Originally posted by Teeson1111

View Post

Announcement

Collapse

No announcement yet.

FC RX7 5.0 race car thread

Collapse

X

-

Bravo-Christian.

'91 318iS AW2/blk slow garage queen/build...

'02 ///M3 carbonschwartz 6MT daily beast

'37 Chevy pickup-garagequeen...

Comment

-

well things can change in a moment

I suppose the music chose this update should be a sad song, but thats not what I've been listening to.

Been trying out the new Coldplay album A Head Full of Dreams. Honestly not as good as hoped but still has a decent amount of tracks I like. Didn't prevent me from buying tickets for when they come to Vancouver next year.

Was coming home in traffic one day, stopped behind a truck, car behind me stopped behind me and the minivan behind it didn't.

Thankfully everyone involved was ok (at least to my knowledge, car behind had a baby in it and went to the ER right away but for privacy reasons I'm not allowed to know more than that) but my car was towed away from the scene. Which was kinda unnecessary, it wasn't leaking and still started/ran, even the signals were working. But the cops didn't want to risk anything so they towed it.

So I saw it off in the traditional manner

My back was quite sore the next day, and only got more and more stiff. I spent the next 2 weeks off work, seeing a chiropractor and eventually transitioned back to work. As a result I couldn't physically push the drift car out of the tent by myself and didn't work on it for over 2 months.

But in the meantime I had other things that needed dealing with....

They towed the car to the yard for the insurance adjusters to look at, where they left the ignition on for like 10 days and ruined the lip and proceeded to lowball me over the phone. Some arguing later I came and took the car home, still not sure what the settlement was going to be.

At this point I was pretty pissed with the whole situation. I'll avoid complaining about the monopolized insurance that we have in BC. But I dragged it home and slowly pulled everything that I could use for the new car off of it.

Time to make some decisions. I was now way off my time line for the new car, still mostly unable to work on it, and I hadn't had much of an income since the accident and had no extra money to play with cars.

So I said screw it, Pumpkin Smash was coming up and I wanted to drift again. I tore apart my garage and all my spare parts, wrote it all down and sold everything I didn't need.

As of typing this I still have a few items left, including my gauge cluster. Felt good to clean up my work space (lol yet again) (made my dad happy I had less crap) and free up some money to drive pumpkin and continue working on the new car.

Somewhere in the midst of that I got my new car, a 1996 Toyota Mark 2.

I bought it off a friend of mine. I was looking at importing one but he decided maybe it was time to sell. I liked this option better, I could see and drive the car before buying it, it had also been well maintained and had a lot of work recently done on it. The only catch was it had a dent from a hit in a parking lot fender bender that had to be taken care of first. So I brought it back to the only auto body place I trust Candy Automotive (same shop that did my RX7 fender last year). Helps that my sister started working there when she was finishing her auto refinishing school.

It didn't take me too long to start playing with it

I ended up sticking with the Works. I also put my Grip Royal in there and my quick release.

Have to say I like these cars. Much different from my FC but a much more suitable car to daily drive. VVTI 1JZ is pretty fast, 4 doors and a roomy backseat is convenient, automatic trans is something I want to change but its not terrible. RHD isn't that bad to live with either. New challenges are learning to source parts and research. JZX100 doesn't have a stateside equivalent, its a mix of other toyota's and lexus's and even some that are specific to it only. Parts for it are also expensive and generally imported. But I happen to live 15 minutes away from Serial Nine, the toyota sedan kings.

Moving on, had some prep to do before I could go drifting.

Put some led's I had laying around around, threw my little batteries in it as the yard killed my old battery and flooded the engine to the point where I had to remove the spark plugs to de-flood it. More on that later.

Seeing this as an opportunity to learn from this, as I had a car I did not care what damage happened to it, I swapped rear subframes with the shell and put my Villains knuckle kit on.

Needless to say this kit is good. 0 ackerman and more angle than most wheel tire setups can clear. But since I have no fenders, 8" wide wheels, and basically what ever size spacer I need I found more.

By grinding the control arm a little, the knuckle moves further and the stop point is now the ball joint extension bracket.

I didn't measure it but there more angle (well after some hammering to the frame) available then I had the last time I measured the kit on the shell. Over 60* is my guess.

Knowing I had little horsepower and would need all the help I could get, I put 60 psi in all my spares and welded the n/a diff I had.

This is the auto diff the blue car came with, a 3.93:1 ratio. Hoping it will help the gearing with the V8 car. I also have quite a few n/a axles if for some reason it breaks them.

So put plastic over the back wall, cut the silencer out of the exhaust tip, threw a spare set of tail lights on and loaded it on the trailer.

Now I was far too busy driving that weekend to take pics but maaaaan what a time. And all that fun with maybe 100 hp to the wheels. I learned a completely different way to drive. It quite changed my perspective on a lot of things.

Spent the morning of day 1 however with the car not running right at all. Was overheating, had no power, smoking a ton and felt like one rotor wasn't firing. But I had spark and fuel, had tested the compression not too long before. Had a few friends who know rotaries better than I helping diagnose and it almost seemed like it had a blown coolant seal. We had a lunch break and the track officials gave me a few minutes to use the back straight to see if I could get it working (as waiting in the line up, failing and limping it back to the pits wasn't efficient). I ate something, said a prayer I didn't drag a a broken car all the way there, and stared at it again. I'm like "I'll just check the plug wires, cuz I took them off" and sure enough I had switched rotor 1 and 2. With that sorted it was time to actually have some fun.

Learning the angle kit was weird/scary for the first bit, as the steering is so fast and sensitive. I did the usual amount of wheel movement on the first initiation and was instantly backwards. a couple laps later I began to get a feel for it.

End of day one I could hang with the rest of them and had some really close tandem runs. Car actually got a lot of looks for what it was, and not everyone was revolted by how missile it was.

Day two was a different layout, was faster in some spots and was really hard to link for me in one or two areas. Had some friends come visit and do some ride alongs and filming (lol you can see mikey in that pic).

Had a great time all around though. Slept in my truck, went through like only 1 set of tires, watched my friends break their cars and wheels, met some new people and would do again.

When life gives you lemons make lemonade. Reminds me the big man upstairs has a larger plan than I can see sometimes. I still **** missile cars, not proud of how it looked but glad I could use it to learn. That weekend literally changed my perspective on style, car setup and car building. So much so I'm thinking of selling my V8 setup next year and going back to the plan I had when I started building my first drift car.

I have gotten back to building the new shell, started with the rear over fenders.

Cut the fenders after measuring and mocking up with the fibreglass overs

Then tacked them together

Fully welded

And cleaned up

The inside too, though the pic makes it look much more wrinkly than it is. Its decently smooth, to the point i'm not worried if the tire makes contact with it.

Then my sister brought my some sealer primer which I painted on with a brush. She's adamant this is better than spray can primer. She also has gotten me on sanding and using weld thru primer on the back of things. One issue I had with the old chassis was that rust was present after 1 winter. PNW climate is not the friendliest.

But then I forgot to take a pic of the finished product

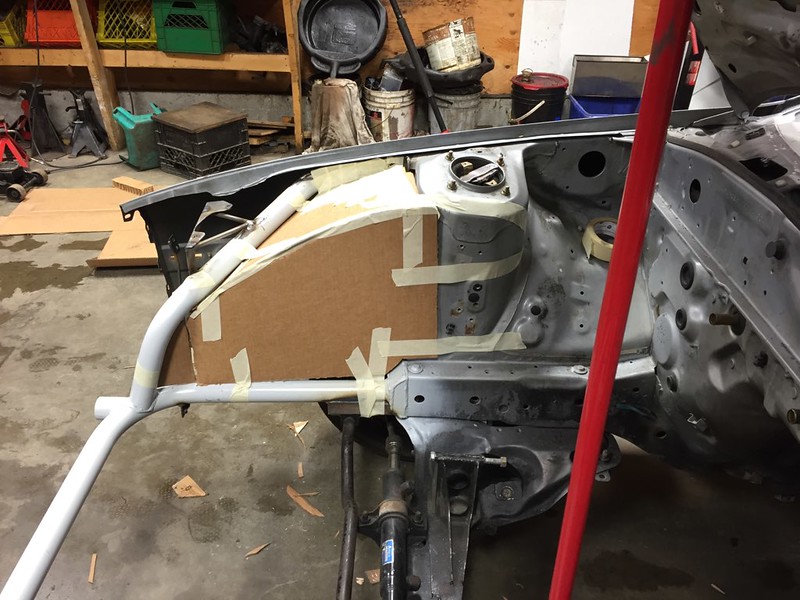

Moving on to the tube front

made these sway bar brackets, though I don't think I will ever be able to run a sway bar in the stock location and have a decent amount of angle. Another thing learned from the missile.

Welded them on, my welds have been getting decent since getting a gas bottle for the lincoln welder me and my dad split some time ago.

like I was saying. I may make a bump stop that is similar to PSM's control arms with a bolt on as the stop. That I can run the sway bar on the street but it will still be quick and easy to remove when I want to take it to the track. I don't like even highway speeds without a front sway bar, but drifting I don't even notice without it. If anything less understeer without.

made a piece for the fender to bolt onto

made a small bolt on piece for holding the bottom of the fender in place with the idea that it will get wrecked and is kinda sacrificial. Might change them a bit to hold two bolt holes and where they are at the moment they might interfere with the splitter mounts.

Front end is starting to come together. This weekend I hope to do some stuff in the interior and the headlight mounts and if I have time the headlight motor mounts as well.

Comment

-

thanks man!Originally posted by I_Haz.:R32 View Postgahdamn there is some really high quality FC content here in this last post. Very nice! I just bought my first FC, and I'm already thinking about buying another, as mine is a bit more rough than I initially thought. Keep it up tho man!

pretty typical of 25+ year old cars to have some bad spots. nice thing about these is they are pretty cheap though.

Comment

-

Merry Christmas everyone!

I've been back into the 1975's newest album. I didn't like the singles, didn't like it the first time I heard it, grew to like it, stopped for a while and now I'm into it again.

Really 80's in some songs, I still don't like the sappier acoustic stuff I really don't feel like thats what this band excels at. This has some good songs, but I do still like their first album better. Worth a shot, just don't expect to fall in love with it instantly.

Getting time to work on the car has been a bit difficult again lately. Had a few people ask me whats taking so long or a question to that effect, and really its time. I no longer have the ability to just walk out my back door into the garage and work on it. It takes about 25 min to drive there from my house and then I have to get the car inside etc. Don't mistake this for complaining, I'm still very blessed to have the shop and a place to keep the car. It just takes a little more effort then it used to I guess. Let's me spend more time thinking before I tackle something on the car.

That said, I had my local metal supply place Metaltropolis bend up some 14ga sheet for my headlight brackets.

Tacked them in place to where they needed to be.

Then debated how to make them look "cool" and not just square flat things.

I did other things, slept on it and came back to cut a bunch of it off.

3 captive nuts, and a bunch of it missing looks much more race car to me.

When the headlights are on you can't even see them. They mimic the factory bracket mounting so I have the ability to adjust the fit like I would if it was OEM.

I also much to my annoyance had to notch the drivers side down tube just a little bit to get the light to clear. I guess the front end isn't perfectly symmetrical, not surprising really.

Once both headlights were done and fit time to move onto the motors.

Now the first way I did this the forward most point ended up being too weak, well the weld was. I tried welding a nut on the end of a 3/8 rod and them shaving it down with an angle grinder in a vice while the rod was on a drill. Took too much out and became weak, looked crap anyway.

They now fit, are study and are fully functional. I've really grown to like the look of 1/4 rod and 3/8 for things. Especially with the tube front it fits the look much better than other ways to do brackets.

I trial fit the front bumper (it needs some shaving to fit properly, which I haven't done yet) to get an idea of what i'm gonna have to work with for the rest of the front end pieces.

Because I can't waltz into the garage I now take a lot of pics of everything I do and test fit. That way when Im supposed to be at work or something I can glance at the pics and think through how I'd like to do something. Aesthetics are important as well as strength, but an even larger part of the design goals is crash ready. Easy to rebuild and keeping important components far out of the way of any crumple zone or other car or wall.

I've recently been really liking tubs in engine bays. It just looks so clean and tidy, keeps the engine bay more free of road grime than open tubs.

I'm stuck on the fence doing these or not. If I do have a serious crash they will be hard to repair, though it will likely be replace in that case. The car is so nice to work on with open tubs, you can reach the entire front end.

I want it to look good with the body work removed and with the body work on. When I originally did the tube front I had decided against tubs, but now that Im rethinking I wish I had done it differently, event though that would have made the headlights even harder. I strongly dislike the look of dimple die plate that joins the tube and the tub. If anything ill do it how my cardboard template is and weld to the underside. Then its a new set of challenges to fit the intake and the reservoir bottles etc in the bay.

I'd like to say I haven't made up my mind yet but when trailer fenders went on sale locally I bought one.

I've been reading Engineer'd To Slide blog on his Hilux build. The amount of metal he cut off after putting a ton of work into it when he wasn't happy with a piece for what ever reason is kinda inspiring. Worst case I'll tack it on and wait to finish weld.

Added a rear fender mount point, it was kinda flimsy with out it. Might have made it stronger than I wanted, but in a crash the fender is gonna get ruined anyway.

You can see my revised headlight motor mounts here.

Then I started figuring out the centre bar

This was a bit tricky as a lot of things needed to be considered. I wanted a stock style hood to fit just to keep my options open for aftermarket hoods. Rad had to fit and have room for fans and things. Couldn't impede headlights or ideal hood pin locations.

The white tape is the approximate location of the crank pulley. Sits quite far forward off the engine.

Grabbed some off cuts of EMT from work and guessed at the bend angle then bent it till it kinked in my vice at home haha. But it gave me a good idea what was going to fit. Made a

cardboard template and bent the real thing back at SCG performance.

Sometime later

Spent far too long measuring and staring at it to make sure it was straight and parallel with the tubes around it and the firewall/rest of the car.

Then something awful happened.

R.I.P. job mate grinder

2011-2016

My buddy Andy gave me this grinder as a hand me down when he got a better one from work, it served me quite well over the years. But the motor kinda gave up the ghost and I laid her to rest.

Next up was to drill some holes in hopefully the right places (lol jk i measured twice)

And quickly make some of these.

While theres been a lot of learning new things doing the front end, The pedal box was one area where i've been there done that and had a pretty good idea how to do it.

Remove pedal box, which I purposefully did not weld to the cage this time, and remove most of it leaving a small upright section for strength (something I didn't do last time)

I drilled out the holes on the pedal set just enough to bolt through 3/8 ready rod (also scrap pile from work). It will hang on these and be much easier to remove than supporting from the bottom like last time. They are also height adjustable this way.

Tack a plate with the correct spacing drilled out

Check position and fitment a few times, I liked where I had it before just to the left of the steering column. I didn't find braking awkward and it made left foot much more comfortable and easier.

Then weld the top nuts and weld the plate fully to the box. I didn't take pics because it really wasn't pretty welds. Strong but not very consistent.

Now while I do like in the Great White North I live near Vancouver BC and we usually just get rain for winter. Maybe a small snowfall or two. But this year has been different, and thats added a new challenge to working on the car.

Wet heavy snow is terrible for pushing through.

Solution is to quickly borrow the farm truck, or the tractor.

This gets worse though, after a bit of freezing sub zero nights, combined with rain, thawing more snow and more sub zero I had a lot of wet, heavy snow stuck to the tents.

they didn't like it.

My dad texted me about it and I cancelled my plans for that evening and went over to deal with it. Car was full of snow but thankfully it was the back where I don't have a lot of bare metal showing. Pulled it inside and spent the next few hours with a heat gun and an air sprayer getting as much of the water out as I could. Wrapped the car in a tarp and put it back in its home.

The missile had straight water in it from the last track event, I totally forgot about that. So the rad is frozen solid and so is the water pump. Not sure if rotaries have freeze plugs but it did start, I'll deal with it in the spring. Even if the motors gone in it Im not that broken up about it.

These two things have kinda killed my motivation, that and work is crazy as we are nearing our deadline for the project. Taking the holidays off from it and praying the weather gets better. So heres to progress in 2017 lol. Fab work feels like its almost done, until I decide I want to shave the firewall or something right?

Comment

-

What a story man. Damn... But at least you have learned a ton from those setbacks. I'm hitting that subscribe button in the top right corner now. So please keep them updates coming Lucas

Lucas

Former daily: 2002 CLK 500 AMG - (sold) . . . . . . . . .

Project: 1986 W124 260E rebuild - (3.0 swap) . . . . . . . . . Follow me on IG : @loekaazDaily: 2004 Pontiac GTO. . . . . . . . . Daily Econobox: 2009 Mini Clubman CooperOriginally posted by LCGHigh 21! It's like a high 5 but includes both hands, both feet and a boner.

Comment

-

I'm so glad you're still around and still working on an RX7.

Total bummer about the first one flipping and going to hell in a handbasket, but good on you for sticking with it and not giving up.

Here's to hoping you have a prosperous holiday and a successful build.BB6 Prelude . . E36 ///M3 . . VA WRX Limited . . 1969 Nova

Originally posted by OllieWe all love to turn heads. Sub-consciously we're all materialistic attention-craving dickheads.

Comment

-

Originally posted by loekaaz View PostWhat a story man. Damn... But at least you have learned a ton from those setbacks. I'm hitting that subscribe button in the top right corner now. So please keep them updates coming Originally posted by MommysLittleMonster View PostI'm so glad you're still around and still working on an RX7.

Originally posted by MommysLittleMonster View PostI'm so glad you're still around and still working on an RX7.

Total bummer about the first one flipping and going to hell in a handbasket, but good on you for sticking with it and not giving up.

Here's to hoping you have a prosperous holiday and a successful build.

Thanks guys!

Comment

-

Once again, lol been putting off and forgetting to post an update. But that means theres a lot to tell.

Been kinda listening to this Weeknd guy. Not my usual taste but so good to work to, great beats. Though every song seems to be about cocaine in one way or another. Much catchy.

Where I last left off I had a couple brilliant unnecessary make work project ideas.

I've never liked how these cars look with the rear tire well hanging below the rear bumper. (also side note the rear crash bumper has some spring things in the mounts and not only do they do nothing, they weigh a lot) So I decided to make it more S Chassis like, cuz those cars look good with no bumper and no crash support.

I forgot to take pics of the finished product, but needless to say it was a lot of grinding and welding thin crappy metal. And I later drilled a drain hole, as now its a great water catch.

I started tackling the firewall and the rest of the engine bay smoothing

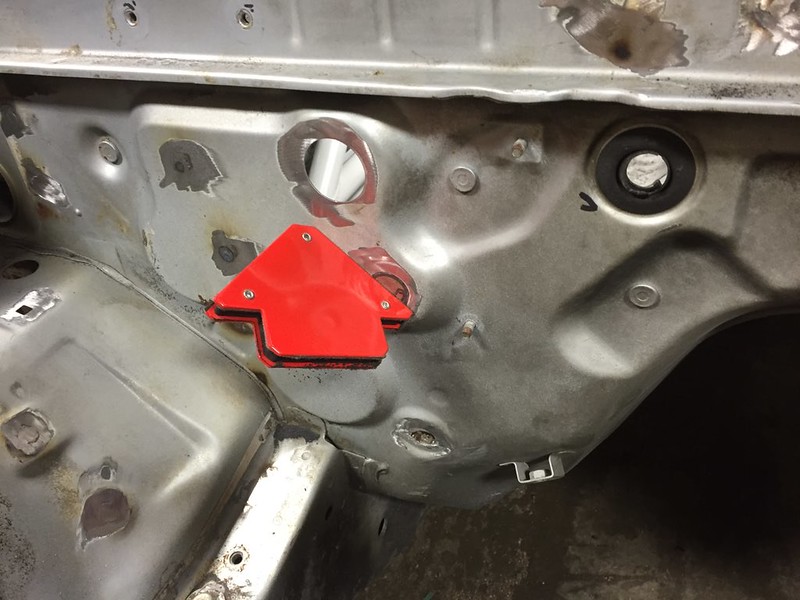

I don't know why it took me so long to buy a few of these magnet helpers. They are so handy.

Basic process was take some scrap metal, hold it behind and draw the outline of a circle on it. Then cut and grind till it fit inside, then magnet and weld. The smaller holes I just fill welded and grinded flush. All of it will still need some filler to be perfect.

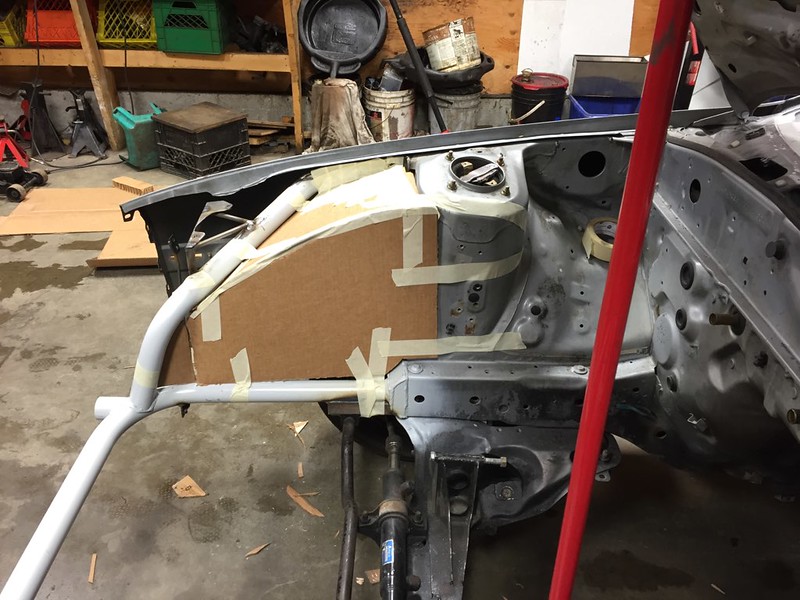

I've been on the fence about tubs. I really grew to like the look recently. But up until this point I had decided to not do them and had designed and built the tube front with that in mind. Buuuuuuuut I kinda changed my mind.

So while these were on sale I went and scooped one up. Managed to somehow fit it in the toyota..

I knew this was going to add a lot of fab time onto my schedule but I deemed it worth it. Keeps the engine bay a bit cleaner and makes the car that much more street style. I figure worst case I can always cut them out.

A tip given to me by a guy who's crashed a car or two and has seen what they can do told me to not do them. He said if you get in a crash it can pull the strut tower out of whack. I'm planning on holding each in with a bunch of tack welds and seam sealing it all for a seamless look.

So many hours of deciding, and using cardboard to help figure out (these pics are actually from when deciding whether to do them or not) I had a game plan

Spent a lot of time making sure the gaps were stupid tight. Which will be a waste of time after the first time I tap the car into something I'm sure but oh well thats drifting.

Then ran out of gas and moved onto something else.

Long way off but trimmed the cubby frames around the cage.

Picked up bottle #3 of this project

Also had the metal place bend up the pieces for the tub fills while I was there. A little 1' lip on a big sheet that I will trim down to fit.

like so

Heres a pic of the bending rig I came up with to do the one corner

The spot where the fill meets the fender and the tube was kind of an awkward one. But I strived to make it as small an area as possible, and am pretty happy with how it came out.

keeping the gaps real tight

angle of this pic makes the gap look really big but its not much larger than the others. That was a tough area to kinda guess where to cut then bend it, struggle to fit in place, shave down some more and then find out you went too far in one area. Did some adding to a few edges.

But came out good. Once its seamed and painted I'll never be able to tell.

I'm big on how this car looks when fully dressed but also while its fully naked and the steps in between.

Around here I was very into how it looked with the tubs and nothing else on. It looked fine with the fenders and headlight in but not when those were off. Not too interested in throwing all that work in the bin yet I decided maybe it'll grow on me and carried on.

I've been reading through Engineered to Slide's hilux build, not only inspiring work the hours that dude put in were crazy. He is also completely not afraid of cutting off a piece he's not happy with regardless of how much work it was to make. That kinda added a new element to how I was looking at my own work.

I'm refusing to weld them in yet, until I have some primer to put on them right away. With the tent situation the way it is the car now hides in the tent but under a tarp. We have been getting a ton more snow than expected and when its not snowing it's raining. The car has started building up light surface rust all over the bare areas. As much as this pains me theres little I can do about it yet.

So that done, the next thing was to cut more car out.

first had to take out the fuel lines and the subframe

And remove all of the bump in the bottom of the cubbies. When you install Parts Shop Max subframe risers, the toe arms, trailing arms and subframe move closer to the car. This combined with how low a ride height I want to be at and running 0 camber means the floor can't be there. Last time I took a hammer to it but I wanted to be better this time. I also plan on mounting the battery and a few things in the cubbies so a flat floor makes it easier.

Finished cutting and trimming the pieces to fit, (but lol forgot to take a picture naturally) and decided before I do any final welding I should test fit the subframe. Which is on the missile car. Which is parked outside...

So thats gonna have to wait till like march lol.

Before I forget, boxing week brought upon me great deals. I needed some 18V drills for work and love the M12 stuff I have from Milwaukee already. Local place had a deal on where you buy the drill set and get a free grinder. Nice having 2 grinders again and the cordless part it handy. Its a shame it rips through batteries so fast haha.

Have a whole family now. The impact actually has enough torque to remove lug nuts so thats sweet.

Per Gaelen's recommendation about tubs he also told me to make the bash bar out of a really thin wall tube. It took only like 6 weeks to get (kinda silly), and I wish they had some on hand first because when I picked it up it was really thin. I figured we use .095 wall and thats pretty strong so the next size down .065 wall is like exhaust tubing lol. Gave it a shot aaaaannnnndd

nope.

fun fact, with some creativity you can fit and 8' tube in a sedan.

So stole some 1.5 0.95 wall off Neil and bent up 2 pieces based off templates I made using the bumper.

Went and started fitting the bumper, now I don't really know what I'm doing here as I've never fit a kit before. But it doesn't seem like rocket science. Big surprise though, rep kit fits like a rep, poorly

With the bumper in place a lot closer than it was I released a problem that I somehow missed before.

The mounts for the bash bar are a little bit close for the centre vent. Now I could have shaved the vent and cheated the angle of the tube a bit but thats not howI roll.

So out comes the grinders and to take it back down to nothing

And fixed. First location was keeping the tubes all merged in the same place. This is still pretty close to that but now has the bash bar mounts more inline with the frame rails, so I guess thats an added plus.

Then start to fit the bash bar in place to realize another problem. The bottom of the bumper flares out considerably more than the stock bumper. But this flare starts at the top. I gave myself some room inside the bumper when making the template, just to be on the safe side. But the metal factory fenders are right in the way. Some trimming of the, will probably have to occur as well, but I'm going to have to re do the top bar. I can get it in place if I wiggle it in there, and then put the crumple pieces in, but I'm not ok with that.

It also just barely contacts the headlight surround trim. The difficulty of bending a piece when the tube bender is in the next town.

However

Me and my welder buddy Andy have bought a Jd2 bender between us. He has been doing side work for off road vehicles and wanted one to make stuff for that. I wish we had done this like a year ago but I can still do my bash bars front a rear and do any future repairs with it.

His company is now Heavy Artillery Fabrication if you wanted to check him out on instagram.

Then I started on the part I've been dreading doing. Rust repair. Its always on of those things that you think "oh it won't be that bad" and then you start and keep finding more and more and more.

It's also gross and rust bits rain down from above, and the metals thin and covered in primer paint and or this wax stuff that they fill the rockers with so it welds poor. This car had it in basically each corner, I was expecting it here under the drivers feet because it seems like every S4 has rust there. Also under the antenna where the wheel well meets the interior.

Patched it up best I could keeping each layer there and connected at the pinch where it should be. Weld thru primer is your new best friend as well as a good wire wheel.

Passenger front side

Driver rear was really bad too.

I still have the passenger rear corner to do. Not sure how bad it will be yet, but my dad is redoing the kitchen so I can't make a dirty mess in the garage right now to finish it.

Got some new new though

Not totally sure about these, but I'll give them a try. White line says they change camber at the knuckle, which will hopefully allow me to get all the way past 0 degrees and allow my camber bar to not be maxed out. I fear they might rotate in the knuckle but we'll have to see.

Now I ordered this based on specs. I knew it was gonna be rather big but on paper it outflows basically all other fuel filters, has a 7 micron filtering and is serviceable. Once I received it I now see its actually meant for like gasoline pumps, and has a max rating of 50 psi. Not sure if I should use it but provided my fuel pressure is fine and stays at 40 I don't see an issue besides finding a place for the it to fit. Had to laugh when I was looking up info on it though, apparently its a very common DIY weapon silencer.

Got the thing I was in real need of to mockup the rad mount, these Derale fans

I knew when I ordered them they were gonna take some trimming to fit. But between the two of them they flow 4000 cfm. I've got some ideas, I'll make them work.

I'll be re-using these again

60 amp max current relays. The fans come with some cheapo ones but meh.

Got these done (finally). Tried 2 different plasma CNC tables and neither of them were up for it, so I had to find a laser. Local place I hang out at sometimes Serial Nine gave me the info for the guys that cut all their metal. So big ups to the guys at Brenco for helping my out with this.

Very excite.

So like I mentioned, dad had the garage on lockdown for his kitchen reno, I had to keep it clean. So I moved onto the next thing up the to do list that didn't involved cutting, welding or grinding.

Pulled down and organized the interior pieces I have

Trimmed the ECU bracket to fit. conveniently my old 5.0 eco bracket fits on it so I guess ill use that.

Trimmed kick to fit

Started the rear panels

Threw the cubbies in a trimmed up the carpet. I knew this already but the cubbies won't be able to flip open anymore. Going to have to come up with a solution to remedy this. Thinking black Dzuz fasteners or try use the key lock on them.

Going to use velcro once the interior is painted to hold the carpet all nice and together and in place.

It was a battle but got the headliner to somewhat fit. Only took cutting it into 2 pieces.

Picture doesn't do it justice but these side panels juuuust fit in there. Have to kinda force them in but it all fits.

Here's another pic with the A pillar gussets in place. You can see I also started trimming the dash top piece but stopped until the gusset is actually welded in place.

tiny little piece of A pillar being used up there. Kinda unnecessary but can't help it.

the rest of the A pillar that I can actually use

Have another thing to figure out. The vents that blow air at the windshield obviously don't fit anymore with a roll cage in the way. They are pretty close but I'm likely going to have to cut and glue to get something that will fit.

Have spent tons of time grovelling over what I should do behind the tubs...

Theres a little corner I had to hammer for wheel clearance, so now what to do with the space.

A full rear tub is cool but takes up too much space that I need to mount things. Also makes getting at the rear of the engine too difficult.

Tried a larger piece of fender

And a smaller one.

I don't like any of it. I thing ill go with a flat ish piece that curves over where the corner was. Make it look oem ish.

I will try to update more frequently. Maybe. Probably not though. But maybe

Comment

-

well true to my vague word, here we are months later and I've finally found time to update this ole thing.

Been listening to a lot of stuff but keeping it to one or two more recent albums. Snak Tha Ripper Just Giver, a local guy (well to me) but I believe he's more well known than just the lower mainland. A mix of non serious rap and the real stuff (I like the real stuff in general but both are good on this).

And for something completely on the other side of the spectrum

John Mayer's latest; The Search For Everything. Been a fan of his for a long time, since sometime in high school. lol was hassled then and still am today but I don't really care. Dude is hands down one if not the best guitarist in the world, I say this after seeing him when he came to town a week ago. Show was great and each ticket came with a copy of the album.

Life's been whack lately, between family stuff, Nissanfest, starting school (well trades school sooooo) and general busyness it feels like I never get more than a few hours to work on the car but thats not really true. Thats just how it feels lol. Probably has more to do with how slowly stuff is going, but as they say double your timeline and double your budget. Doing things how I want them done means me doing it twice sometimes.

Been stripping my wiring harnesses of loom so I can start piecing it all together, found that Netflix added Monster Garage and chose to start watching that. Made it through 1 episode and remembered why I can't stand Jesse James and proceeded to watch other things instead.

After almost a month delay UPS finally gave me my package from Parts Shop Max. Last time I ship with UPS ever. Some of the worst customer service experience I've ever received. Don't ship with them especially if crossing the border.

Got a set of spacers that also fit the daily driver toyota and their spherical conversion kit for the rear trailing arms. Now I've read and been told that because I have solid everything else and poly trailing arm bushings that this would cause binding. Can't say i've experienced this but most of the time I think the trailing arms bottom out on the chassis before they could articulate so much that they could bind. New chassis the body isn't in the way so I figured I'll solve it before its an issue and order the last piece for the rear subframe that they sell that I don't have.

stackable spacers are sick too btw

spent a few minutes on the front end with the tie rods disconnected just to make sure I had ample clearance from things before I did the rear tubs.

you can see where some cutting needs to happen

the front however, the tub sits perfectly as I planned. Tire would hit the frame rail before the tub.

Then pushed it outside to where we usually park the farm truck so me and my dad could start on a new wood shack/car thing where I usually park the car. However it rained, no monsoon-ed for like 2 days and flooded the back yard and I ended up pulling it out of about 6 inches of water. not amused.

after much thought and consideration for use of space, I came up with these for the rear tubs.

start with stock, well minus hammer marks. (was making sure the intrusion bars didn't fowl wheel clearance)

filled in the holes while it was easier

then the majority of it

then welded and grinded

repeat for other side. hoping this looks oem when its filled and painted. it allows for me to have wiring and or catch cans etc in the space, doing anything else would have taken up so much room.

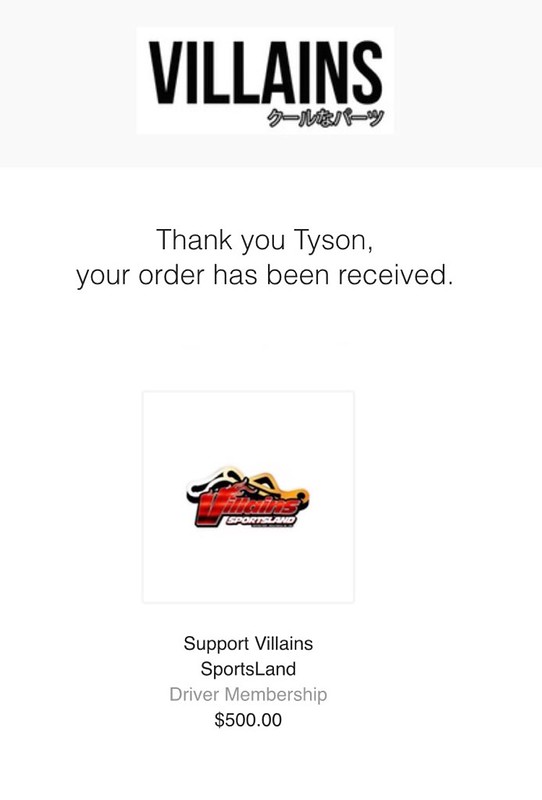

Bought one of these, was really looking forward to this project. I think what Nate and the guys with Villains are doing is amazing, good for drifting in the PNW but also for drifting in general. Since buying one the project hit full funding and Paypal didn't hold up their end. You can read more about it on Villains Sportsland Facebook page. After having a good conversation with Nate at Nissanfest about it Im still hopeful this will happen, though it may not be until 2018.

anyway back me making more work for myself

besides how rusty it looks (though it does come off pretty easy) I did not like how it looked. Went to the Vancouver Auto Show and me and my buddies must have spent like 45 min just looking at Brody Goble's Pro2 s14.5 build. His fabricator does great work and with lots of clever details. I went to the shop the next day with the ambition to step my game up. I want this car to look like it came out of a shop, not a hobby garage. That said not a FD car but close to that level of build quality I can get to within reason.

so cut that out. Didn't like how the mount plate sat on top of the tube, didn't look clean and I can't do pretty welds so would rather them sit more flush on the tube instead.

remade the plate, cut more of the tube out and tacked in place

shape aside it maintains the amount of material (if not more) than the wall the tube would have if it wasn't cut. I am mildly concerned in the event of a crash the tube will behave different than the crash testing but my thinking is that it will fold after the bend anyway.

and done one side

and both. much better. OCD satisfied for now

while I had the welder going I put a captive nut on a plate for a ground wire from the engine. May re do this, but its pretty low down and functional.

got some primer from the body shop my sister worked at

and set up for doing some primer. finally everything won't rust on me

start with wire wheel

sand with 260

give it 2 layers of primer

as it turns out, this is fairly time consuming. And I have to allow for drying time at the end of it before I put it back outside in whats usually rain.

so still putting the car outside under a tarp

but me and my dad are working on making that better. 2 parts firewood storage and 1 part shelter for my car. Once we're done building it and framing in the sides I'm planning to frame a door and completely enclose where my car is. When we measured it out I planned for enough room to build a tire rack in front of the car and some small shelves etc. But as I've learned thrifty ways from my dad, we are trying to find as much used wood and roofing etc off CL and save money where we can there.

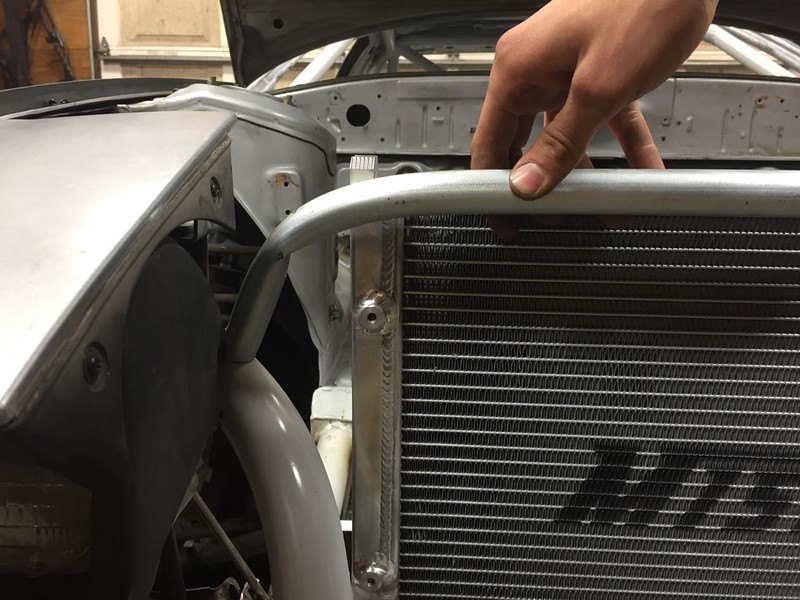

spent a few minutes with my radiator and fans, did some trimming and hole saw action

need to get some PVC pipe to finish the shroud. but fits just so.

Took the missile out for its last hurrah before I disassembled it completely.

Friend was having a private day up at Penticton and I managed to snag a spot out of 5 cars. Paid for the event thinking "missiles fine, haven't touched it since october but it ran when I jumped it last"

well...

needless to say we had a rough winter and I forgot to drain the coolant or put antifreeze in it. Not 100% sure where the coolant and oil are mixing but my best guess is the front iron cracked. This was after the car was loaded on the trailer and we were otherwise set to leave early the next morning. So I threw new oil in, (didn't help) some lucas stabilizer and put premix in the tank hoping to limp it through the day.

needless to say it made it, though down on power and smoking like it was on fire (apparently shot fire balls too). Managed to get my girlfriend in a drift car. Told her "I'll take it easy and you can get used to it". kinda did that for the first pass. 2nd pass I threw in almost 2 fast and closer to the wall then I had all day. But she wasn't phased and stayed in until we both felt sick from burning engine. Brought a buddy along to let him have a chance to do some donuts and experience drifting and well basically get him hooked on it before he does something like autoX or track racing haha.

Spent some time playing with front suspension settings and alignment settings. Private days are great for this cuz you have so much track time. I'll get into more of it later

was super surprised by how long it lasted, especially since I was not being nice to it, as I didn't really have much to lose if the engine did go. Ended up being a long day though, its about 4 hours to get to the track, then we detoured on the way home and hit snow at the summit of the Coquihalla on the way home. Left at 7 am, home at 2:30 am.

So the next weekend after that, we headed up to Nissan Fest. was thinking "ya this will be a nice chill weekend, Im not driving or drifting. maybe change some tires for the guys and get some ride alongs"

nope.

Krew Chief Keil's Allison blew up about 10 minutes from the border. So we pulled it off the hwy with Pete's LS powered 240, and I got a ride to the border and walked across to get another ride to get my dads truck. Ended up towing the trailer and all the tires for the team. worked out because my dads truck and kris' is the same except his is a diesel. But was a fun weekend, weather was all over the place. Everybody practiced in the dry and our guys got in a groove, then we had a lunch break where it rained hard for an hour then cleared up in time for the competition. But it was 100% different than practice and was super slippery. Kudos to the guys that won though, they had it pretty figured out by the end of the comp and put down some clean runs even for how wet and inconsistent it was.

Then one of our cars (lol not one of the drift cars but he did drift in the open drift after the comp) broke like 20 minutes down the high way leaving the track so we loaded him on the trailer and dragged it eventually all the way home.

Fun weekend, however not was I expecting at all but when is it ever.

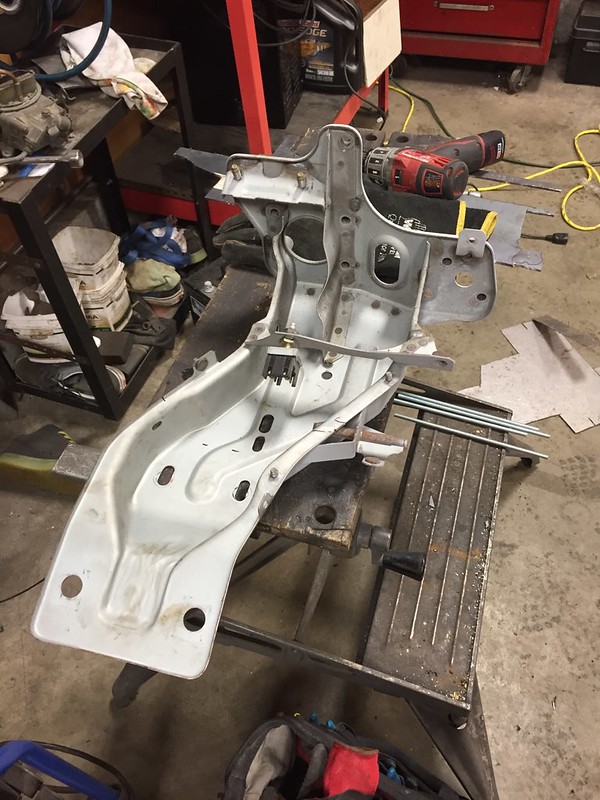

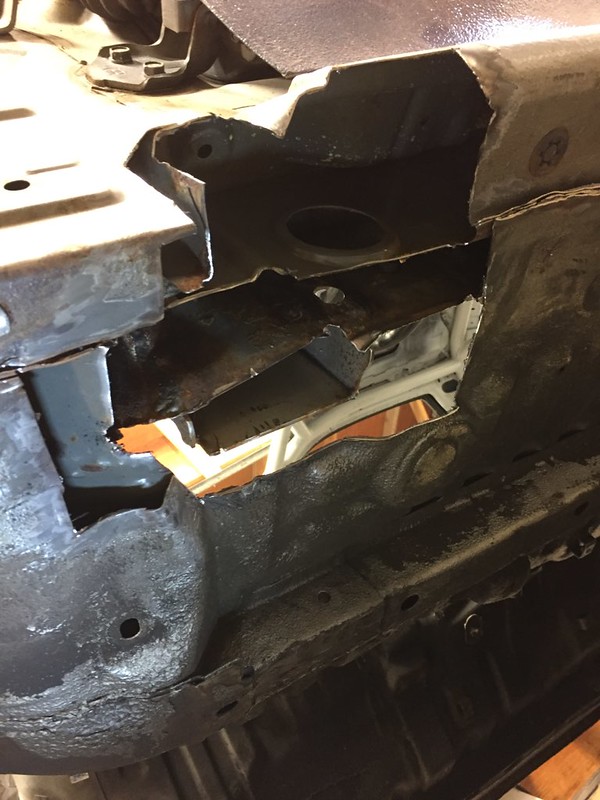

Started tearing the missile down and found things I wasn't expecting

I always had this idea that I would one day build this car into the new drift car, but the roll happened much sooner than I was ready for and the accident with this car also happened unexpectedly and too soon. I always thought it was the cleanest of the 3 i've owned but turns out its the worst.

The usual areas I see rust on S4's there wasn't any but the passenger rocker was baaaaaaddd

so ripped the interior and windshield out. I plan on keeping a large amount of the parts from this car. The interior while blue was in great shape and when I go to die a dash black again I wanted matching colours so starting with the same colour dash pieces. The suspension is also full of parts from the drift car anyway, and having spares of some stuff aint a bad thing.

got these up around black friday (shoutout to Neil @ SCG, he's a dealer btw and I think the only Canadian dealer), they are 18x9.5 instead of the 17x9 I have currently. I think I want 18" up front but if they don't fit or clear etc I will likely use them as rears.

I was hiding these in my basement so they would be clean and mark free when I went to use them but my daily was lacking cool wheels (and I corded the tires on the CR-Kai's drifting). Picked up a set of tires cheap off a buddy in Kelowna while I was out that way (thanks again Caetano!)

had my bud Pete (same dude with the LS 240) put them on for me and before they went on the mark 2 I test fit them on the missile.

at its current more function oriented ride height they clear everything with no spacer needed. Even the fenders on, they are pulled probably 15-20mm more than rolled flat I'd guess. Keep in mind that this is with the Villains angle kit (40mm ball joint spacer) and a bit of hammering and removal of the brake line mount, also around 7* of camber.

even a bit of room between it on the fender.

however once I got it sitting more like it should the wheel and the spring touch so I need around a 10mm spacer but I used a 15 cuz thats what I have and it still fits.

sitting the car on the ground it actually sits higher than I thought. Switching from a 215/40r18 to maybe a 235/30 or similar might help. or 17", don't know yet.

real issue is going to be this, but I had the same one with 17" wheels as well. Its not a lot of suspension travel.

When I was at the track I was advised by a new friend Garrett to try adding caster. I tried castor on the old V8 car and it felt terrible and smacked the wheel around. Now that was probably due to the weird geometry that giant rack spacers give at angle on stock ackerman knuckles. Now that the car has 0 ackerman it doesn't self steer very much and as a result its very twitchy and I had to be steering ahead kinda guessing where the wheel needed to be. This was a great way to learn where it should be but man is it hard to be smooth and precise. so at the track I added a bit of caster by maintaining camber and rotating to the middle position on the PSM top plate.

Car drove much better the rest of the day, I wish I tried it sooner and had a chance to try it with even more caster added.

The other thing I noticed test fitting the 1552's is that the knuckle no longer hits the tie rod into the ball joint/control arm. The rack now stops before anything hits, much to my surprise. Seems like a lot of change for like 2 or 3 degrees caster, but am doing a bunch of reading on steering geometry to figure out if something else also changes.

as I type I plan to take the missile to its new scrap metal yard home tomorrow. sad day for sure. Looking forward to having 1 project car and having the parts I need to test fit accordingly.

till next time heres the Mark2 at Serial Nines block party blocking SCG's cars hehe

Last edited by Teeson1111; 05-02-2017, 09:02 PM.

Last edited by Teeson1111; 05-02-2017, 09:02 PM.

Comment

Comment