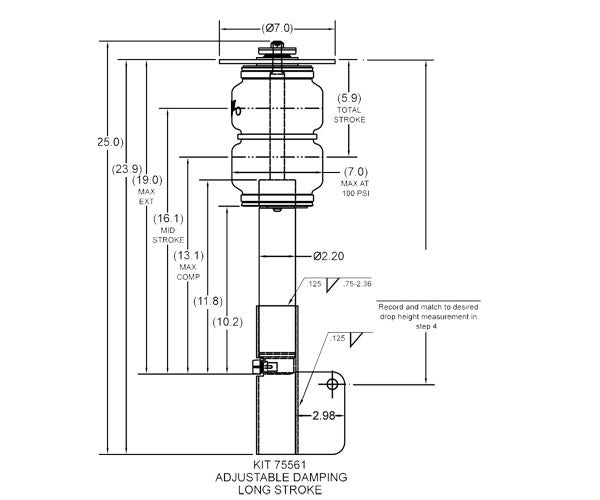

So I'm bagging two BMW's here pretty soon, a friend's 1972 Bavaria and a 1973 2002. We are both using the Airlift 75561 Universal Struts for the front. Upon reading a few write-ups regarding the universal struts, I have a few questions.

All the write-ups mention that you should measure where you want full lift or aired out to be and weld from there. That makes sense to me, but none of them mention any sort of modification to make it all line up. For instance, the "sleeve" that is supplied has the rectangular cutout for the dampening adjuster knob on the strut assembly. Since it is crucial for those two to line up, doesn't that mean that in order to get a specific overall length of the assembly when everything is welded up, then the sleeve would either need to be shortened or lengthened appropriately to achieve that given length? It seems in every write up, they just weld the sleeve on as it came out the box and everything works fine. There is no mention of modifying that sleeve. It seems so simple to me, I just want to make sure I'm on the right track here.

Also, when the bag is at max lift, does it physically look the same as how it looks right out of the box? Meaning when the assembly has no weight on it whatsoever, is it appropriate to use that as your "max lift" measurement? Might be a confusing question, I'm just not sure if the bag extends more once air is involved.

Is it better to measure from an "aired out" or "full lift" standpoint?

Any help would be appreciated.

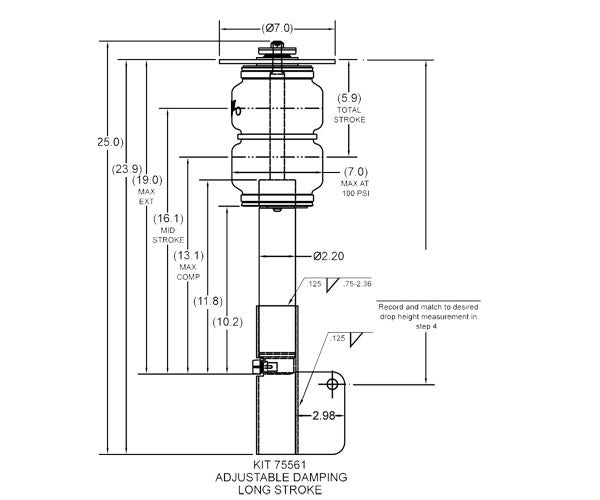

All the write-ups mention that you should measure where you want full lift or aired out to be and weld from there. That makes sense to me, but none of them mention any sort of modification to make it all line up. For instance, the "sleeve" that is supplied has the rectangular cutout for the dampening adjuster knob on the strut assembly. Since it is crucial for those two to line up, doesn't that mean that in order to get a specific overall length of the assembly when everything is welded up, then the sleeve would either need to be shortened or lengthened appropriately to achieve that given length? It seems in every write up, they just weld the sleeve on as it came out the box and everything works fine. There is no mention of modifying that sleeve. It seems so simple to me, I just want to make sure I'm on the right track here.

Also, when the bag is at max lift, does it physically look the same as how it looks right out of the box? Meaning when the assembly has no weight on it whatsoever, is it appropriate to use that as your "max lift" measurement? Might be a confusing question, I'm just not sure if the bag extends more once air is involved.

Is it better to measure from an "aired out" or "full lift" standpoint?

Any help would be appreciated.

Comment