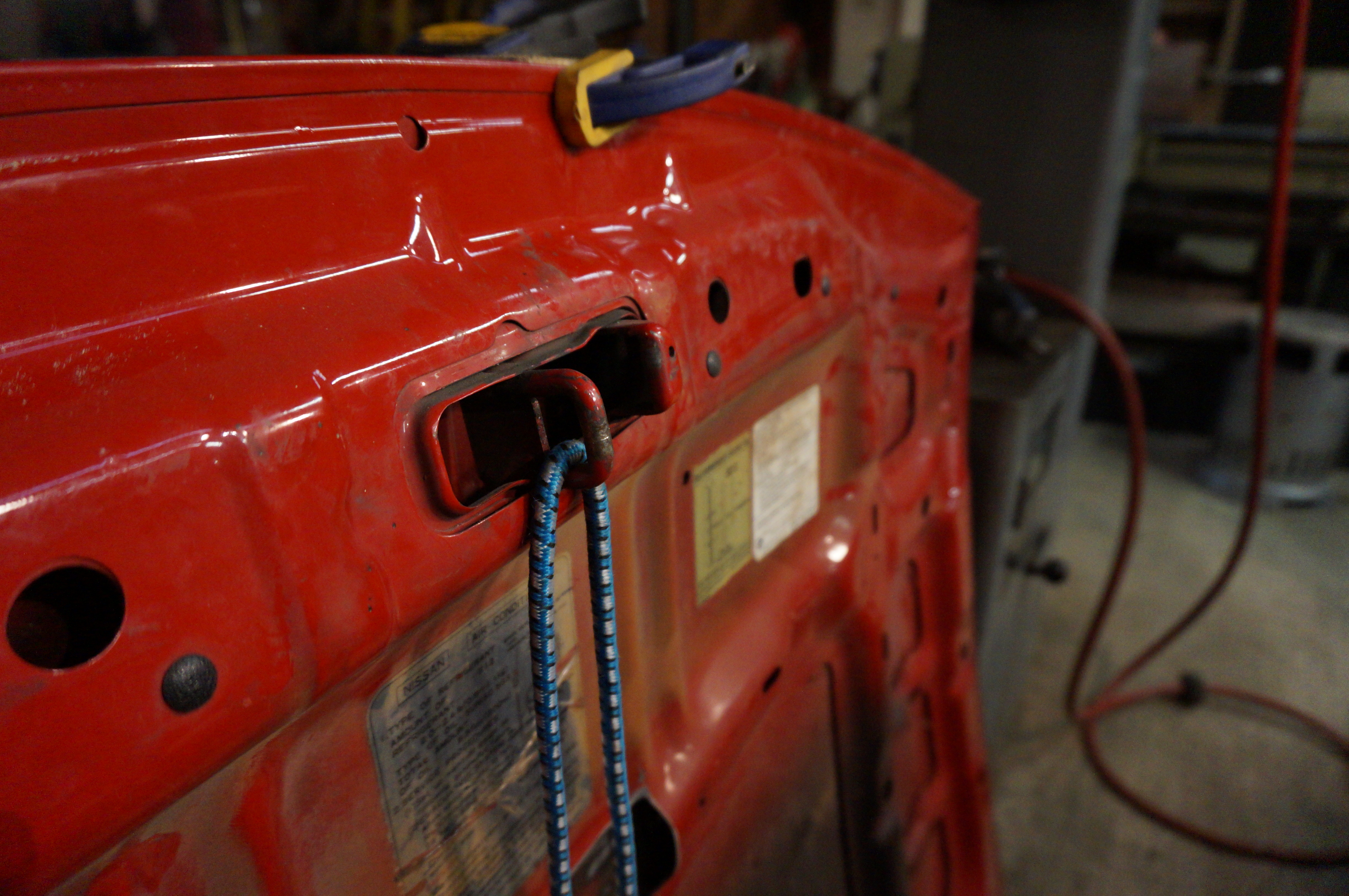

Currently ditching the factory hood release

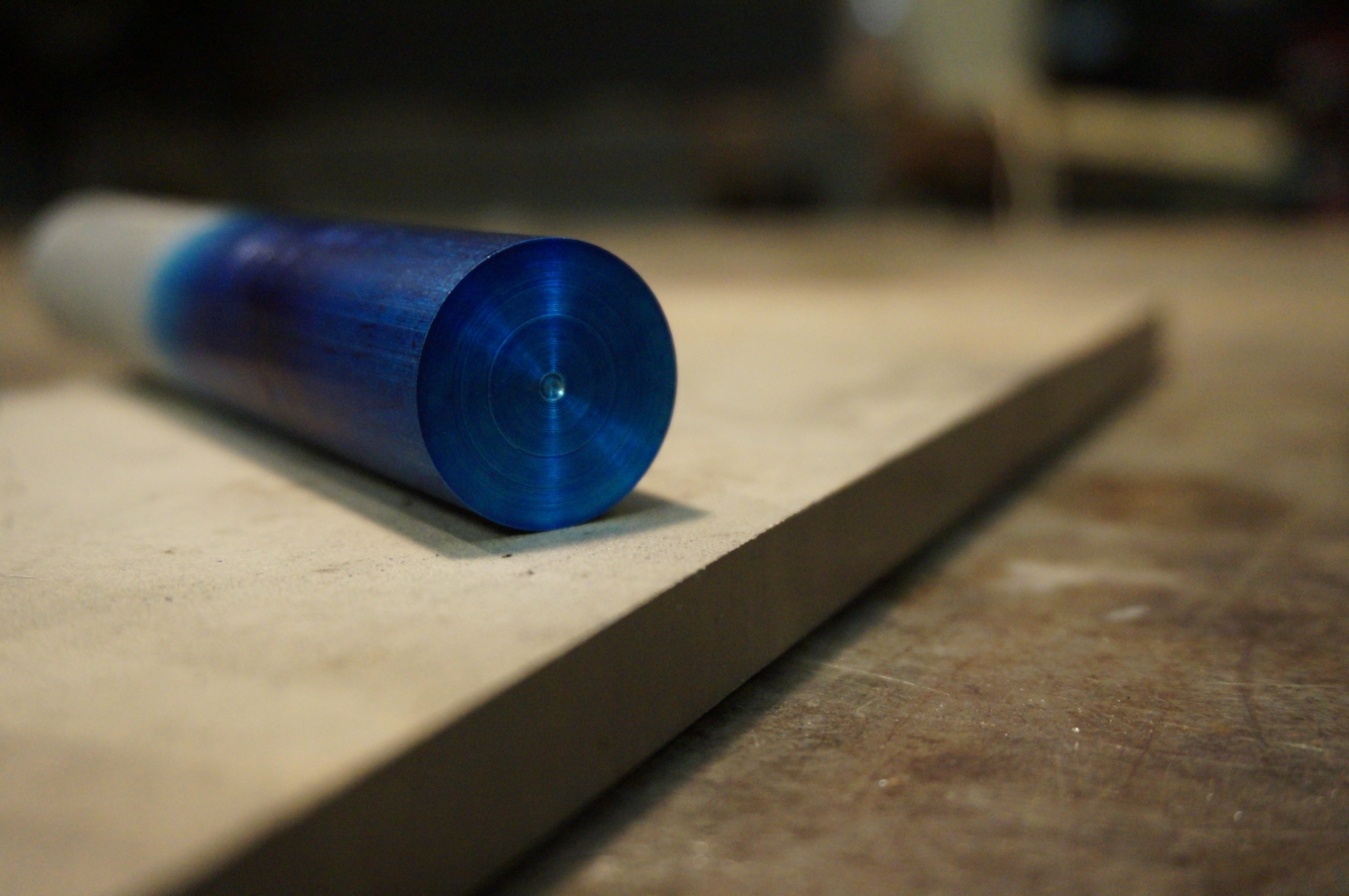

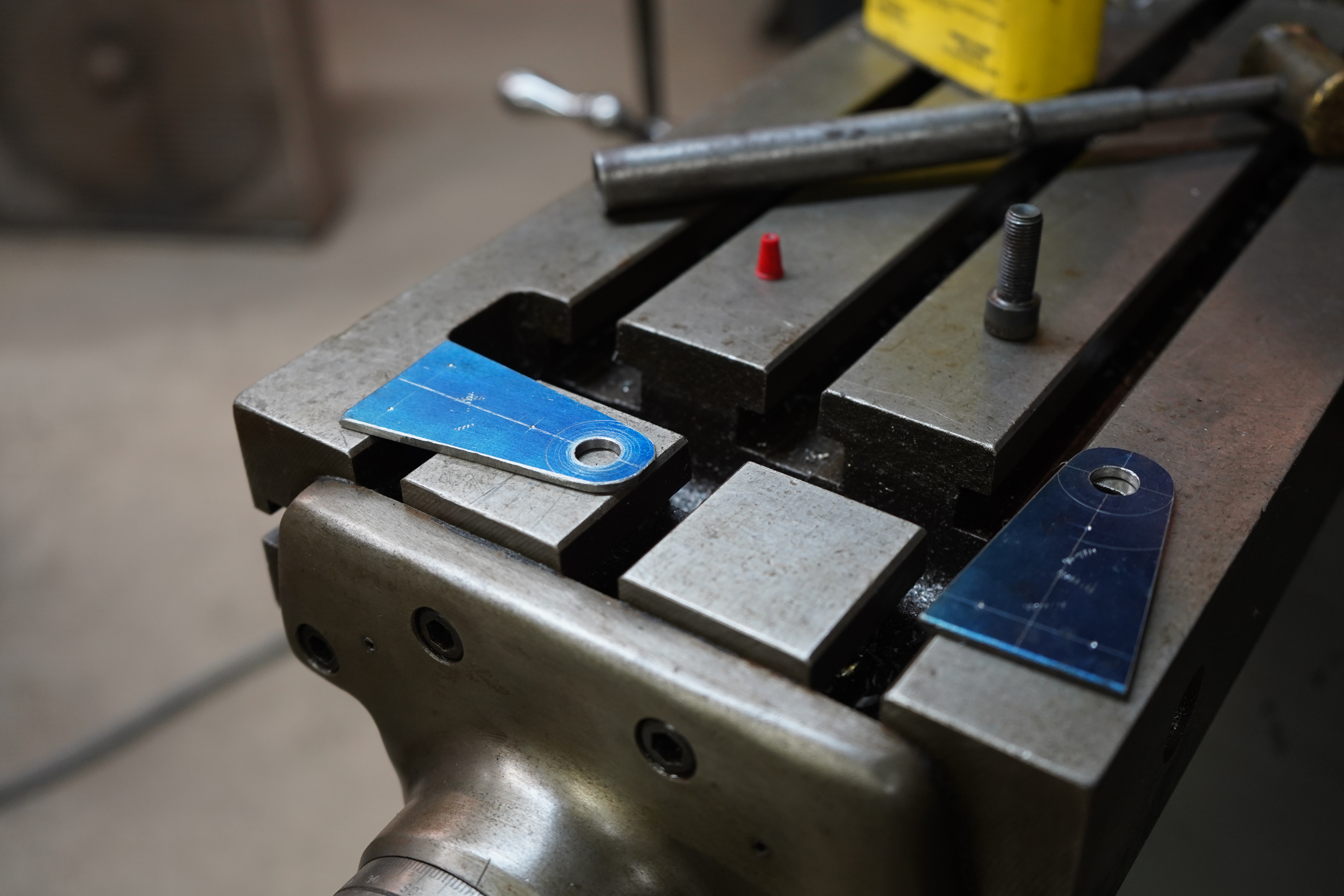

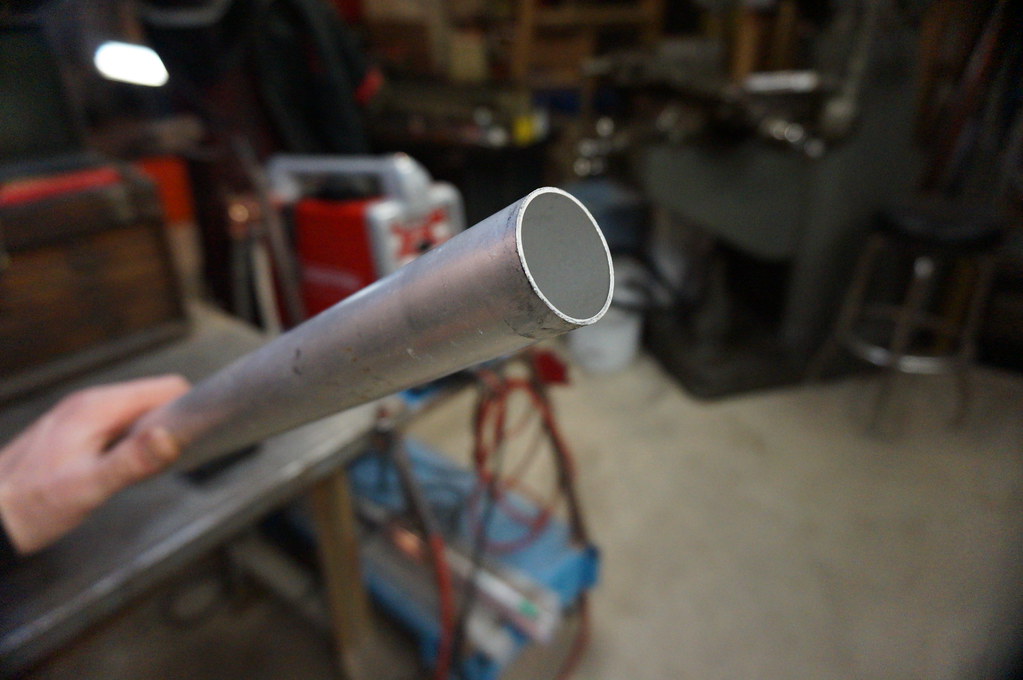

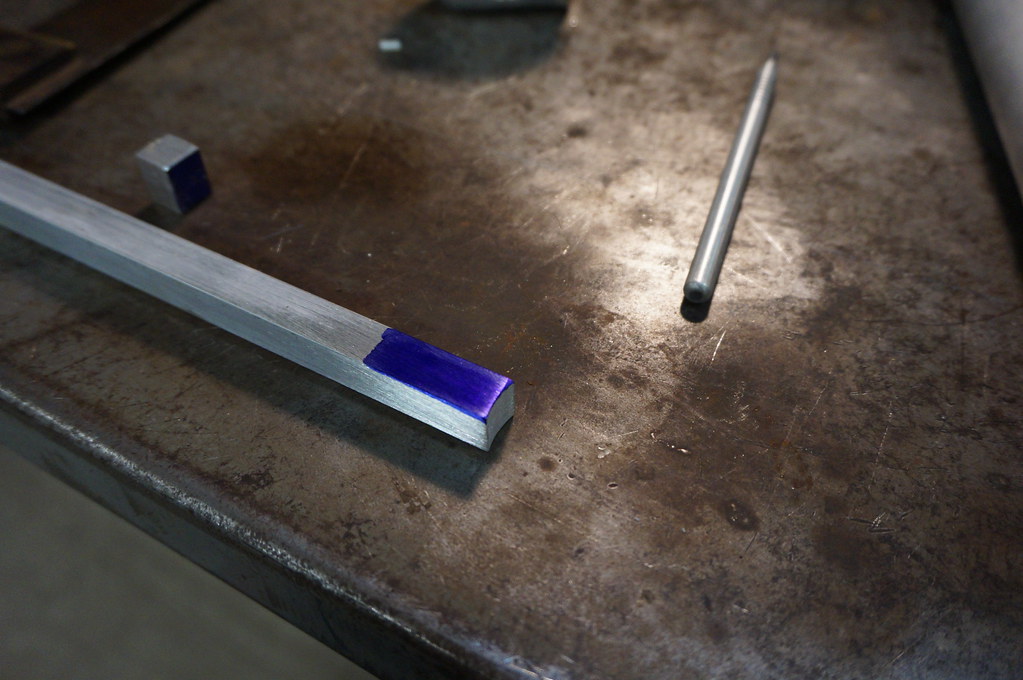

As usual a nice chunk of aluminum to start with

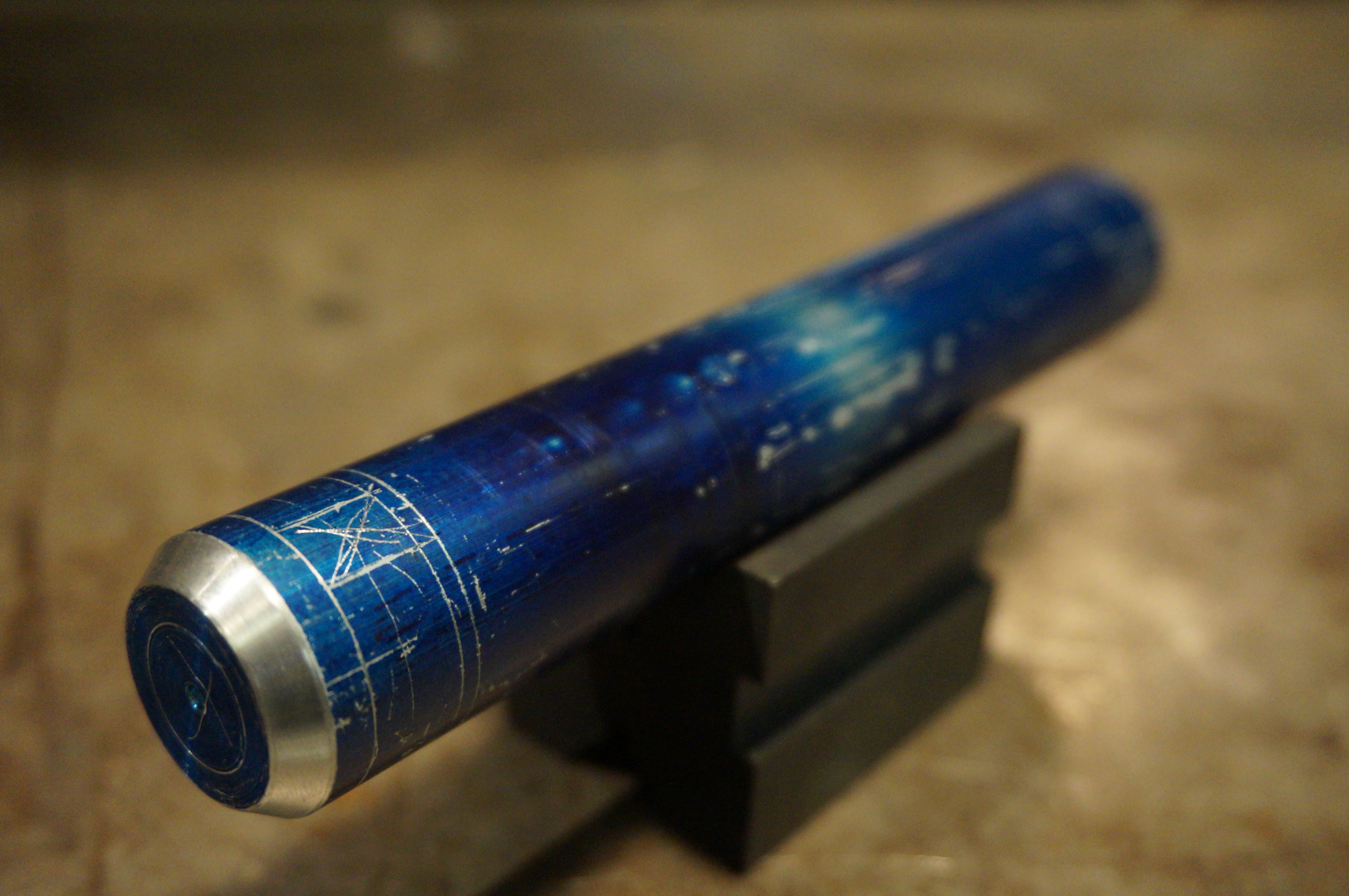

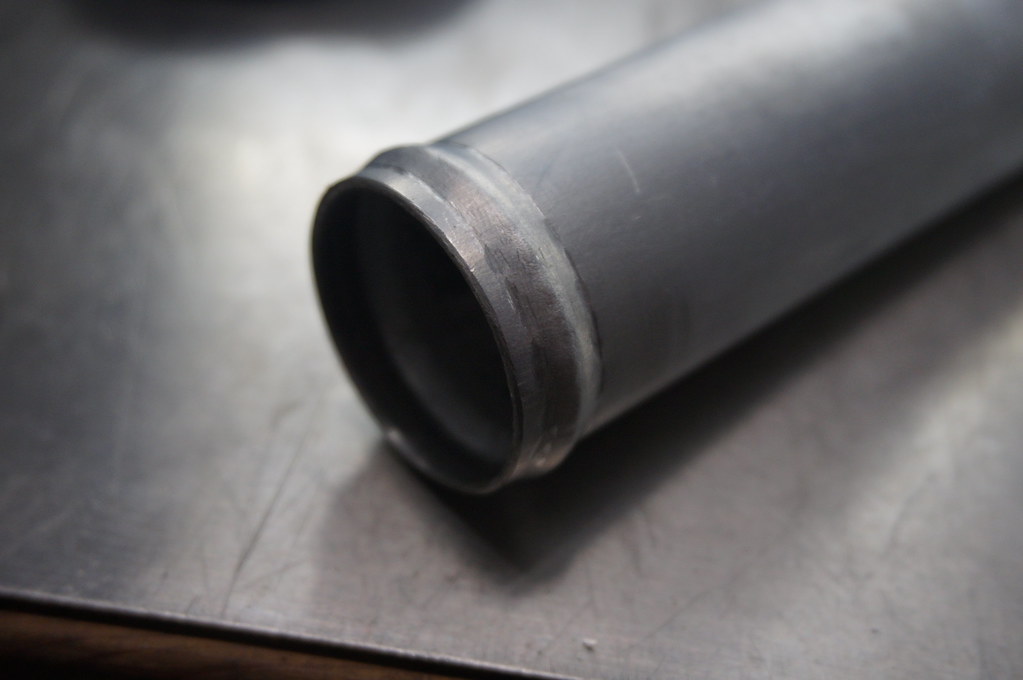

Dykem looks so cool with just a bit of wear

Made a slot

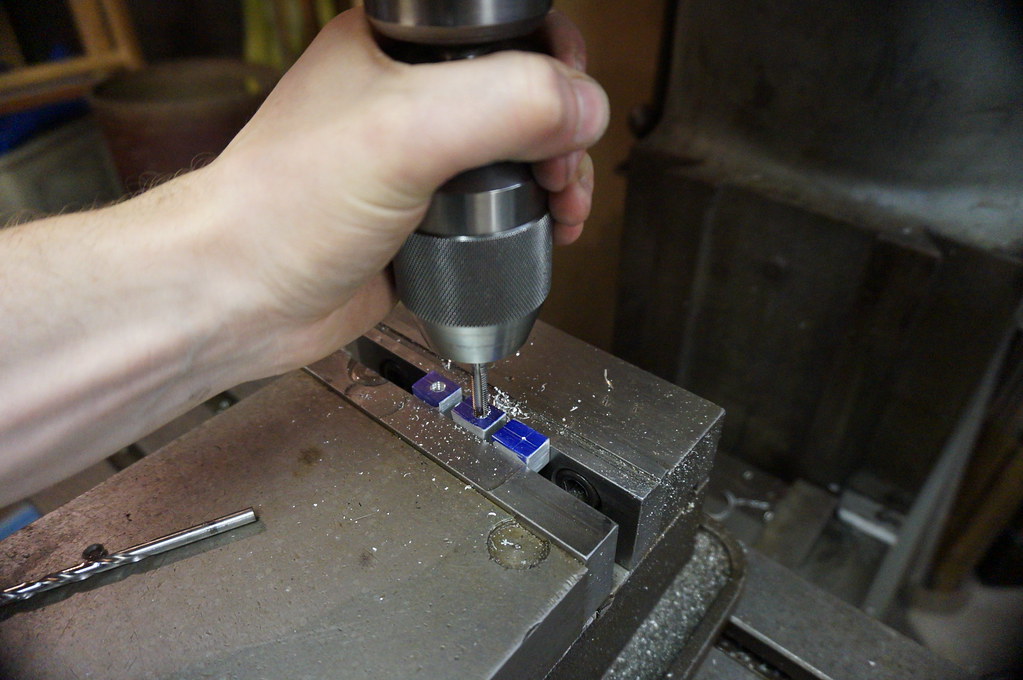

Drilling out the center

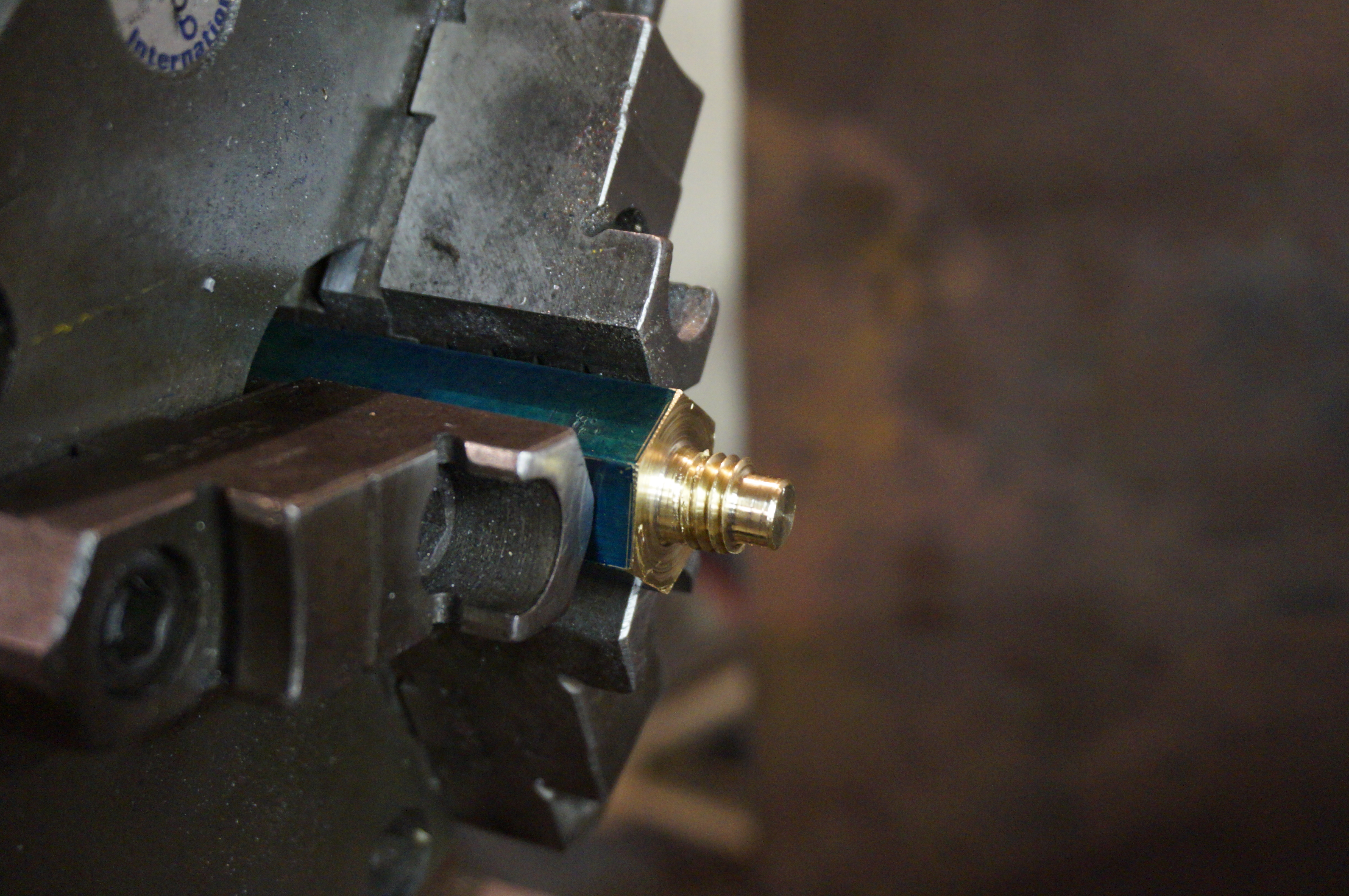

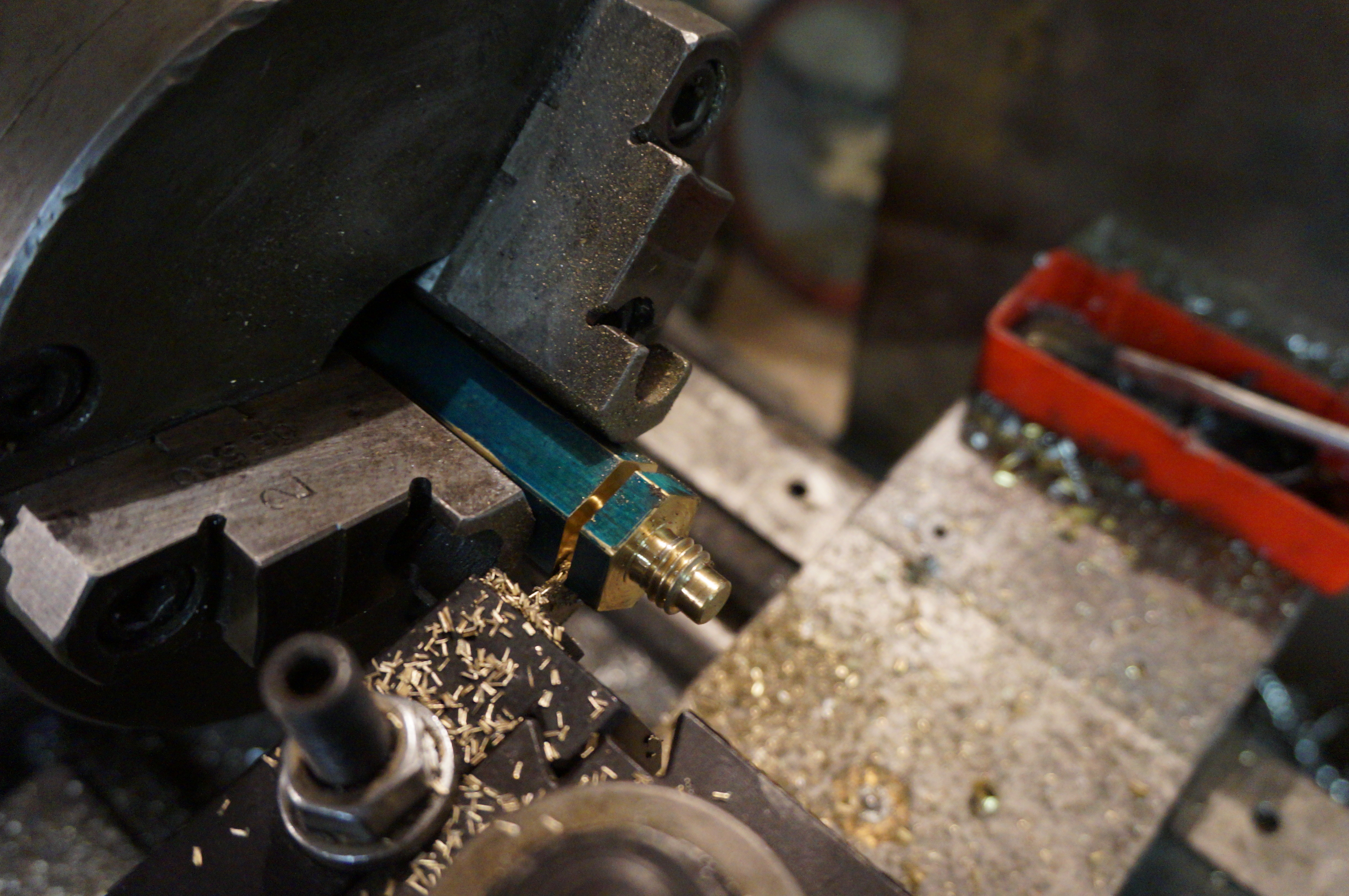

Brass for great contrast

Threaded the brass Hex

Made a nice little clamp

So everything you have just looked at forget it ever happened. I decided to ditch the whole brass clamp (I am sure I will find a use for it later)

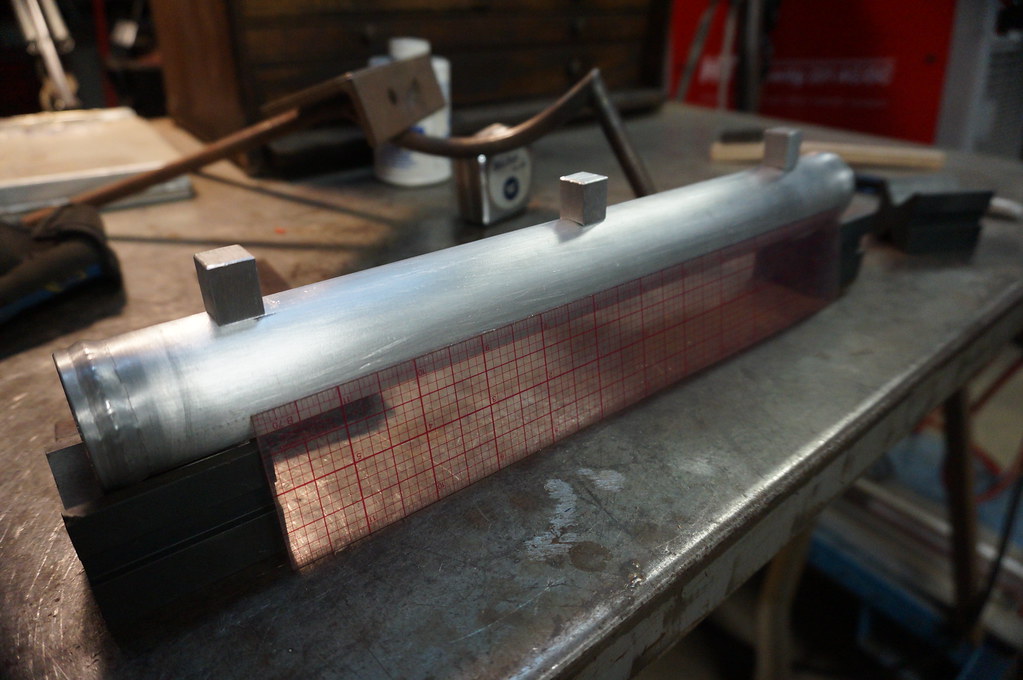

The new plan is to make more traditional type hood pins

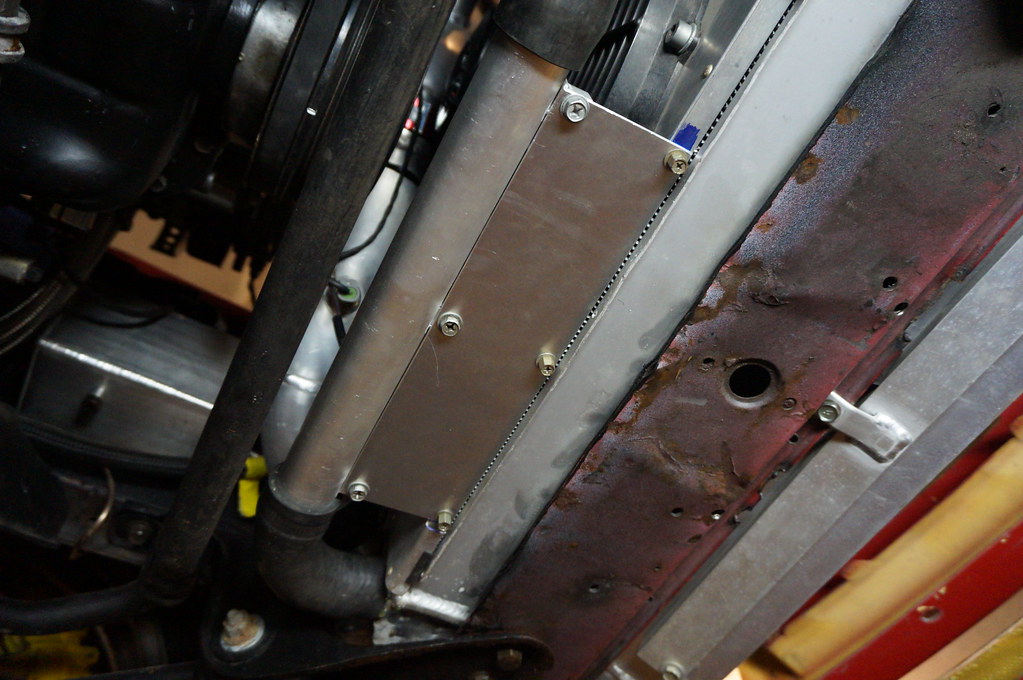

Using these little holes on the inner fender for a mounting point

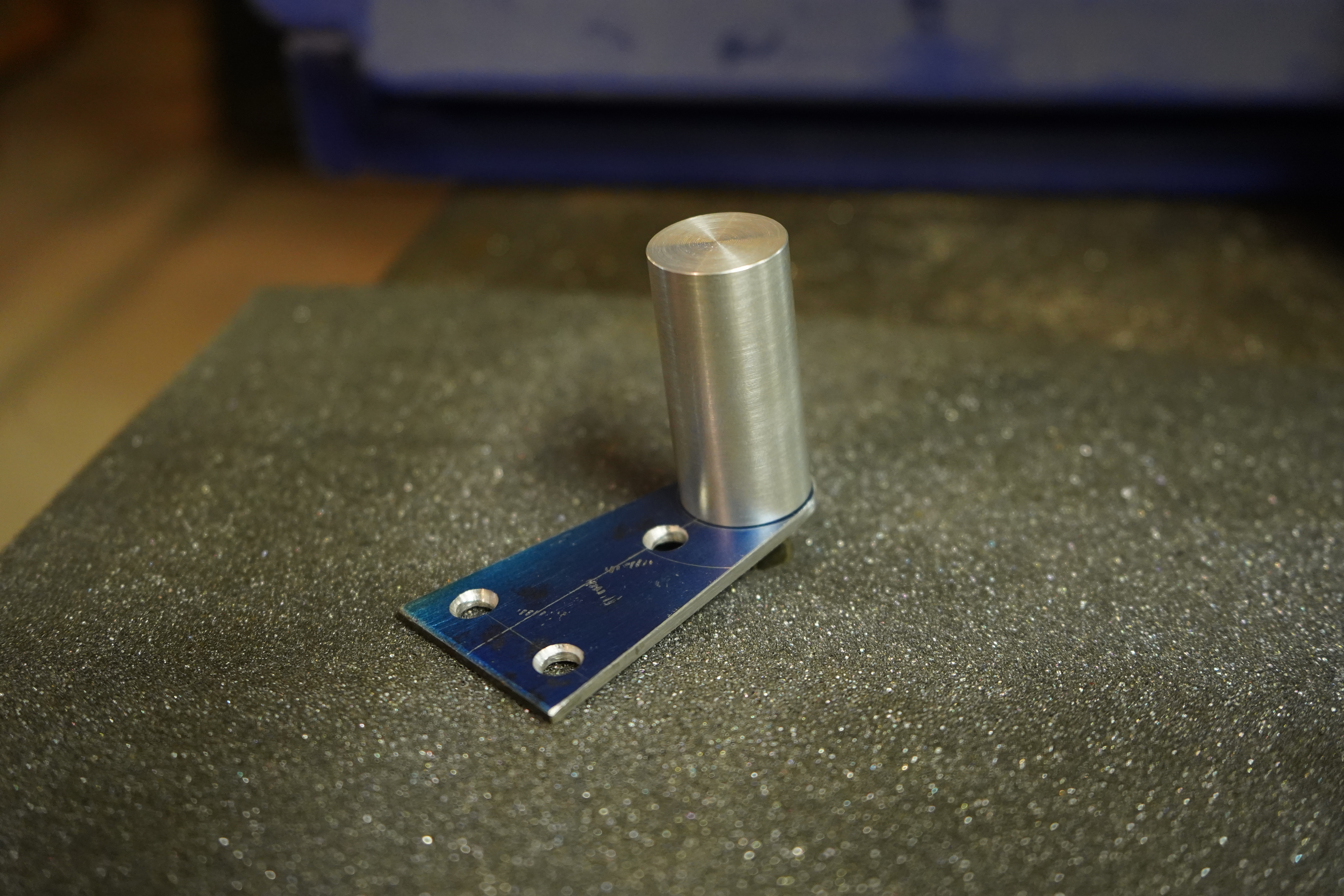

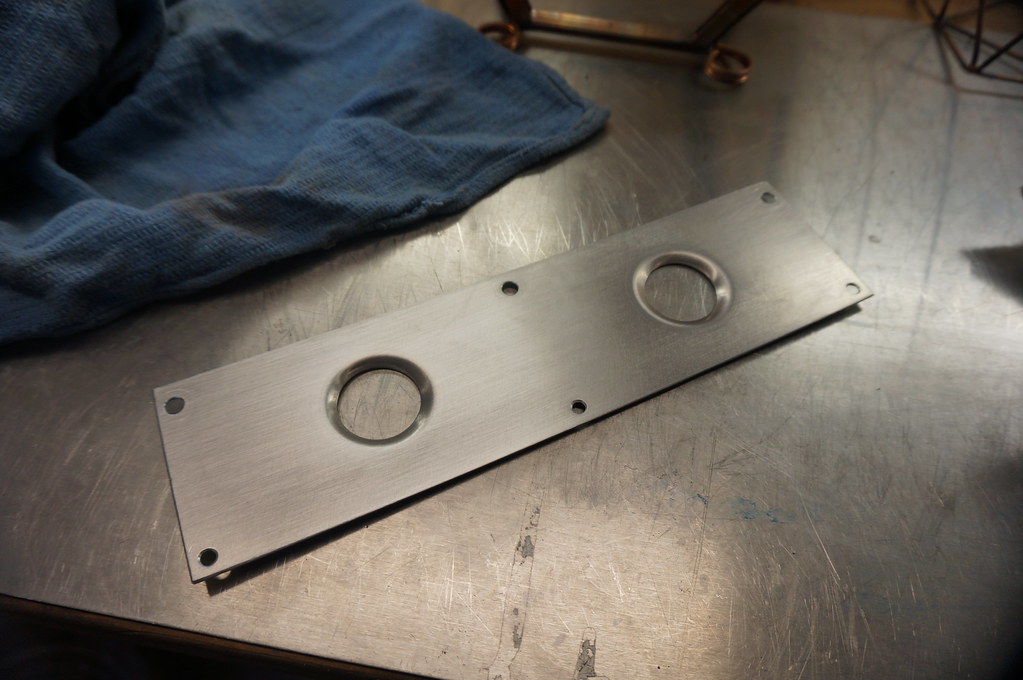

Need to make a couple backing plates to mount the pins to

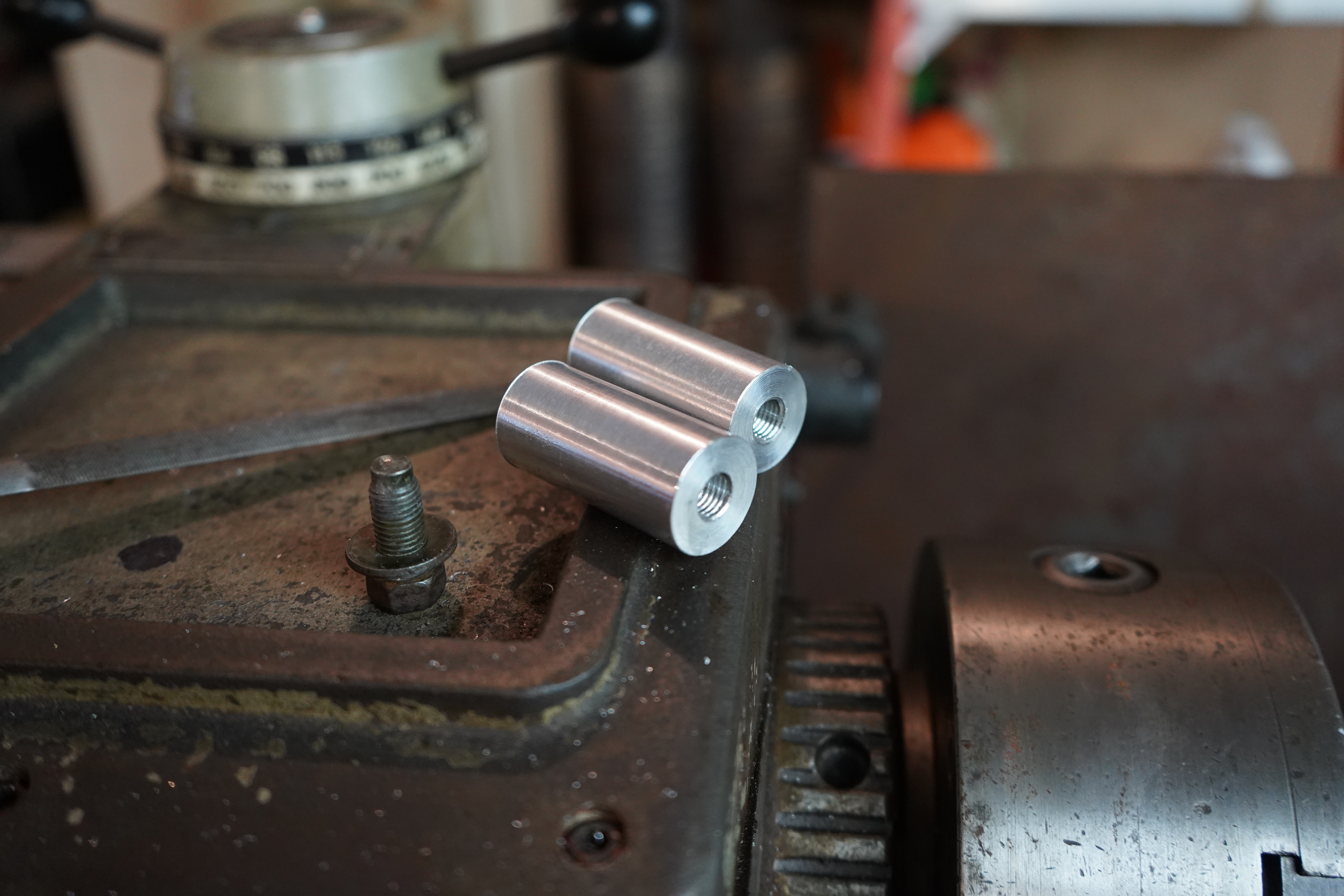

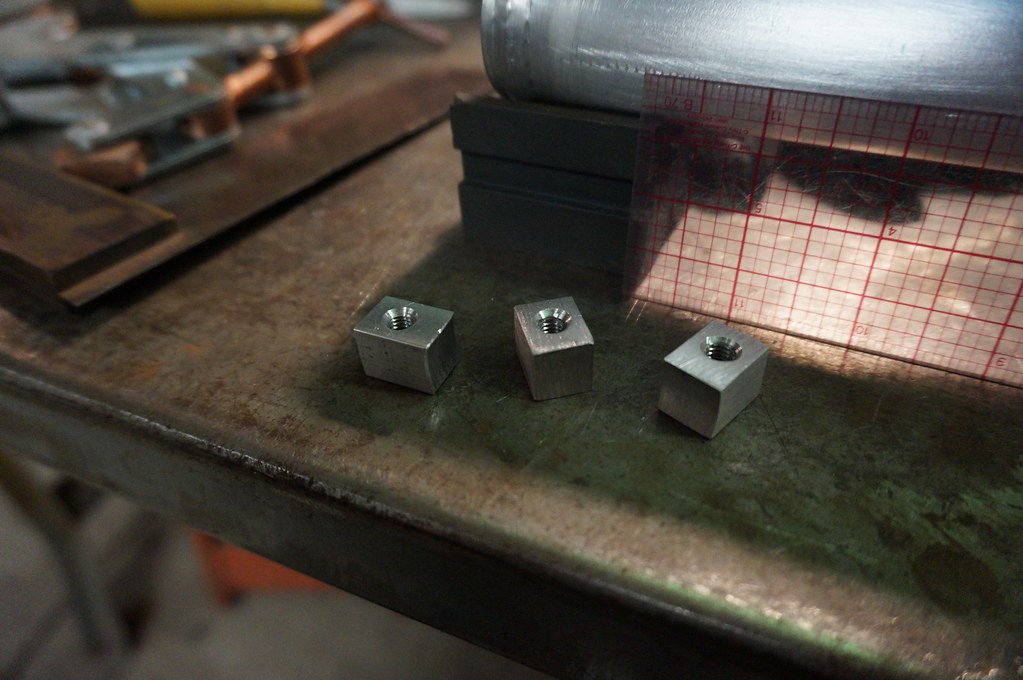

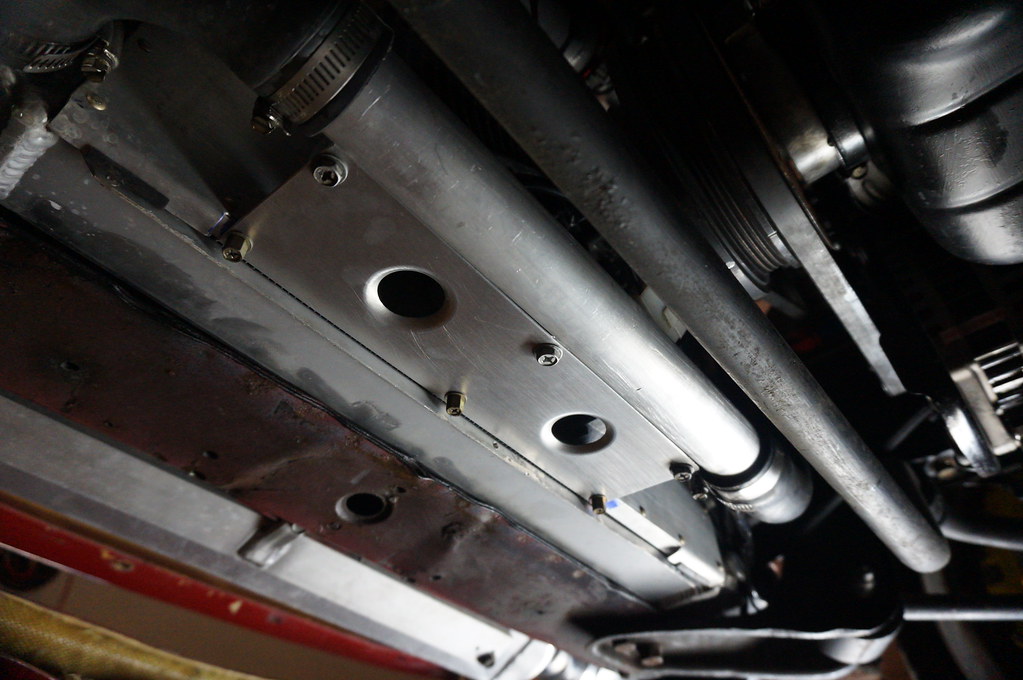

These aluminum bosses are going to be what sets the height of the pins

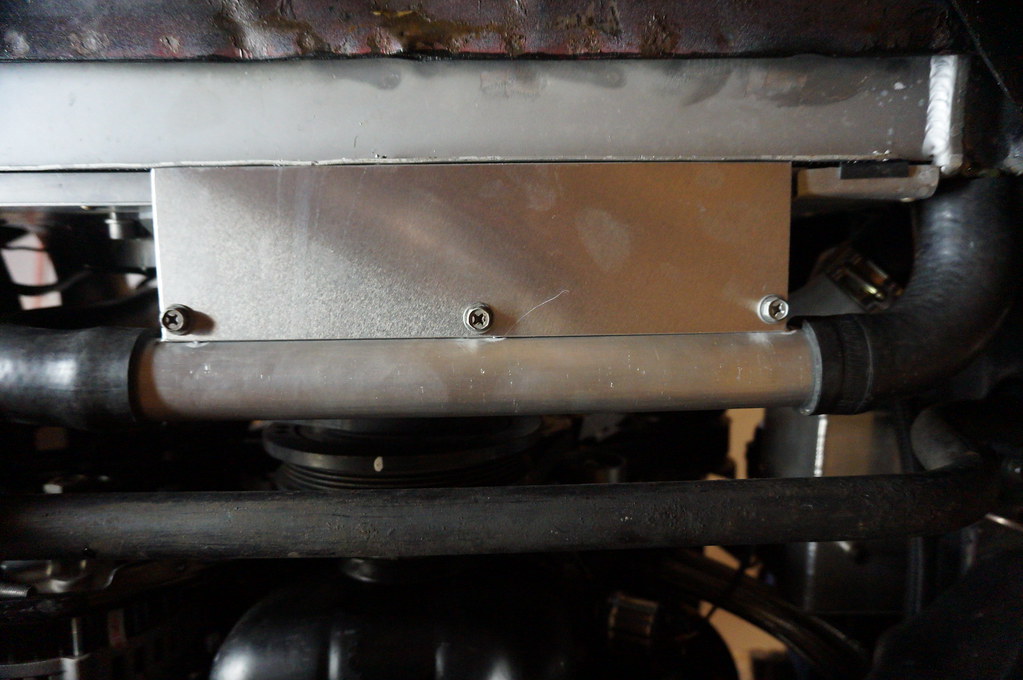

Using some more threaded inserts to mount the backing plate to the inner fender

The aluminum bosses will now be in position to attach the hood pins

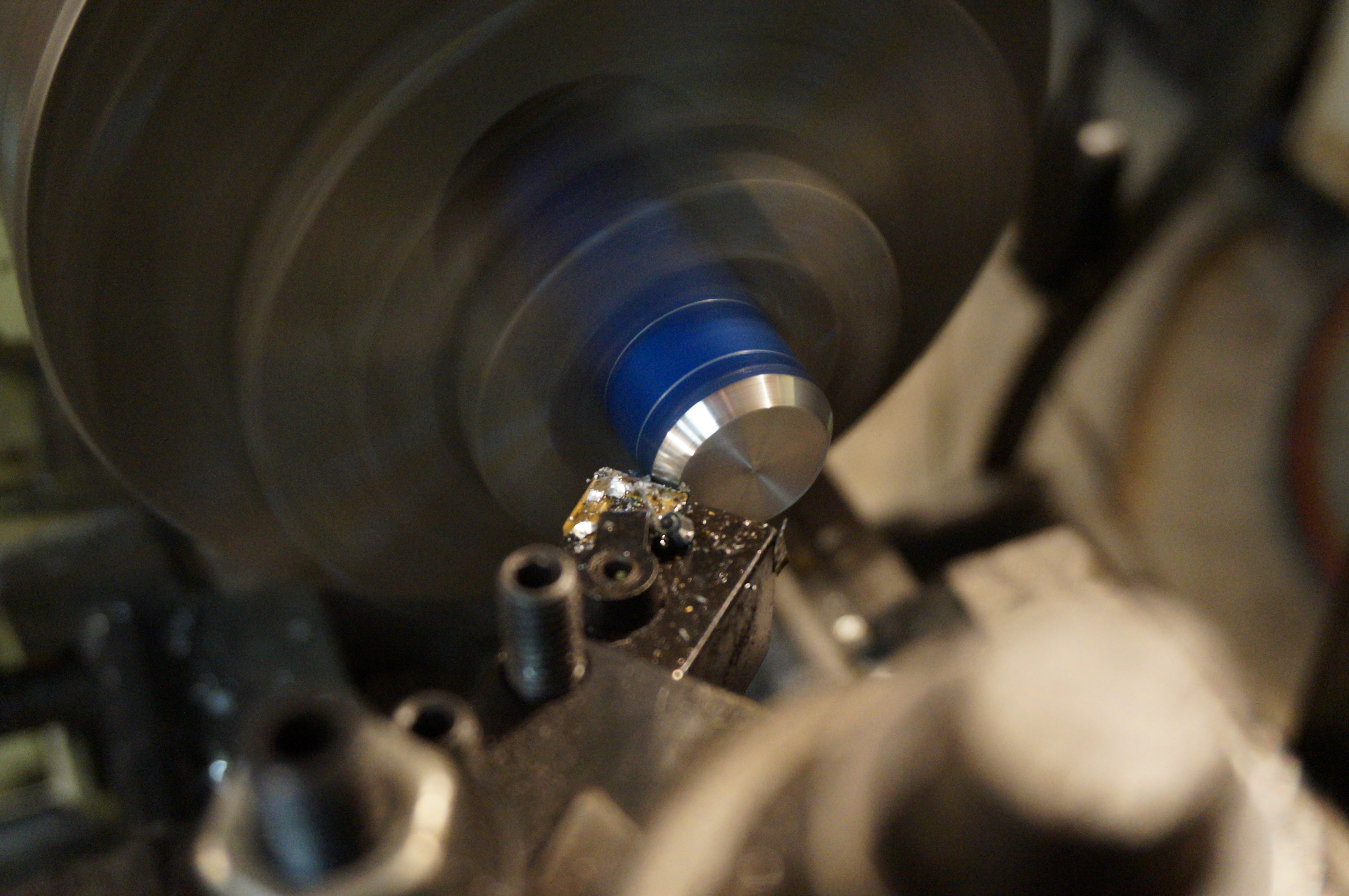

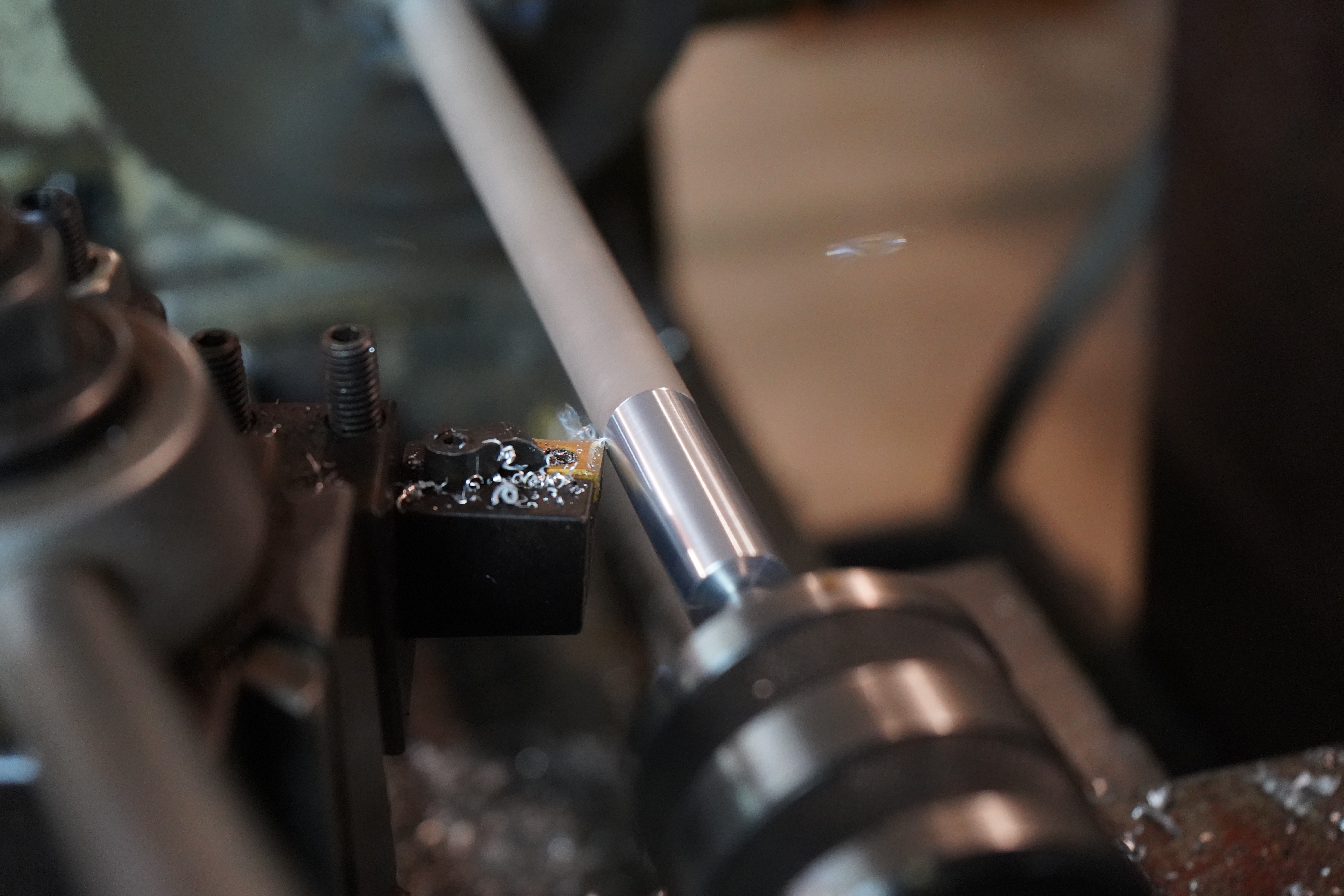

Cutting the pins to diameter

That is all I got for now!

Leave a comment: