Subject at hand.

I've been wanting to do this swap for quite some time now, especially with my background of building V8 cars and hot rods, it was just something I needed to do! I already have a turbo S50 E30, so this car needed something different. I went back and forth selling this car for a while, but I've had it 6 years now, bought from the original owner, and I know I would kick myself in the ass, especially with everything I've done over the years, this car is basically new from the top to bottom.

WHile I was at the yard one day picking up an M54 for a customer car at the shop, I asked if they had an LQ9s sitting around. I wanted an iron block LS engine, I plan to spray this thing once I have it all together. I didn't want an LQ4 with the lower compression, and luckily they had one in stock from a 2003 Escalade with 79k miles. I bought the M54, the LQ9 and a SUPER CLEAN 5.3 they had for a hell of a deal. I guess buying in bulk does work.

I stripped all the accessories and unwanted parts off the LQ9 and it didn't seem to shabby. I knew I was only using the shortblock from the get go. I want to make at least 450whp on just the engine.

I cleaned up the block, masked it, and shot some fresh satin black on it. Also cleaned off the gasket surfaces and the tops of the pistons. No scrubbing was needed, just some lacquer thinner.

A few days later, I started stripping the M3 to prepare it for its heart transplant.

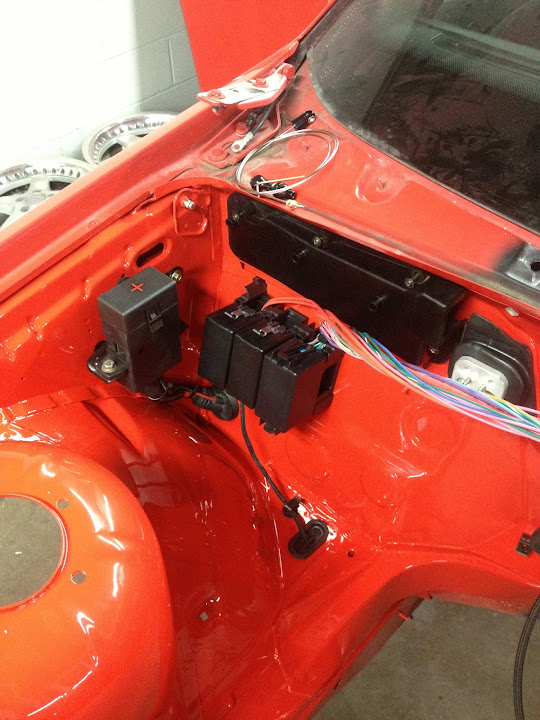

On a lot of my past builds, I shaved the engine bays pretty extremely, but with this car, I wanted to have the fusebox in the bay so I could access everything readily and not clutter up under the dashboard. I plan to have all accessories on the engine, but no ABS, no cruise, nothing that would make the bay aesthetically unappealing. The A/C lines will be custom made and tucked down low. More on that as I get there. Brakes are handled by a Tilton proportioning valve with custom lines, etc...

I started by removing all seam sealer, cutting off all tabs, removing the real shelf that the secondary air pump sat on, and all wiring, grommets, and pieces that would interfere with the new paint.

Wiring rats nest that BMW stuffs in the fusebox

Wiring that was not needed was cut out.

All prepped at this point

Epoxy primer

Primed

Color laid

Cleared

And untaped

I started on getting the fusebox and wiring back in the car. I ran the wiring that run on the core support through the fenderwell out of the side of the fusebox. No wiring cluttering the bay here.

I've been wanting to do this swap for quite some time now, especially with my background of building V8 cars and hot rods, it was just something I needed to do! I already have a turbo S50 E30, so this car needed something different. I went back and forth selling this car for a while, but I've had it 6 years now, bought from the original owner, and I know I would kick myself in the ass, especially with everything I've done over the years, this car is basically new from the top to bottom.

WHile I was at the yard one day picking up an M54 for a customer car at the shop, I asked if they had an LQ9s sitting around. I wanted an iron block LS engine, I plan to spray this thing once I have it all together. I didn't want an LQ4 with the lower compression, and luckily they had one in stock from a 2003 Escalade with 79k miles. I bought the M54, the LQ9 and a SUPER CLEAN 5.3 they had for a hell of a deal. I guess buying in bulk does work.

I stripped all the accessories and unwanted parts off the LQ9 and it didn't seem to shabby. I knew I was only using the shortblock from the get go. I want to make at least 450whp on just the engine.

I cleaned up the block, masked it, and shot some fresh satin black on it. Also cleaned off the gasket surfaces and the tops of the pistons. No scrubbing was needed, just some lacquer thinner.

A few days later, I started stripping the M3 to prepare it for its heart transplant.

On a lot of my past builds, I shaved the engine bays pretty extremely, but with this car, I wanted to have the fusebox in the bay so I could access everything readily and not clutter up under the dashboard. I plan to have all accessories on the engine, but no ABS, no cruise, nothing that would make the bay aesthetically unappealing. The A/C lines will be custom made and tucked down low. More on that as I get there. Brakes are handled by a Tilton proportioning valve with custom lines, etc...

I started by removing all seam sealer, cutting off all tabs, removing the real shelf that the secondary air pump sat on, and all wiring, grommets, and pieces that would interfere with the new paint.

Wiring rats nest that BMW stuffs in the fusebox

Wiring that was not needed was cut out.

All prepped at this point

Epoxy primer

Primed

Color laid

Cleared

And untaped

I started on getting the fusebox and wiring back in the car. I ran the wiring that run on the core support through the fenderwell out of the side of the fusebox. No wiring cluttering the bay here.

Comment