Announcement

Collapse

No announcement yet.

homemade DIY split-rims

Collapse

X

-

Thanks mates, currently i'm sick of all wheelpolishing, but you do help me!

Three of'em are now ready. I'm doing these slowly... that's my trademark The reason is that i buy a car that i will never sell so i have all time in the world.

The reason is that i buy a car that i will never sell so i have all time in the world.

i have 2 other wheelprojects going on too......

Leave a comment:

-

Looks great. Seems like you know what you're doing too. Can't wait to see this when done.

Leave a comment:

-

It shows that you have done your research.. Will be amazing once finished.. Cant wait to see them finished and on the car. No pokemon shit steppin up!

Leave a comment:

-

love this project. great work!! the possibilities are endless when thinking about doing this to certain wheels.

Leave a comment:

-

No no i used a Hacksaw Joke

Joke  actually with structural bond they will be stronger than the stock rim

actually with structural bond they will be stronger than the stock rim  But i have to keep it in my mind that these are 70's wheels and are made for lesser stress and wear compared to modern wheels. As long i have them on my old boulevardcruiser, so it won't be a problem.

Last edited by Sergey; 07-05-2010, 09:47 AM.

But i have to keep it in my mind that these are 70's wheels and are made for lesser stress and wear compared to modern wheels. As long i have them on my old boulevardcruiser, so it won't be a problem.

Last edited by Sergey; 07-05-2010, 09:47 AM.

Leave a comment:

-

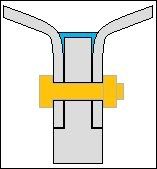

Wow, I didn't see that you were going with a milling machine to cut off the existing barrels. Since that's the case, I see no reason to believe that these won't work. It's not like you're adding new stress points.Originally posted by Sergey View Postwhat, no eye measurements are used ... rimrings aren't hanging in the air. They are milled in in the centerpiece, even the spokes had to be milled couple millimeters (flush mount? look the pic i drew)

... rimrings aren't hanging in the air. They are milled in in the centerpiece, even the spokes had to be milled couple millimeters (flush mount? look the pic i drew)

and has less than 0,2mm tolerance to fit the rimrings in. BBS RS rimrings are manufactured to the same tolerance. It is a snug fit and i had to use rubbermallet to get the rimrings to the bottom. Three of them are perfectly balanced with 5-10g weights and one has 35g and that one has a welded crack on it... actually we managed to do two of these perfectly round and two shows some eccentric wobbling by micrometer, about 0,22mm if i remember right.

Leave a comment:

Leave a comment: