Originally posted by toyomatt84

View Post

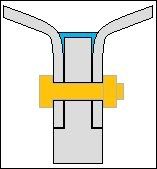

... rimrings aren't hanging in the air. They are milled in in the centerpiece, even the spokes had to be milled couple millimeters (flush mount? look the pic i drew)

... rimrings aren't hanging in the air. They are milled in in the centerpiece, even the spokes had to be milled couple millimeters (flush mount? look the pic i drew)

and has less than 0,2mm tolerance to fit the rimrings in. BBS RS rimrings are manufactured to the same tolerance. It is a snug fit and i had to use rubbermallet to get the rimrings to the bottom. Three of them are perfectly balanced with 5-10g weights and one has 35g and that one has a welded crack on it... actually we managed to do two of these perfectly round and two shows some eccentric wobbling by micrometer, about 0,22mm if i remember right.

Originally posted by *96tegls*

View Post

EDIT... it seems that Some Lorinser, AMG and BBS LM rims has 1/4" thick mountingface too. material grade is the same.

Leave a comment: