Well having just bought a house which we will hopefully be in by mid August, I can turn my efforts to getting this old thing back on the road for next years show season.

Needs a few bits and pieces doing to get it to a standard I would like..... so commence my inner thoughts and dreams! Obviously not all of this will be done by next year buuuut its a plan of everything I wanted to do to it but couldn't during the rebuild. I just need to get it roadworthy again to be happy for next year.

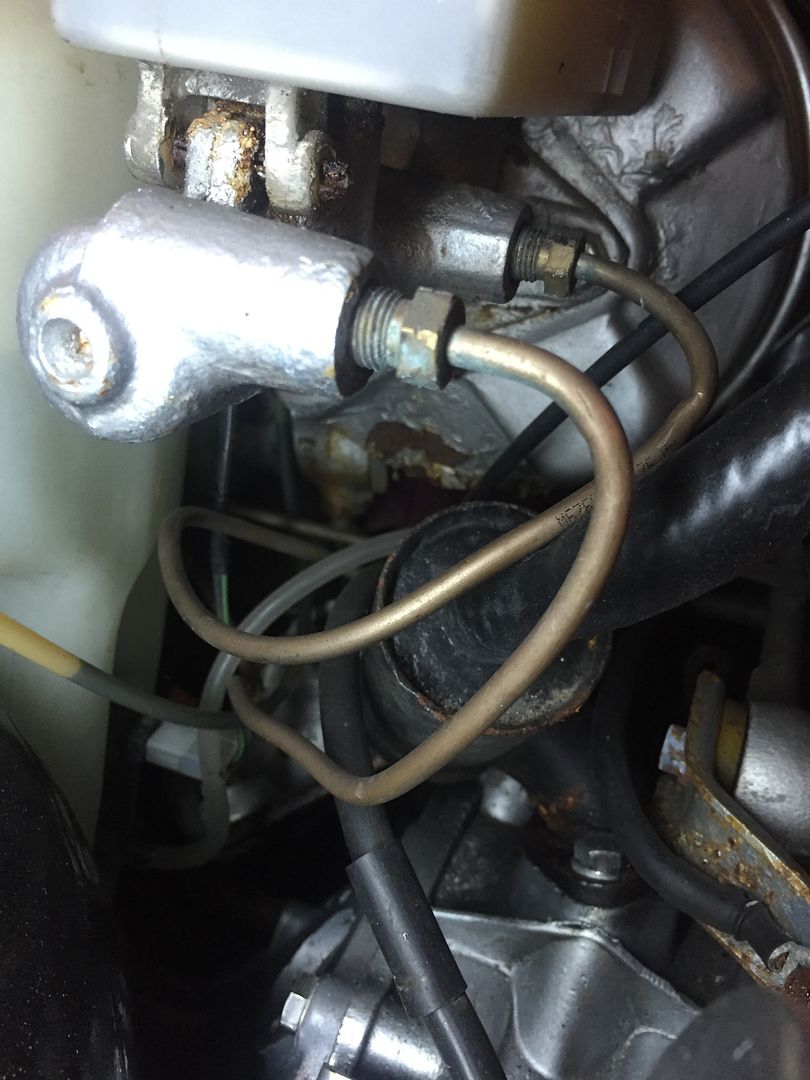

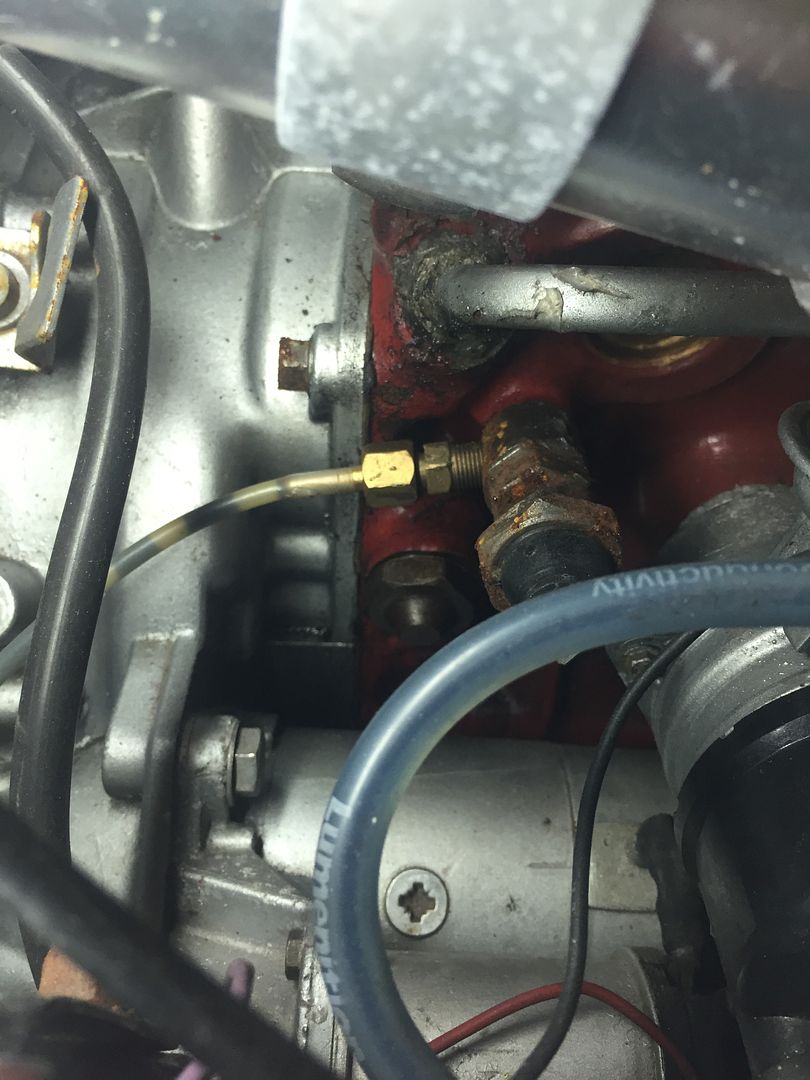

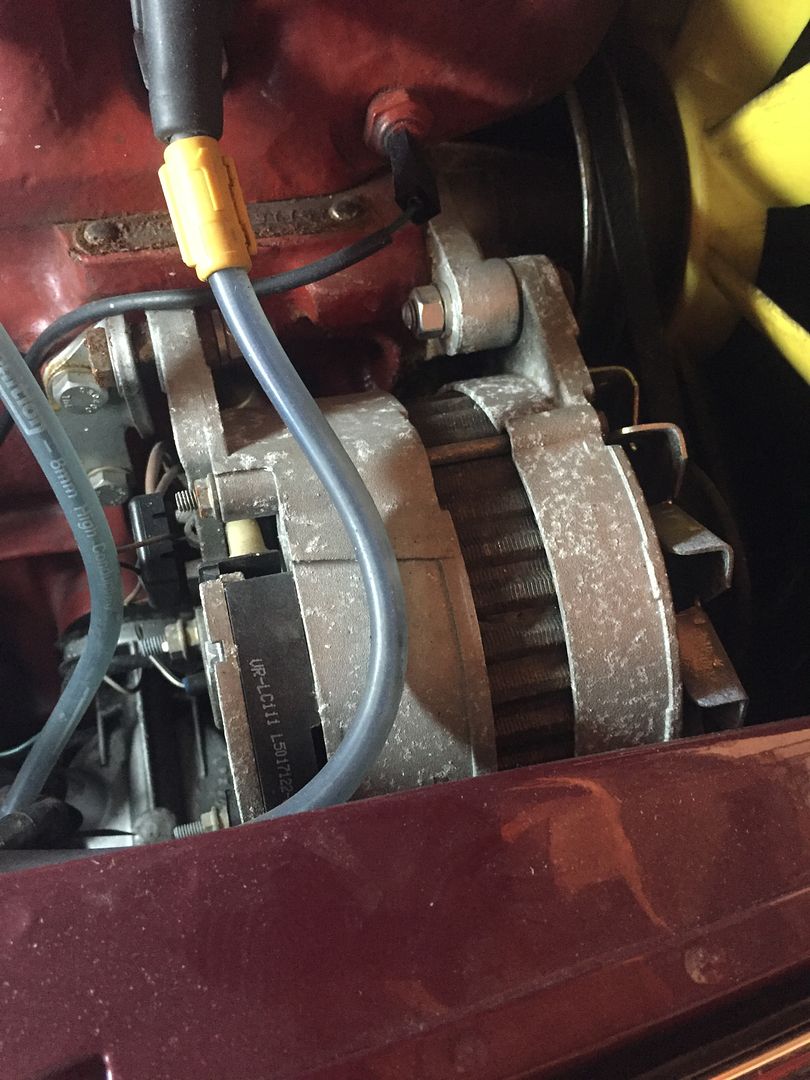

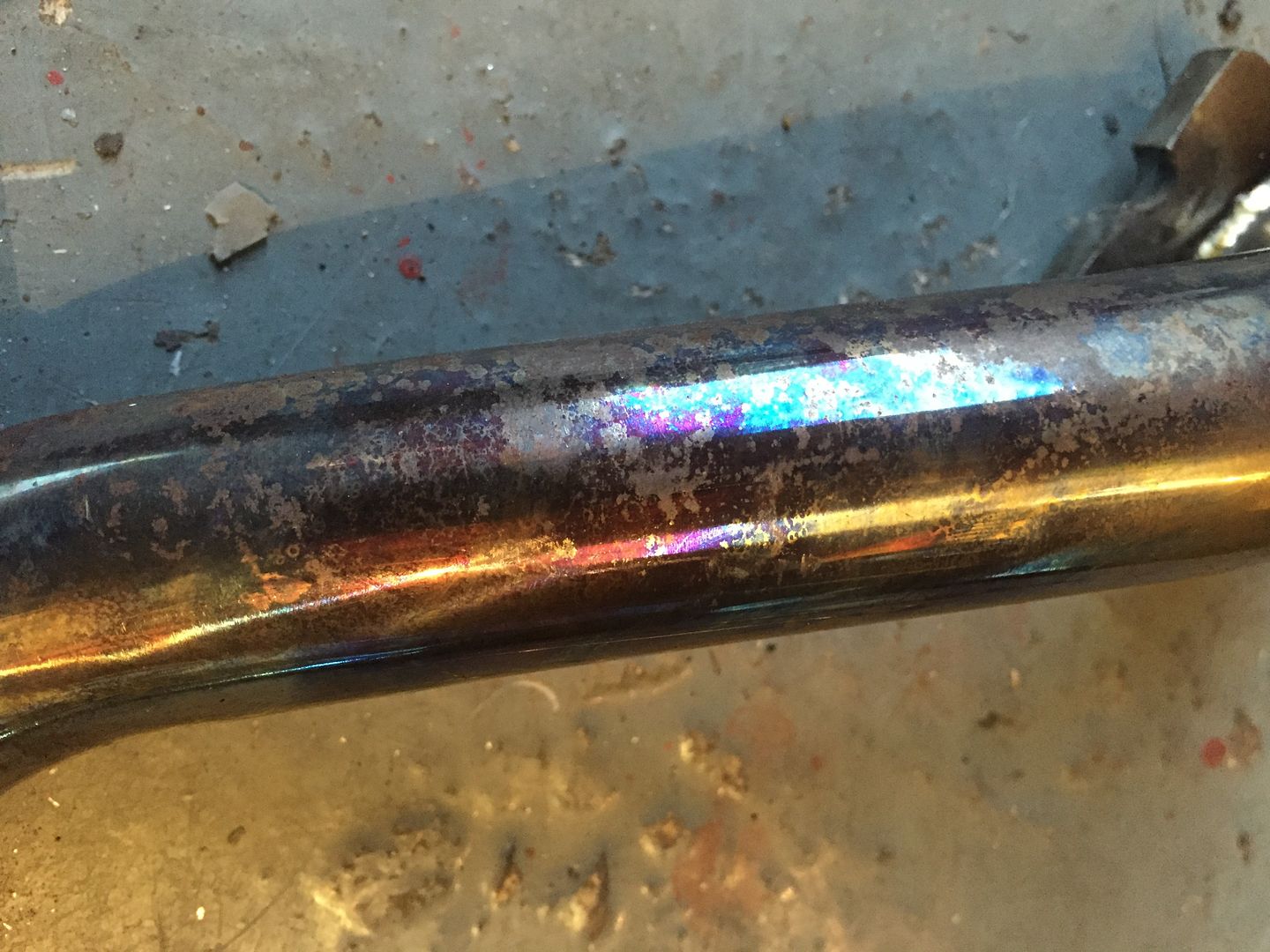

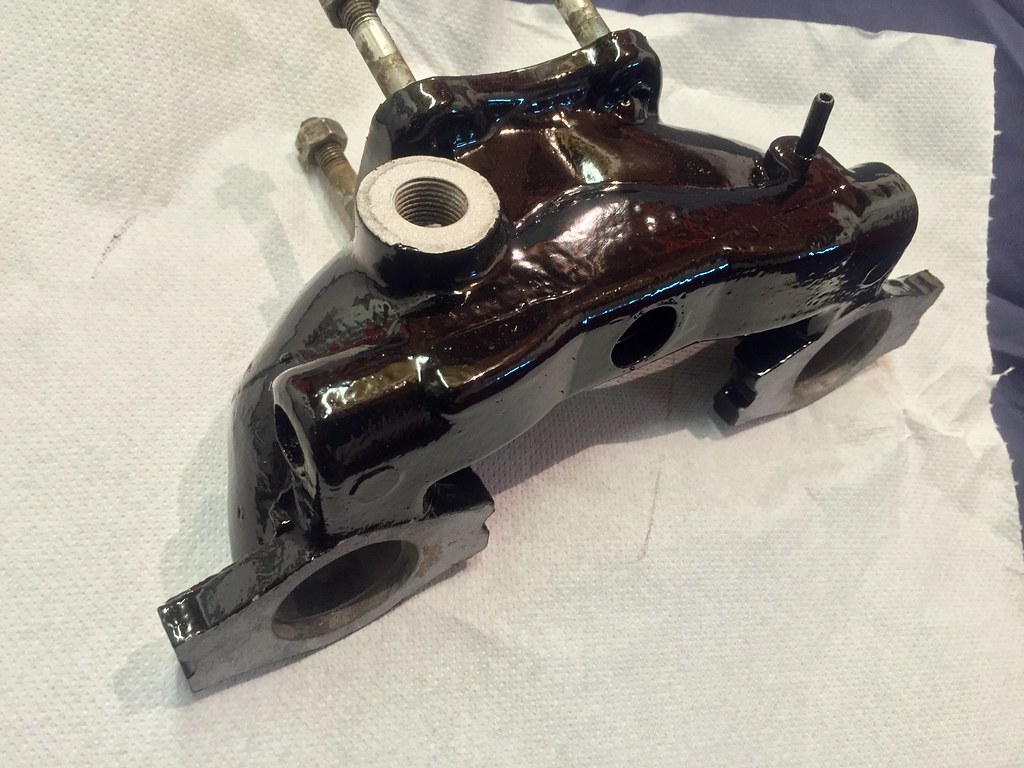

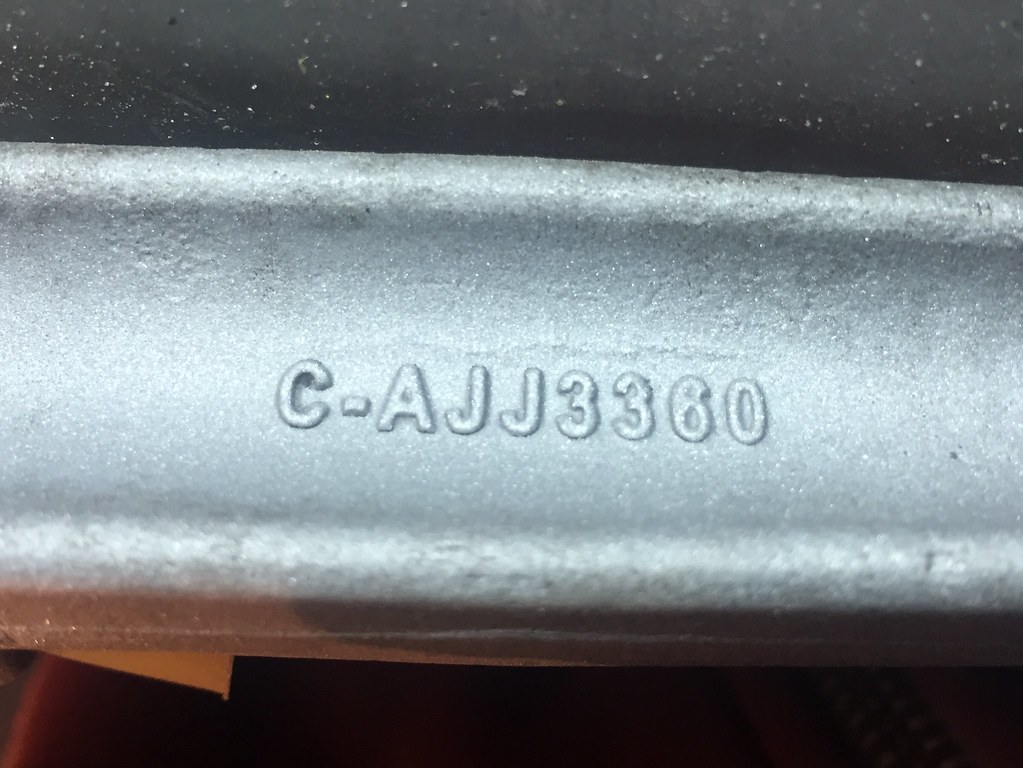

Engine/engine bay - Its a mess. Wires all over, various little leaks have stained parts and peeled paint. I want to strip everything out again and powder coat all ancillaries and update a few bits things with DSN Retrospect billet alloy parts. Wanting Minivation hinges too for a vertical lift bonnet for easy access. Exhaust is leaking slightly between manifold and link pipe so that needs sorted too. Superchargers are also highly interesting things.....

Suspension - Its harsh as hell and twitchy. Thinking of saving for Protech dual-adjust coilovers having read incredible things about them (plus they look epic and are designed and built in the UK). Until I can afford them though, I think an update with fresh cones will suffice. The GAZ shocks are designed for the lowered height but they are harsh even at 3 clicks from full soft which is a tried and tested setup. Also needs a new rear radius arm and wheel bearings on the back too. Crap wheel alignment (won't name and shame...) meant they got destroyed on the IMM trip last year.

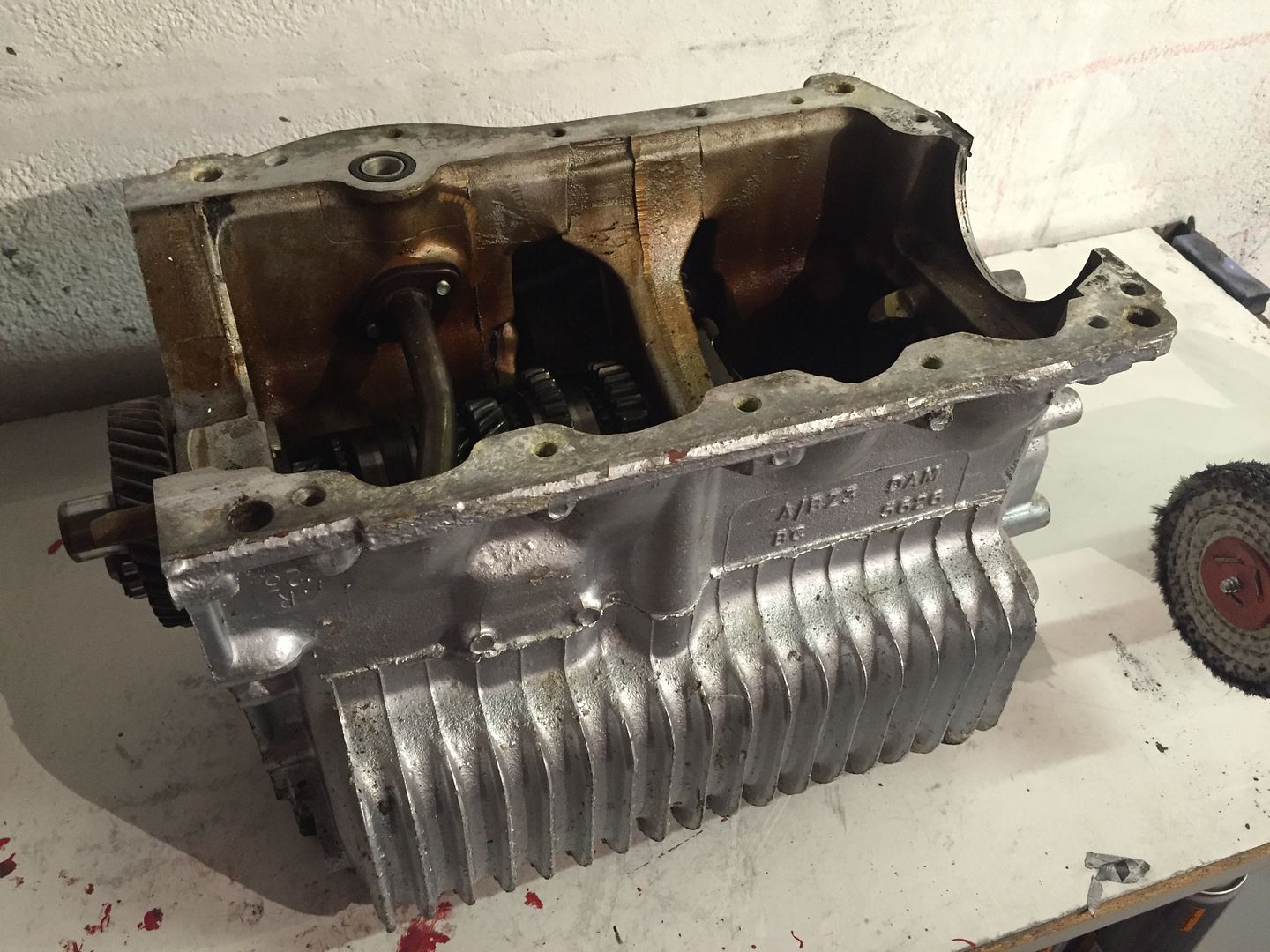

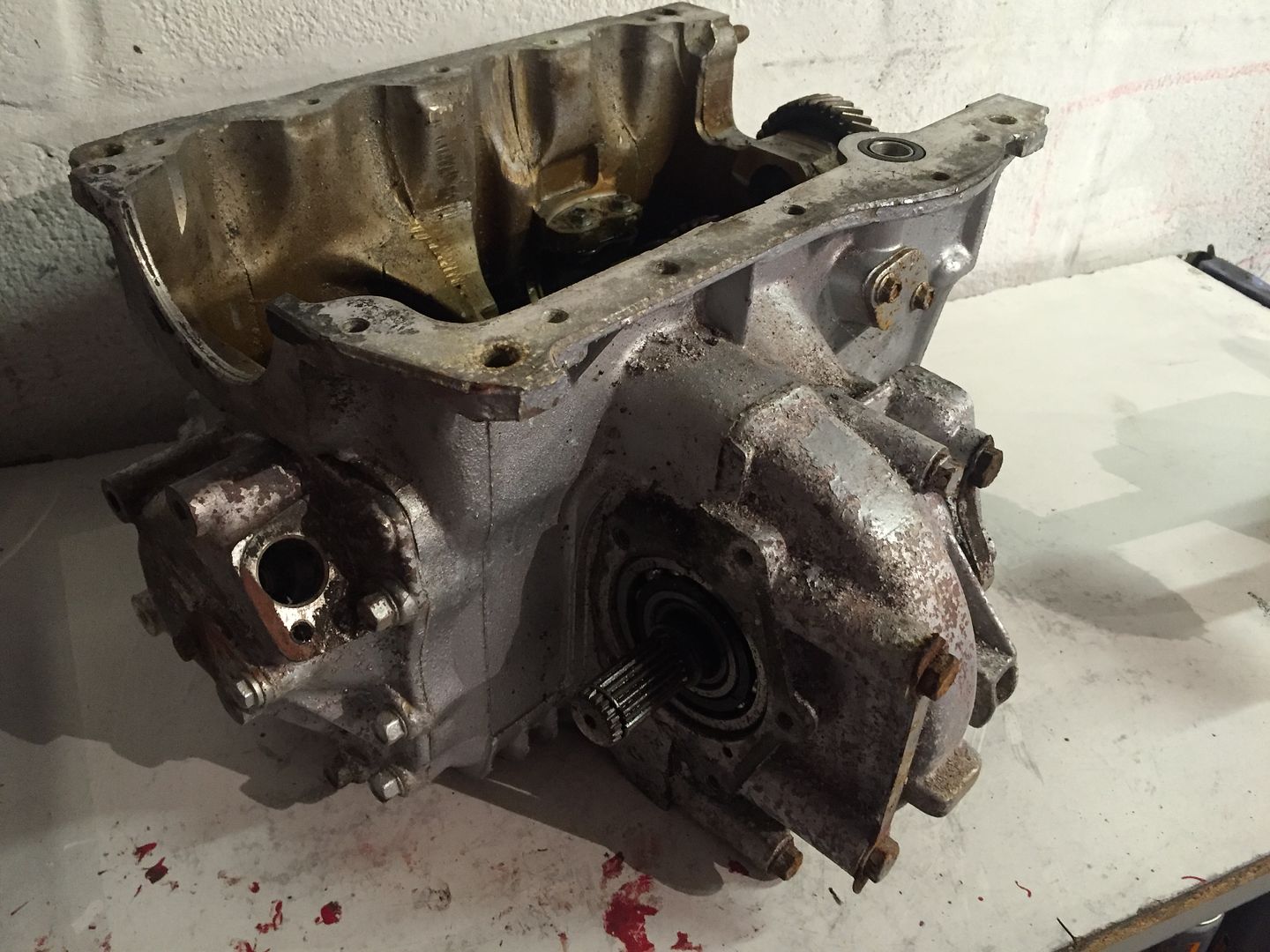

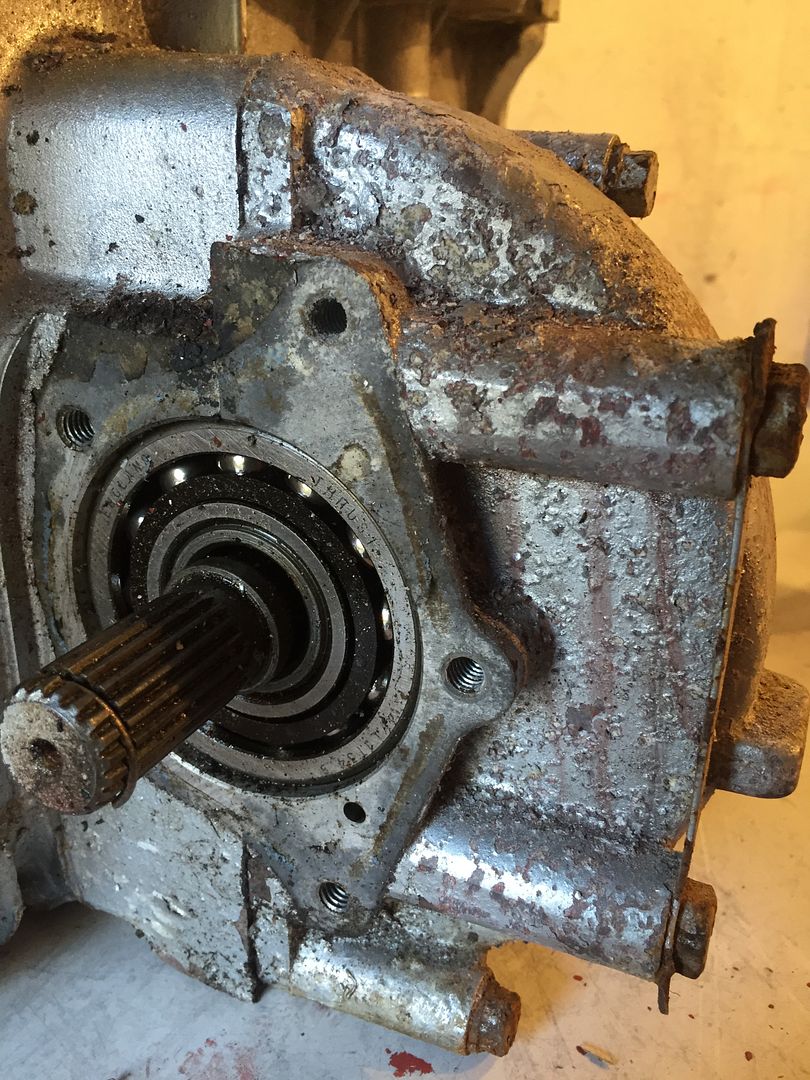

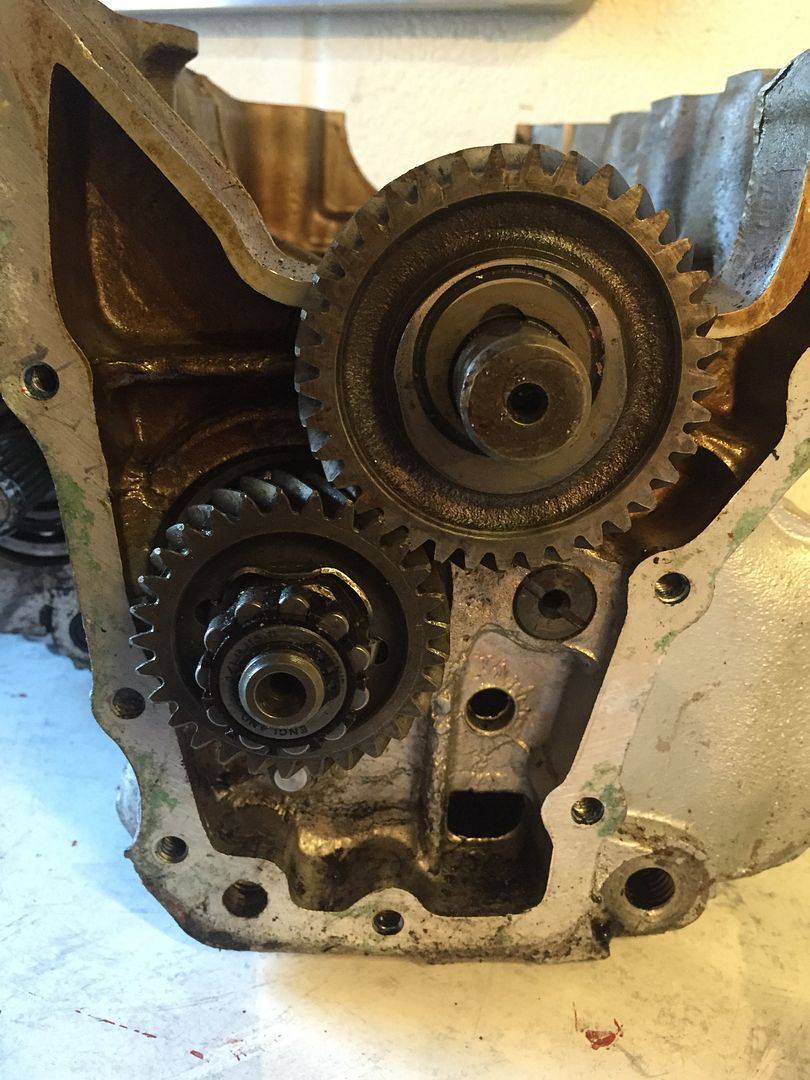

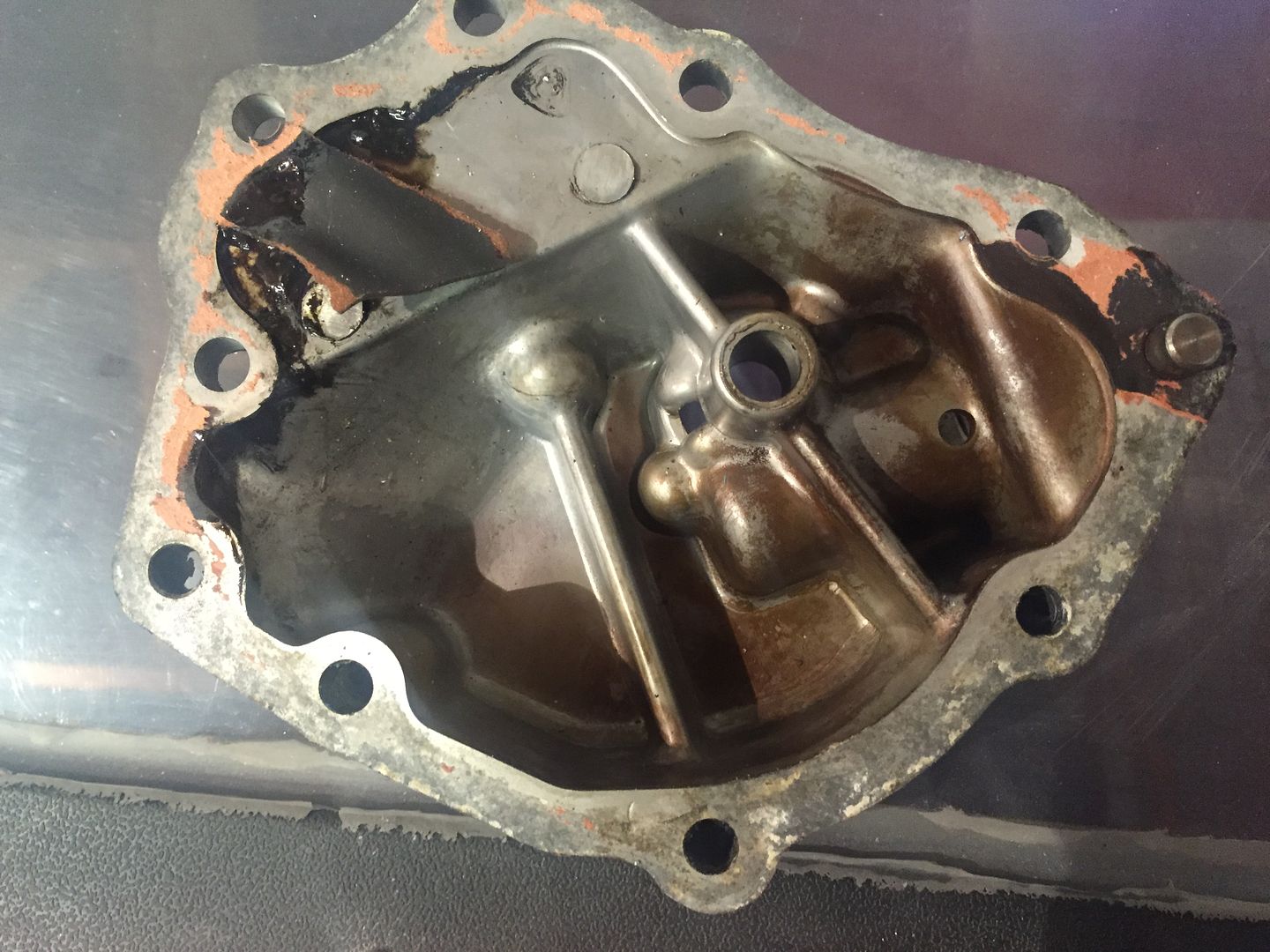

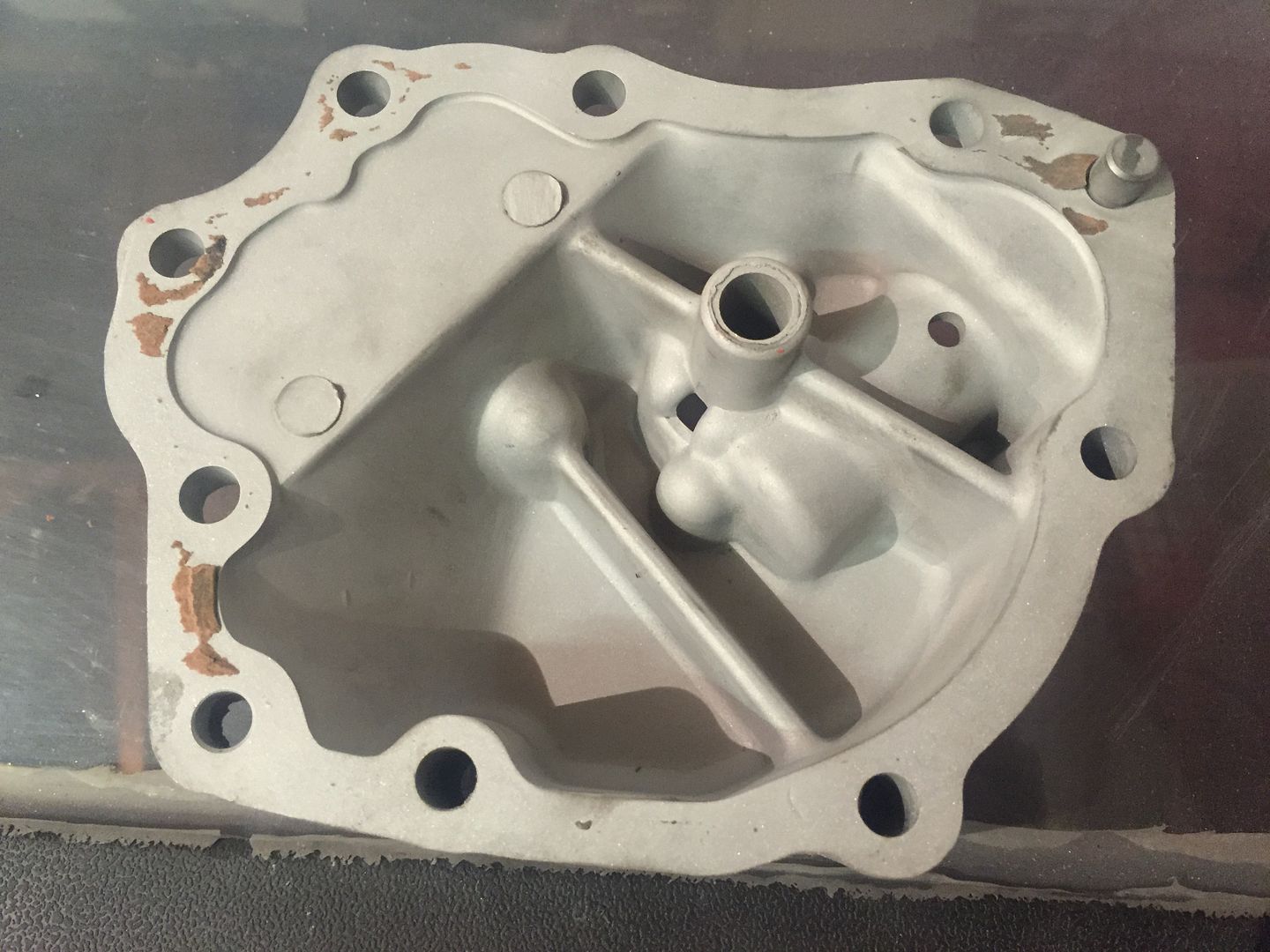

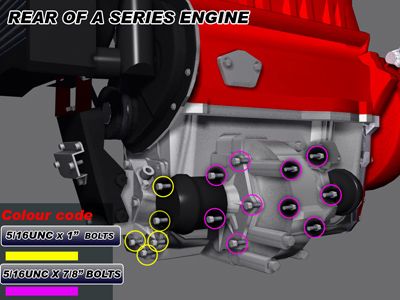

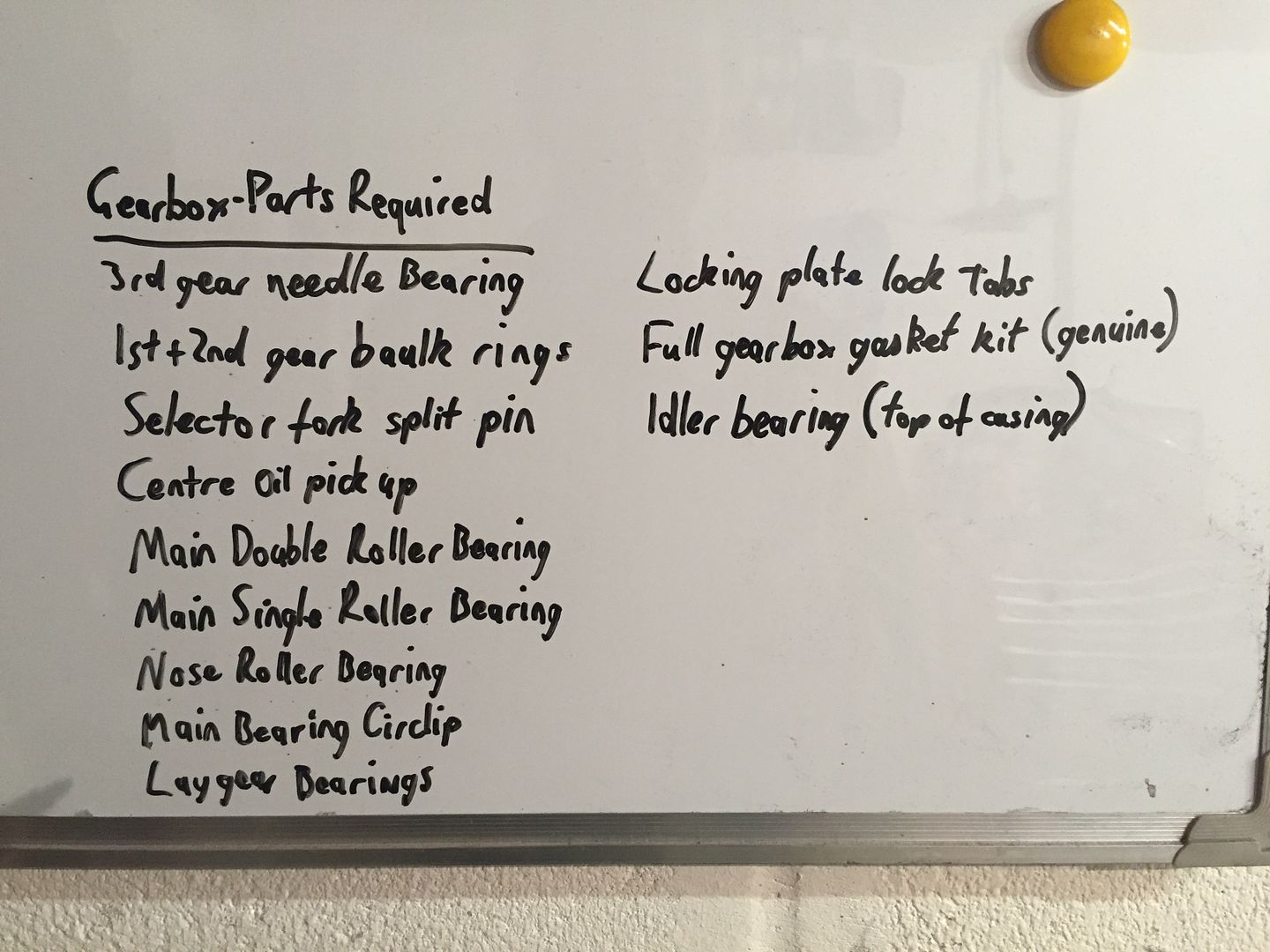

Gearbox - Struggles to stay in 4th gear and crunches into 2nd both up and down. So a rebuild of that will be required. Not going to go straight cut as Im not a fan of bleeding ears and they don't offer any benefit on a road car in my opinion.

Interior - Get nicer harnesses (thinking schroth or the likes) than the cheap crap Sabelt ones I fitted. Seats are nice but I really want a set of recaro Speeds. Had them in my old DC2 Integra and they were incredibly comfy but still enough of a bucket style to keep your arse in the right place. Get them retrimmed in diamond stitched alcantara to match the rest of the interior.

Carbon Fibre - Plan to get some bits and pieces carbon skinned too (no, not crap 'carbon' vinyl or just as crap 'carbon' hydrodipping) Looking at the column cowl, switch plinth in the dash, door caps, mirror plinths, rear view mirror, harness bar, air intake in the bay, carbon rocker cover and I'm sure a few other bits and pieces too!

Wheels - Been offered money for my current ones more than once and all offers have been above their original purchase price so I think they will get the heave ho for a set of Force Racing splits as I've lusted after a set for years but could never justify them.

All that in an even smaller single garage will be tricky but I'm up to the challenge as it can't be as tough as the rebuild was. Can't wait to get tinkering with cars again over winter again!

Needs a few bits and pieces doing to get it to a standard I would like..... so commence my inner thoughts and dreams! Obviously not all of this will be done by next year buuuut its a plan of everything I wanted to do to it but couldn't during the rebuild. I just need to get it roadworthy again to be happy for next year.

Engine/engine bay - Its a mess. Wires all over, various little leaks have stained parts and peeled paint. I want to strip everything out again and powder coat all ancillaries and update a few bits things with DSN Retrospect billet alloy parts. Wanting Minivation hinges too for a vertical lift bonnet for easy access. Exhaust is leaking slightly between manifold and link pipe so that needs sorted too. Superchargers are also highly interesting things.....

Suspension - Its harsh as hell and twitchy. Thinking of saving for Protech dual-adjust coilovers having read incredible things about them (plus they look epic and are designed and built in the UK). Until I can afford them though, I think an update with fresh cones will suffice. The GAZ shocks are designed for the lowered height but they are harsh even at 3 clicks from full soft which is a tried and tested setup. Also needs a new rear radius arm and wheel bearings on the back too. Crap wheel alignment (won't name and shame...) meant they got destroyed on the IMM trip last year.

Gearbox - Struggles to stay in 4th gear and crunches into 2nd both up and down. So a rebuild of that will be required. Not going to go straight cut as Im not a fan of bleeding ears and they don't offer any benefit on a road car in my opinion.

Interior - Get nicer harnesses (thinking schroth or the likes) than the cheap crap Sabelt ones I fitted. Seats are nice but I really want a set of recaro Speeds. Had them in my old DC2 Integra and they were incredibly comfy but still enough of a bucket style to keep your arse in the right place. Get them retrimmed in diamond stitched alcantara to match the rest of the interior.

Carbon Fibre - Plan to get some bits and pieces carbon skinned too (no, not crap 'carbon' vinyl or just as crap 'carbon' hydrodipping) Looking at the column cowl, switch plinth in the dash, door caps, mirror plinths, rear view mirror, harness bar, air intake in the bay, carbon rocker cover and I'm sure a few other bits and pieces too!

Wheels - Been offered money for my current ones more than once and all offers have been above their original purchase price so I think they will get the heave ho for a set of Force Racing splits as I've lusted after a set for years but could never justify them.

All that in an even smaller single garage will be tricky but I'm up to the challenge as it can't be as tough as the rebuild was. Can't wait to get tinkering with cars again over winter again!

Comment