Okay. Progress time! And I mean real spanner throwing action!

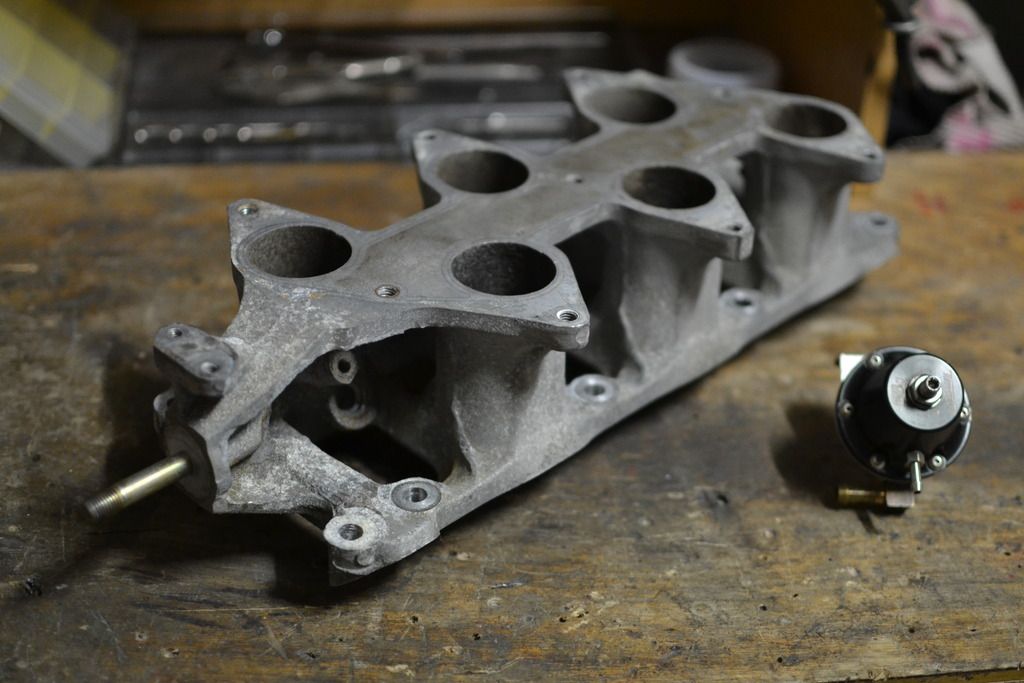

With semester over and time on my hands the first job I started back on in the garage was one I was really looking forward to - a good motivator. Fitting my new TRust heat exchangers. The first step of course was paint stripping the fuck out of them to remove the "wanker blue" finish.

Oh yes. I totally bought another one.

Fitting these up properly took quite a bit of effort but the end result is great. A few brackets on the chassis had to be cut off but nothing too bad. I'm already moving the radiator overflow bottle but a new washer bottle will have to go in too (no big, actually looking forward to it, trust do an after market one which is kind of fitting seeing as why I need one lol).

I ended up putting wayyyy too much work into designing these brackets (get too into these things) and ran myself clean out of material. At the time I was still go go go, so dad's ladder became a sacrificial lamb:

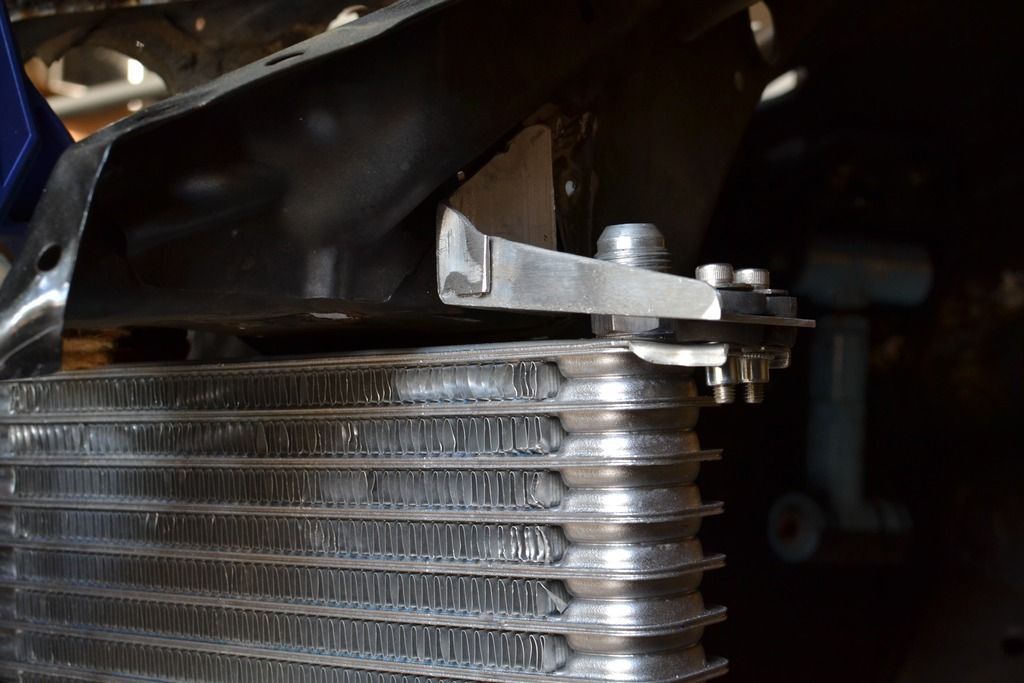

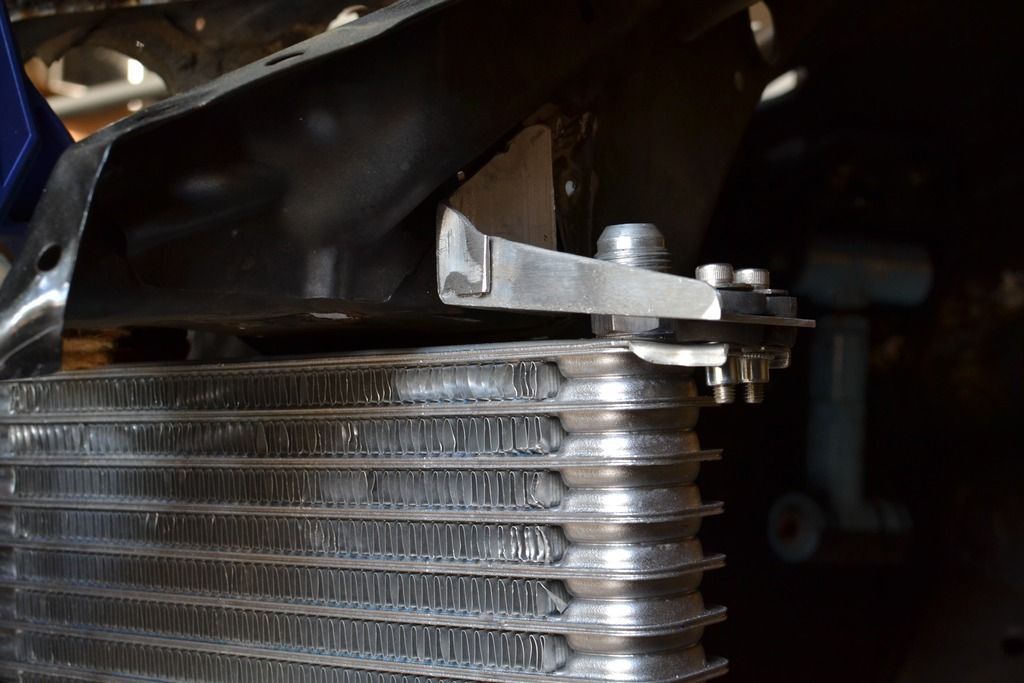

The upper brackets rivet to the chassis for simplicity and reduced weight while Nissan OEM rubber vibration isolators mount the cooler.

Folding the bracket over to an L shape with an overlap to be fastened for extra strength;

Coming together - nutserts installed into the oil cooler, a pop rivet was put through the fold overlap later on;

The lower brackets are folded 1" flat bar riveted to the coolers and attaching to the chassis via more vibration isolators.

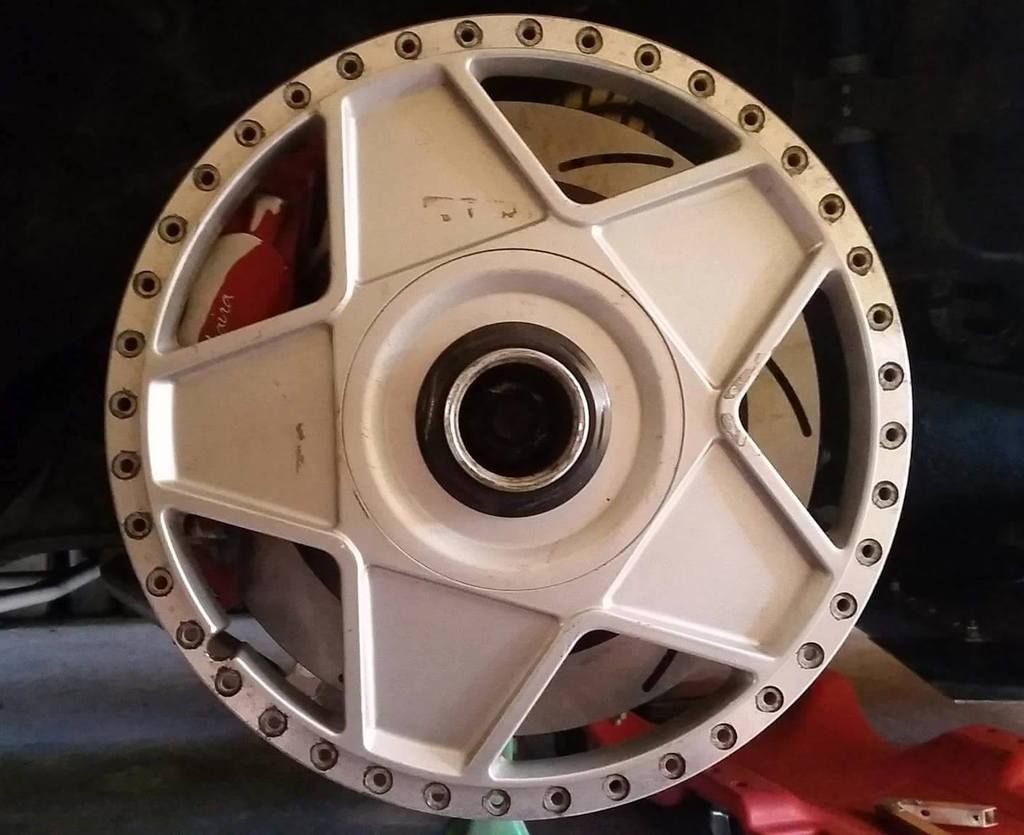

I went with the brackets set up this way and made them (remember what I said about overthinking) they're light as all hell, reliable with the rubber eating up bumps rather than the coolers, none of the hosing or bracketry will block air flow to the cores and lastly they're serviceable; the coolers can be removed via the wheel wells without having to take off any bodywork.

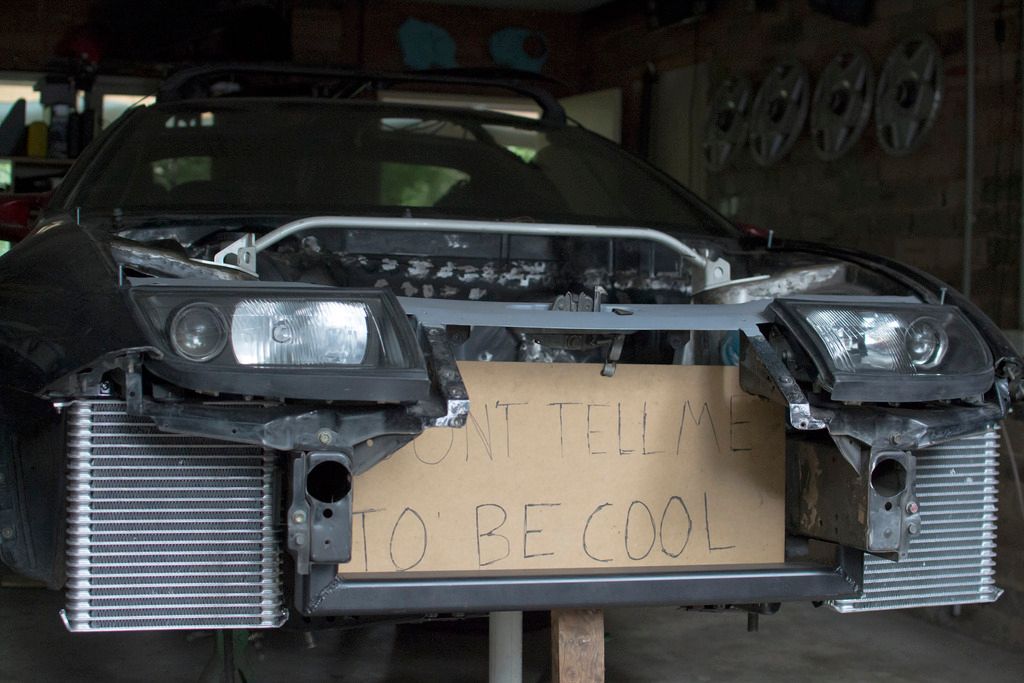

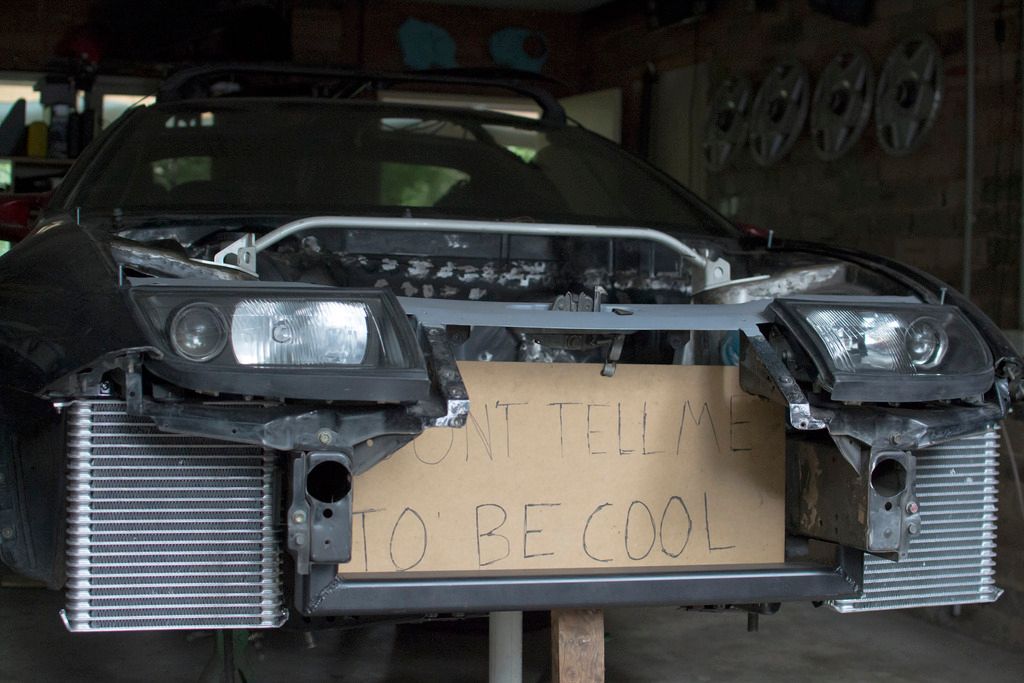

If you're wondering if they clear the bodywork... the answer is no, absolutely not. but with some bumper bracket trimming they should have just a hair of clearance. most importantly though is that they do have a decent amount of road clearance; they're still about an inch from the underside of the bumper. achieving this took a considerable amount of work... bye bye headlight buckets

Next up was a job I started ages ago; a custom rear strut brace. I wanted to strengthen the rear towers without having a bar through my interior.

With a bit of planning the OEM metalwork came out;

My old strut brace (still nicely trimmed) stayed on throughout the process to stop the towers shifting. I grabbed some DOM tubing from a local roll cage material supplier and set about fish mouthing;

The outer pieces were angled as steeply as possible before they would foul on the boot trim.

Some new brackets were made up to replace boot trim retaining flanges on the OEM brace. No quality concerns with rattles and flimsy trim.

Welding welding welding. That's some stripped sound deadening hanging off the bar. I haven't picked up a mig since before semester started and to be honest I kind of dicked it here. They're over done and ugly but at least they're strong. The good news is that I figured out what the issue was and I'll be pulling off way better work in future.

The OEM brake line shielding brackets were kept and with light work wrapped nicely around the bar, which was drilled and tapped to suit.

Done and dusted, this is how the trim fits up:

While I'm not overly enthused with the welds the end result I am happy with. The two points fused to the boot floor are actually running across body seams, tying the structure together. The remaining sheet metal that previously connected to the OEM brace was trimmed, folded down and welded to the tower.

I also fitted up my seats! With an ungodly immense amount of relief that my cut 'n' shut driver's rail from a few posts back worked. They fit the chassis well which was sweet confirmation seeing as I don't know of these ever going into a Z32 before.

This takes us up to about two weeks ago maybe, and since then I've been up to my ass in more car work so much more to come.

-A

With semester over and time on my hands the first job I started back on in the garage was one I was really looking forward to - a good motivator. Fitting my new TRust heat exchangers. The first step of course was paint stripping the fuck out of them to remove the "wanker blue" finish.

Oh yes. I totally bought another one.

Fitting these up properly took quite a bit of effort but the end result is great. A few brackets on the chassis had to be cut off but nothing too bad. I'm already moving the radiator overflow bottle but a new washer bottle will have to go in too (no big, actually looking forward to it, trust do an after market one which is kind of fitting seeing as why I need one lol).

I ended up putting wayyyy too much work into designing these brackets (get too into these things) and ran myself clean out of material. At the time I was still go go go, so dad's ladder became a sacrificial lamb:

The upper brackets rivet to the chassis for simplicity and reduced weight while Nissan OEM rubber vibration isolators mount the cooler.

Folding the bracket over to an L shape with an overlap to be fastened for extra strength;

Coming together - nutserts installed into the oil cooler, a pop rivet was put through the fold overlap later on;

The lower brackets are folded 1" flat bar riveted to the coolers and attaching to the chassis via more vibration isolators.

I went with the brackets set up this way and made them (remember what I said about overthinking) they're light as all hell, reliable with the rubber eating up bumps rather than the coolers, none of the hosing or bracketry will block air flow to the cores and lastly they're serviceable; the coolers can be removed via the wheel wells without having to take off any bodywork.

If you're wondering if they clear the bodywork... the answer is no, absolutely not. but with some bumper bracket trimming they should have just a hair of clearance. most importantly though is that they do have a decent amount of road clearance; they're still about an inch from the underside of the bumper. achieving this took a considerable amount of work... bye bye headlight buckets

Next up was a job I started ages ago; a custom rear strut brace. I wanted to strengthen the rear towers without having a bar through my interior.

With a bit of planning the OEM metalwork came out;

My old strut brace (still nicely trimmed) stayed on throughout the process to stop the towers shifting. I grabbed some DOM tubing from a local roll cage material supplier and set about fish mouthing;

The outer pieces were angled as steeply as possible before they would foul on the boot trim.

Some new brackets were made up to replace boot trim retaining flanges on the OEM brace. No quality concerns with rattles and flimsy trim.

Welding welding welding. That's some stripped sound deadening hanging off the bar. I haven't picked up a mig since before semester started and to be honest I kind of dicked it here. They're over done and ugly but at least they're strong. The good news is that I figured out what the issue was and I'll be pulling off way better work in future.

The OEM brake line shielding brackets were kept and with light work wrapped nicely around the bar, which was drilled and tapped to suit.

Done and dusted, this is how the trim fits up:

While I'm not overly enthused with the welds the end result I am happy with. The two points fused to the boot floor are actually running across body seams, tying the structure together. The remaining sheet metal that previously connected to the OEM brace was trimmed, folded down and welded to the tower.

I also fitted up my seats! With an ungodly immense amount of relief that my cut 'n' shut driver's rail from a few posts back worked. They fit the chassis well which was sweet confirmation seeing as I don't know of these ever going into a Z32 before.

This takes us up to about two weeks ago maybe, and since then I've been up to my ass in more car work so much more to come.

-A

Comment