Originally posted by ZammoTheChoppa

View Post

Originally posted by Daviticus

View Post

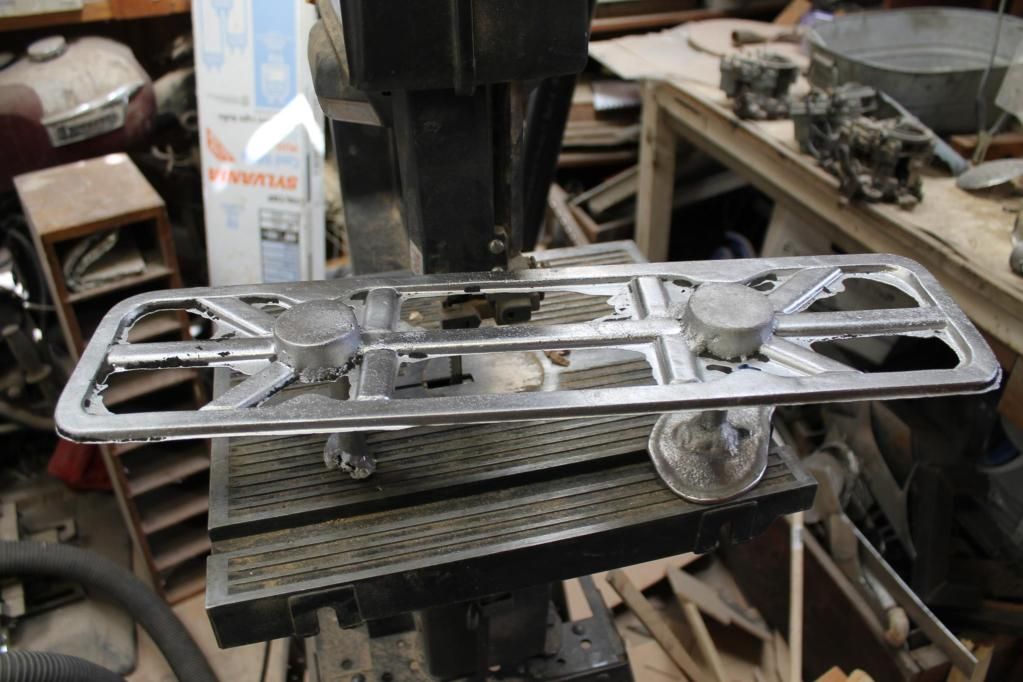

I ended up having to cut up my griffin radiator more, as it had the wrong o.d.'s and angles on the outlet and inlet, as well as a vapor accumulator fitting. So I spent the day turning fittings and welding them up. But now the cooling system is about done!

Comment