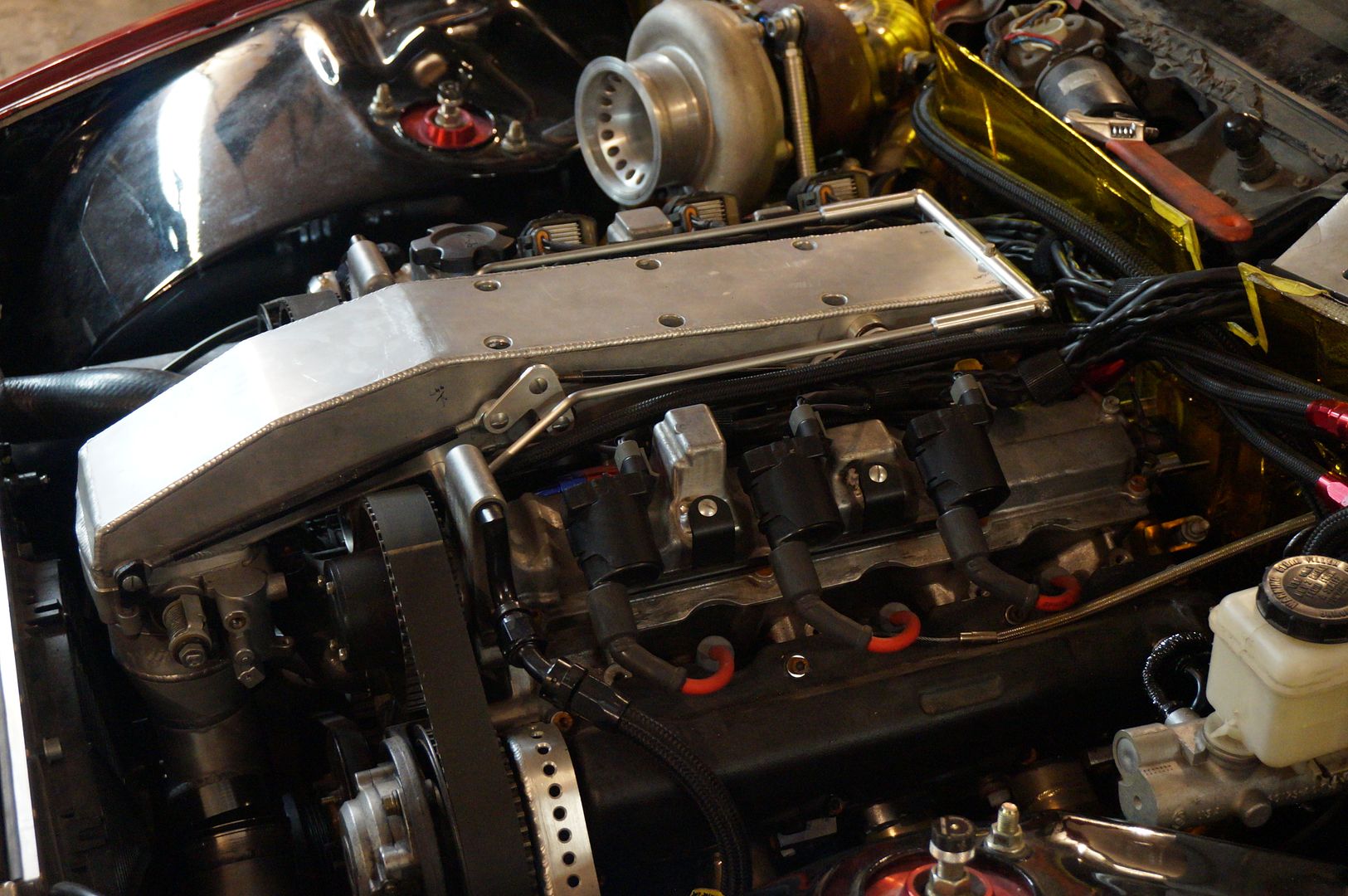

I made 2 of these, this one will be welded to the underside of the plenum eventually

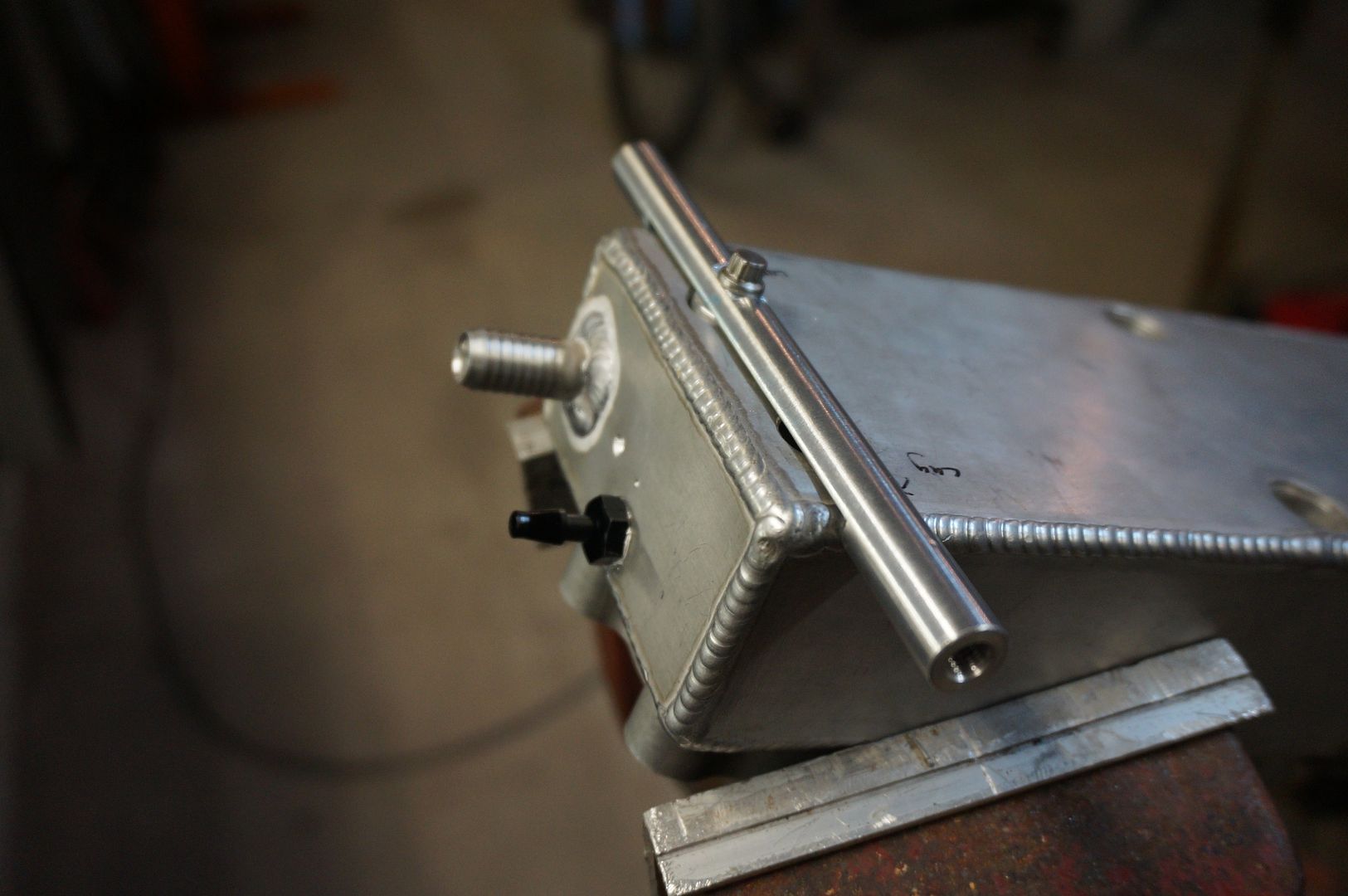

This is the second one

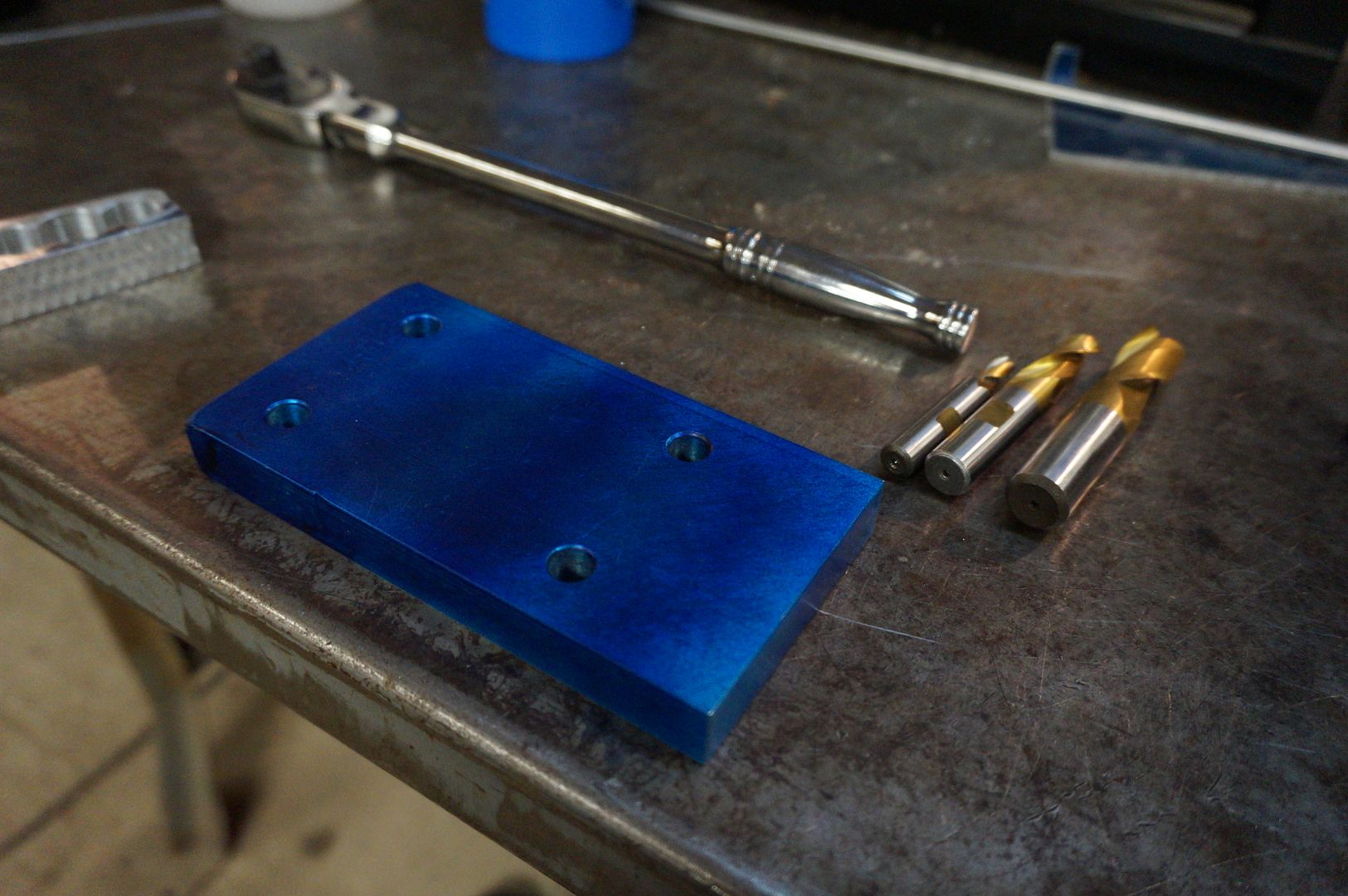

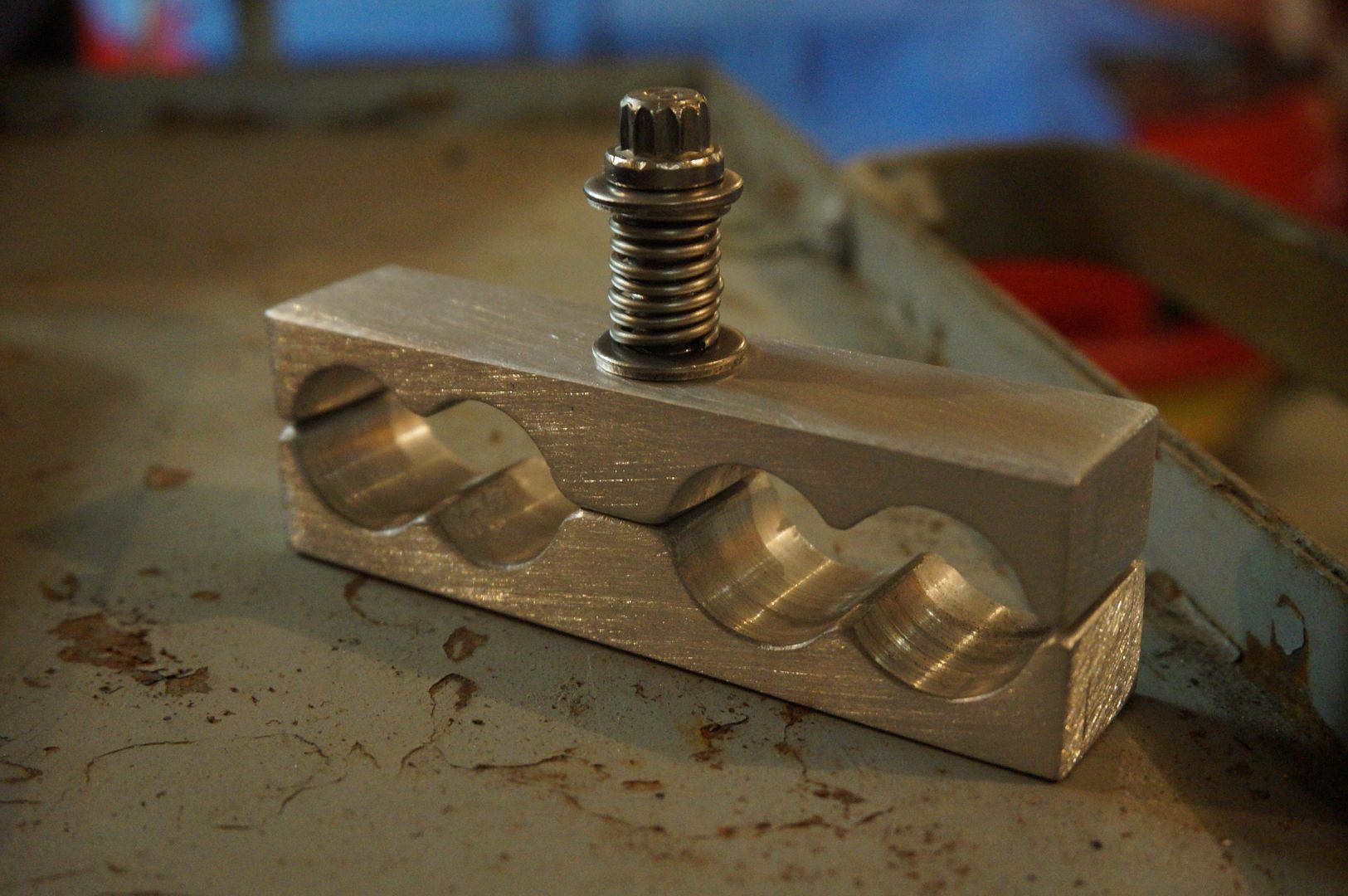

Made a plug anchor

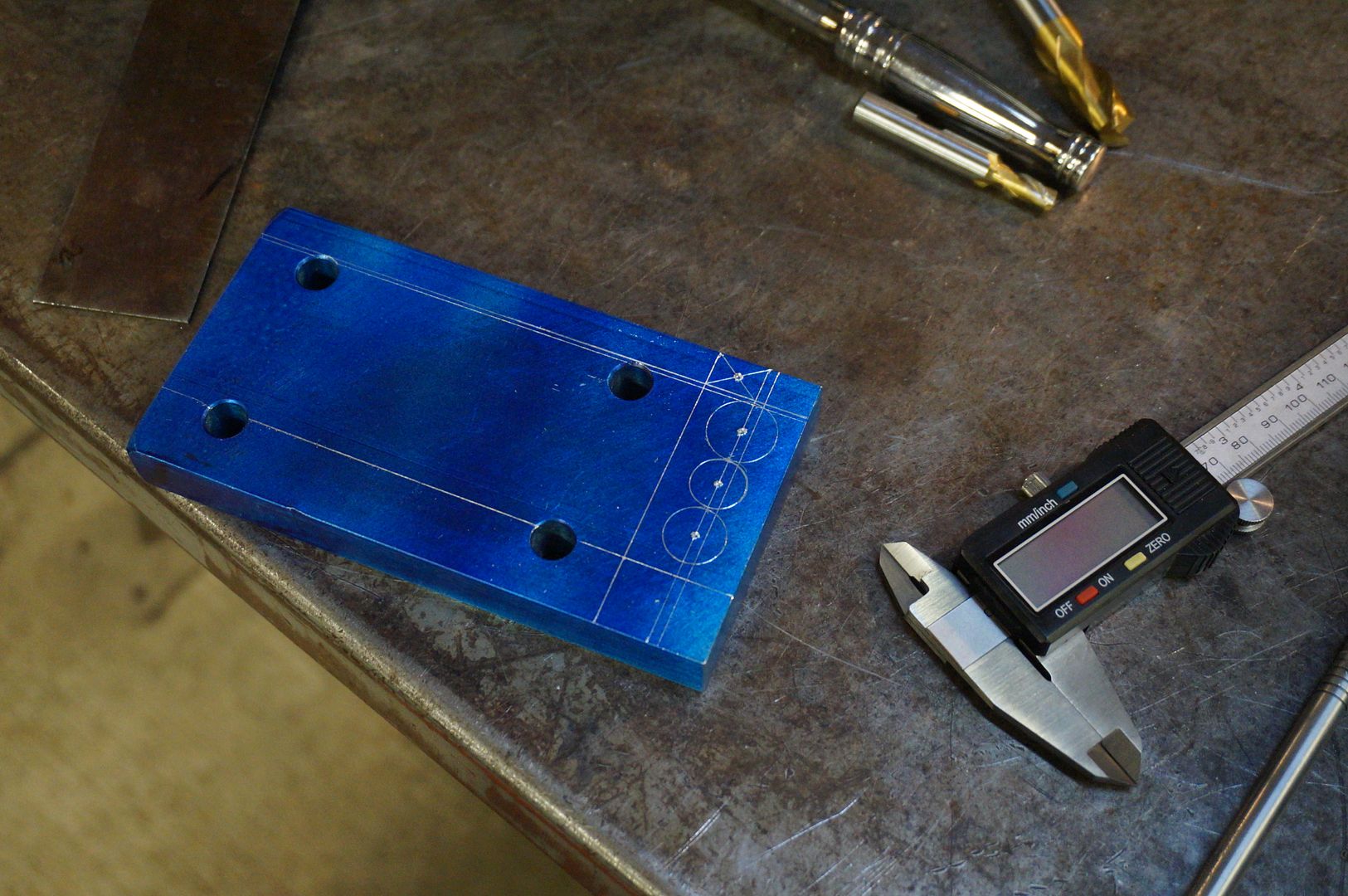

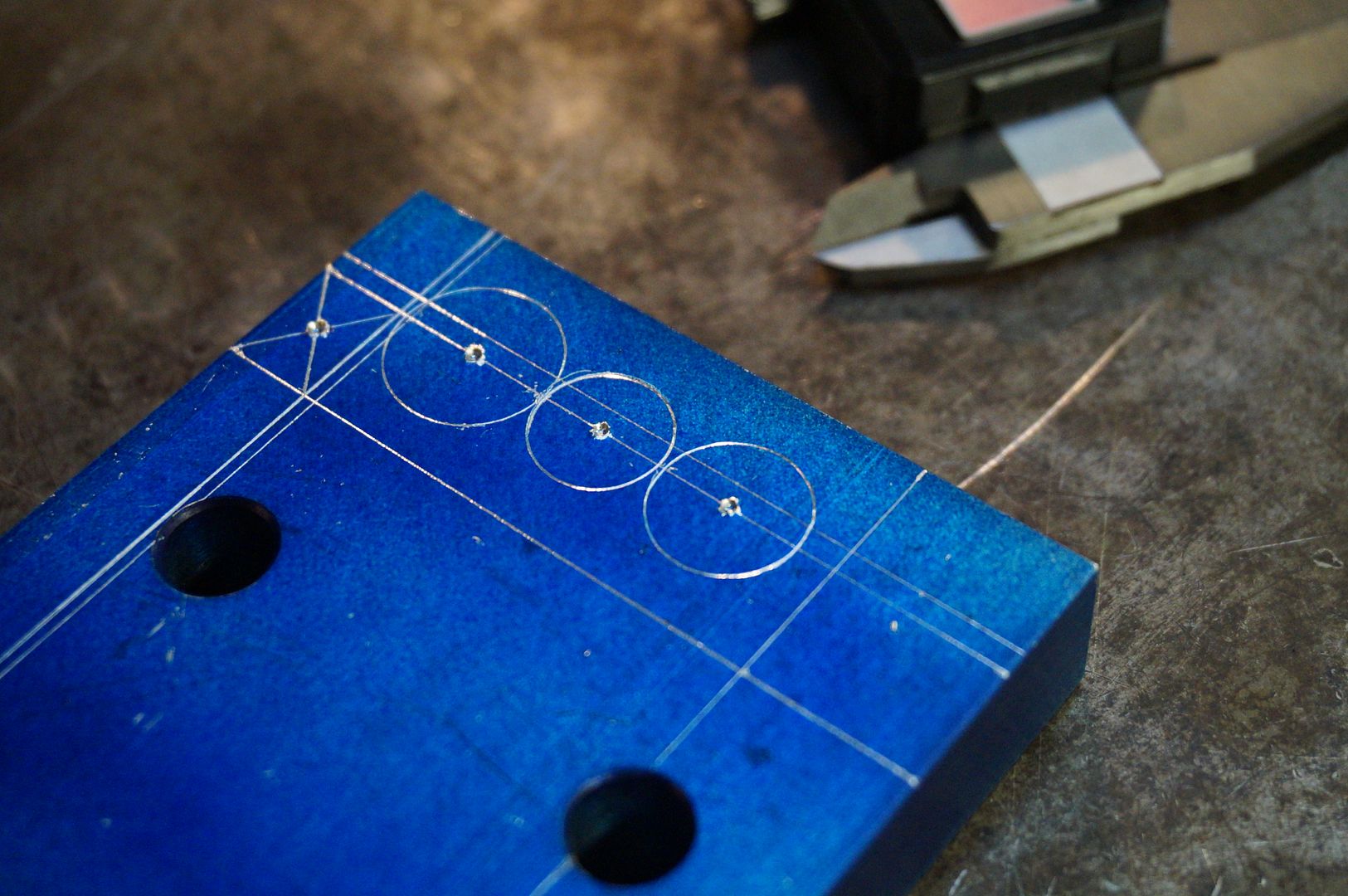

Plug anchor is inserted into plenum bolt holes

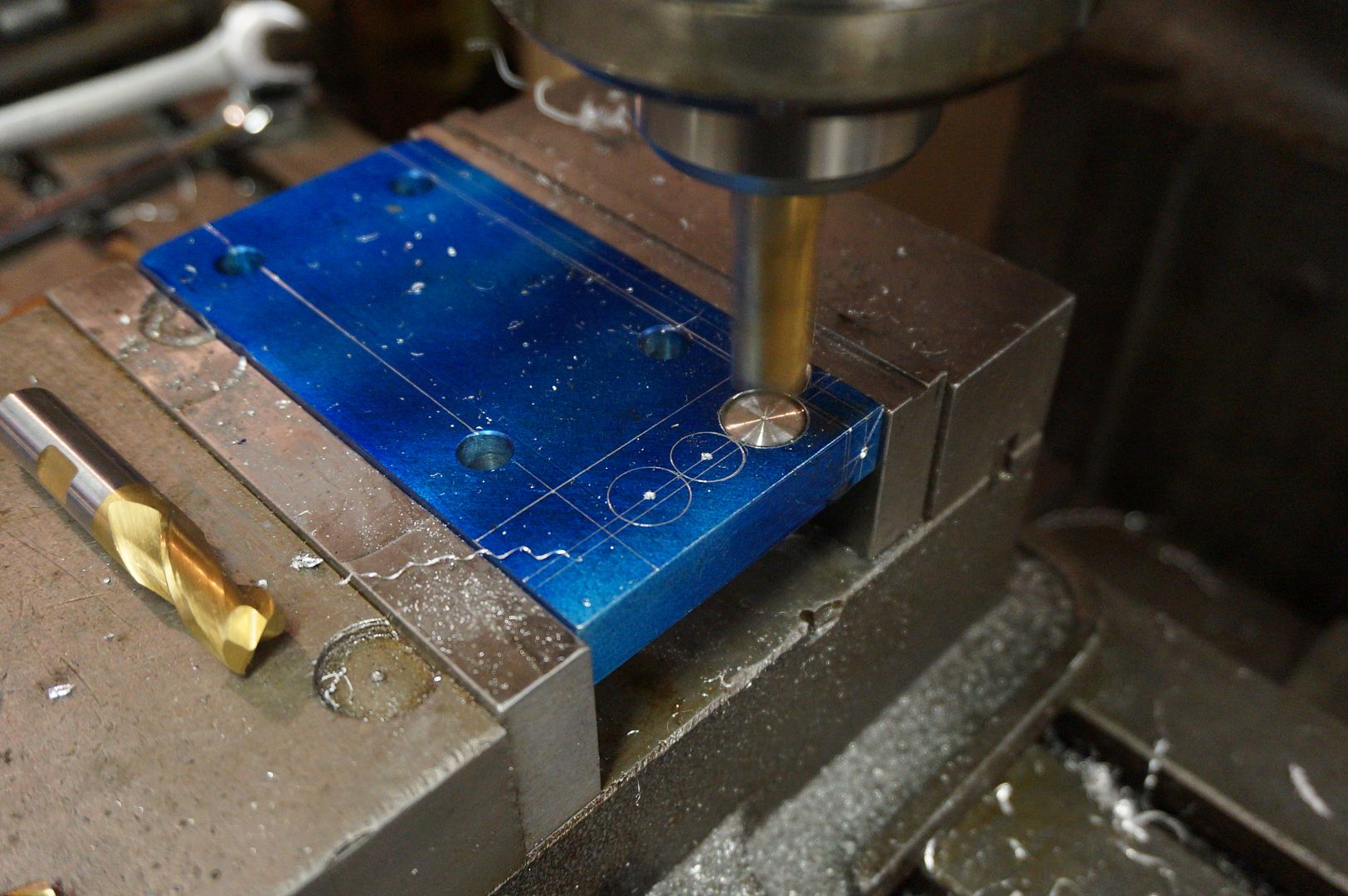

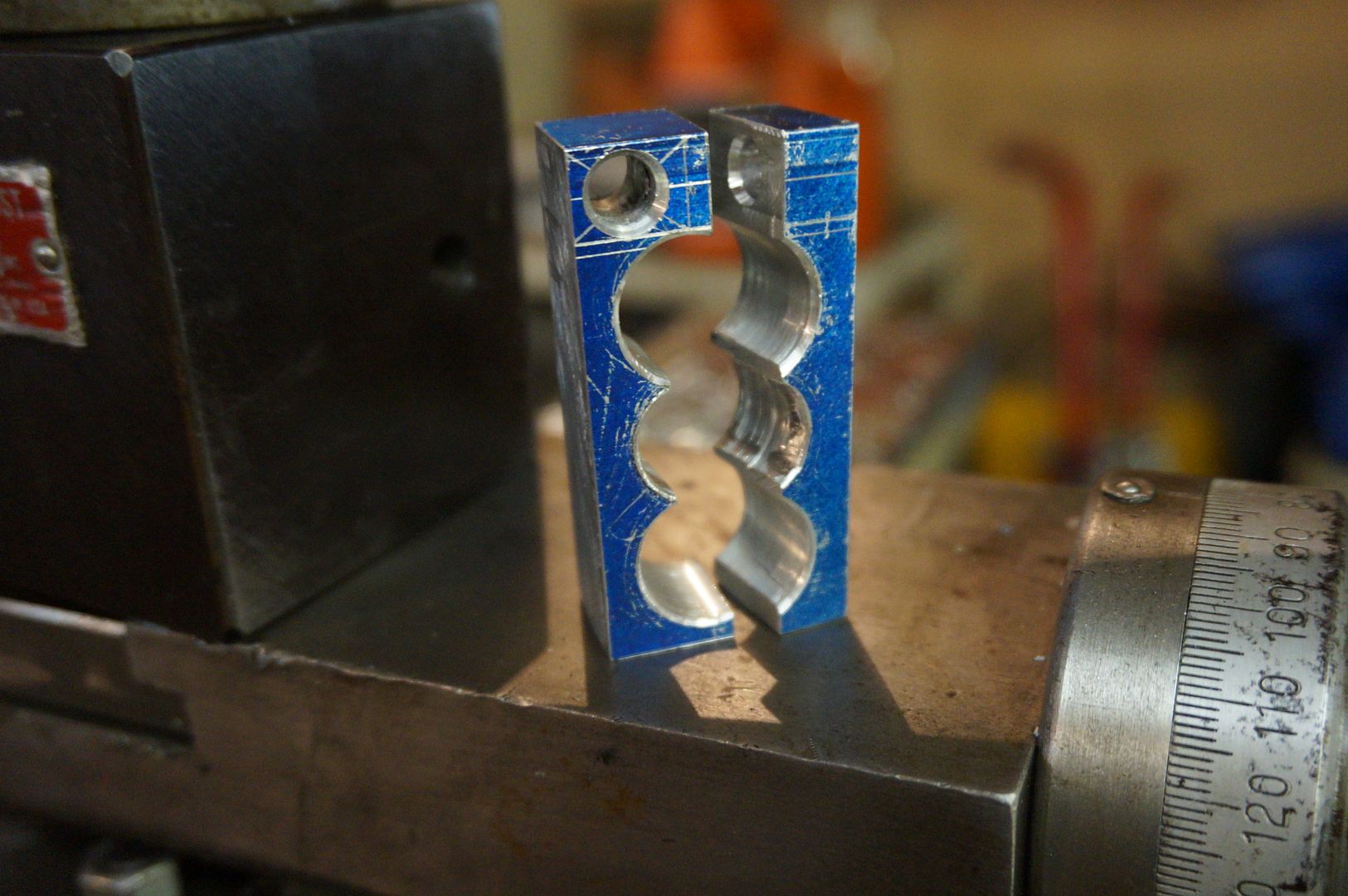

Machining a hole and facing the hole for the plug anchor

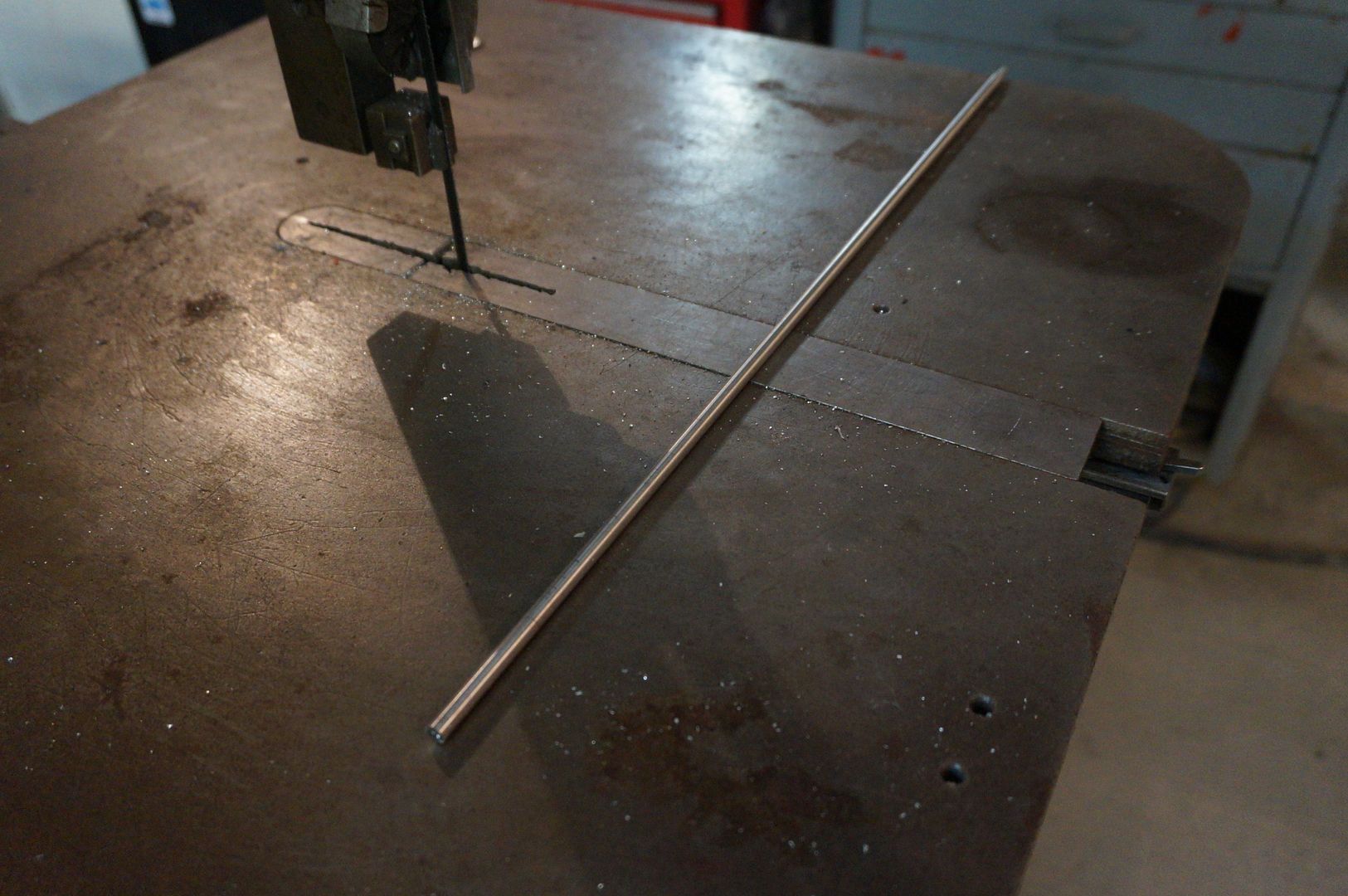

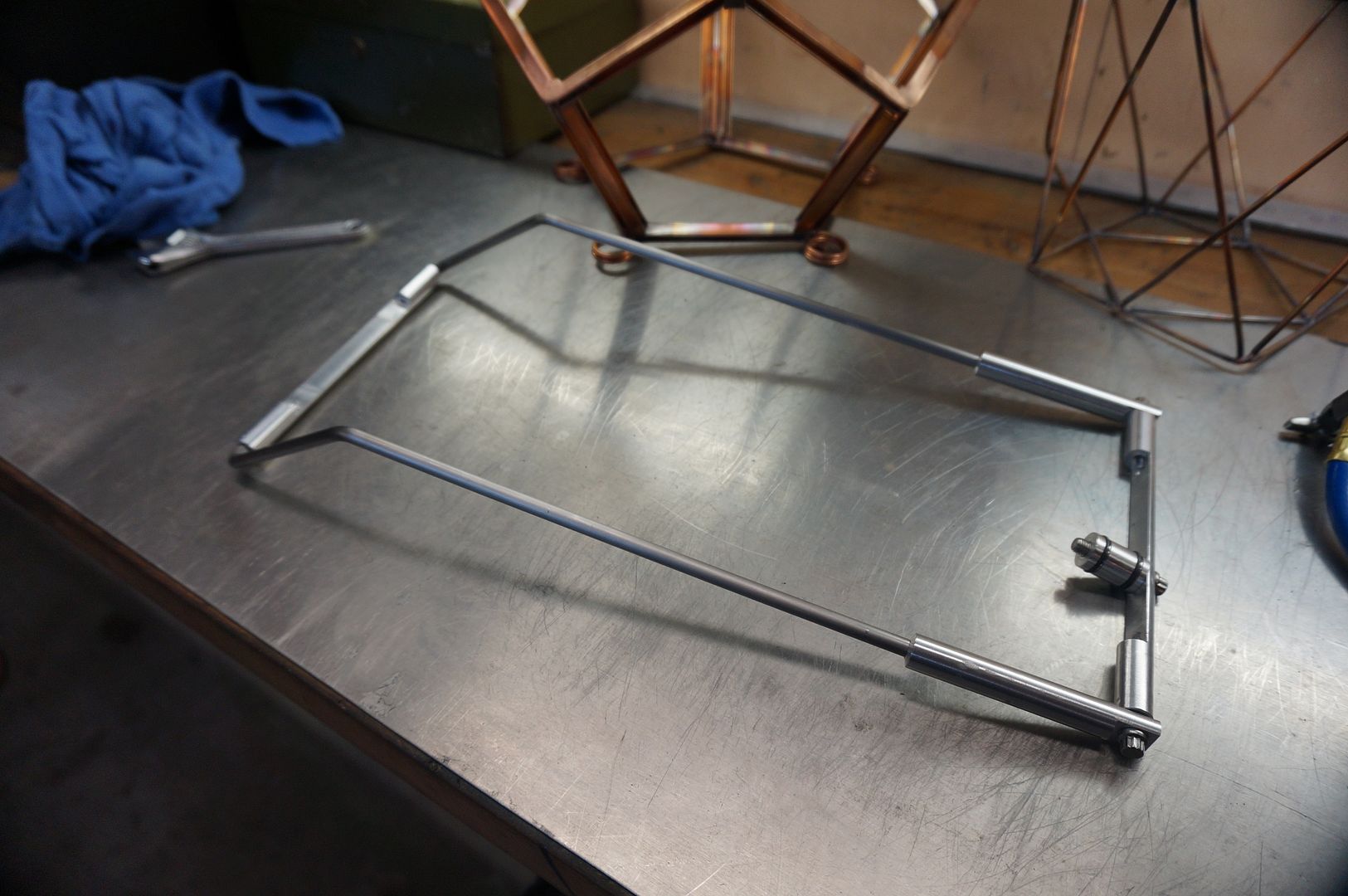

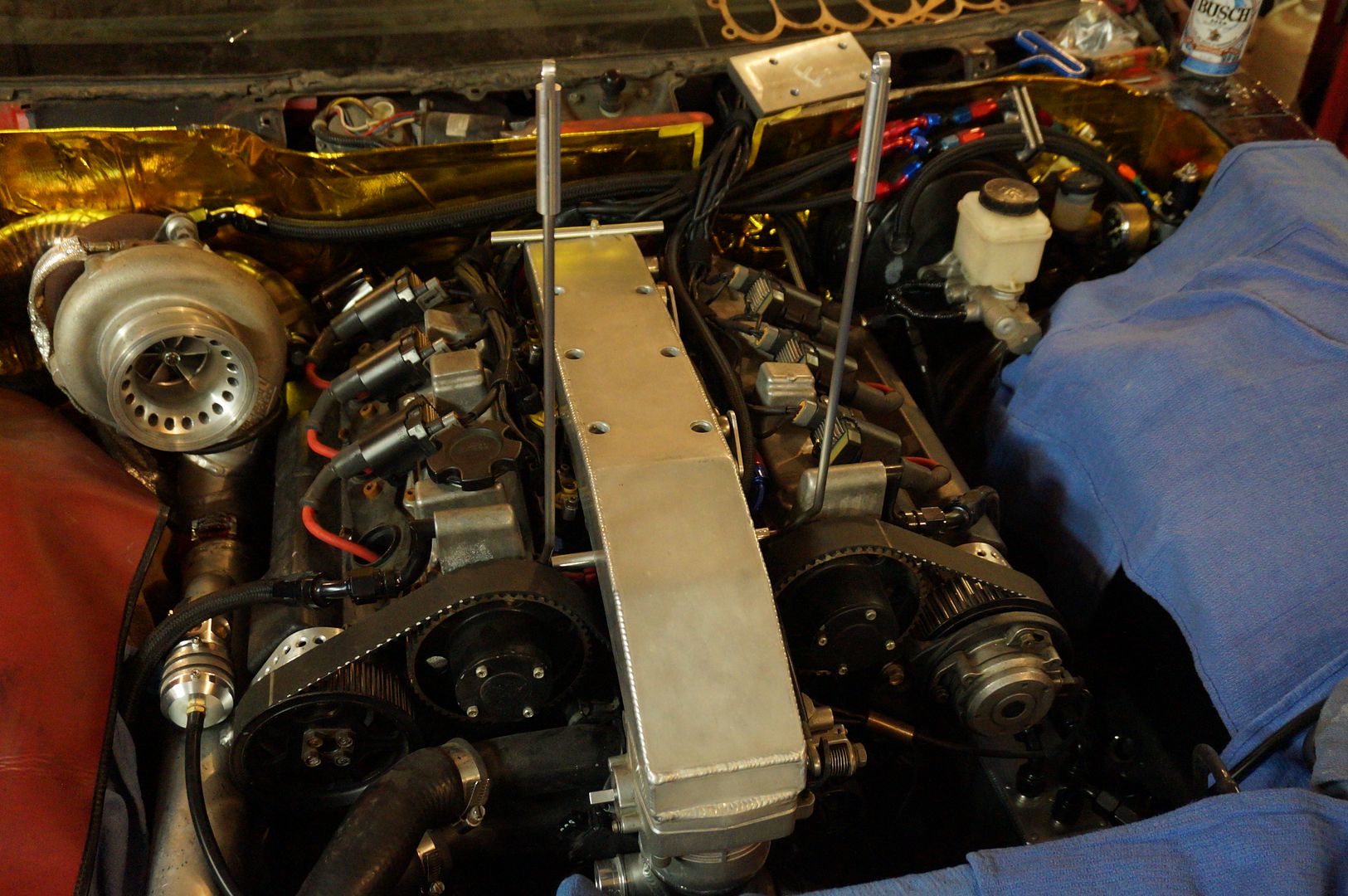

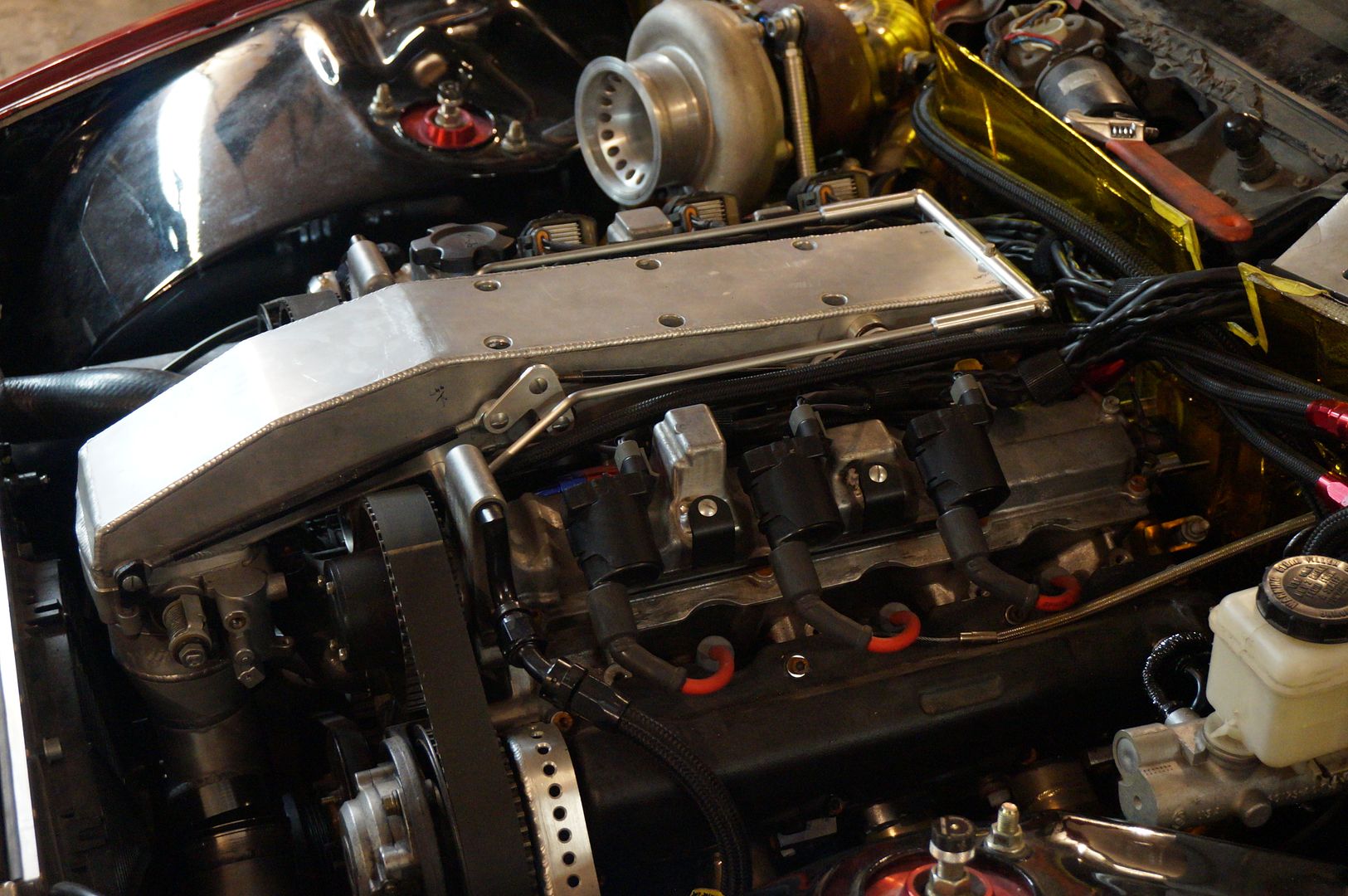

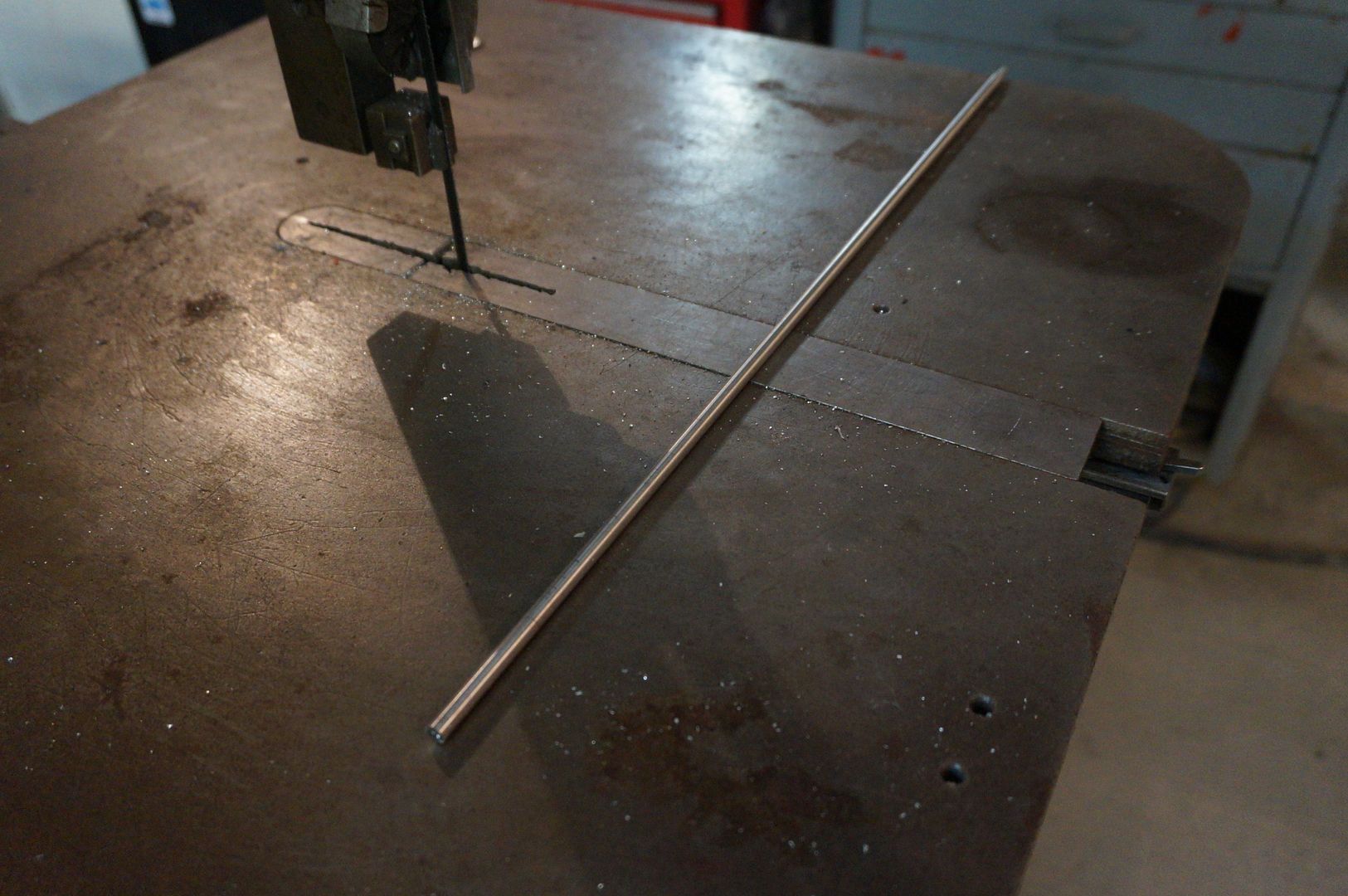

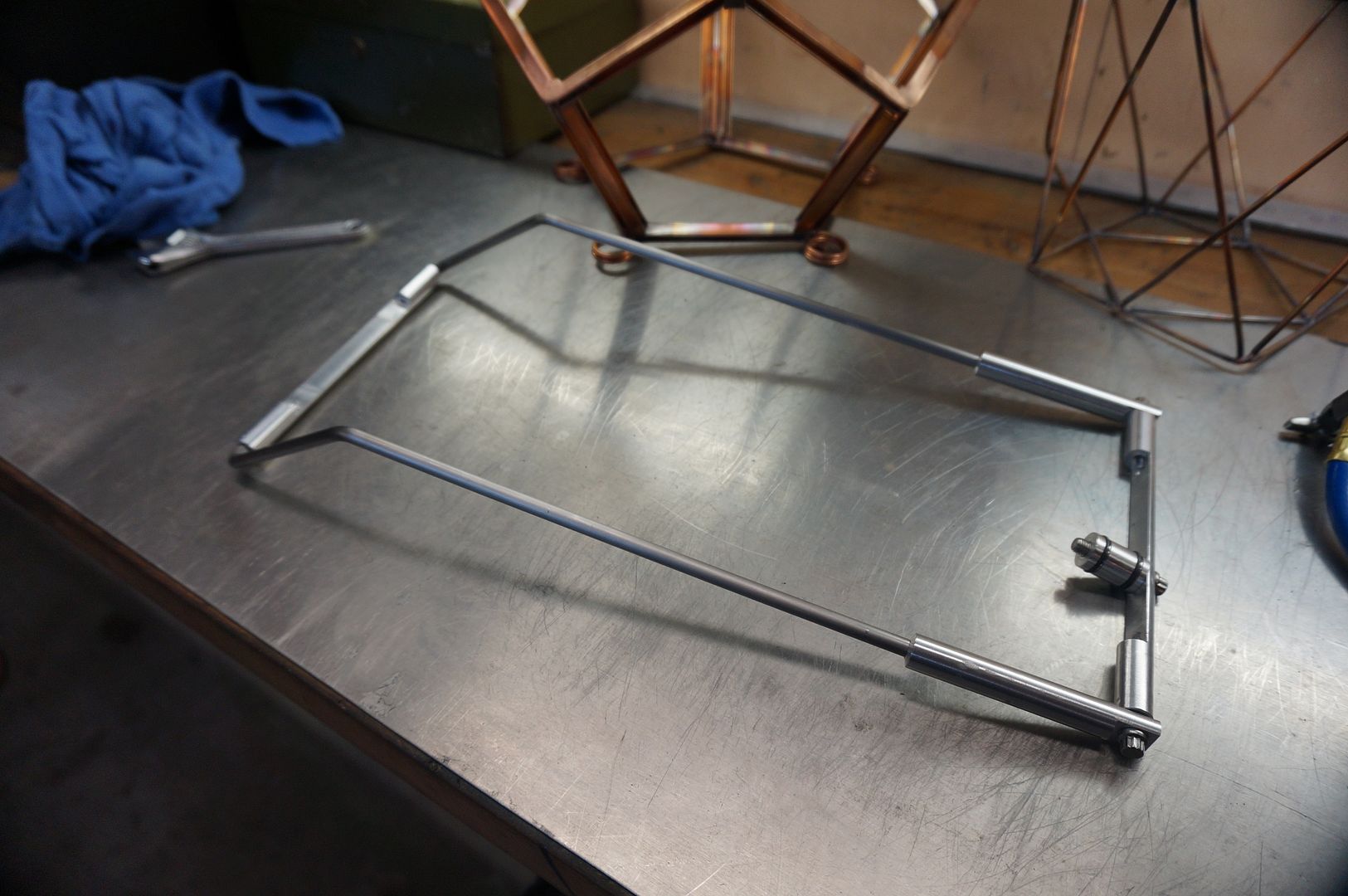

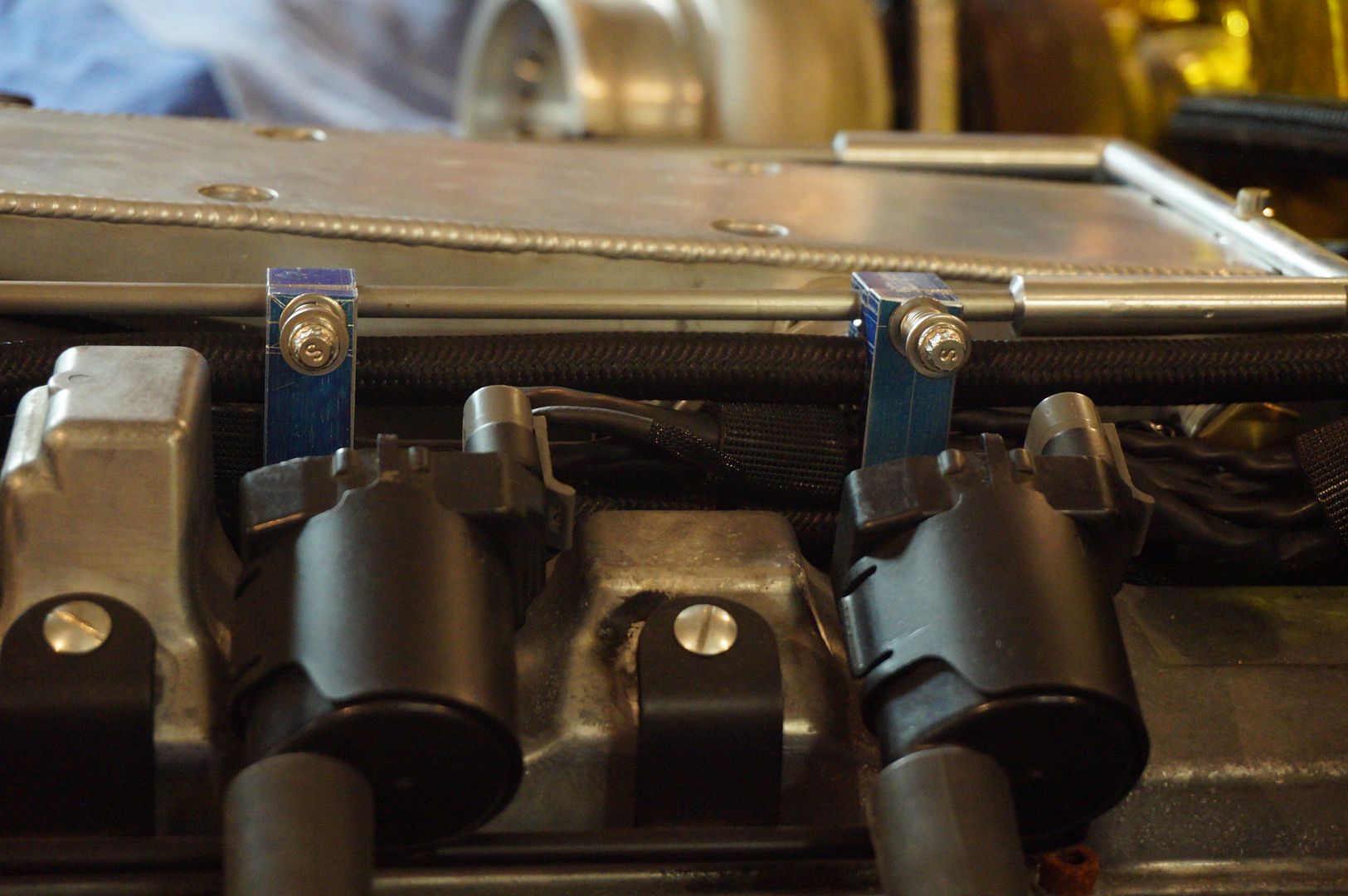

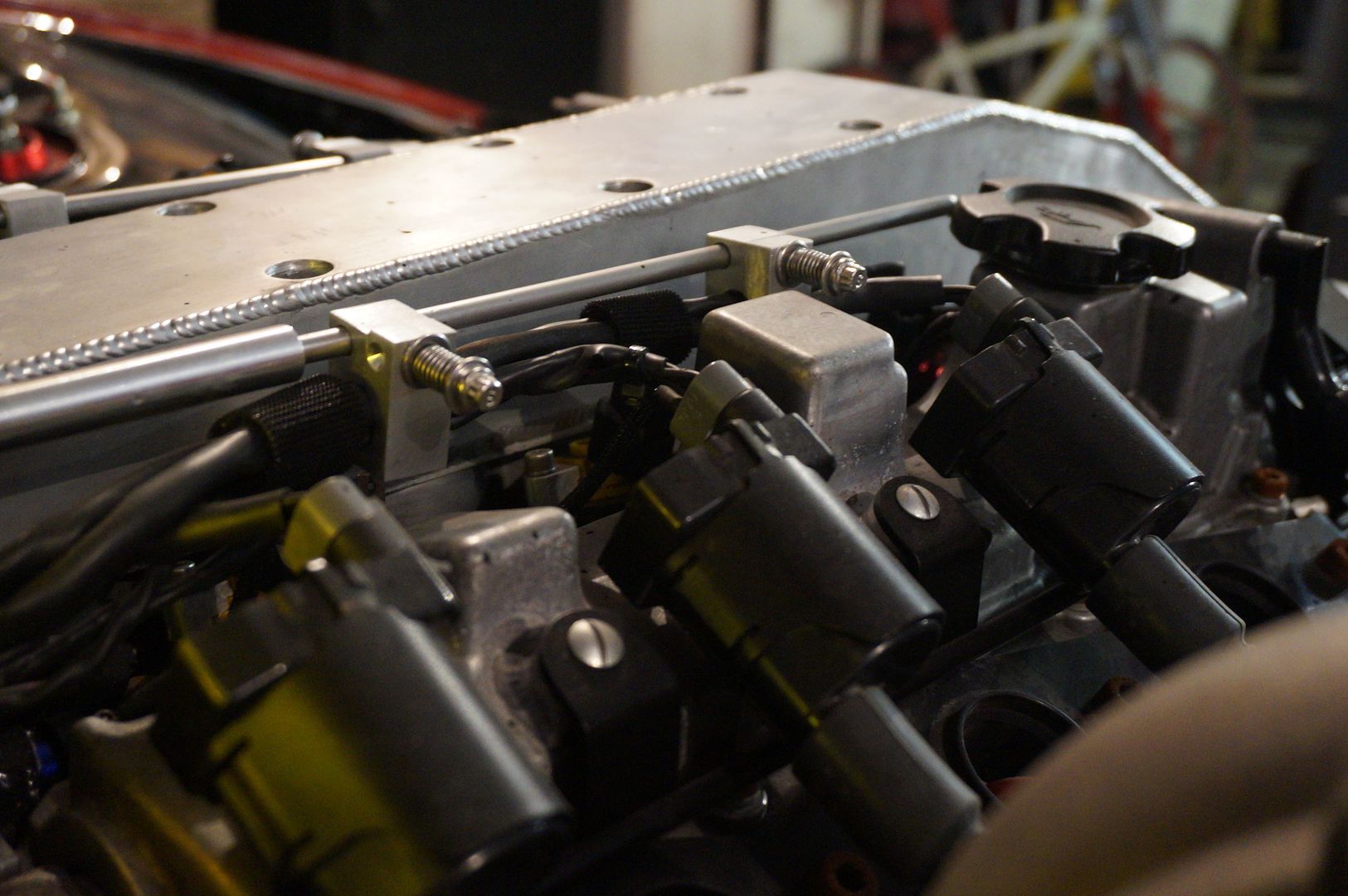

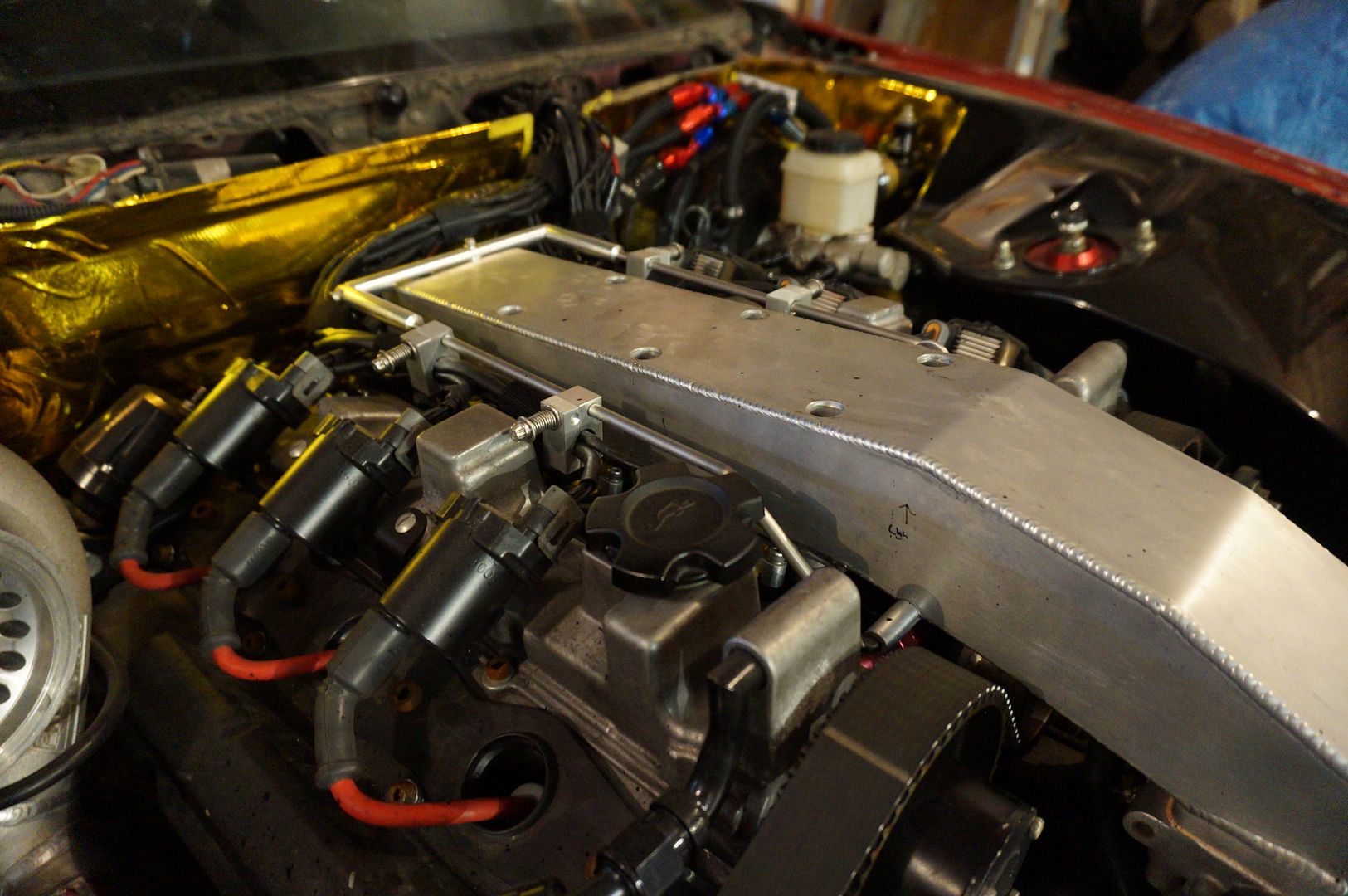

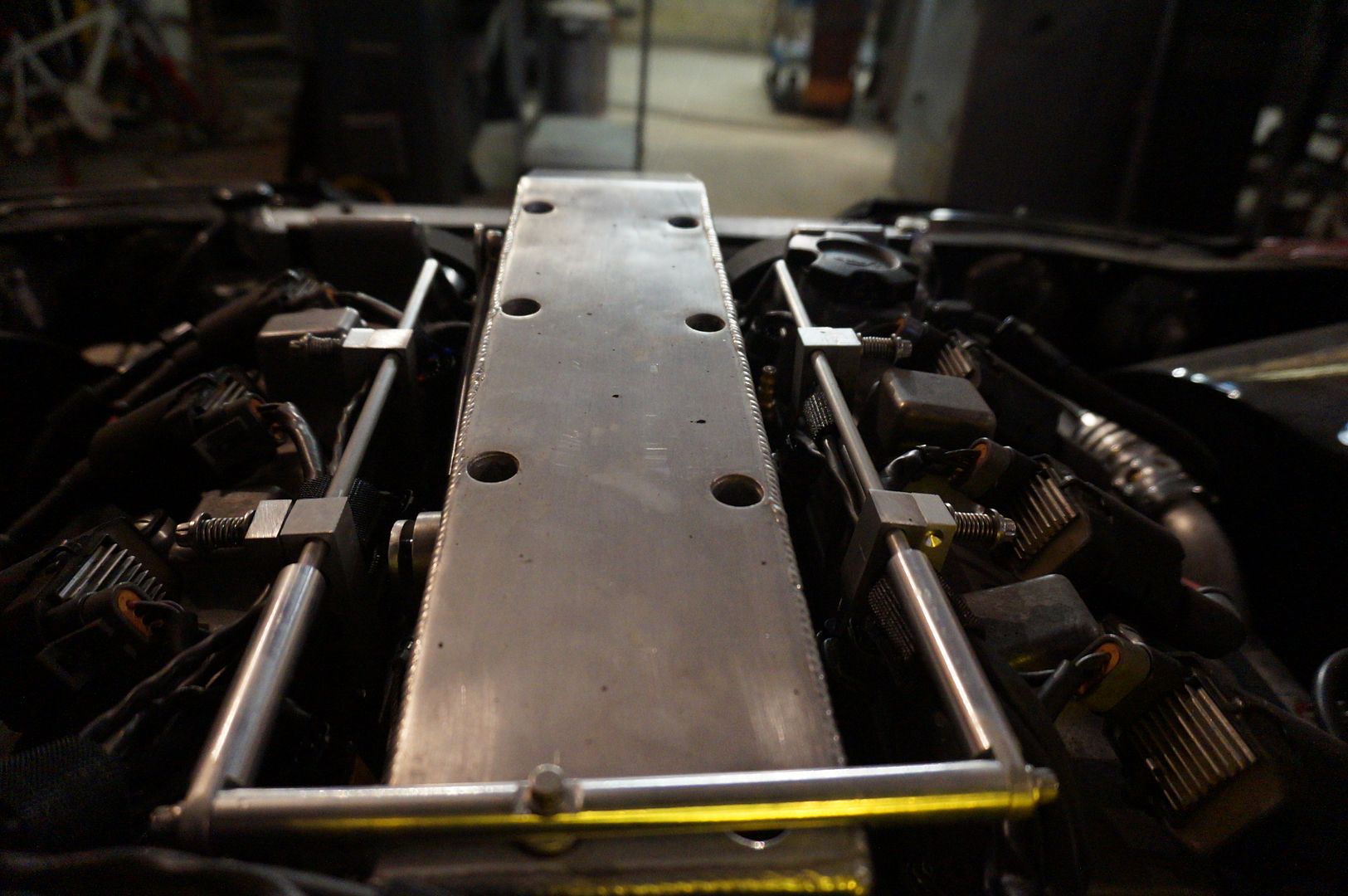

Bent 2 of these 1/4" stainless bars for the fuel line/engine harness to mount to

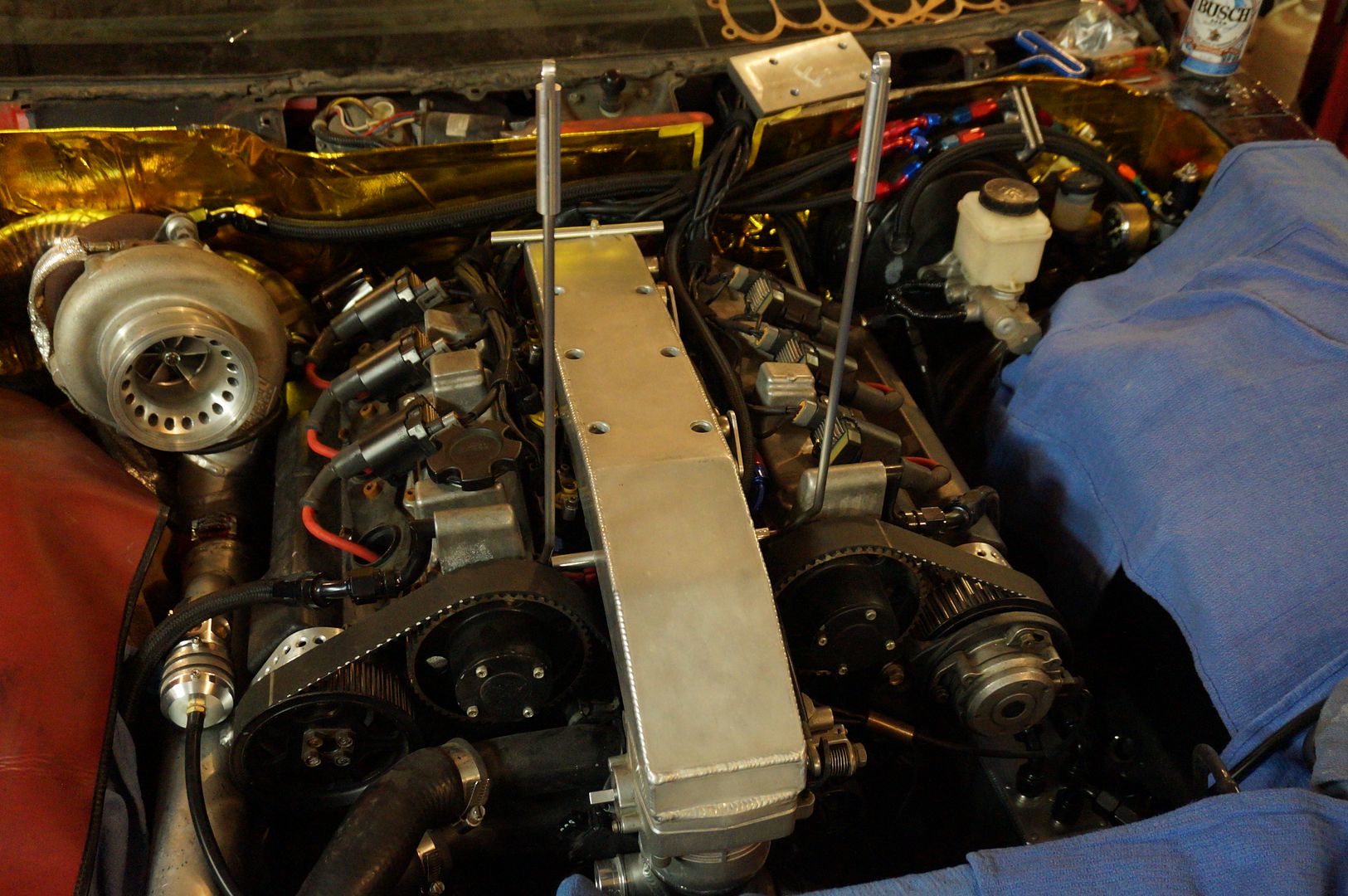

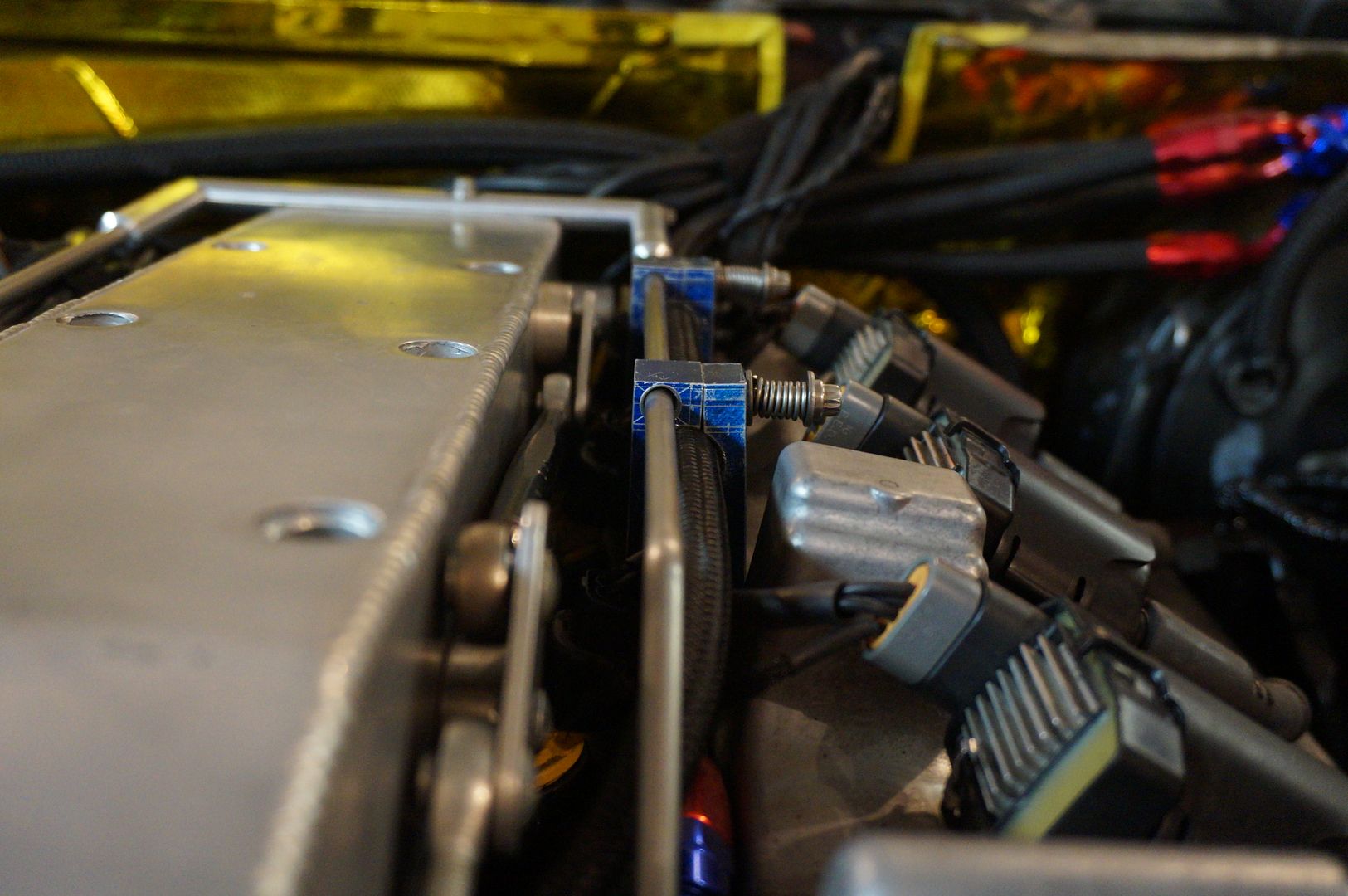

They run the length of the plenum

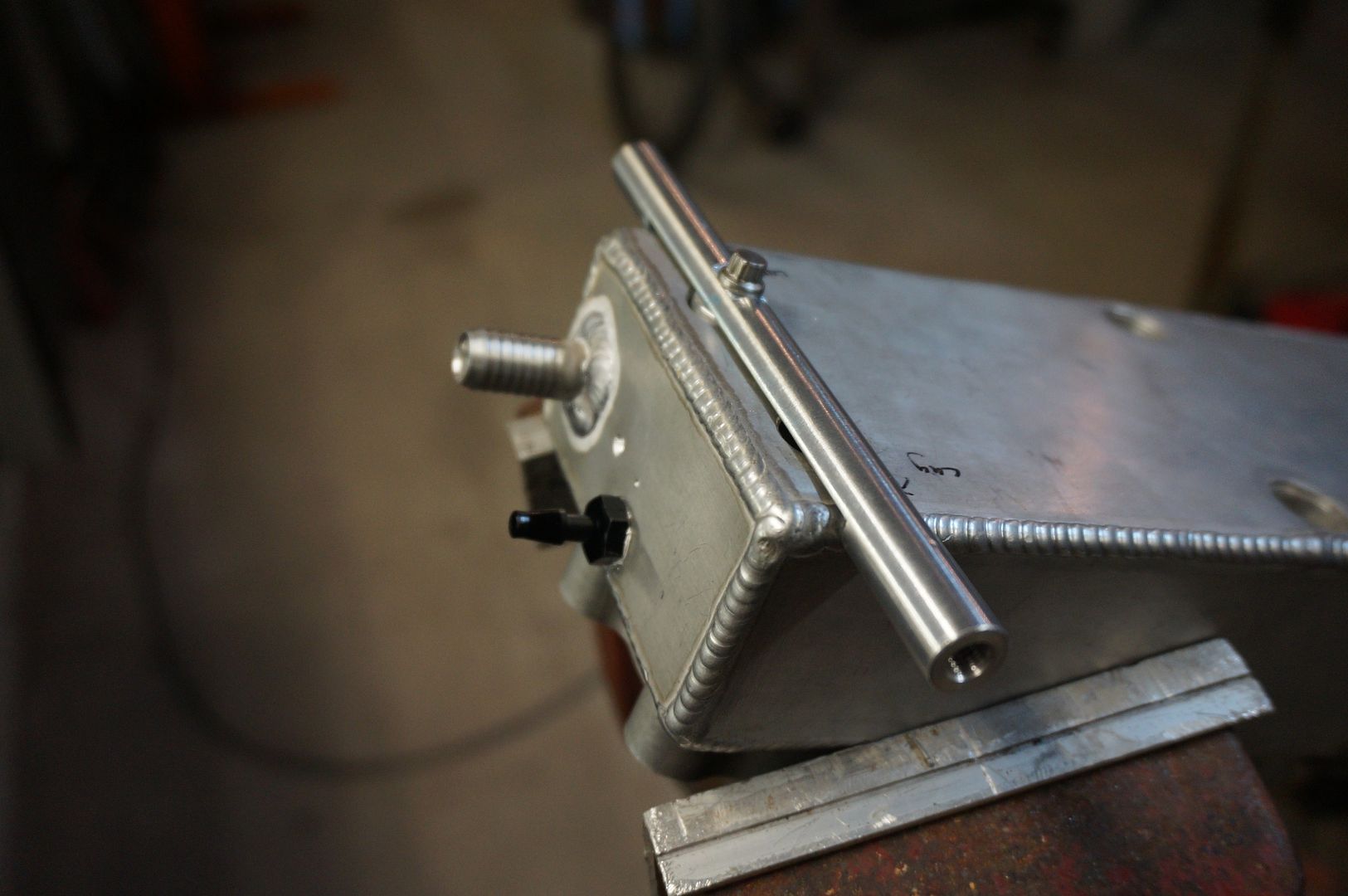

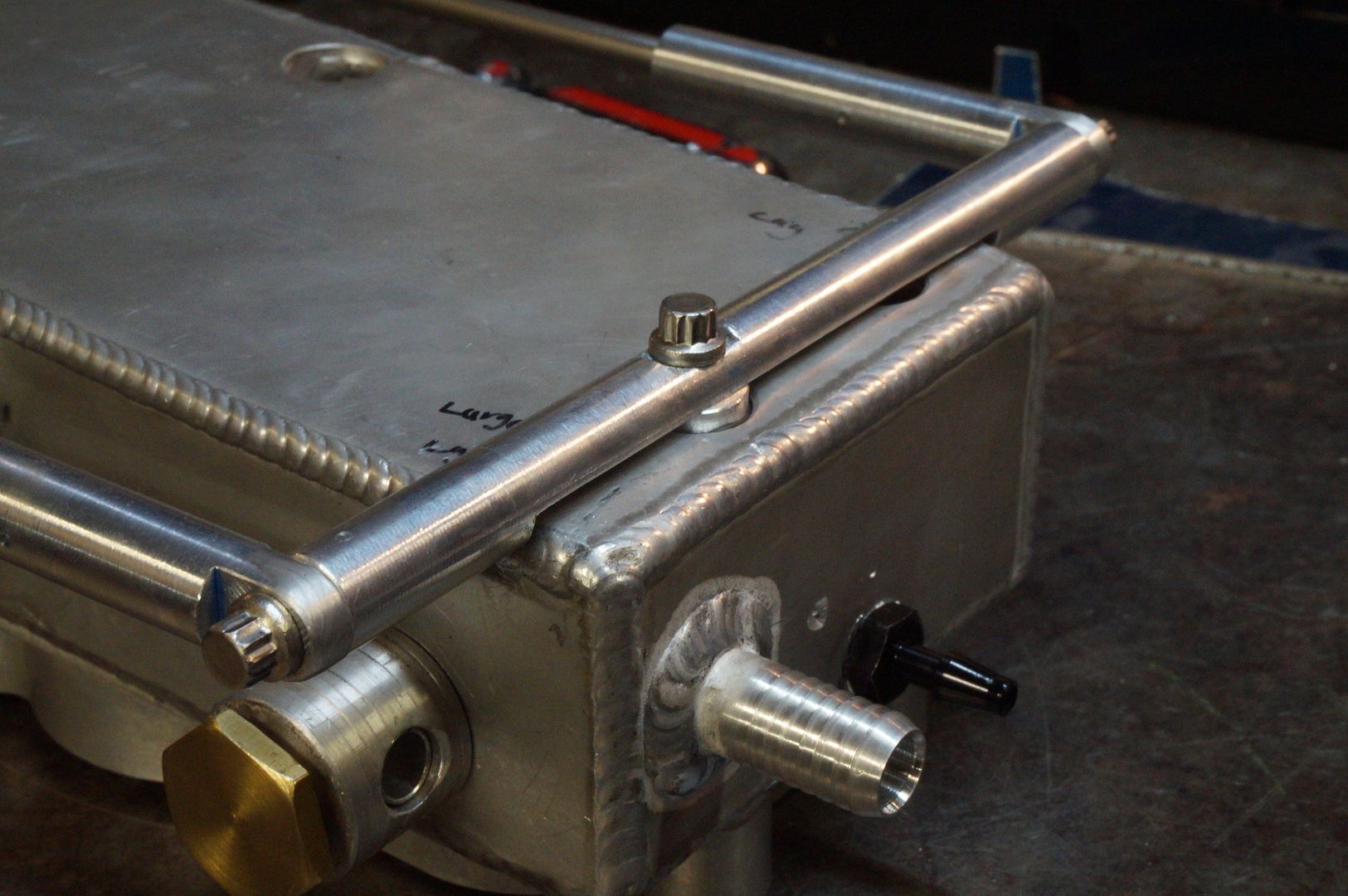

Threading the ends of both stainless rods

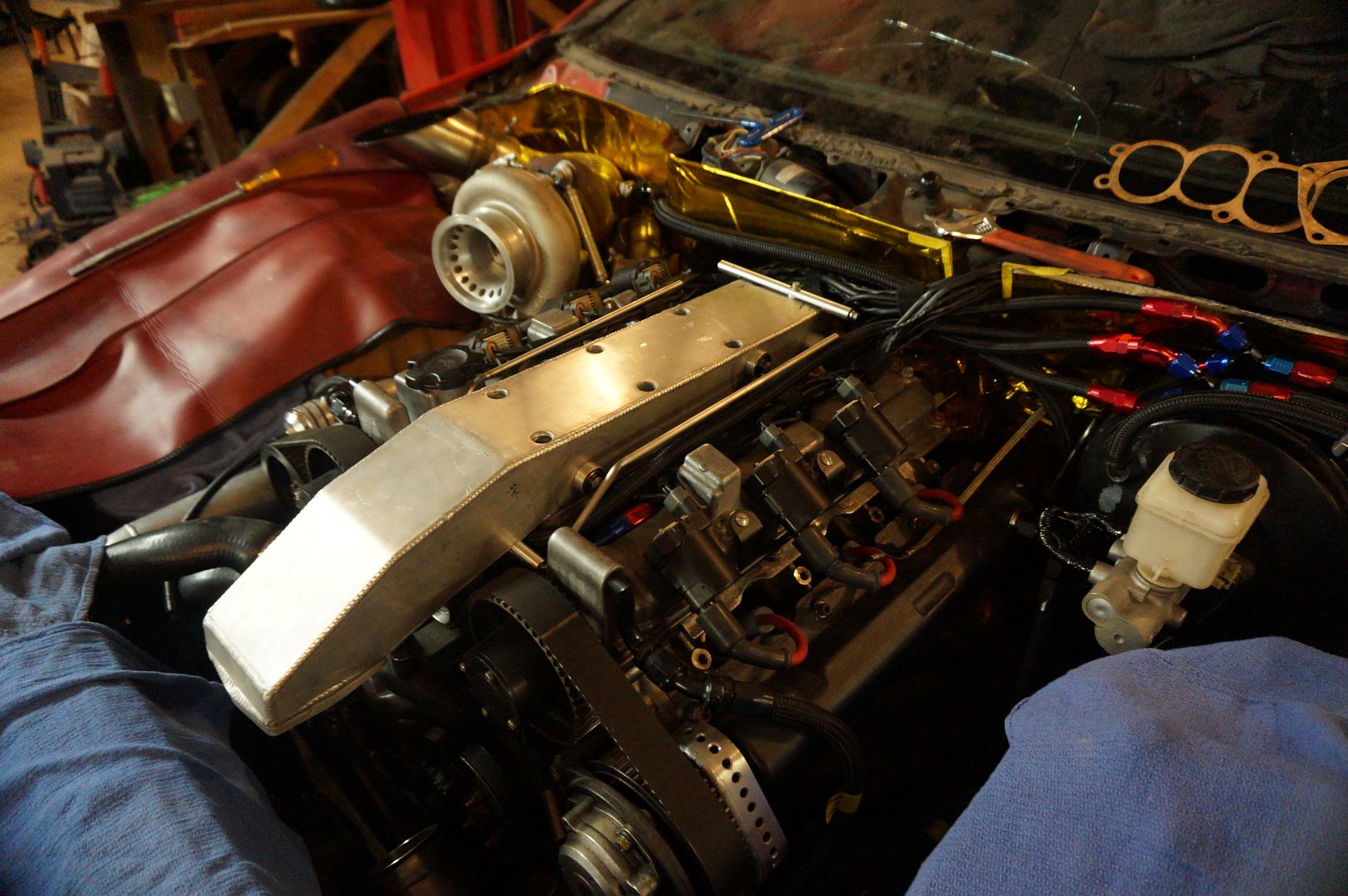

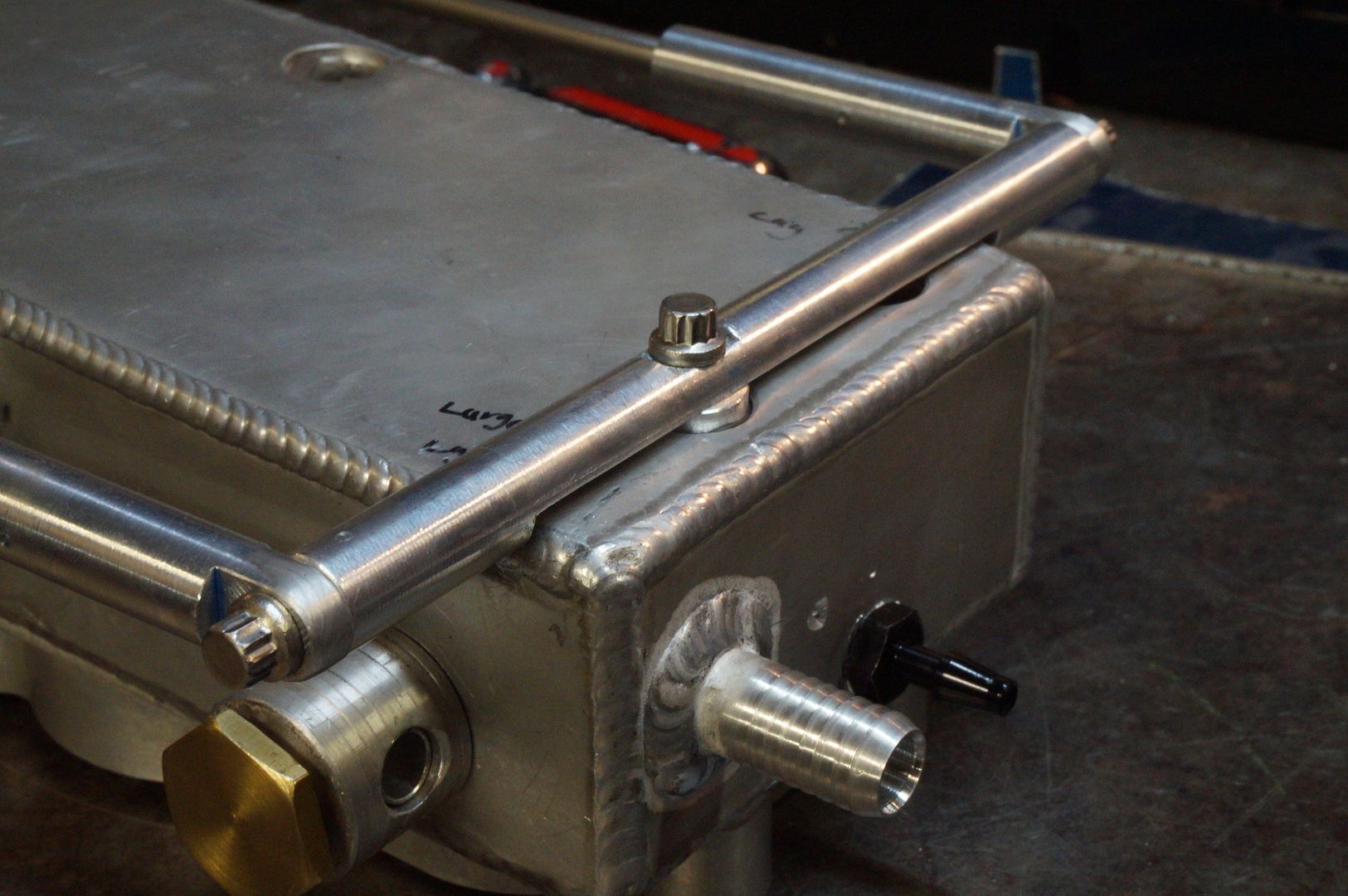

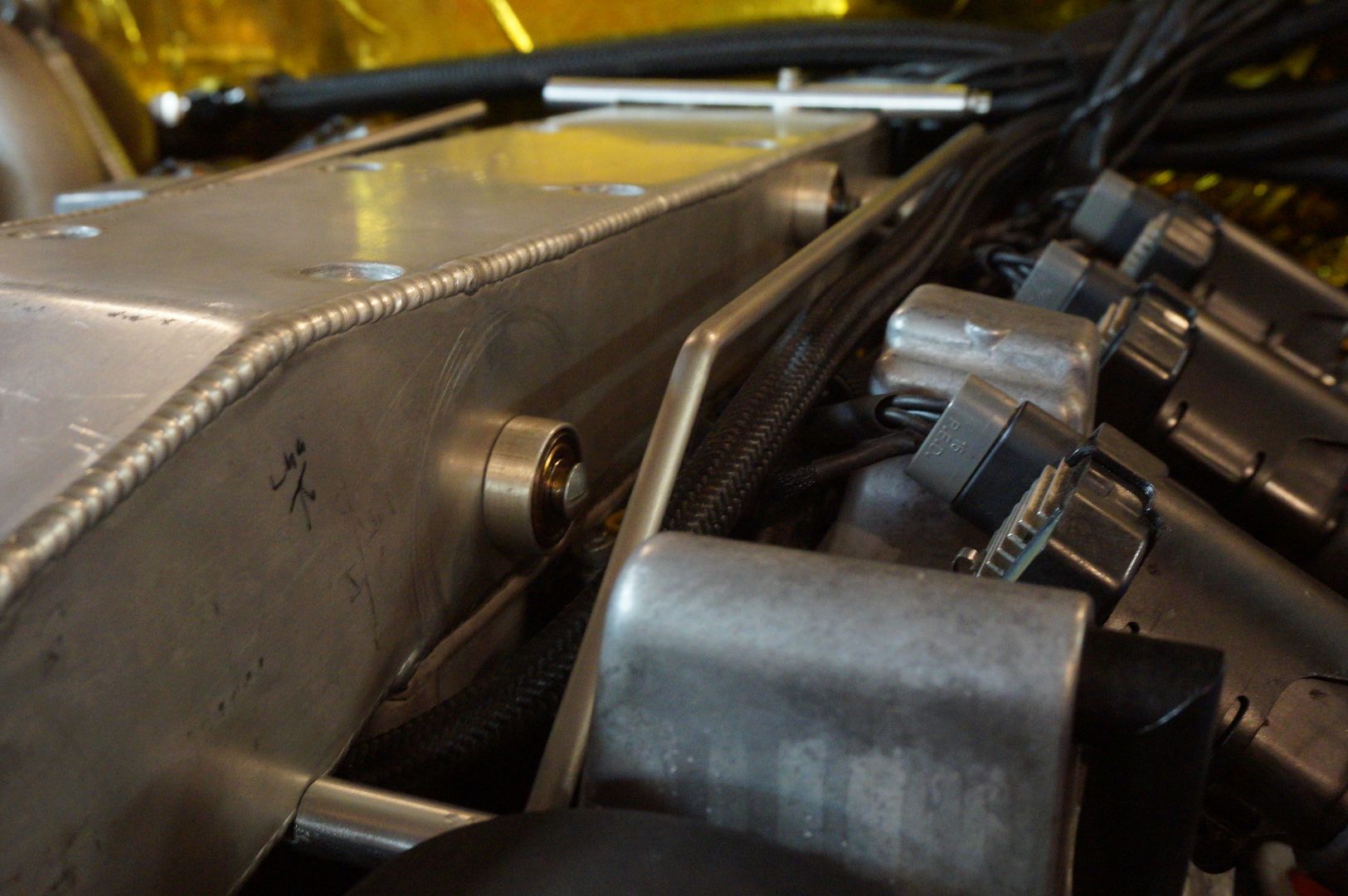

Aluminum sleeve threads onto the rod end

Faced sleeve and drilled hole for 12 point fastener

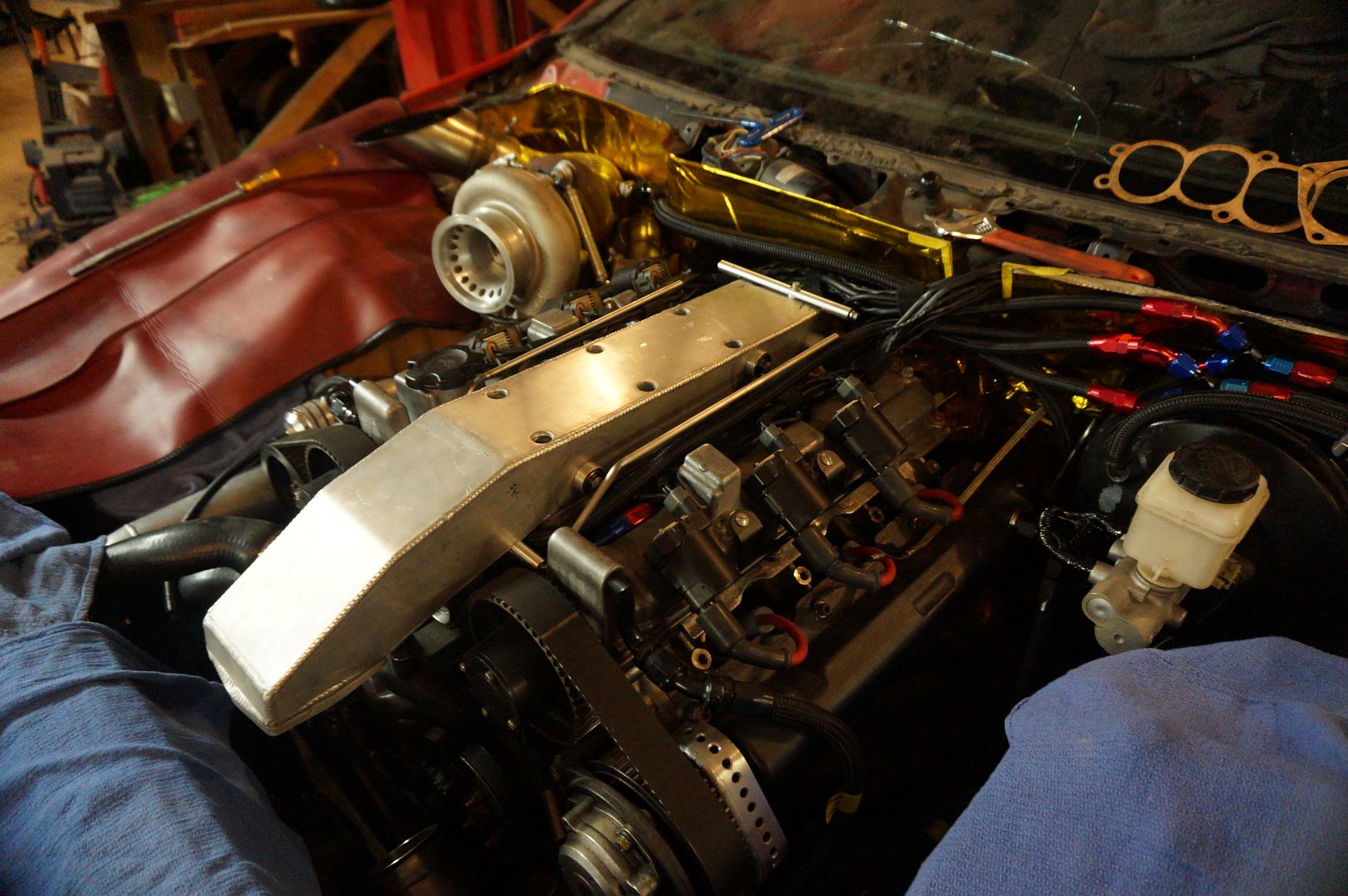

Its like a little exoskeleton

Contoured end for maximum ocd effect

I have incorporated a service mode that will allow ample room and doesn't require any fasteners to be removed just loosened

But ya this is just the build of the main frame that will hold my fuel lines and engine harness, I will continue the actual mounting system in an upcoming update

Finally painted the headlight housings Black!!

Had a few completely valid comments on the headlights looking better black, I can assure you I didn't like them as well so I buckled down and went through the joy of separating the headlight assembly and repainting them, came out nice

Using v blocks to machine a face on the aluminum bar

V blocks are almost a necessity when milling round materials

I made 2 of these, this one will be welded to the underside of the plenum eventually

This is the second one

Made a plug anchor

Plug anchor is inserted into plenum bolt holes

Machining a hole and facing the hole for the plug anchor

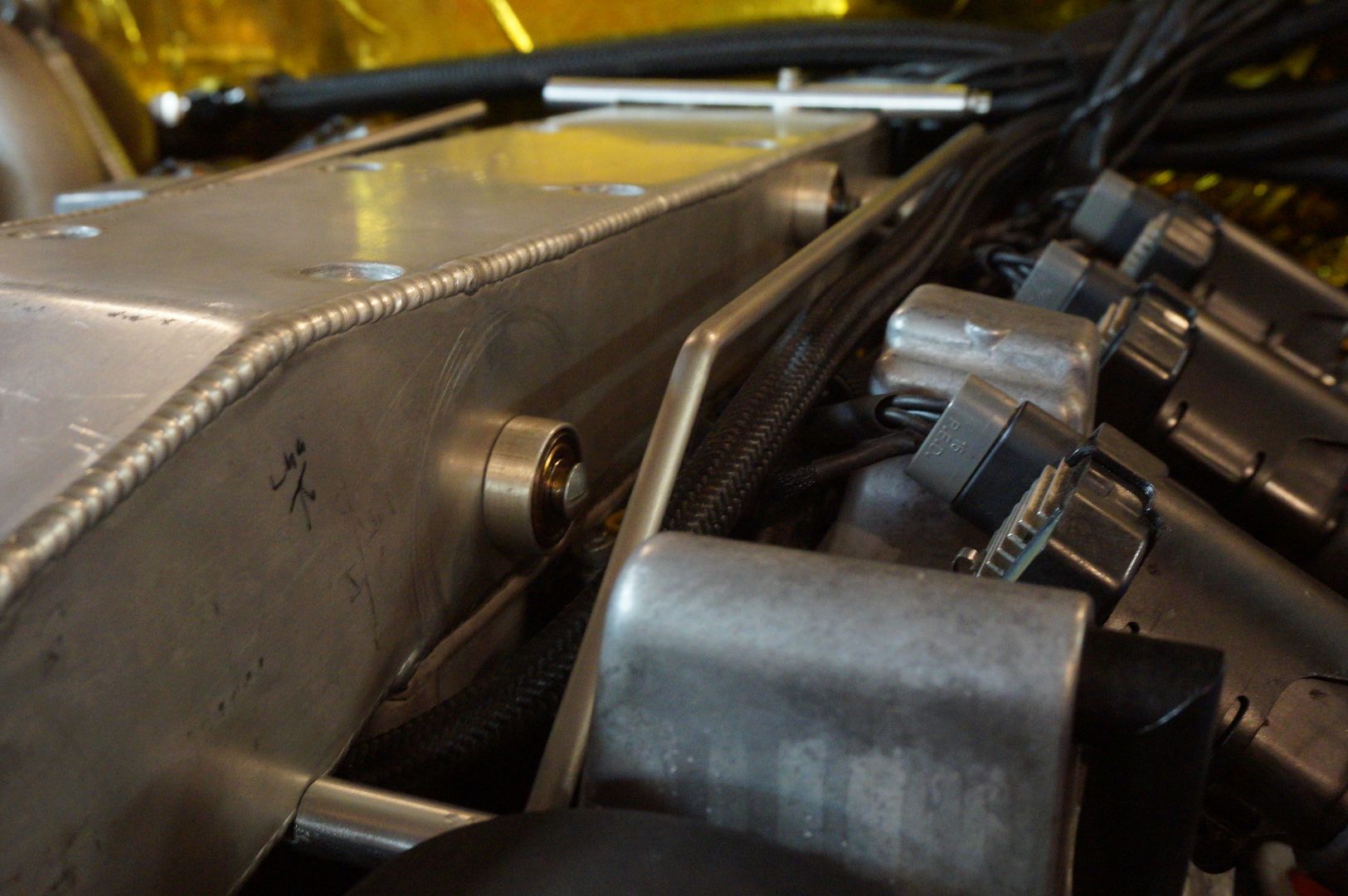

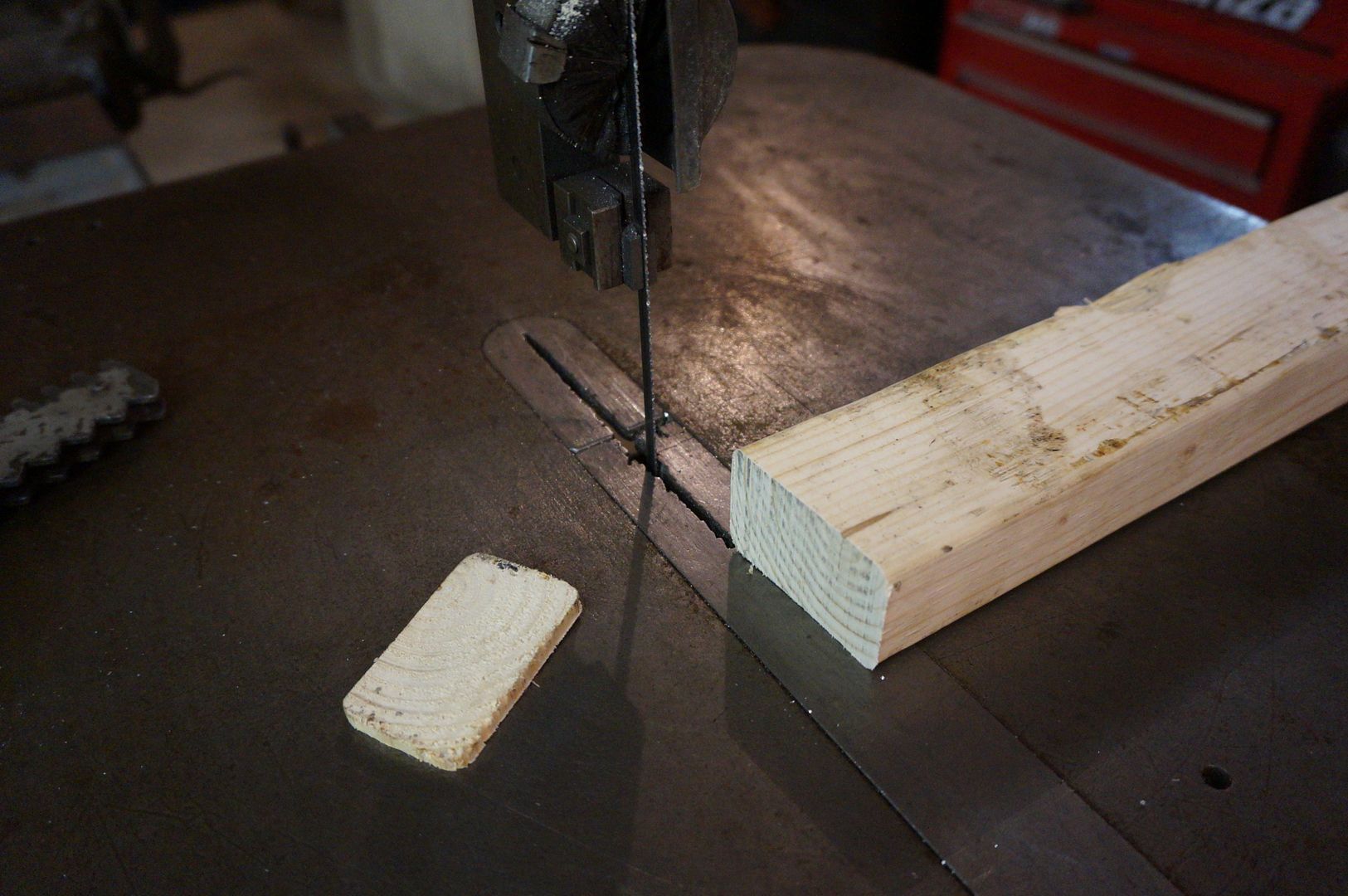

Bent 2 of these 1/4" stainless bars for the fuel line/engine harness to mount to

They run the length of the plenum

Threading the ends of both stainless rods

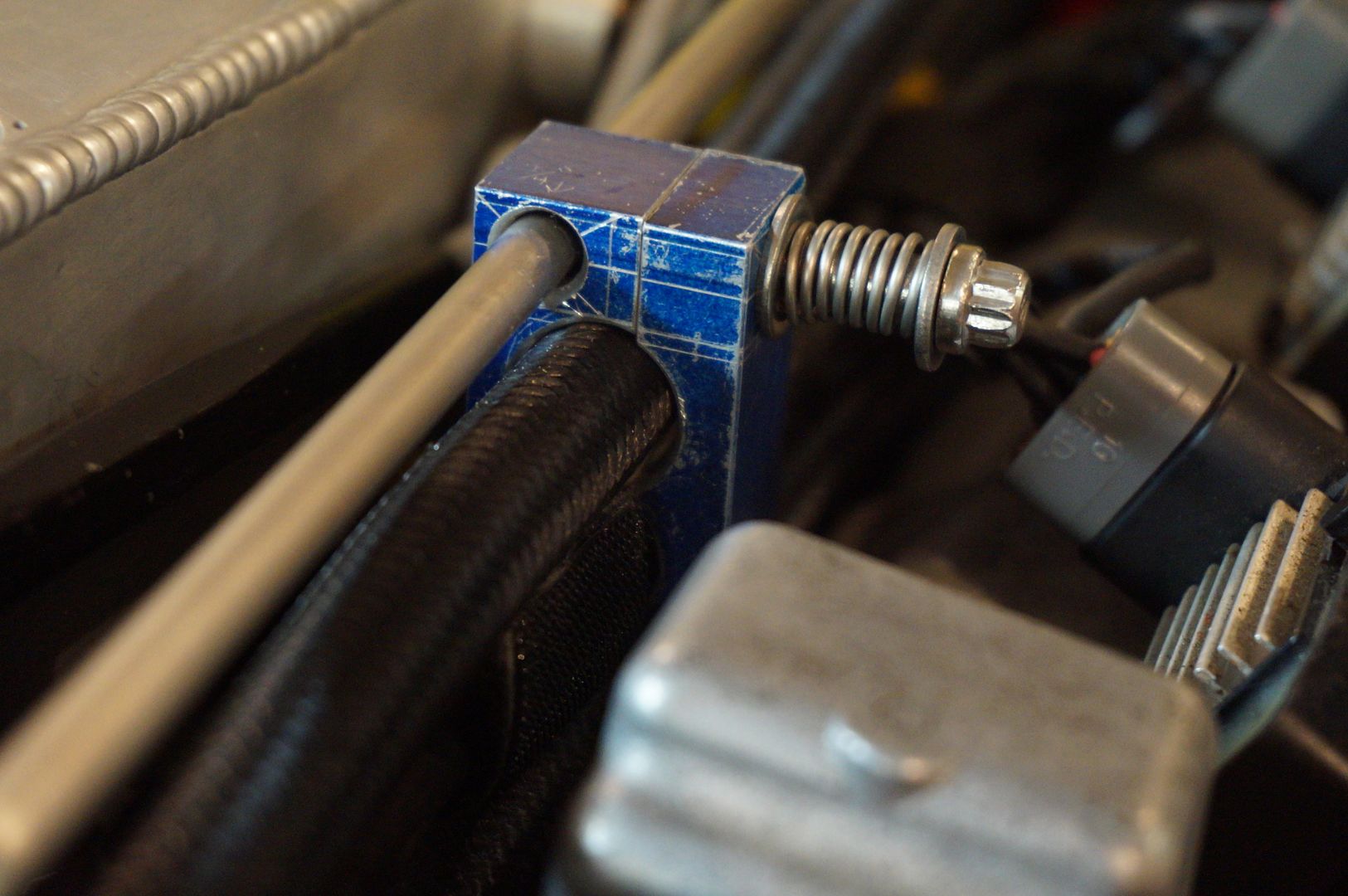

Aluminum sleeve threads onto the rod end

Faced sleeve and drilled hole for 12 point fastener

Its like a little exoskeleton

Contoured end for maximum ocd effect

I have incorporated a service mode that will allow ample room and doesn't require any fasteners to be removed just loosened

But ya this is just the build of the main frame that will hold my fuel lines and engine harness, I will continue the actual mounting system in an upcoming update

Finally painted the headlight housings Black!!

Had a few completely valid comments on the headlights looking better black, I can assure you I didn't like them as well so I buckled down and went through the joy of separating the headlight assembly and repainting them, came out nice

Comment