The world of air suspension is one full of intricacies, details, and a multitude of components; frankly, it requires a certain level of knowledge, understanding, and heaps of research in order to become wholly acquainted with. With companies offering bolt-on kits using air struts and air bags, achieving unparalleled levels of low has never been easier; however, the challenges that come with the set up can often be an intimidating barrier to entry for enthusiasts across the board. Today, with Air Lift Performance, we’re taking a look at the components that comprise the management side of an air ride system. From the parts that are required, to the luxuries of digital management as a whole, StanceWorks is here to explain the ins-and-outs of a complete air management system, and to prepare you for your first (or next) air ride system purchase.

We hope it goes without explanation that before anything else, you’ll need air struts or air bags for your car. A multitude of options exists, and thankfully, our friends at Air Lift Performance offer more bolt-on kits than anyone else in the industry. With those in hand, it’s time to decide how you want to manage them, hence “air management systems.” A number of options exist, with a few key differences and components denoting each type.

The simplest form of management and control is the classic “paddle valves” – manual control over air flow to and from each bag, front and rear, side to side, or all four, depending on your plumbing. While they’re simple, reliable, and cost-effective, they also offer no flair or convenience what-so-ever. The car’s balance is left in your own hands, and managing the system is up to you in every fashion.

Digital management, on the other hand, takes control of the air system, leaving you to enjoy the road, the car, or the benefits of air suspension without a second thought. Air Lift Performance’s latest take on digital management is their 3H system, which combines both height and pressure-based sensors, paired with a computer, to manage the suspension. A number of 3H’s components are equatable to other systems, some are universal, and of course, some are geared directly towards the 3H product. When building your own kit, or purchasing a complete system, it’s important to understand the parts that comprise it, and how they work together.

It’s likely easiest to start with the air tank and compressors: essential components found in every air ride system on the planet. Air tanks come in dozens if not hundreds of configurations, but their purpose is the same in every application. The air tank contains your air supply, used to raise and lower the car. Choosing the correct air tank requires some measuring – you want to ensure you have a place to install it, often in the trunk or spare tire well. Typically, the bigger tank you can fit, the better; a bigger air supply means running the compressors less often and in turn, gives you more air to use in adjusting your ride height. Tanks also vary in their number of ports – used to connect the air management system, air compressor, and other air tank accessories, like a shrader valve, a drain, or an air line hookup. You’ll want at least 3 ports if you’re running one compressor, and 4 ports if you’re running two. Too many ports is better than too few, as they’re easy to plug with a simple fitting. Lastly, tanks come in a few different compositions, most often steel and aluminum. Steel is stronger, but doesn’t resist corrosion from the water that can accumulate within the system over time.

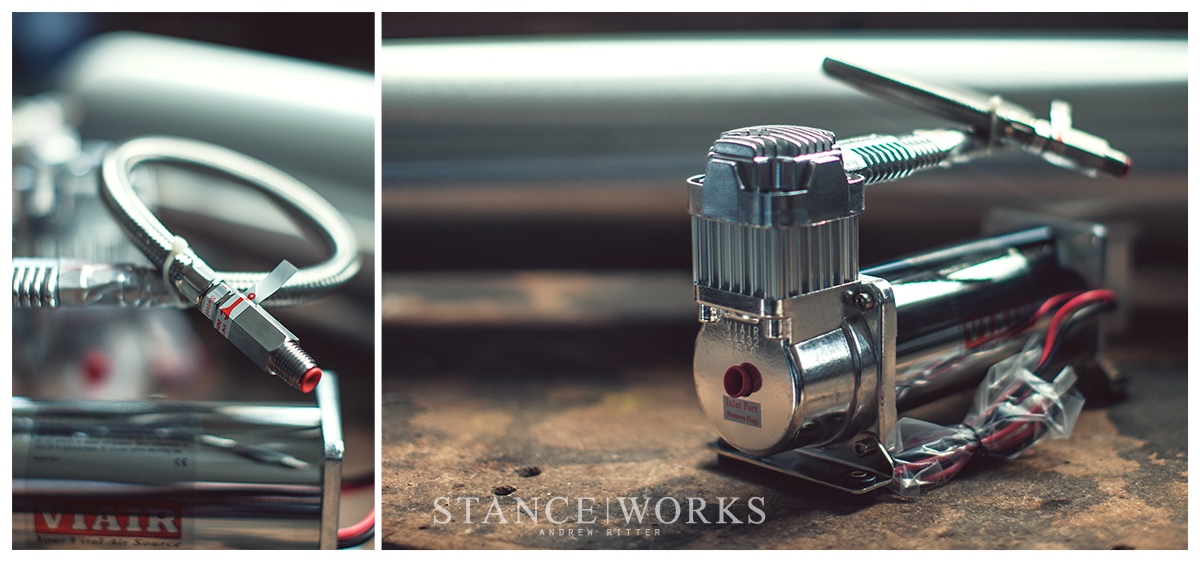

Air compressors will require a bit of research, as there are so many out there that they deserve an article of their own. Our 3H system came with two Viair 444Cs, one of Viair’s many options when it comes to compressors. 444Cs offer a 100% duty cycle at 100PSI, meaning you can’t harm them by running them continuously. For your application, it’s important to decide your needs: how often will you be adjusting your air suspension, how often will you air out completely, and how often will you use other air-powered accessories? A single compressor is more than adequate for most users – those who simply want to raise or lower their car “as needed.” For those who enjoy adjusting on the fly, carrying a varying number of people, or those who like to air out their car at any given chance, two compressors is undoubtedly the better option. Some even opt for 3 or 4.

Another group of parts important to any air ride management install is air line and fittings. Air line size is often debated – some prefer small line which slows the rise and fall of the car, for that classy, stealth style. Others prefer bigger lines, which will earn you that quick clack of frame-rail-on-asphault, and will hop the car back up to ride height almost instantly, although often with less precision. The choice is yours, and yours alone! As both will function similarly, it’s entirely preferential, and more often than not, all about style. Fittings are needed to mate the air lines to the bags and the components of the management system: the tank and the manifold or switches. Usually, a few T fittings will do the trick, and most air install kits will come with everything needed to plumb your car – but you may wish to order some other fittings to tailor the system to your needs. If your schedule allows, it’s often best to install your air ride components, and route your lines. Order or buy your fittings after you’re sure of what you need.

When it comes to digital management, there are a number of “brains” on the market, all capable of controlling and managing your air ride to varying degrees. Most entry-level systems utilize pressure-based height control, most famously with Air Lift Performance’s previous “V2” management. Pressure-based control makes installation a breeze – there’s no sensors to mount and no math required – however, the yielded results are far less refined than height-based alternatives. The idea behind pressure-based control is simple, though. The computer monitors the pressure in the system at each corner. If the pressure changes, the computer sends more air, or releases some, to return to the established pressure. With the ride height set by pressure, things such as additional passengers or luggage can still cause lower ride heights than intended, but things such as leaks in your system will still be countered by the management.

Some systems operate with height-based sensors, which utilize small sensor armatures mounted between moving suspension components and the body. This type of control offers precise inputs, and yields a better end-result, but at an extra cost (both monetarily and physically, via install.) Instead of adjusting to match preset air pressures, heigh-based systems adjust to keep the car at a given ride height. Adding passengers or a load in the trunk will have no visible affects: the system simply compensates, and adjusts the air pressure to return the car up or down to the preset ride height. Beyond that, the 3H system utilizes both height and pressure based control together, and it does so seamlessly, offering an unparalleled level of control for your bagged car. The 3H’s manifold and computer are housed in a single unit, simplifying installation as much as possible. As you piece together your digital air management system, decide what system works best for you. For those looking for the best management possible, we’d struggle to suggest anything but the 3H. For those on a budget, the 3P by Air Lift Performance is a solely pressure-based alternative.

For those that decide to venture into the arena of height-based management, you won’t regret it. However, it’s important to familiarize yourself with the necessary components. Height based systems use height sensors, as seen above. Mounting them will require a bit of fabrication, although we’re confident most readers can do the job with a bit of ingenuity and elbow grease. In fact, you can see our install write-up for a bit of help. The sensors, one for each corner, are mounted to the car’s body or chassis, and will need room to move through their full range. Air Lift Performance provides four easy-to-modify linkages to mate to the sensors. The other end will need to mount to the suspension components of your choice (control arms, strut housing, axle links, or others.) From there, simply route the supplies harnesses to each corner, plug in, and the computer will handle the rest.

The final major component in the mix is the controller. Every digital management system offers its own solution – sometimes they take form in simple key-pads, and sometimes they offer touch screens and full read-outs. Rarely are options plug-and-play from manufacturer to manufacturer, so your choice in digital management will decide your resulting controller. Air Lift Performance’s 3H controller offers 5 presets, individual corner control, a color display with active 4-corner height and pressure readouts, and a slew of other nuances that make for an impressive system. Additionally, the 3H works seamlessly with the iPhone and Android for remote control. Your experience from system to system will vary, but these days, almost all digital management systems offer the ability to define preset ride heights, such as aired out, “show low,” “daily driving,” and “take mom for a ride” presets. Presets are perhaps one of the biggest draws to digital management, along with computer-controlled adjustments and out-of-sight out-of-mind operation.

Believe it or not, that’s just about all there is to it. There’s nuances and details, but you should be well on your way to building or purchasing the perfect air management system for your car. So, get to planning, or saving – you’ve got a tank layout to solve and goodies to buy.