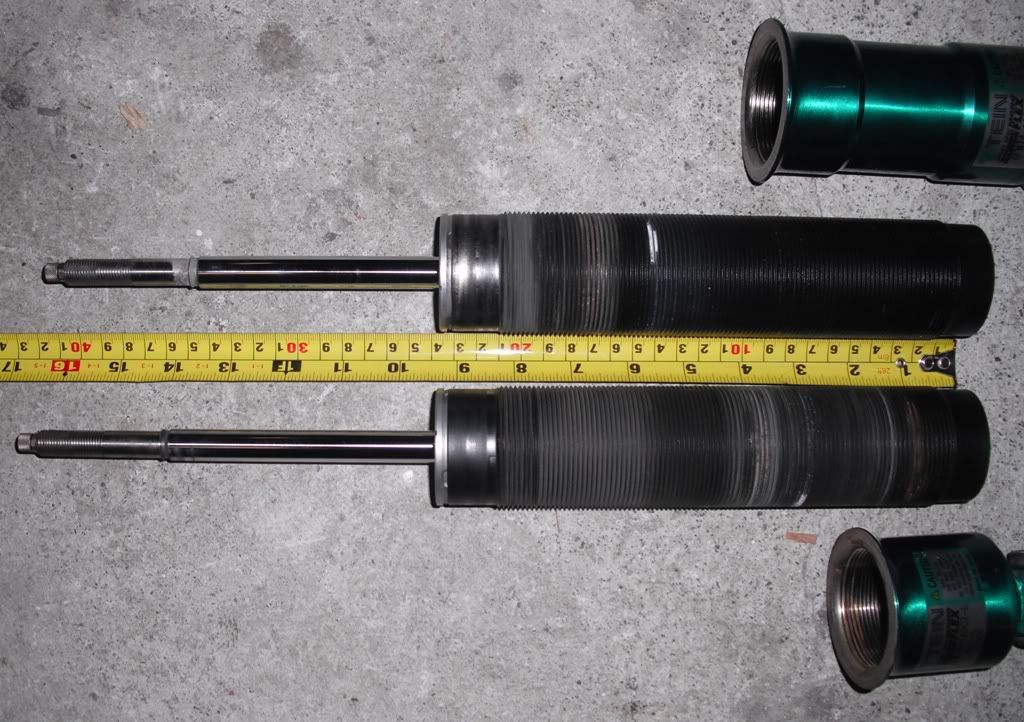

Its been a while so I thought id do another update. Due to the stupid laws around custom built suspension in NZ, I've been held up for a few months with getting approval for my new designs for the front end and also I had to re-do the threaded inserts.

Basically, because the inserts that were made could only be welded 90% of the circumference of the tube (due to space limits on one side the welder physically couldnt get in there), it was rejected by the certifier (they must have a 360 degree weld and full x-ray test to prove the quality of the weld). The new setup has been made so that it presses in where the original shock tube goes, but is actually inside the cut-down shock tube (rather than replacing it). There is a rule here that says it is illegal to weld to any cast/forged suspension components (even though the original design did this). What I've done is to convince the certifier that I have had the insert welded to the original tube, not to the casting. Rediculous, I know, but welding to weld is legal and welding to a casting is not...

the stupid thing about the new setup (other than having to do it twice) is that there is actually less weld on it now than the old one!

on the plus side, the new setup allows the shock to be mounted another 10mm or so lower, and i think they look better (almost oem?)

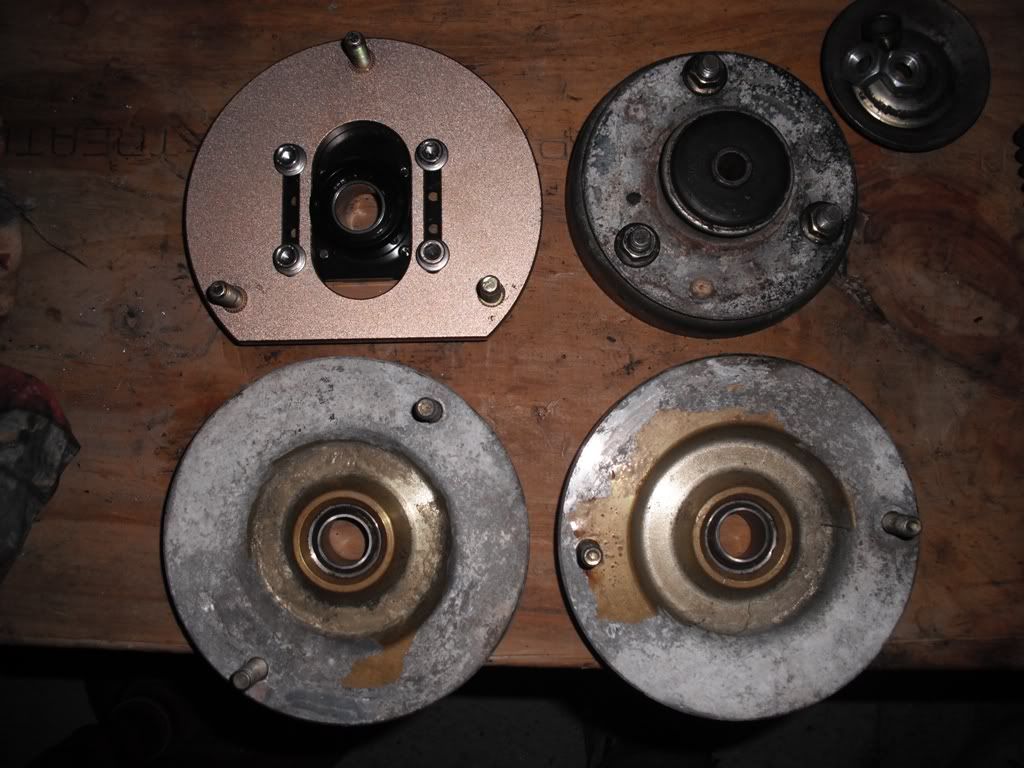

and in other news, heres where my wheel build is up to... (the rears)

im gonna do the centres black (or the 'centers' for my american friends...

)

)

)

)

Leave a comment: