Announcement

Collapse

No announcement yet.

52 chevy pickup

Collapse

X

-

Haha we are basically living parallel lives. Building a car, helping friends out with cafe racers, building custom furniture and starting own business. That's really funny

-

It looks like your tig skills are up to the task. Now it's going to be about finding the balance between doing what you love, and doing the jobs that just "pay the bills". Good luck in your new venture!

Leave a comment:

-

Well It has been a a very exciting couple months. After getting the truck all mocked up I built a new support for the rad, fenders, grill and hood. Once I had put it all together I decided with the engine in the stock mounts in the Gbody clip the engine was about 4 inches too far forward. So I started taking the truck apart and ended up breaking my hand. This put me in a cast for 5 weeks but also I am off on disability now which is awesome! So I put the truck on hold as It was too difficult and frustrating to work on. I started taking on some smaller projects that are easier to handle. I started on some furniture. It fun to have smaller stuff to work on. As a learn more about materials and practice the more I keep refining the end project.

Doing the furniture gave me some good practice with the TIG. It was hard to keep everything stead as I could just barely hold on the to filler rod but it turned out alright.

I also have been doing a few bikes for friends. They are big into the cafe racer scene. A lot of seat hoops and bracket deletes. They are fun projects and nice that they are short term.

This was my first time doing some stainless work. Turned out nice and looks much better then the bulky plastic covers.

Now that I have had some time off my wife and I have decided that it is time to quit my job and start pursuing something that I actually enjoy doing. So I have started my own business!

Not sure quite sure what the business will look like but I am super pumped to be diving into a new adventure!

Leave a comment:

-

It's not too cold here in B.C. but I am ready for spring. It was super sunny and hot yesterday and then today it was snowing and back down below freezing. Not super pumped. But I have been able to get lots of work done. Been trying to rally up some friends to help out so I can get this thing rolling this summer but nobody is ever able to so I have just been trying to get as much done as possible. I finished off most of the frame work. Smoothed out the welds. finished up a bunch of the welding. Built a crossmember and and tranny mount. It felt good to set the motor and tranny in and pretend I could hear it running!

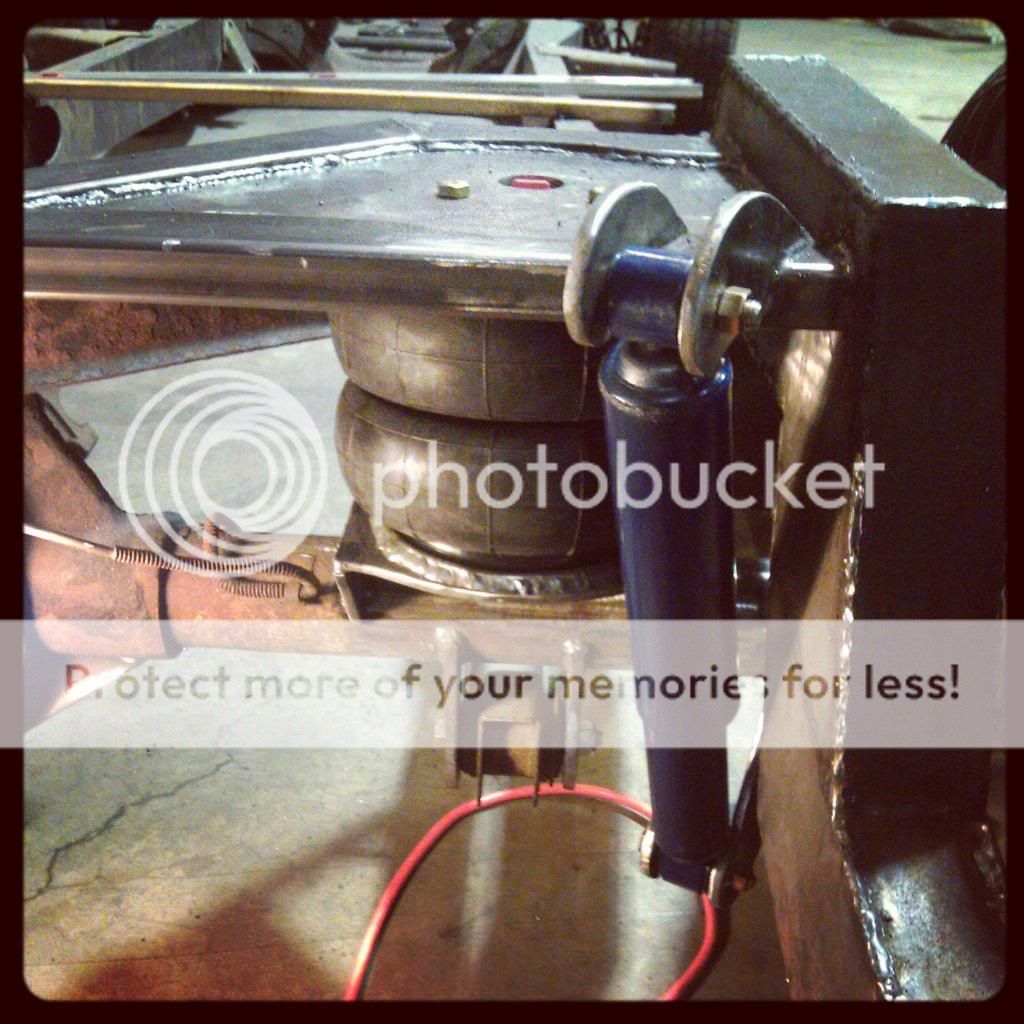

I bought a bunch of fittings and such just to get the bags hooked together so I could see it move up and down. It was awesome!

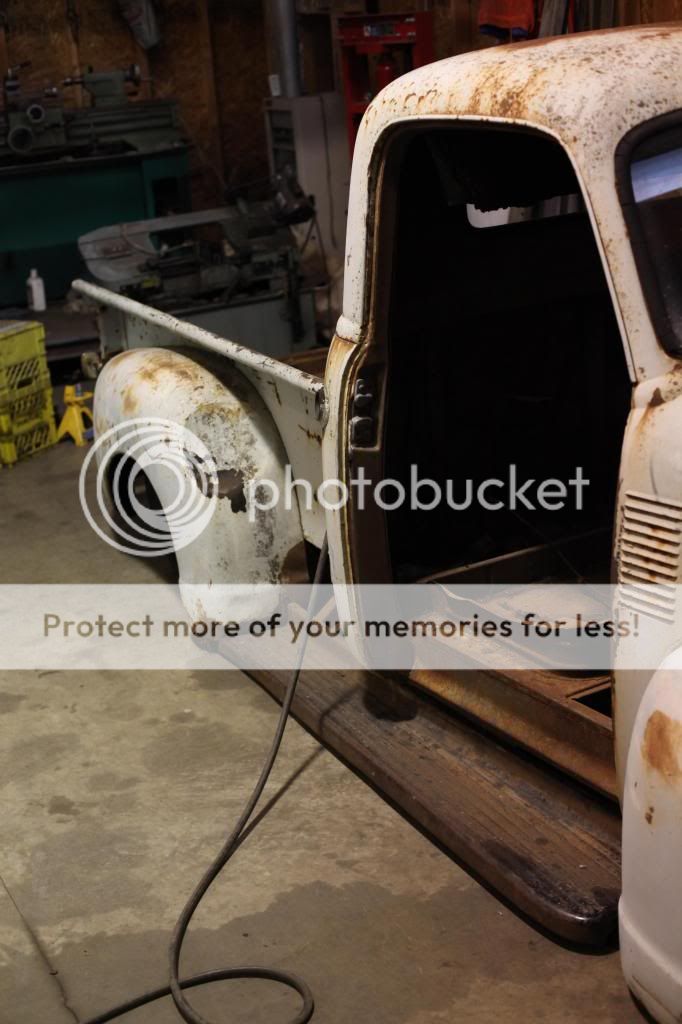

Luckily a buddy was able to come and help. After rallying up some help from around the neighbourhood we were able to get the body all mocked up.

Feels good to see it somewhat together. I just want to hop in and do a massive burn out! Hoping this will give me a boost to keep working!

Leave a comment:

-

Subscribed. I can't wait to dig into a similar build someday, just need a shop to do it in! I feel your pain on working in the cold, it's been in the -5 to -20*c range here in southern Ontario the last few weeks, my little propane heater can't get the chill off in my crappy rental 1.5 car garage.

I've dealt with Kevin at AirAssisted trying to find parts for my girlfriends air ride setup, great guy, easy to deal with and very knowledgeable!

Keep up the good work!

Leave a comment:

-

Well I guess I should update. Haven't been taking a lot of pictures. Really trying to get this frame done so I can move on. But this week has been super cold and even though bundling up works fine your hands can only take some much and then they don't do what you tell them. So this leaves some time to catch up. The only camera I have other than my phone is my wife's DSLR and considering she is a photographer I haven't been able to take it out much to get many pictures. Plus once I start working I tend to forget about taking pictures so here are some crappy cell phone pics.

Got the rear bag and shock mounts all built up.

If I was to do this again I would probably have just built the lower shock mounts in to the lower links mounts. Would have saved a lot of time but I guess this is how you learn.

Once that was all done I flipped the frame over and started on the front bag mounts. I was really unsure on how to do these. So I looked on line and saw there was two buyable options. Once being a cup that basically acts like a spacer and adapter. I wasn't really a fan of this option. Looked kinda light duty to me and I didn't the the end product look very tidy. So I decided to go with the "pocket eliminator". So got online to find some and it was going to be like 200-250$ for these things once shipped plus I had to wait so long for the cheap shipping. So I figured they looked simple enough I would just build my own.

Control arm pockets took me a bit but it all worked out. It added some strength to the frame and the control arm so I am quite happy with the finished product. Little smoothing out and they shall look good. Now I just have to mount some shocks on the front and then smooth out the frame welds and then its time to start fitting the motor and tranny.

Been using my tig welder way more. Really starting to enjoy it. Found I was using almost to thick filler rod so it was working but just making it a little tricky to keep the puddle moving. So I picked up some thinner filler and it is just been way more user friendly and allowed me to focus on other aspects of technique.

Built a little crossmember to connect the upper links. I didn't need to notch it like this to clear but I wanted to try some pie cuts and thought it would look a little better. Here I was still using thicker filler rod.

And to finish of the week I pulled the motor and tranny out of the parts truck. Decided to do it on the coldest week which was foolish but it needed to get done and a buddy said he could help! Can't wait to be cruising in this truck. I am really itching to start putting some body panels back on this thing to get some motivation!

Leave a comment:

-

I **** Heims with Rear link bars. Too sloppy IMO. Simple Bushing's on a tube end work great.Originally posted by aLaFleur View PostI feel like it would be much safer to just make new link bars and crossmember to mount them to. Not to mention you could probably achieve much more articulation with some heim jointed links. But I hope that works out for you. Still interested to see how it all turns out.

Leave a comment:

-

I feel like it would be much safer to just make new link bars and crossmember to mount them to. Not to mention you could probably achieve much more articulation with some heim jointed links. But I hope that works out for you. Still interested to see how it all turns out.

Leave a comment:

-

Great build man! I think 3/16 would do fine as well, but happy to see you went with the 1/4 inch. I would also maybe step up the frame plate you used to box.. maybe.

Leave a comment:

Leave a comment: