Very nice work so far. I'll be checking in for updates for sure!

Announcement

Collapse

No announcement yet.

FC RX7 5.0 race car thread

Collapse

X

-

Haha yup!Originally posted by Suburuuh View PostThe start (and running) of an engine in a build is like putting fuel on a fire!

This gives even more motivation to continue and finish it.

Loved your bug eye when it was on works!

Comment

-

Thanx! I'll keep posting themOriginally posted by pDubs View PostVery nice work so far. I'll be checking in for updates for sure!

Comment

-

-

Car is looking great! Reusing the factory harness has been a struggle for me as well, and having nearly non-existent soldering skills hasn't helped lol. I'm falling so far behind you, its hard to not run into the garage every time I see an update to this thread!

On your 3 fuse panels you have...are those just the $10 apiece ones you can get on Summit and Jegs? I was thinking about using those as well, was just curious if they're decent enough quality. The glovebox setup will be pretty cool, I was going to shove it in the storage bins but I'm curious to see how yours turns out.

Comment

-

Originally posted by Zach Thomas View PostCar is looking great! Reusing the factory harness has been a struggle for me as well, and having nearly non-existent soldering skills hasn't helped lol. I'm falling so far behind you, its hard to not run into the garage every time I see an update to this thread!

On your 3 fuse panels you have...are those just the $10 apiece ones you can get on Summit and Jegs? I was thinking about using those as well, was just curious if they're decent enough quality. The glovebox setup will be pretty cool, I was going to shove it in the storage bins but I'm curious to see how yours turns out.

Ya the fuse holders are Hella, very good quality.

I would throw everything back there if I had an interior lol.. Glovebox ends up being a shorter run as well..

Thank you!Originally posted by aeok18109 View Postepic job here sir

Comment

-

You should ditch the whole plastidip idea - You did really well painting the inside and roll cage (which one was painted first??)

So just continue with that and paint the entire car!

"Never argue with an idiot; they'll drag you down to their level and beat you with experience"

Comment

-

lol thanx! but no... It worked ok (looks better in pictures probably) I think because the stuff I painted was huge and flat. The hood and much of the body would be really hard to get clean with rattle cans.Originally posted by TeckniX View PostYou should ditch the whole plastidip idea - You did really well painting the inside and roll cage (which one was painted first??)

So just continue with that and paint the entire car!

Plastidip offers the ability to change colour often too, and easy to repair

I painted the cage first, then masked it and painted the interior.

minor update:

been rocking out to this. Found The Parlor Mob some time ago from a random snowboarding movie (Iseneven - Let's Go Get Lost (great movie)) and quite enjoyed the rest of the album. Haven't heard much of their new stuff but it seems a step away from the kinda small time rock band sound they have. I wish I could sing along a little better too, but it doesn't stop me from trying haha

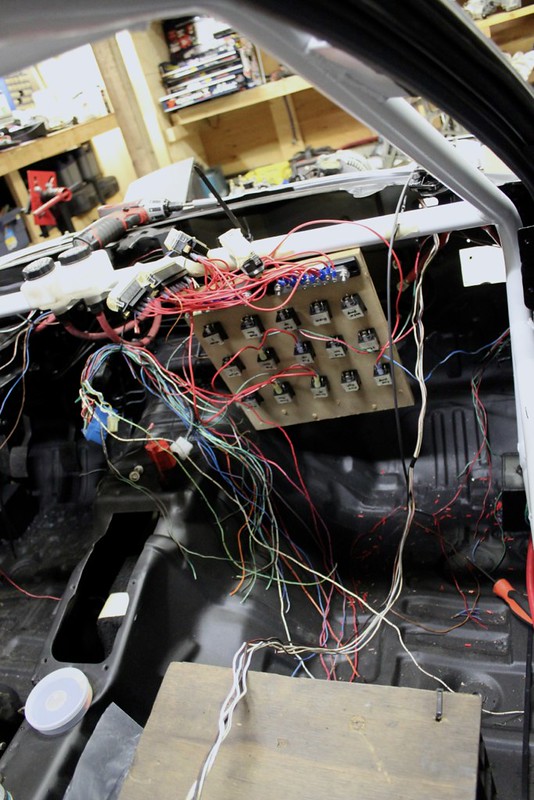

did some heavy gauge wiring

quite time consuming actually heating up the terminal, filling it with solder, dipping the wire in it, heat shrink, route it and check length. Repeat. Then I ran out of 1/0 so I need like 3 ft more or so.

tried (yes tried) to watch Formula Drift in Atlanta while working, but between my poor internet and the drift stream being cranky I didn't get to see very much. Oh well, Cory Hosford still liked my IG of it haha. Made my day.

made a mock panel out of MDF I had laying around, this way I can change things if need be. I have it so I can swing it in and out of position so I can check wire lengths but still actually work on it.

we attempted to weld that diff mount I modified... that didn't work

the rubber was catching on fire and the gasses created were blowing holes through the weld pool. So after about halfway we just called it. I'll be buying a Parts Shop Max one later, this is more solid than the stock one still but not a permanent piece.

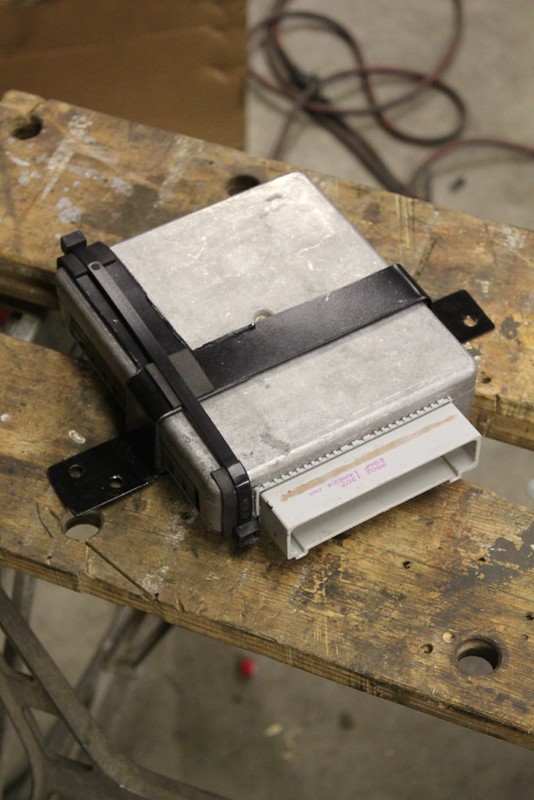

went to the local ladies craft store and grabbed some foam and did this:

The zap strap will probably not be staying, I'll get a huge worm gear clamp or something, but for now a pair of jumbo zap straps work well. ECU sits in there good, 2 layers of foam made a good snug fit.

seems like every day is a trip to the parts store for some small thing, but I'm making progress. I know theres not much to see but theres a good amount getting done. I keep changing my mind on how to do things, and when I do I stop the portion I'm working on and figure out the changes before actually crimping/soldering/cutting. As I get closer to finished the faster it should all go.

on a slightly different note I think my deadline is well dead. My buddy's most likely going to drive his dads 201x (haha not sure) Mustang instead of his fox body. My car which would be on stock wheels will kinda be out of place without his factory looking-ish Mustang there. So I'm kinda demotivated to get the car finished by then. I suppose the silver lining is less rush and stress which result in a better end result. I can enjoy the wedding and surrounding festivities a little more too I think...

anyway I'll stop rambling and go do more wiring

Comment

-

hey man just browsed through your whole thread again, is that large piece on the right of your trans mount your engine subframe from grannys? If so im hoping mine is similar when I get back to the states. Two more months of deployment lol.

Comment

-

Yeah mine fits good, mines been running and driving for awhile though. I bought it with the motor in it already though. Upon return will be the first time the motor has been outta my car so I will get to see the actual mount. Hopefully I can figure out something to make it sit lower.Originally posted by Teeson1111 View Postyes it is, its the engine cradle. it bolts into the factory subframe and the engine mounts bolt to it.

mixed reviews on fit, mine fits well but it also been installed for a while (I bought it used) a local guy bought one and his doesn't go in as easy...

Comment

-

lemme know what you come up with! from what I see theres literally no more room, the oil pans highest point is almost touching the steering rack. Way I see it is a few options and none are simple.Originally posted by LaMaR- View PostHopefully I can figure out something to make it sit lower.

1: dry sump, might next you maybe an inch.

2: custom tubular crossmember that relocates the rack (though I suppose that could be done to the stock one as well) this way is a lot of work as well as the change in steering geometry (bump steer!!) but the FD Ls kits deal with that.

The other note is the fox oil pan sits just higher than the subframe, engine goes any lower its now in danger of a strike.

If i had the skills/time/budget I would probably do option 2. tubular subframe may even stiffen up the front end more....

any who llloooooonnnnggg time since an update (ok its been like 2 weeks) so here we go

been listening to Manchester Orchestra lately, mainly Means Everything To Nothing but Simple Math has also had a spin. Just very passion filled raw kind of sound, and his lyrics just peak my interest.

So the thing with wiring is its very hard to jump into for just a few minutes. So I've been needing to dedicate an entire day or evening in order to get anything accomplished. So after a seriously long weekend and a few late weeknights its pretty much done!!!

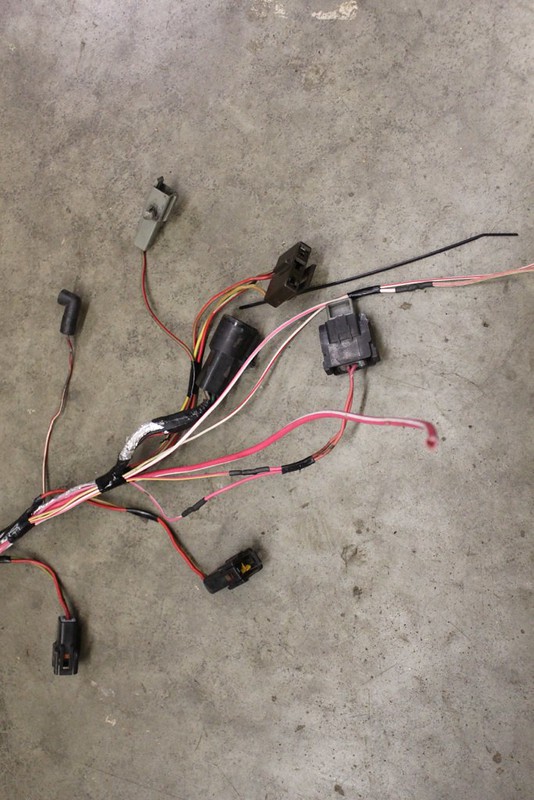

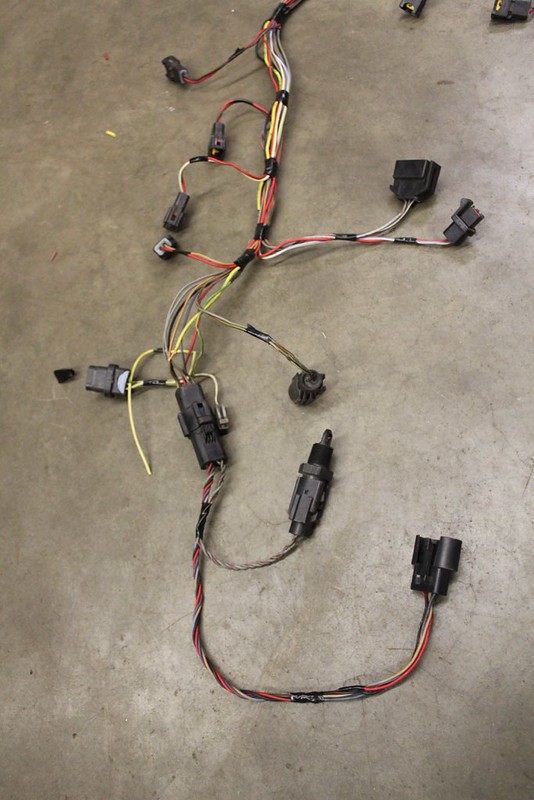

so took the engine harness

gutted it like a fish. Ford makes all their harnesses (or they did back in '94) for all options so this m/t harness has auto wires and any other option the car could come with pre-wired. So all that junk came out as well as the emissions junk.

So much better

(lol can't even tell)

I took the time to change a few things tho

The SPOUT pill for setting the timing used to be on the fender of the mustang, but I put it where they go on fox's

much more convenient. My only fear is that the rest of the spout is shielded so if its a problem and I'm getting interference I will shield the re-located wires as well.

also relocated the MAF and IAT sensors

as well as the 02 and transmission wires (no pic tho)

the completed bulkhead connectors

then I made another stop at the race car candy land store

but after I left I realized I should have grabbed another set of those power wire boots, I used these ones for the rear cut off switch. I want some for under the hood as well.

also ATE Typ200 (cuz it was cheaper than blue, blaming you american DOT law thing)

also got this, because I love these things and it was $3

then the wallet started to hurt...

bought the last of the wire I needed (well until I ran out of 8 gauge) we have black 1/0 and ring terminals and heat shrink, 4 gauge, terminals, heat shrink, and 8 gauge, terminals, and heat shrink. Also a quick disconnect for the ignition switch.

And I pulled the trigger after much research and little math on what size master to use for the clutch. Went 7/8ths, which is supposed to be quite ideal.

finished up the battery area, well minus the box for them. Going to build and get one welded, but all in good time.

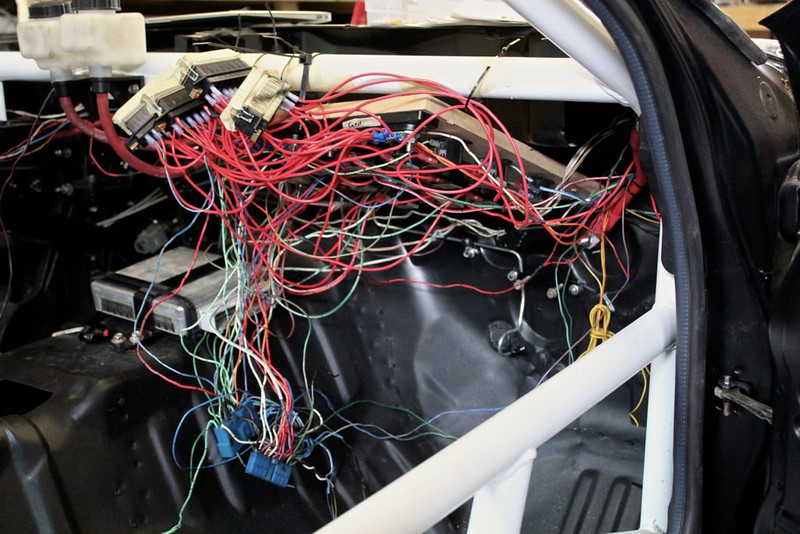

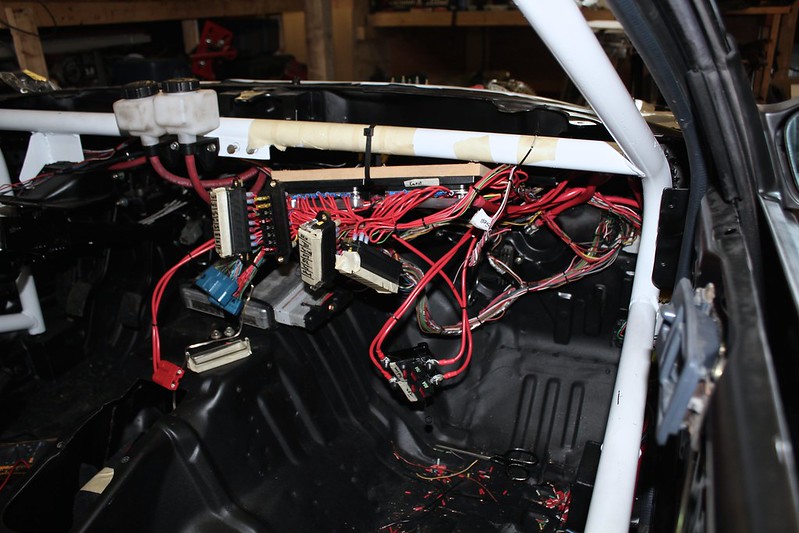

this was getting out of hand... so I made it prettier (only took like a week)

still have a little more tiding to do, but the wipers aren't working and neither are my head light motors, so some de bugging will have to occur.

got me a passenger seat finally. Well technically I still have to pay for it lol. Need to fab a mounting bracket for it and buy another 5 point belt.

The day this things runs I'm booking the windshield appointment. Its still going to be madness for the next 2 weeks at least doing all the small things. But to have the lights and things working is a huge motivator!

Comment

-

Nice progress! I'm hoping to have a few less relays than you do when I'm done, why do you still have so many?? It turned out clean nonetheless! If you end up needing headlight motors I was told mine are still good but I don't need them because I'm going to convert mine to some sort of manual setup.

That engine harness is looking mighty tidy, I'm looking forward to knocking mine down to that status

For hood height clearance you can mill the stock intake down (on the gasket mating surface), but I don't think there's more than a few tenths of an inch to be gained before you hit the valve covers. And on my SN95 oil pan I think I have a little more clearance before it hits the rack or subframe, but I haven't looked down there recently so I might be wrong. I would think modifying the engine mounts (between the granny's kit and the engine block) would be the easiest since they're cheap to replace if you mess up.

Comment

-

Ya I have quite a few relays. The wipers take up 3 and the power windows take up 2 for each window. Headlight motors also use 2. If I were to ditch the street legal thing and run bare minimum I could probably have it down from 15 to say 4 or 5.

Hood clears as she sits, so not gonna alter anything. Though it's close with the gasket in place.

And regarding the engine placement, there's a cm or so separating the rack and pan. Engine needs room to pitch under load so I'd say it's at the limit. Short of a custom pan (maybe one day lol) it's not going anywhere. But for me I'll honestly probably cut a hole in the hood to fit a better intake before finding ways to lower it..

Comment

Comment