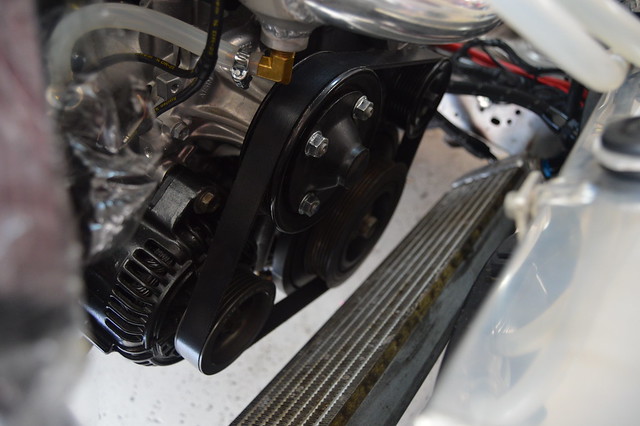

For sake of time and money i ordered this PS delete kit from driftmotion and got that installed.

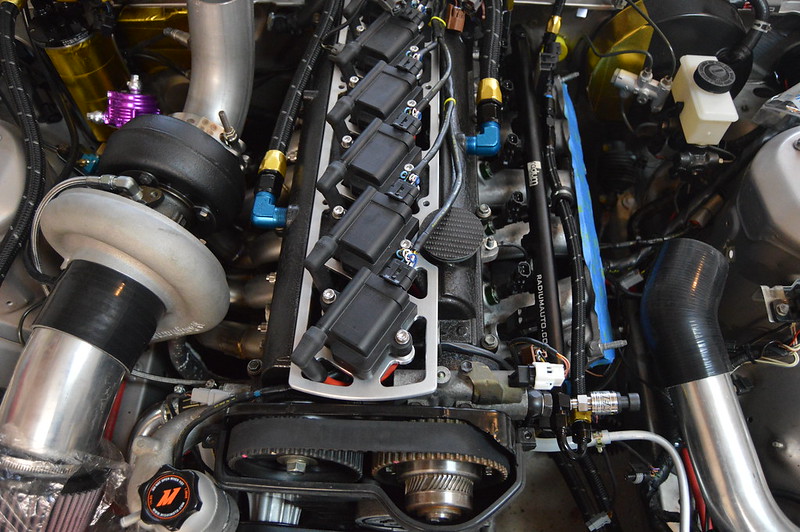

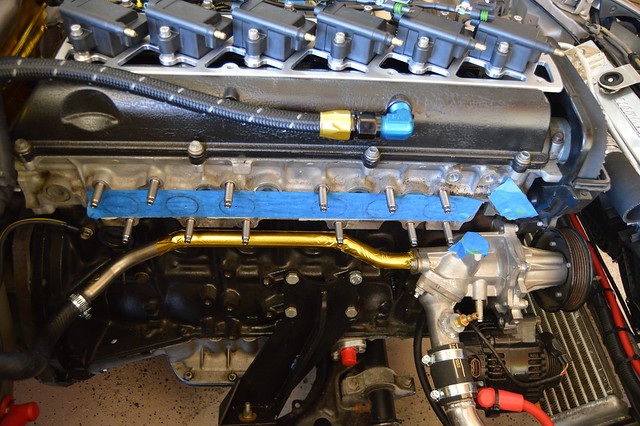

Ordered heat range 7 plugs and gapped them accordingly. installed plug wires and finalized ignition system install.

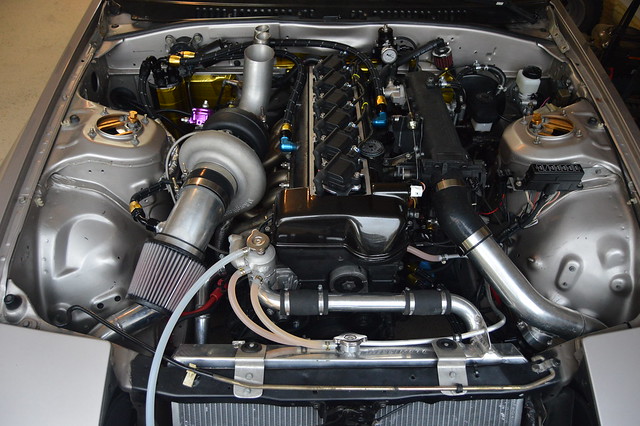

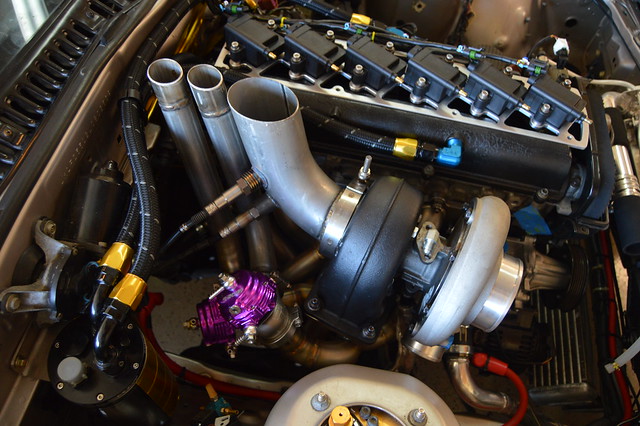

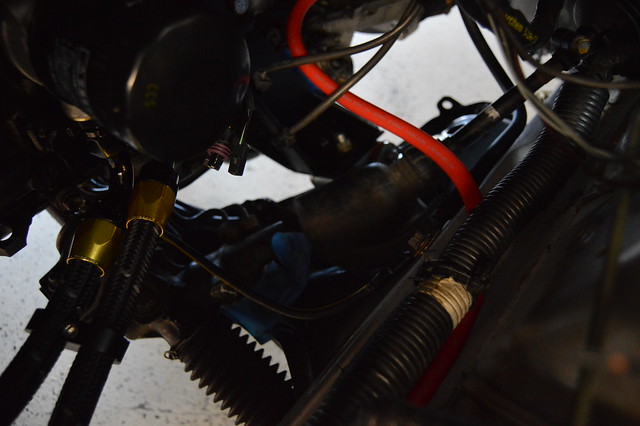

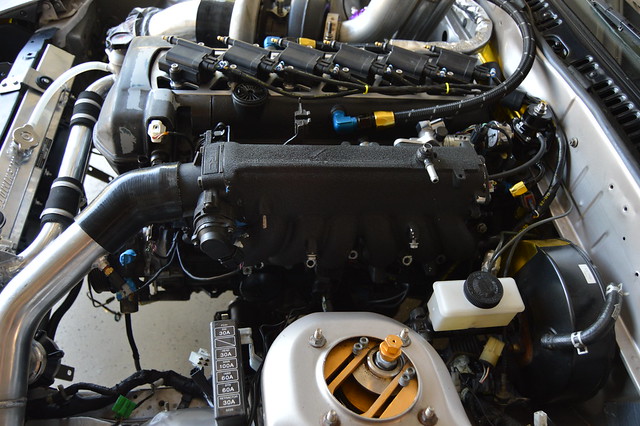

Finally fully plumbed, wired, and awaiting fluids.

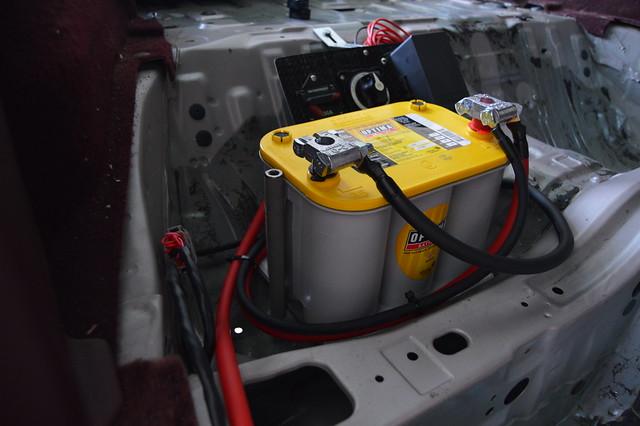

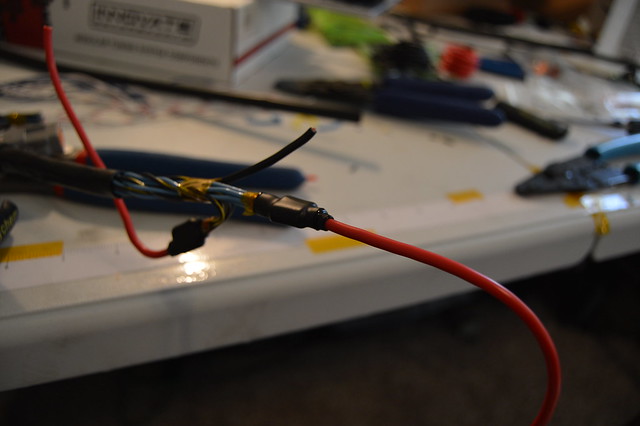

Also ended up switching last minute to AEMs new E85 320lph pump due to struggling to fit the 044 and the looped line into the tank. I ended up not being able to fit the 044 inside the sump chamber at the bottom of the tank, and during that ended up kinking the PTFE line. Ordered up this AEM and rewired the pump and got everything installed. This AEM actually flows more than an 044 and is also more consistent throughout higher fuel pressures per Dsports fuel pump shootout.

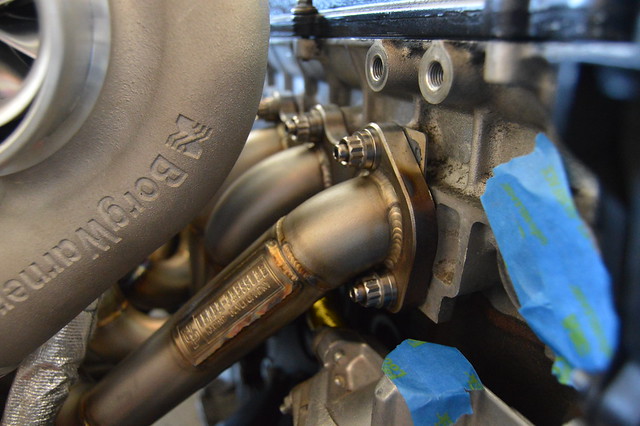

After installing the pump i primed my fuel system to flush the lines and found a large fuel leak at the number 1 injector. Havent torn it down yet but it appeared to be coming from the O ring which seals the top of the injector to the adapter which then inserts into the rail. Figures out of all the fuel fittings i have assembled the only thing that leaks is what i did not check. I actually never bothered to check those O rings or even remove the adapters.

Fuel leak was caused by drift motion using copper crush washers on ORB fittings. I had them really things tight but they still leaked and i also didnt like how the plug on the rail protruded 60% into the bore of the rail. Radium rail installed and this thing is badass and such a high quality piece. injectors got all new O rings as well.

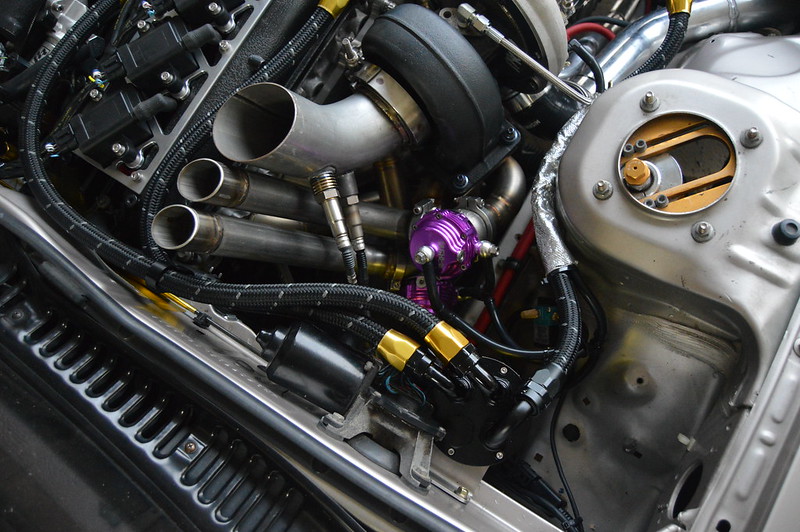

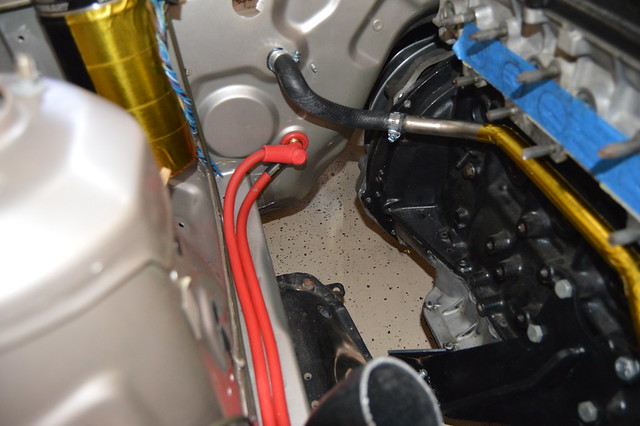

Last plumbing work was for the wastegates. I wanted to keep it tidy and got the job done using 3 tee fittings. May rework it to shorten lines a little more if possible. this is set up per AEM recommendation for max boost/ response and to run spring pressure when EBCS is off.

[img width=800 height=532]https://farm5.staticflickr.com/4649/28250328849_137cbb8f90_k.jpg[/img]

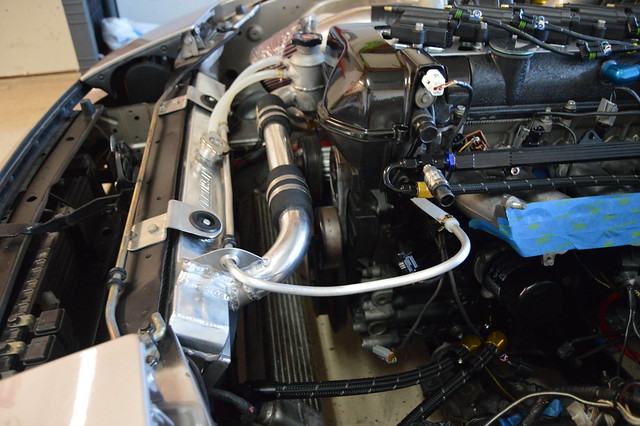

Realized how expensive t bolts/ constant tension stuff was but read through a bunch of reviews and found a great deal on these t bolts on amazon.

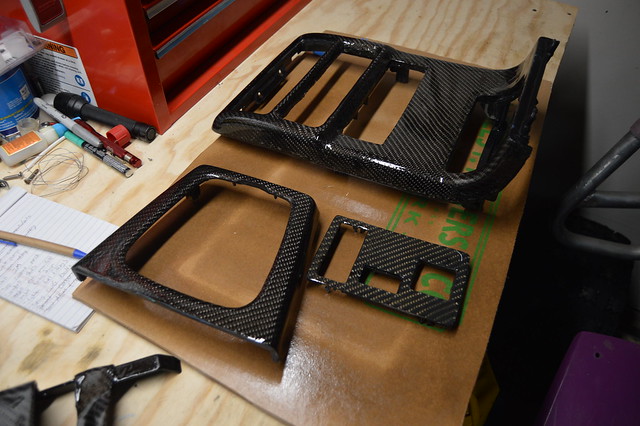

[img width=800 height=532]https://farm5.staticflickr.com/4627/28250328469_0f86d33594_k.jpg[/img]

Grabbed my FTPs when i was home for the holidays as well and threw them back on. I like this look again

[img width=800 height=532]https://farm5.staticflickr.com/4716/25158443807_b3fdbf7221_k.jpg[/img]

I wanted to update this with some info on the last pieces for anyone referencing this thread. As stated earlier, after smoothing out some cold starts and idle tables on the tune, we noticed that my throttle % would read negative when snapping the throttle. Turns out the used manifold i bought to delete the aristo DBW throttle had a 2JZ GE TPS sensor installed which rotates backwards. I have a new sensor on order but it wont be here until next week.

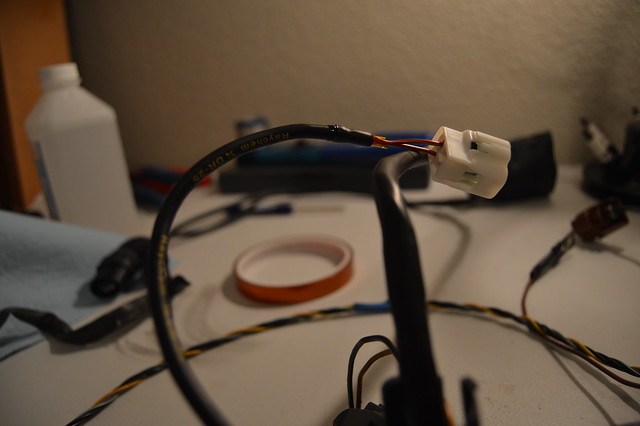

For a throttle cable, i bought a $22 FD RX7 cable from summit and cut the throttle end off and then cut the cable to length. After i did this, i crimped the threaded housing end back onto the cable and then used a set crew type cable end lug. This worked well as the firewall clip and throttle pedal clip were all the same as the OEM cable.

For a driveshaft, i had a custom one made by a local shop - fort worth gear and axle. total distance between output shaft and pinion flange was 34-7/16". Most driveline shops order slip yokes/ flanges from powertrain industries and for a CD009 you will need a 3503-323 slip yoke and the turbo II pinion flange 2602-41. For reference, i am using a TII housing with a Kaaz 1.5way LSD. An 8.8 kit with gearing to match the CD009 is on the list. I already have a complete 8.8 LSD waiting for me to pick up.

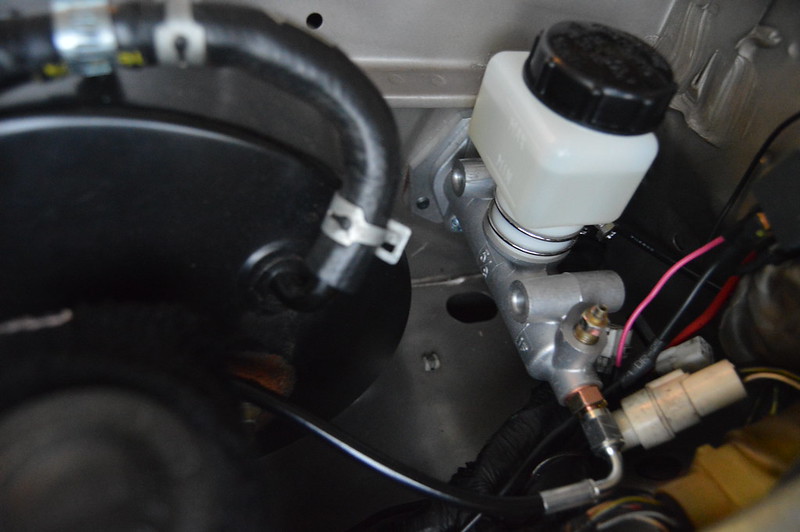

Clutch setup is an ACT sprung 6 puck 350Z clutch on the collins kit with flywheel. I used the 350Z slave cylinder with the 350Z OEM sized master cylinder from Wilwood in 5/8. Stu kelley firewall adapter and trimmed Mazda clutch pushrod. I had a custom clutch line made by chasebays @ 33" length.

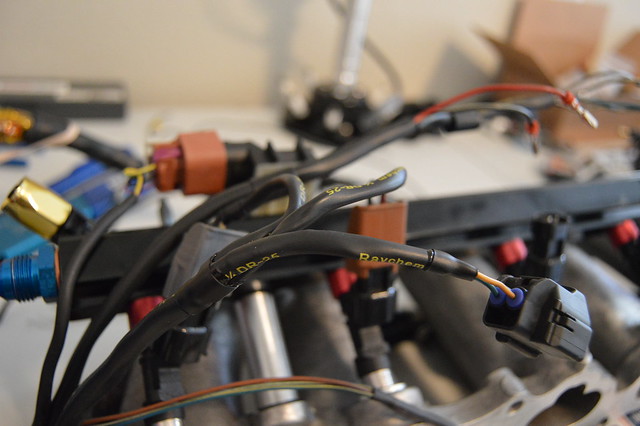

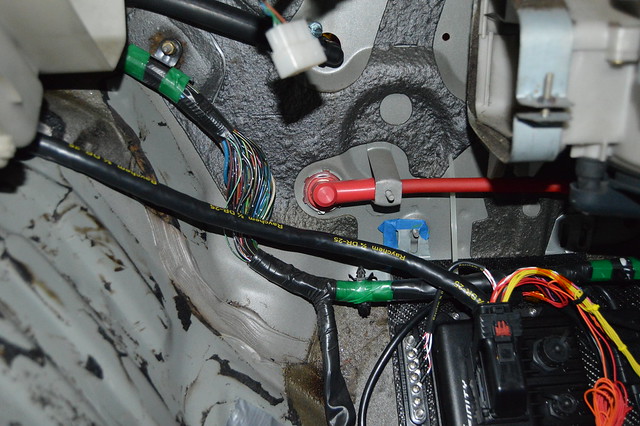

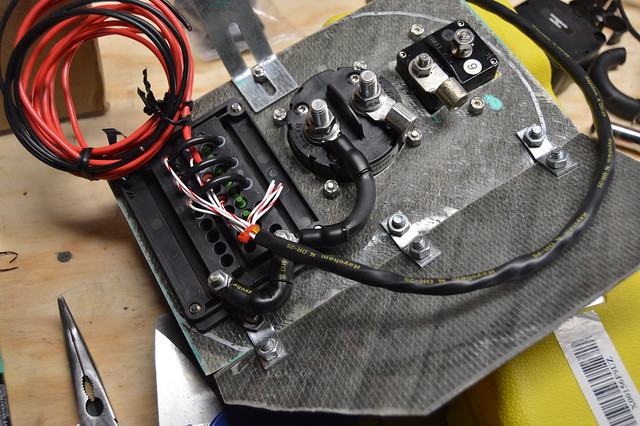

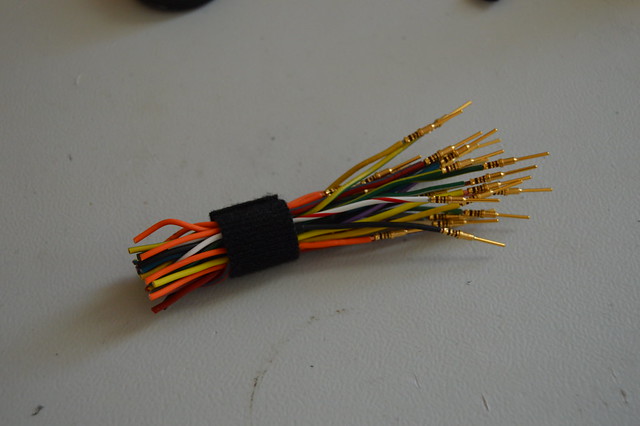

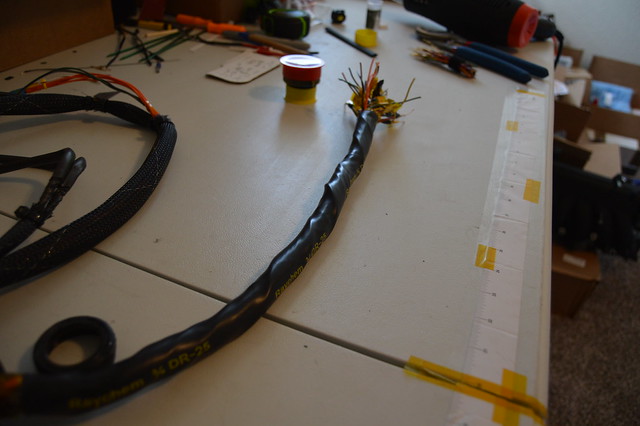

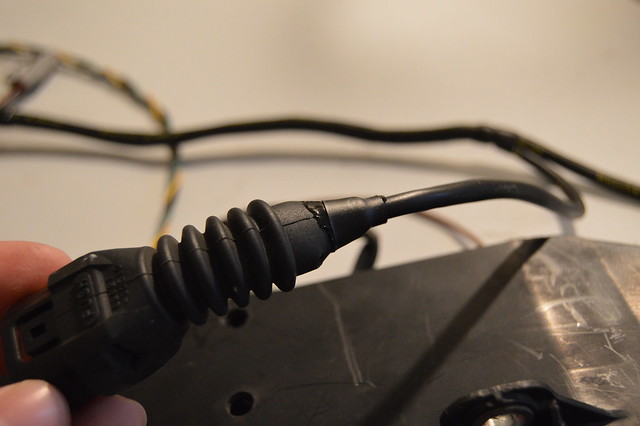

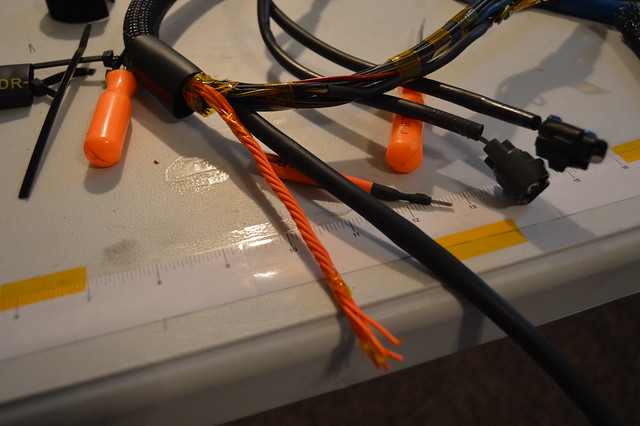

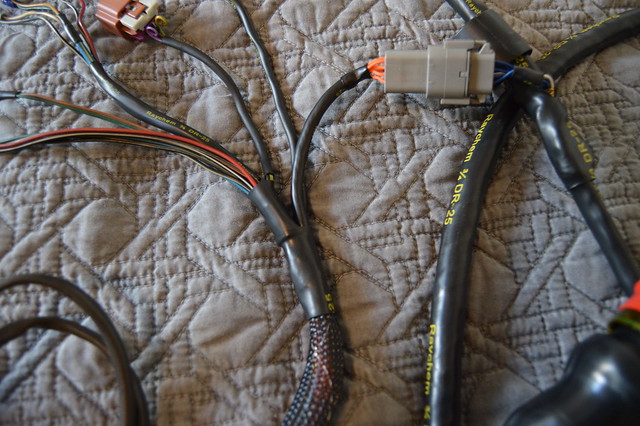

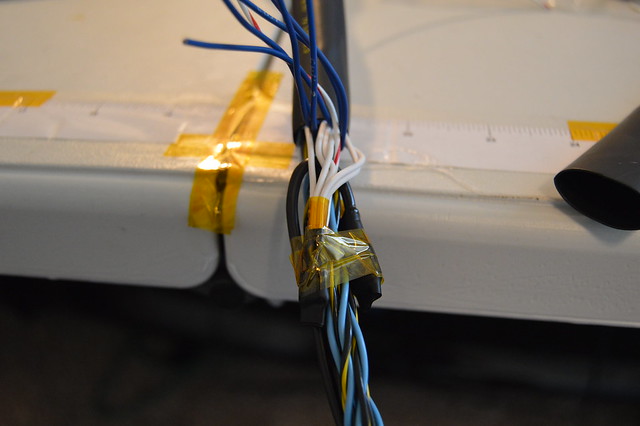

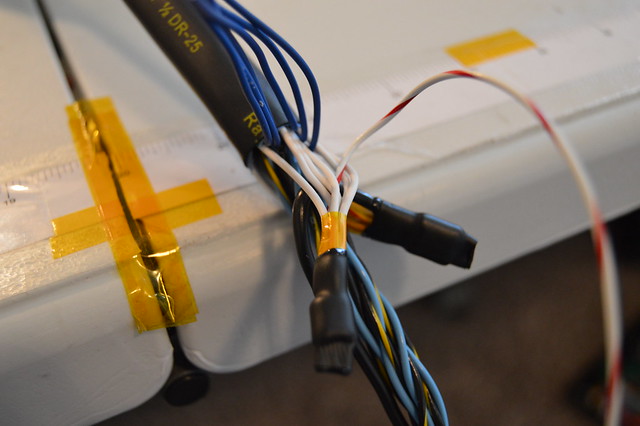

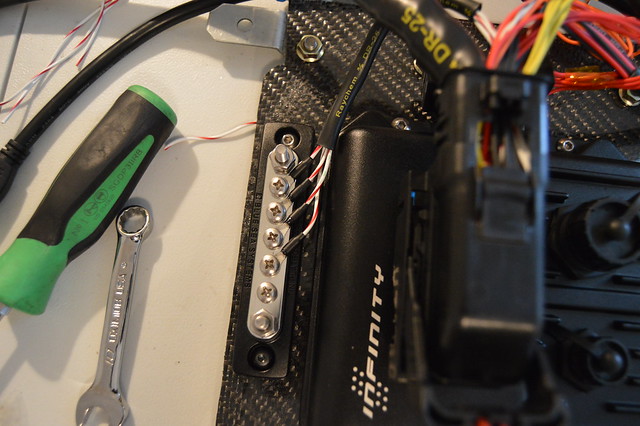

I did have some issues with voltage drop from the Mazda chassis wiring i tapped into in the engine bay. I ended up adding 2 additional fuses to the mazda underhood fuse box using terminals i harvested from other connectors. I then ran 2 relays underhood to supply power to the VVTI, IAC, and injectors. The other relay feeds the cooling fans to reduce any voltage drop from the relaybox mounted in my passenger cubby.

I will be mounting tires soon and will be running Falken Azenis RT615K+ in 225/40/18 in the front and Nitto NT01s in the rear @ 265/40/18. Before the car is truly roadworthy i need to do front control arm bushings, order the Hinson sway bar spacers, and replace the front wheel bearings using the mazdatrix stuff.

I also cleaned up the lines for my breather setup and routed some things differently.

I have a chasebays coolant overflow on order so ignore the line running over the rad support. I will likely mount the overflow under the air filter.

That's what I'm affraid of with my project. I haven't hot wired my car before finishing the looms. So if something is interfering, I might just have a lot of un-wiring to do...

That's what I'm affraid of with my project. I haven't hot wired my car before finishing the looms. So if something is interfering, I might just have a lot of un-wiring to do...

Leave a comment: