The shop got tiddied up a bit - love that wheel poke.

The clutch line got did...and re-did. It's now an AN hose setup with banjo fittings for the master and slave cylinder.

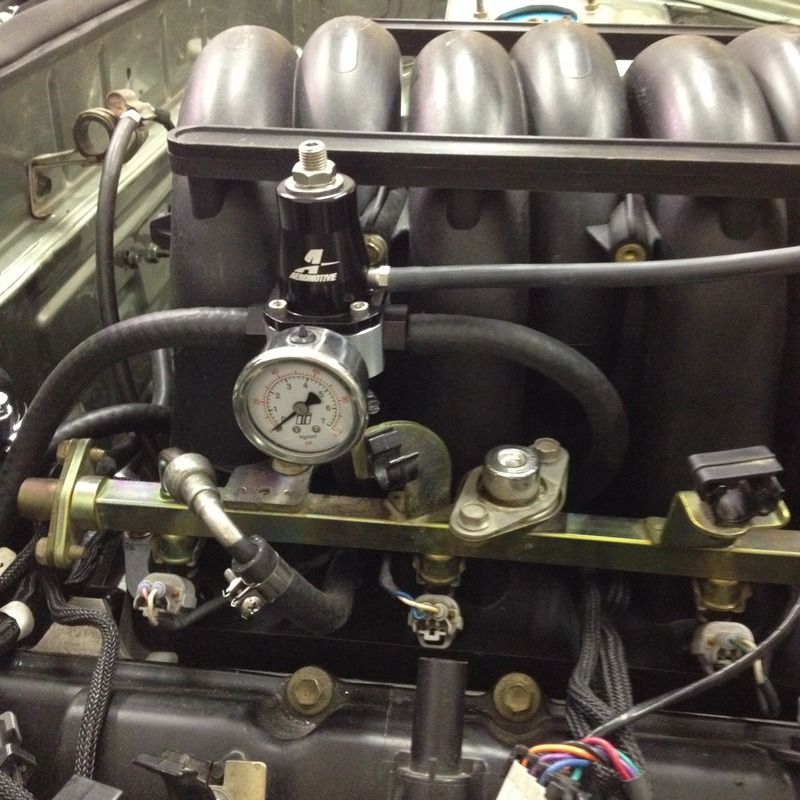

The FPR found a home, albeit not a permanent one. It will get relocated when it's intake manifold time.

And the fuel filter now resides on the firewall and completes the fuel system plumbing.

A little bracket was whipped up...

...which holds the power steering reservoir. This uses the stock Titan PS reservoir but a s-chassis one could be used as well.

On to the brakes, the modified brake pedal setup got a little paint. If you'll recall, we toyed around with ways to keep the stock booster setup. It wasn't in the cards so we're going boosterless. There's now a few kits on the market to make it an easy conversion. We wanted to try something a bit different which seems fitting for the build.

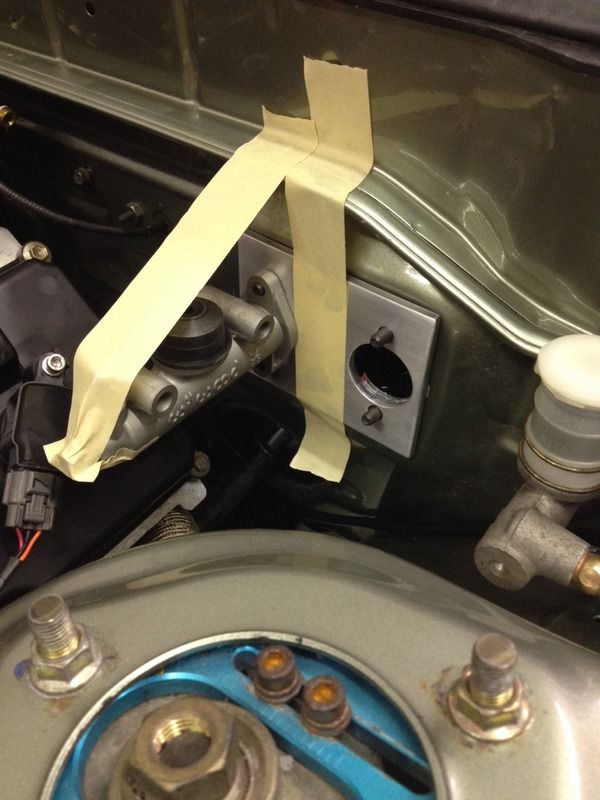

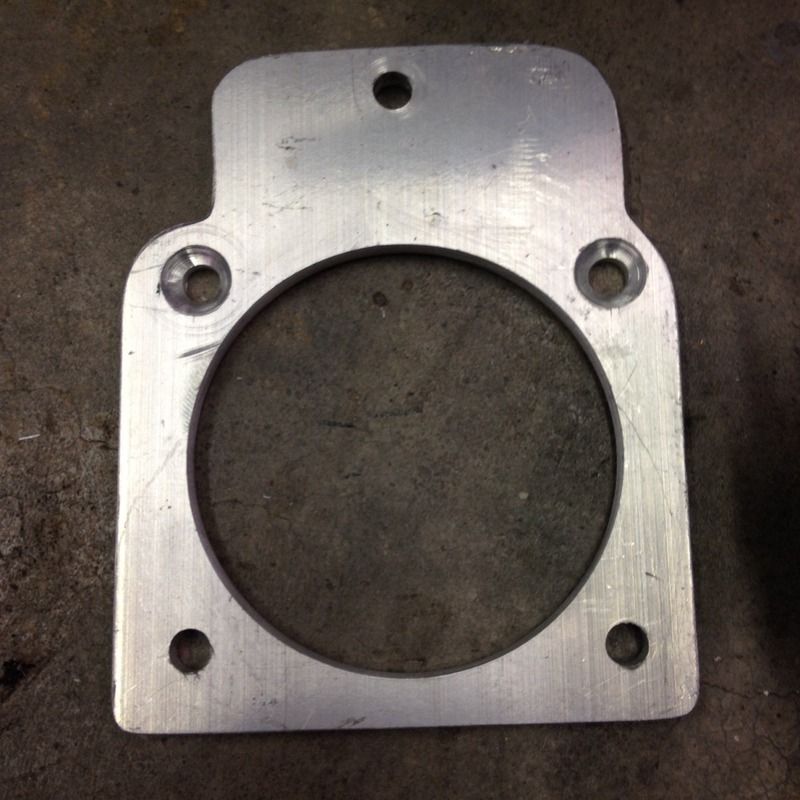

Delete/mouting plate being made.

The grand scheme coming together.

And the new dual master cylinder setup in and waiting to be plumbed. There is a balance bar incorporated into the modified brake pedal.

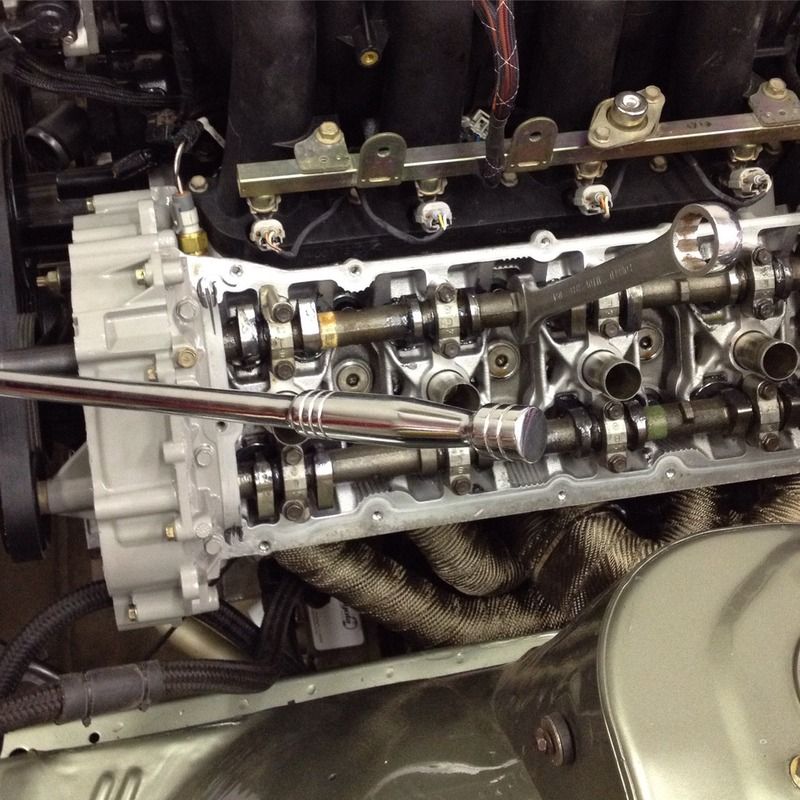

The most recent project involved the above tools.

Out came the intake cam - the one with the cam angle sensor marks.

The stock VK pattern is a 1-2-3-4 notch type pattern. The BigStuff3 needs a single notch so the unnecessary ones were filled and smoothed.

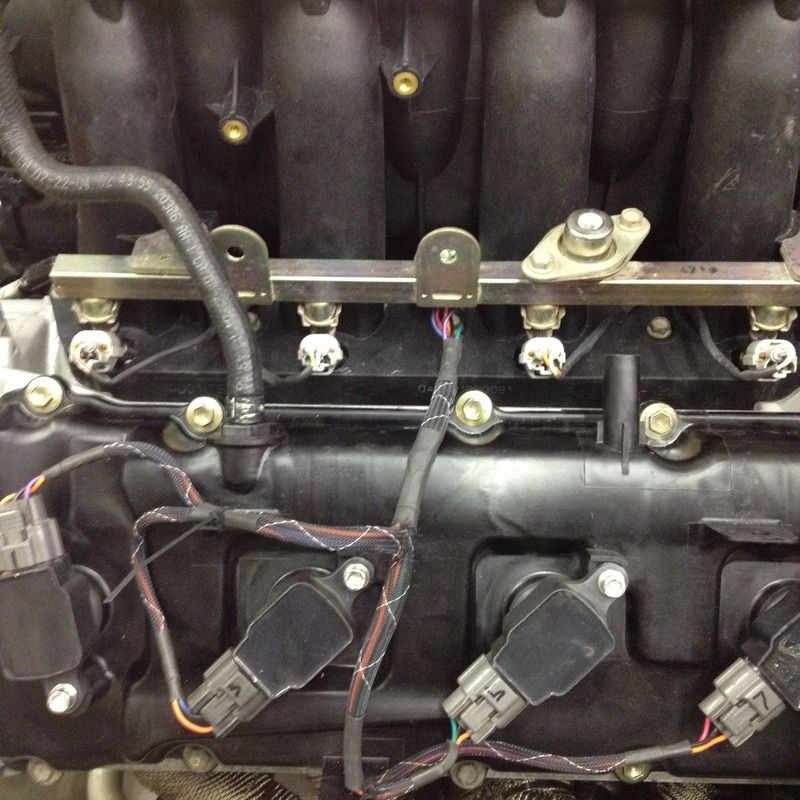

And then things put back together which more or less brings us up to date.

Greg is currently going through the checklist of connections and sensors to make sure the ECU is communicating with the engine. From there, we can maybe crank this thing???

Leave a comment: