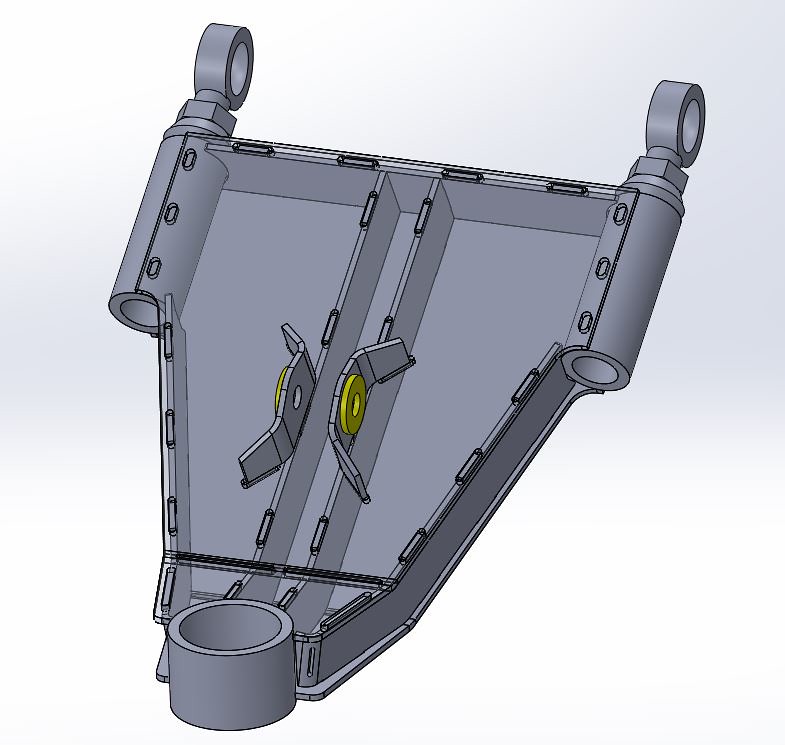

The upper arm should be right at 10 pounds for the weldment, plus a little bit more for the uniball bearing and the ball of the heim joints. Upper arm design:

Exploded view:

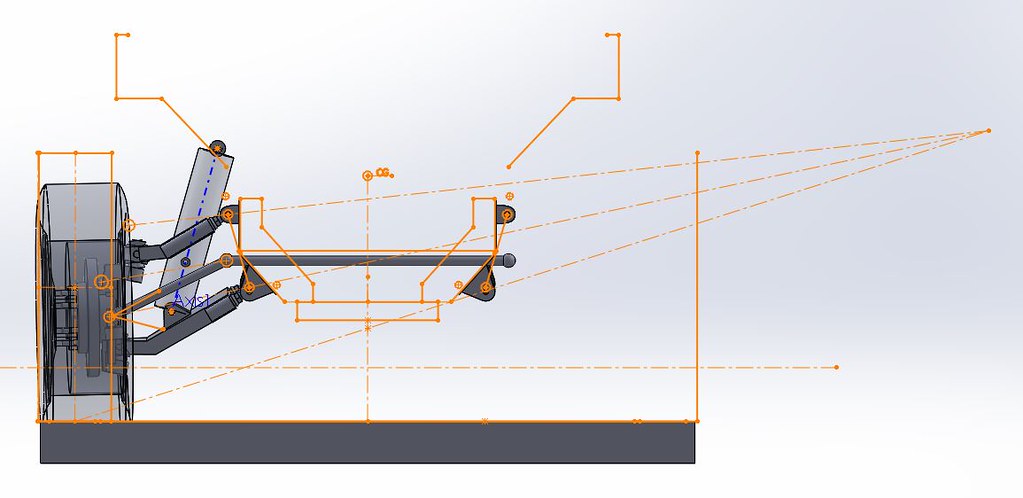

The lower arm is right around 15 pounds. Lower arm:

Exploded:

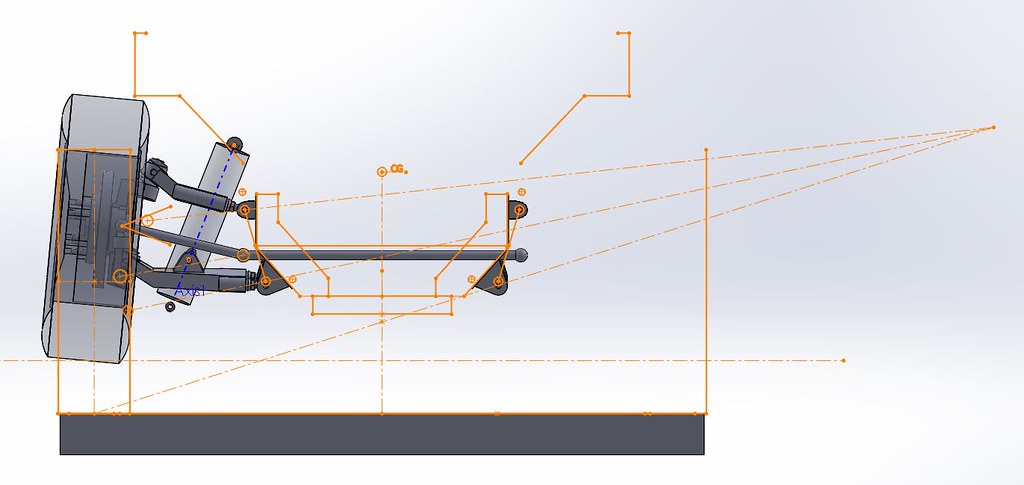

And I also ran a little FEA simulation on a simplified model of the lower arm. The test shown here is at 2000 pounds force at the shock mount, but peak force at end of travel will be something close to 3200 pounds.

And here's both arms together:

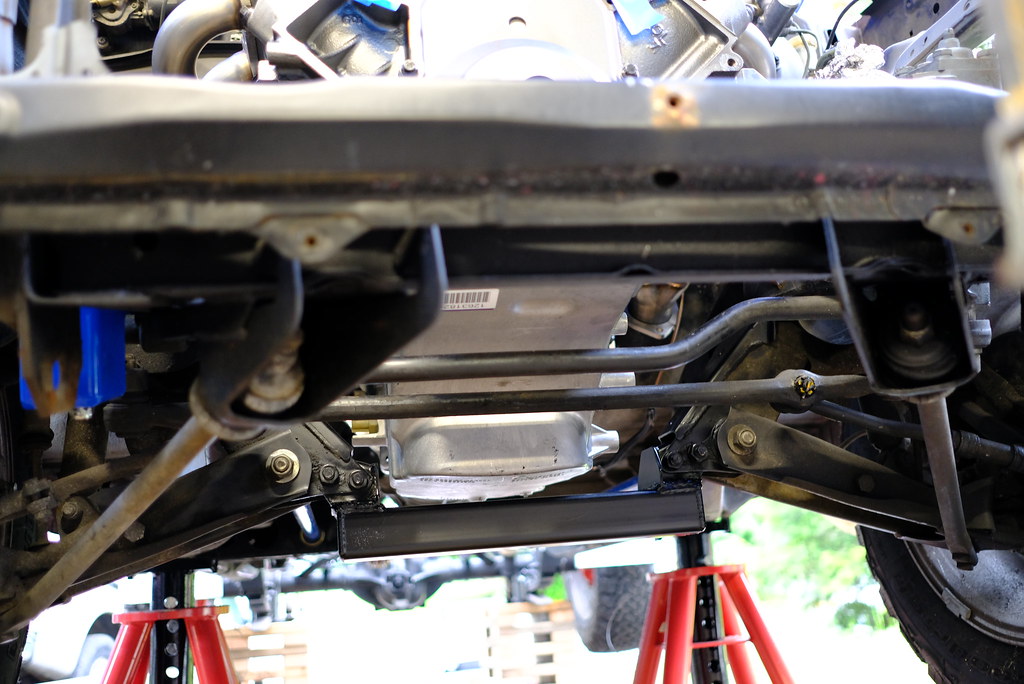

And I played around a little bit with nesting the parts for cutting. Basically an upper lower pair worth of parts fits on a 48x16 sheet.

I sent these drawings off to a laser cutter yesterday, and hopefully I'll have parts next week sometime.

Leave a comment: