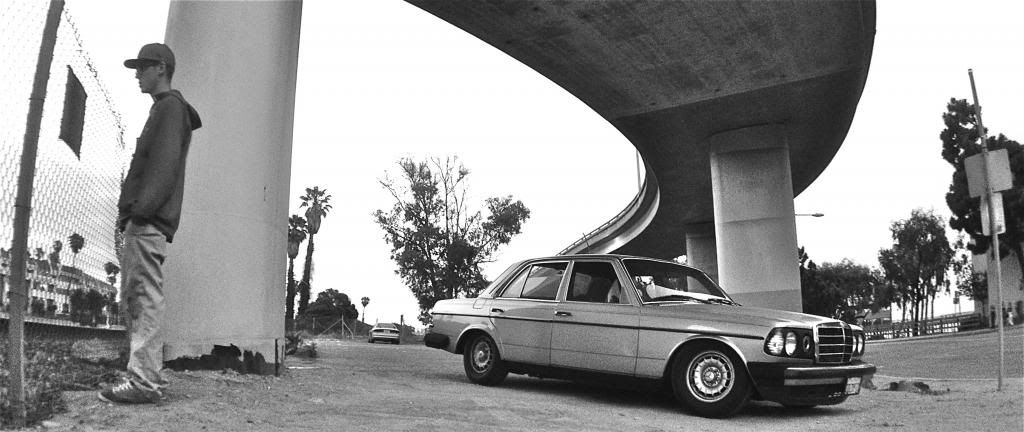

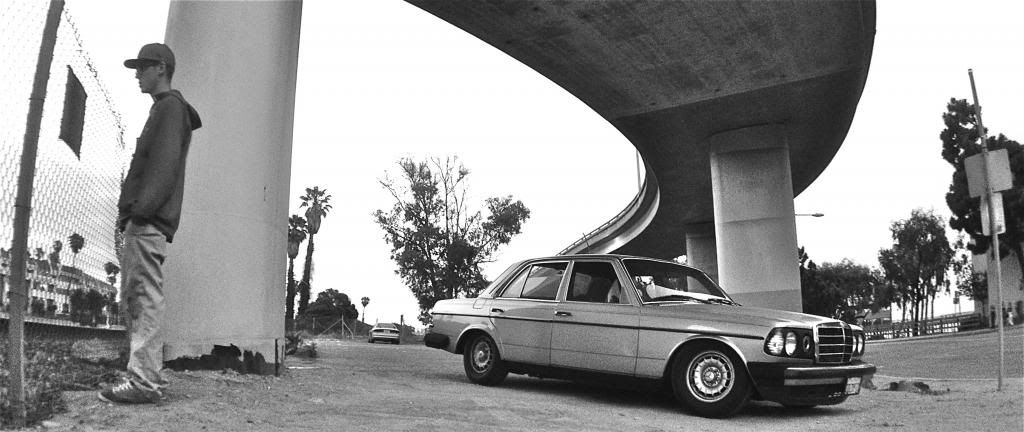

Here we go again. This is my 1977 Mercedes Benz 300D W123 Chassis and her name is Big Bertha. I've been scheming and doing small shit for the past year or two but I think its finally time to get this project really rolling.

Hopefully starting one of these threads will motivate me to keep blowing my paychecks

***WARNING***

I'm too stubborn and impatient to use a measuring tape, the only plans I have are in my head, and if a certified welder actually watched me work a MIG they'd probably cringe so...don't browse this thread for pro-tips.

The coils were cut (I can barely remember how many were removed) and it was sitting on some OE Mercedes CLK Wheels. Interior was pretty much stock, and she had a very abused 200K+ non-turbo diesel engine.

So here she was since the last time I posted something

This is how she looked a few months back before she was parked.

-Lowered a bit more

-Painted front lip

-CLK Wheels

Interior Pics

So! Now for the fun part.

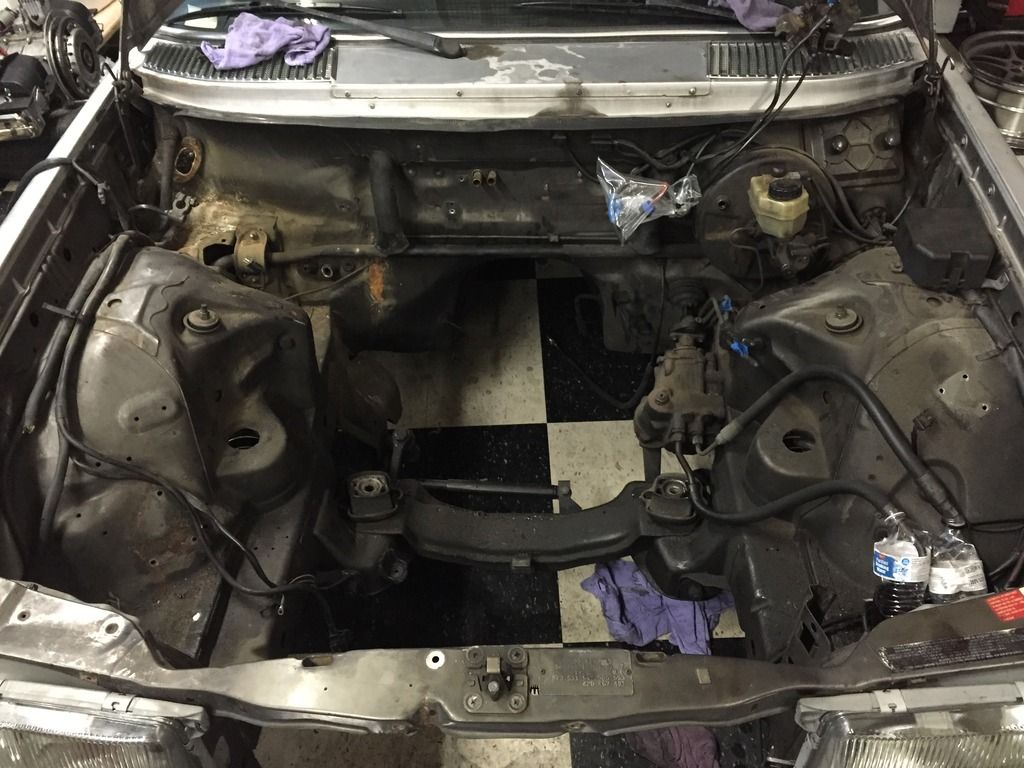

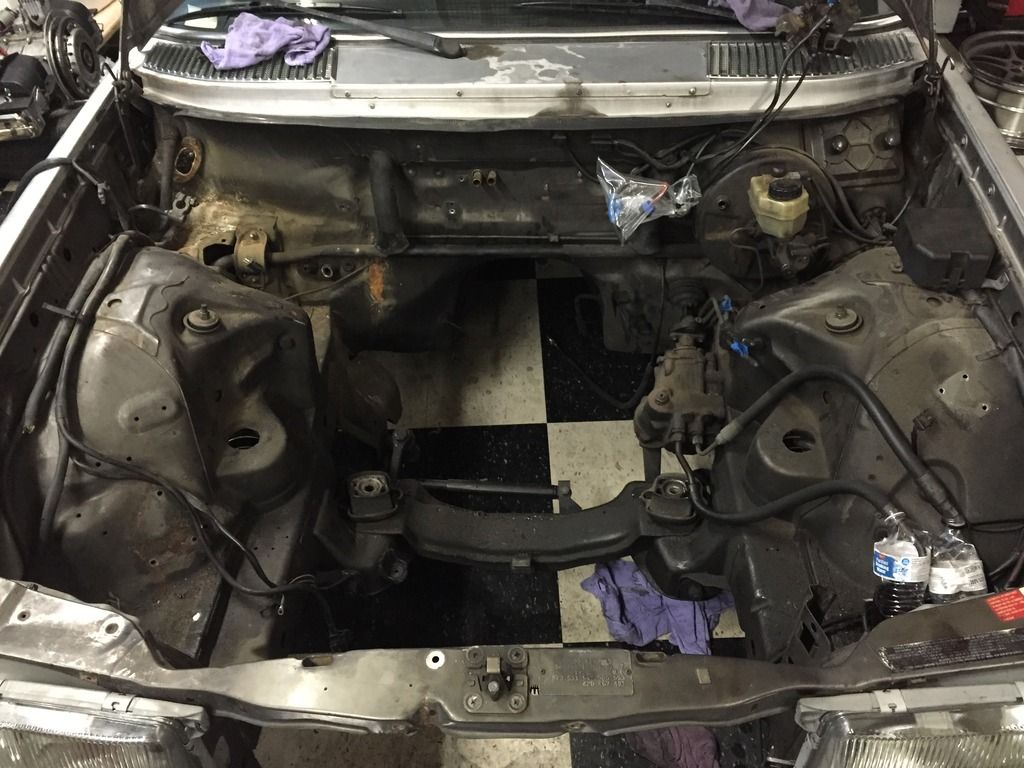

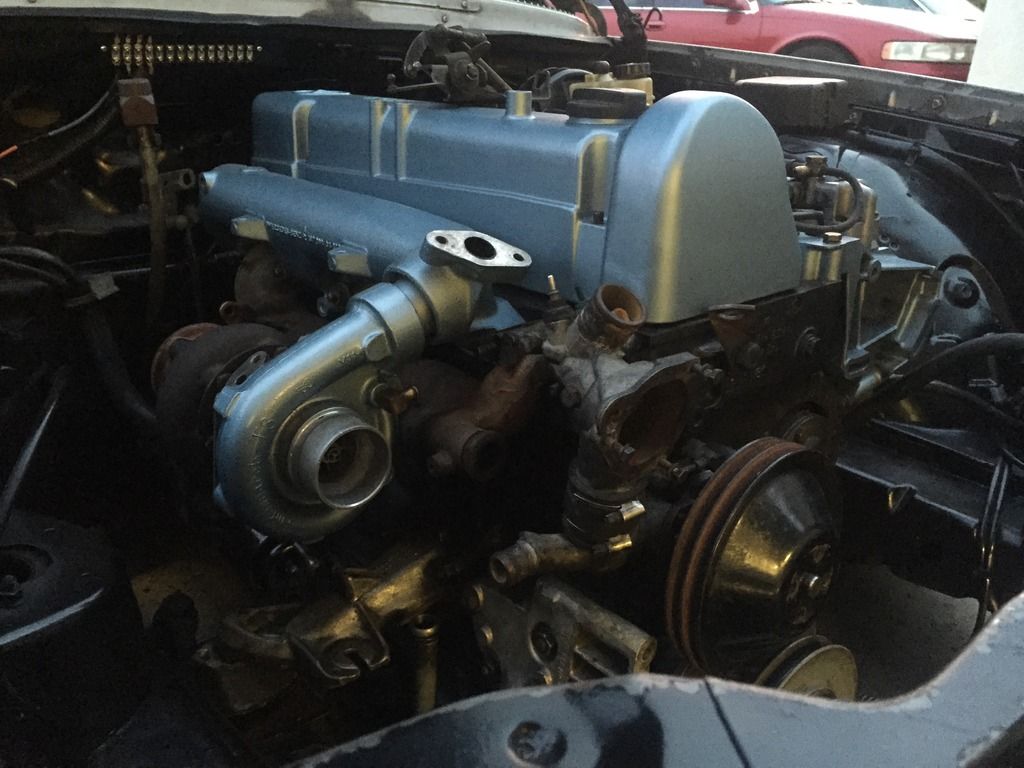

The terrible rod knock was starting to get annoying so I pulled the motor and sourced out a turbodiesel engine and transmission out of a donor benz.

My plan for the engine:

-A couple new gaskets

-Water pump, thermostat, drive belts, blah blah blah

-Heating system removed (because California!)

-Engine cleaned up & painted

-rebuild turbo and exhaust stack

Removed heating system

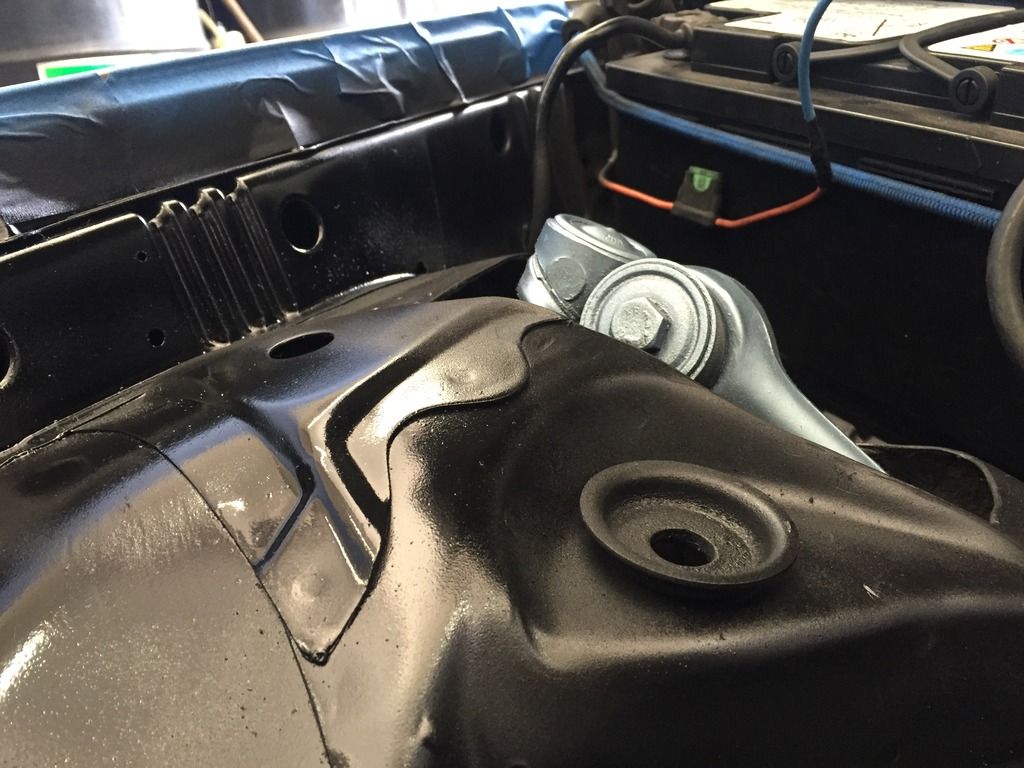

After doing some online creeping and thread reading it seems like most people don't use any wheel past a 15" with the air suspension because of the upper control arm and sway bar hitting on the top of the fender...

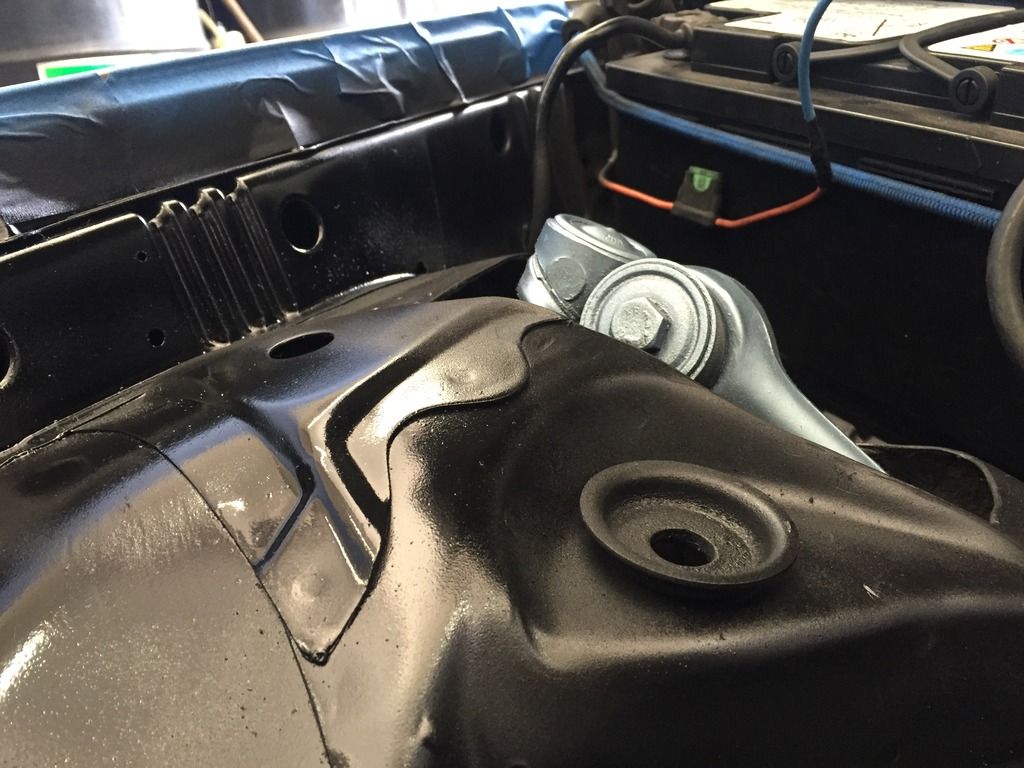

Sadly my stock wheels were stolen when I left them in the back lot of the shop overnight! So i decided to do some cutting to make the 17"s fit..

The sheet metal around the shock mount is overlapped like 3 times over so it seems strong enough to not warp even with what I cut off. And if it seems to start warping I'll try and just build a raised tunnel around it.

But I kind of like seeing the control arm peek through the fender

For the front set-up I used a Universal Air Bag from BagRiders. Then I built my own brackets out of steel, mostly because I don't have the resources to mess with aluminunimum. **PROFFESIONAL FABRICATORS SHOULD JUST SKIP THESE NEXT FEW PICS **

Here's a teaser...

The rears went together pretty smoothly, I decided to just try the Air House Air bags that allow a shock to go through the middle, then I went to Autozone and found some smaller shocks.

I will take some pics of the rear when I get a chance, I just kind of slammed it together so I could get it rolling because I'm impatient.

So she's a rolling chassis again which is nice. Everything is wired up and seem to be functioning properly. I will upload pictures of the management and switch panel in a little bit. I apologize for the iPhone pics but it'll have to do until I find someone with a nice camera **cough**

THAT FRONT TRAVEL THOUGH

Management:

-Analog switches (Front controlled by one switch & Rear controlled by one switch)

-Analog solenoid blocks

-400c Viair Compressor

-6 Gallon Air Lift Tank

-1/2" front air port with 3/8" DOT Line plumbing

-1/4" rear air port with 3/8" DOT Line plumbing

-Switch panel is custom made (pics soon)

-Tank Pressure controlled by pressure switch currently

This is where I'm at right now. A friend dumped some cheap 18x10 wheels with me the other day so I might fit those and see how it looks. I will post pictures of the switch panel and as soon as I have money again I'll start getting that turbodiesel running.

It's going to be slow progress, but I hope you guys will enjoy it as much as I have so far!

Hopefully starting one of these threads will motivate me to keep blowing my paychecks

***WARNING***

I'm too stubborn and impatient to use a measuring tape, the only plans I have are in my head, and if a certified welder actually watched me work a MIG they'd probably cringe so...don't browse this thread for pro-tips.

The coils were cut (I can barely remember how many were removed) and it was sitting on some OE Mercedes CLK Wheels. Interior was pretty much stock, and she had a very abused 200K+ non-turbo diesel engine.

So here she was since the last time I posted something

This is how she looked a few months back before she was parked.

-Lowered a bit more

-Painted front lip

-CLK Wheels

Interior Pics

So! Now for the fun part.

The terrible rod knock was starting to get annoying so I pulled the motor and sourced out a turbodiesel engine and transmission out of a donor benz.

My plan for the engine:

-A couple new gaskets

-Water pump, thermostat, drive belts, blah blah blah

-Heating system removed (because California!)

-Engine cleaned up & painted

-rebuild turbo and exhaust stack

Removed heating system

After doing some online creeping and thread reading it seems like most people don't use any wheel past a 15" with the air suspension because of the upper control arm and sway bar hitting on the top of the fender...

Sadly my stock wheels were stolen when I left them in the back lot of the shop overnight! So i decided to do some cutting to make the 17"s fit..

The sheet metal around the shock mount is overlapped like 3 times over so it seems strong enough to not warp even with what I cut off. And if it seems to start warping I'll try and just build a raised tunnel around it.

But I kind of like seeing the control arm peek through the fender

For the front set-up I used a Universal Air Bag from BagRiders. Then I built my own brackets out of steel, mostly because I don't have the resources to mess with aluminunimum. **PROFFESIONAL FABRICATORS SHOULD JUST SKIP THESE NEXT FEW PICS **

Here's a teaser...

The rears went together pretty smoothly, I decided to just try the Air House Air bags that allow a shock to go through the middle, then I went to Autozone and found some smaller shocks.

I will take some pics of the rear when I get a chance, I just kind of slammed it together so I could get it rolling because I'm impatient.

So she's a rolling chassis again which is nice. Everything is wired up and seem to be functioning properly. I will upload pictures of the management and switch panel in a little bit. I apologize for the iPhone pics but it'll have to do until I find someone with a nice camera **cough**

THAT FRONT TRAVEL THOUGH

Management:

-Analog switches (Front controlled by one switch & Rear controlled by one switch)

-Analog solenoid blocks

-400c Viair Compressor

-6 Gallon Air Lift Tank

-1/2" front air port with 3/8" DOT Line plumbing

-1/4" rear air port with 3/8" DOT Line plumbing

-Switch panel is custom made (pics soon)

-Tank Pressure controlled by pressure switch currently

This is where I'm at right now. A friend dumped some cheap 18x10 wheels with me the other day so I might fit those and see how it looks. I will post pictures of the switch panel and as soon as I have money again I'll start getting that turbodiesel running.

It's going to be slow progress, but I hope you guys will enjoy it as much as I have so far!

Comment