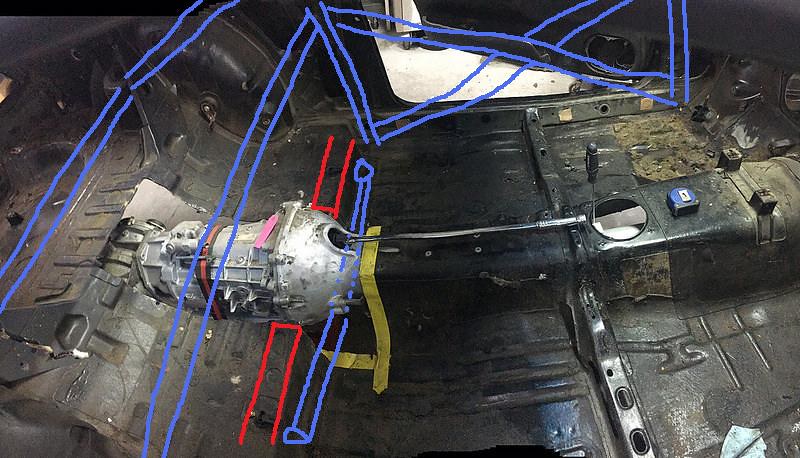

Alright. The problem is when i cut the floor to gain clearance for the corvette transaxle i had to cut through a crossmember just aft of the center of the car. Would be a big no no to not reinforce this as if i were to get t-boned the floor would just crumple without the support.

Biggest issue with adding support back in was how the transaxle sits. It sits above and below the crossmember. So just welding in a much thicker steel single layer plate isnt an option as it would have to bend to go around it.

Second issue is exhaust clearance. I could run a DOM tubing piece from frame rail to frame rail underneath the transaxle, while still having sufficient ground clearance, but then i have zero room to run the exhaust.

So here is my theroized solution, provided there is enough room. When i first bought the car i mocked up my Varis side skirt of my 2012 wrx that i was parting out, just for shits and giggles. turns out, i should be able to integrate it nicely with my widebody plans and helo give the car that gt300 style look im after even more so.

The sideskirt, along with the front bumper i plan to run hang a little bit lower than the pinch weld. So what im thinking, is run the piece of dom tubing laterally from frame rail to frame rail like mentioned before, and run a side exit exhaust, through the side skirt. The added depth of the side skirt will allow me to not just have a exhaust pipe hanging down, and i dont have to worry about snaking an exhuast around the crossmember reinforcement. Running the welded in DOM tube connecting the frame rails also allows me to tie it into the cage, for more added rigity.

And side exhaust are badass. Will def exit out the passenger side and passenger side only. I enjoy my hearing, my passengers can get over it. Now lets just hope the wife doesnt divorce me over it.

IMG_2546 by lawrx, on Flickr

IMG_2546 by lawrx, on FlickrHere is a shot of the side skirts mounted on an sti.To give an idea of what they look like

sti side skirts by lawrx, on Flickr

sti side skirts by lawrx, on FlickrAnd of course, my mad paint skills depicting what im saying again.

side exhaust diagram by lawrx, on Flickr

side exhaust diagram by lawrx, on Flickr s13 roll cage by lawrx, on Flickr

s13 roll cage by lawrx, on Flickr

Leave a comment: