Originally posted by extol1337

View Post

Announcement

Collapse

No announcement yet.

Widening rims?

Collapse

X

-

Originally posted by Zic View PostDo you guys know where I could get inner and outer barrels for a reasonable price?Originally posted by Hillbilly View PostBut it's the rim that he's interested in widening. I'm usually with you on the wheels/rimz thing, but here I believe it's appropriate. somewhere on teh webz is a guy that has made a set of bottlecaps into a 3piece, he had an industrial machine shop cut the barrel and lip off and then drill it so he could bolt aftermarket lips/barrels. dopeness followed.

edit: found 'em

Like I said, dopeness.

The more I read into this diy multipiece wheel the more do-able it seems1990 Mercedes 300CE- 24 valve

Comment

-

in that thread didn't the guy have an industrial machinist do the cutting, drilling and machining on very large/expensive equipment? Not exactly my definition of diy...Originally posted by conski View PostThe more I read into this diy multipiece wheel the more do-able it seems

Originally posted by Sergey View PostThanks! Many have security concerns and no doubt it might be an issue. my friend who is maritime engine engineer working at local ship engine metalworks (thanks for lending the mill) made some calculations that showed it would hold. The orginal made by ATS for Mercedes-Benz wheels are forged wich played a major part in this project. Cast wheels wouldn't hold.

I will glue the rimrings with structural bonding so they aren't quite split after that.

For a curiosity the mountingface is 7mm thick (just over 1/4") wich actually is 3-4mm thicker than the thinnest point on the stock ATS wheelbarrel (they are really light). I have had some japanese forged 15" wheels wich mountingface have been only 1/4" what was actually the main reason why i did continue this.

EDIT: and if the glue fail, then i will weld the rear barrel solid, so they will be 2pc wheels with greater failmargin.

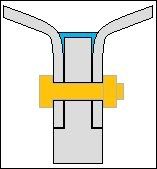

Originally posted by Sergey View Postwhat, no eye measurements are used ... rimrings aren't hanging in the air. They are milled in in the centerpiece, even the spokes had to be milled couple millimeters (flush mount? look the pic i drew)

... rimrings aren't hanging in the air. They are milled in in the centerpiece, even the spokes had to be milled couple millimeters (flush mount? look the pic i drew)

and has less than 0,2mm tolerance to fit the rimrings in. BBS RS rimrings are manufactured to the same tolerance. It is a snug fit and i had to use rubbermallet to get the rimrings to the bottom. Three of them are perfectly balanced with 5-10g weights and one has 35g and that one has a welded crack on it... actually we managed to do two of these perfectly round and two shows some eccentric wobbling by micrometer, about 0,22mm if i remember right.Last edited by Hillbilly; 11-15-2010, 02:20 PM.

Comment

-

I meant if you had those kind of connections, sorry should have been more clearOriginally posted by Hillbilly View Postin that thread didn't the guy have an industrial machinist do the cutting, drilling and machining on very large/expensive equipment? Not exactly my definition of diy...1990 Mercedes 300CE- 24 valve

Comment

Comment