It's not too cold here in B.C. but I am ready for spring. It was super sunny and hot yesterday and then today it was snowing and back down below freezing. Not super pumped. But I have been able to get lots of work done. Been trying to rally up some friends to help out so I can get this thing rolling this summer but nobody is ever able to so I have just been trying to get as much done as possible. I finished off most of the frame work. Smoothed out the welds. finished up a bunch of the welding. Built a crossmember and and tranny mount. It felt good to set the motor and tranny in and pretend I could hear it running!

I bought a bunch of fittings and such just to get the bags hooked together so I could see it move up and down. It was awesome!

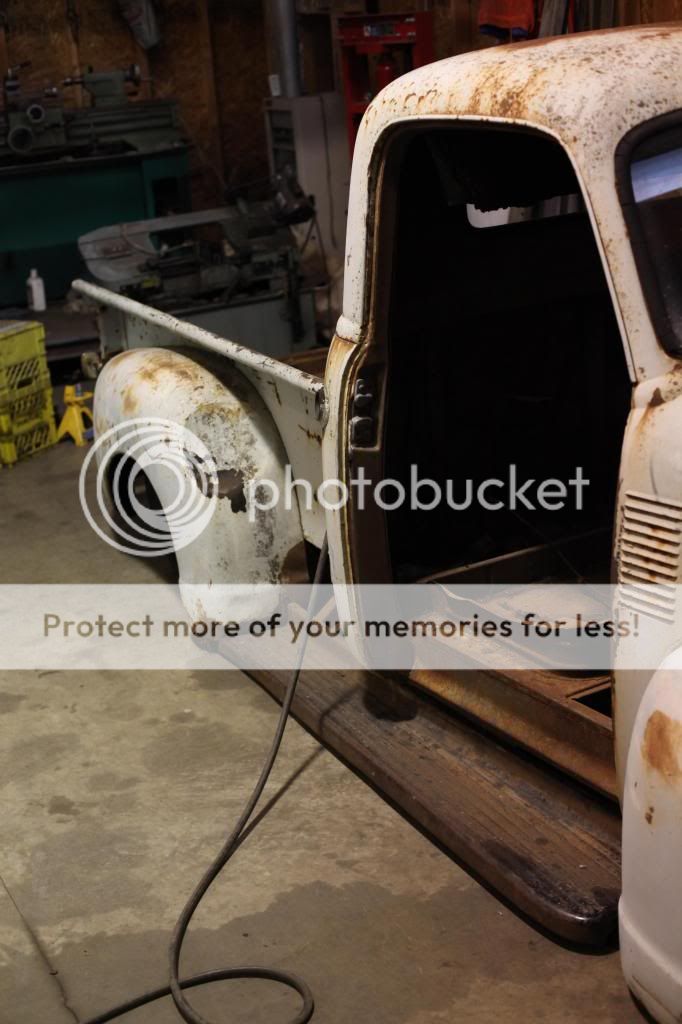

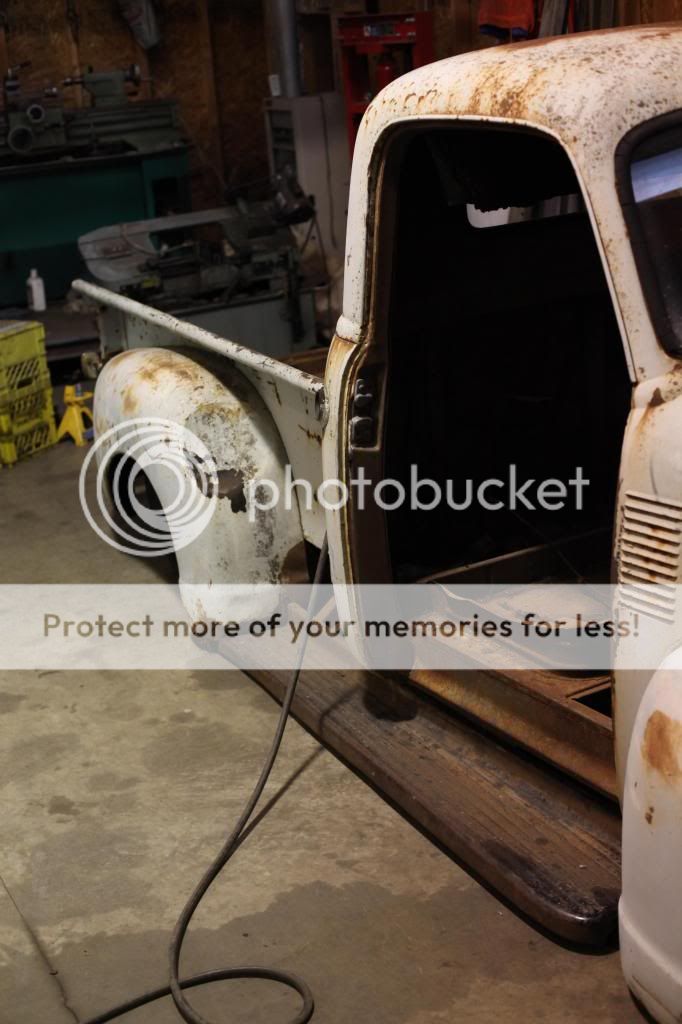

Luckily a buddy was able to come and help. After rallying up some help from around the neighbourhood we were able to get the body all mocked up.

Feels good to see it somewhat together. I just want to hop in and do a massive burn out! Hoping this will give me a boost to keep working!

I bought a bunch of fittings and such just to get the bags hooked together so I could see it move up and down. It was awesome!

Luckily a buddy was able to come and help. After rallying up some help from around the neighbourhood we were able to get the body all mocked up.

Feels good to see it somewhat together. I just want to hop in and do a massive burn out! Hoping this will give me a boost to keep working!

Comment