can you please post STEP BY STEP how u did this ?

i want to do this on my w126

i want to do this on my w126

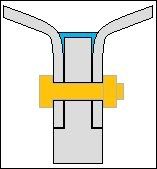

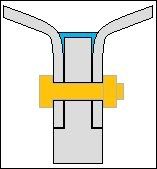

... rimrings aren't hanging in the air. They are milled in in the centerpiece, even the spokes had to be milled couple millimeters (flush mount? look the pic i drew)

... rimrings aren't hanging in the air. They are milled in in the centerpiece, even the spokes had to be milled couple millimeters (flush mount? look the pic i drew)

... rimrings aren't hanging in the air. They are milled in in the centerpiece, even the spokes had to be milled couple millimeters (flush mount? look the pic i drew)

... rimrings aren't hanging in the air. They are milled in in the centerpiece, even the spokes had to be milled couple millimeters (flush mount? look the pic i drew)

Joke

Joke  actually with structural bond they will be stronger than the stock rim

actually with structural bond they will be stronger than the stock rim  But i have to keep it in my mind that these are 70's wheels and are made for lesser stress and wear compared to modern wheels. As long i have them on my old boulevardcruiser, so it won't be a problem.

But i have to keep it in my mind that these are 70's wheels and are made for lesser stress and wear compared to modern wheels. As long i have them on my old boulevardcruiser, so it won't be a problem.

Comment