I am a graduating senior in mechanical engineering at the University of Arizona and for our senior design we are working with a local company to install an Allison t63c18 Turboshaft into a Spitfire to serve as a test platform for a digital turbine controller. Currently, the engine runs a very complex hydro-mechanical fuel pump(similar to the old Porsche and Corvette mechanical fuel injection systems) which was designed with the turbine in the late '50s.

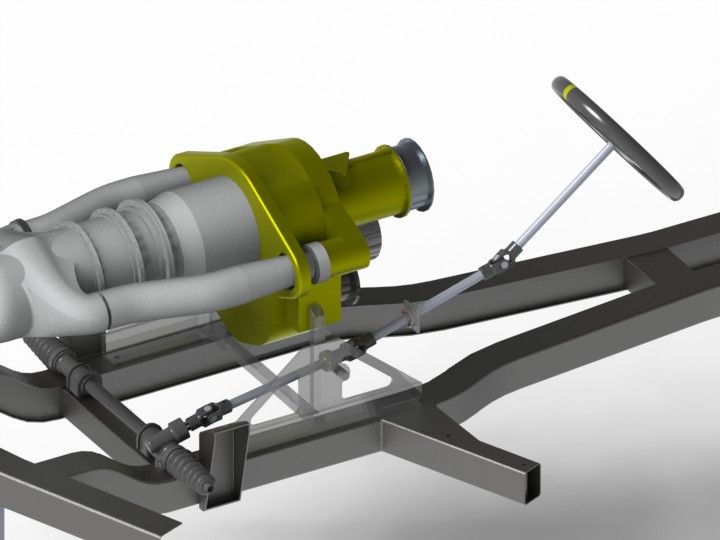

The turbine is fairly ubiquitous as far as turbines go, and was installed in everything from jet rangers to the Goodyear blimp. It makes around 320 hp at 53,000rpm (%100 throttle) and 425ft-lbs. It is of split-shaft design so the drive shaft and n1 turbine shaft spin independently. This lets us not need a clutch or transmission, since the viscous coupling of the n1 and n2 act like a torque converter.

We have been given a turbine with a custom output shaft with an automotive v-belt accessory drive, and a 12v ac-delco GM alternator.

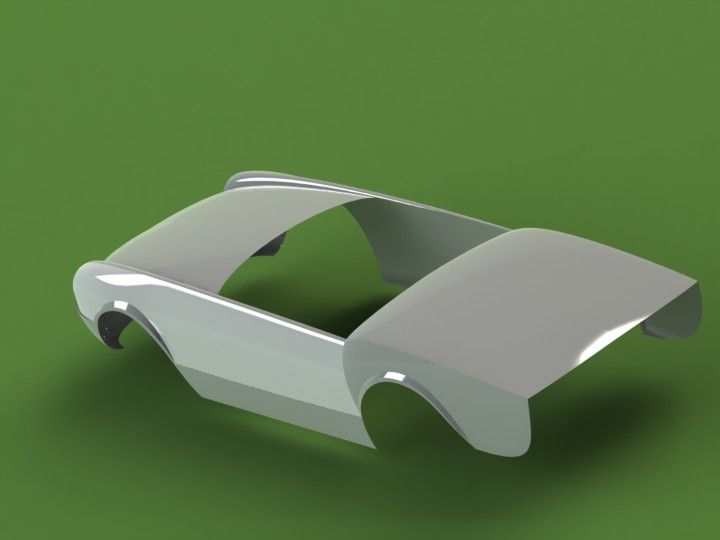

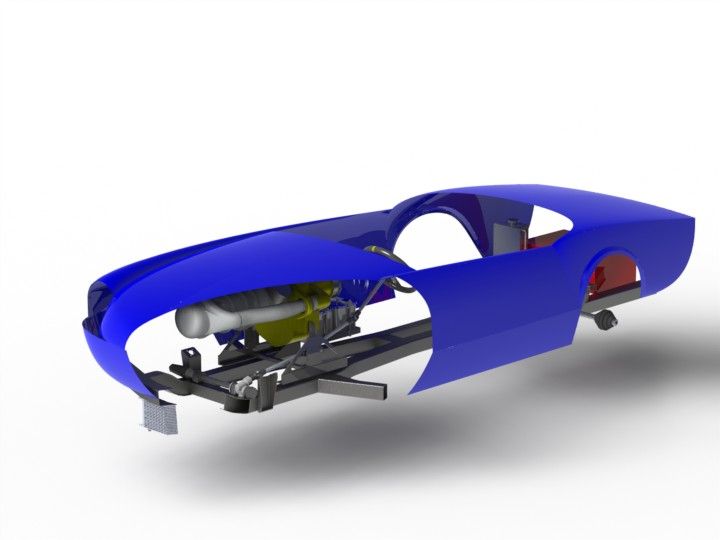

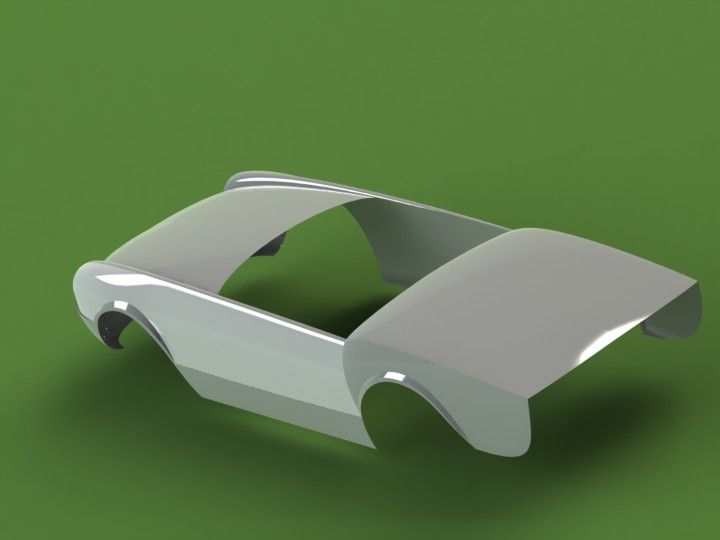

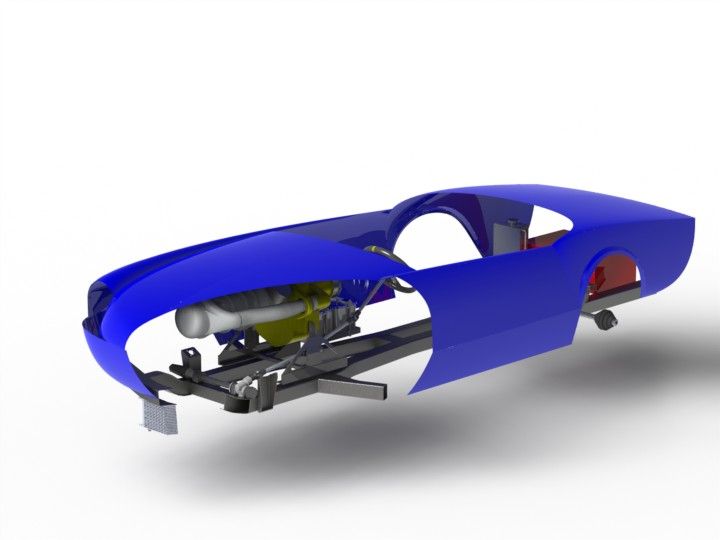

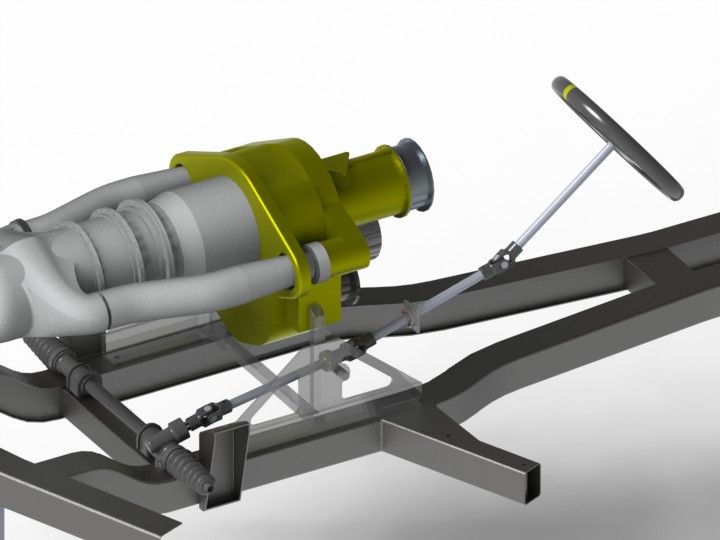

I modeled the frame and turbine to design the steering and do some studies of torsional rigidity. I am also currently modelling the body to verify fitment of various parts, including the huge, 6" oval exhaust tubing.

We received the car for free from a local british sports car shop, and had quite a bit of rust. we have recently patched the rust and got some of the body in primer.

Since we only have a 3000$ budget, we will be using the stock brakes, suspension, etc., so we will never get to drive this thing in anger probably.

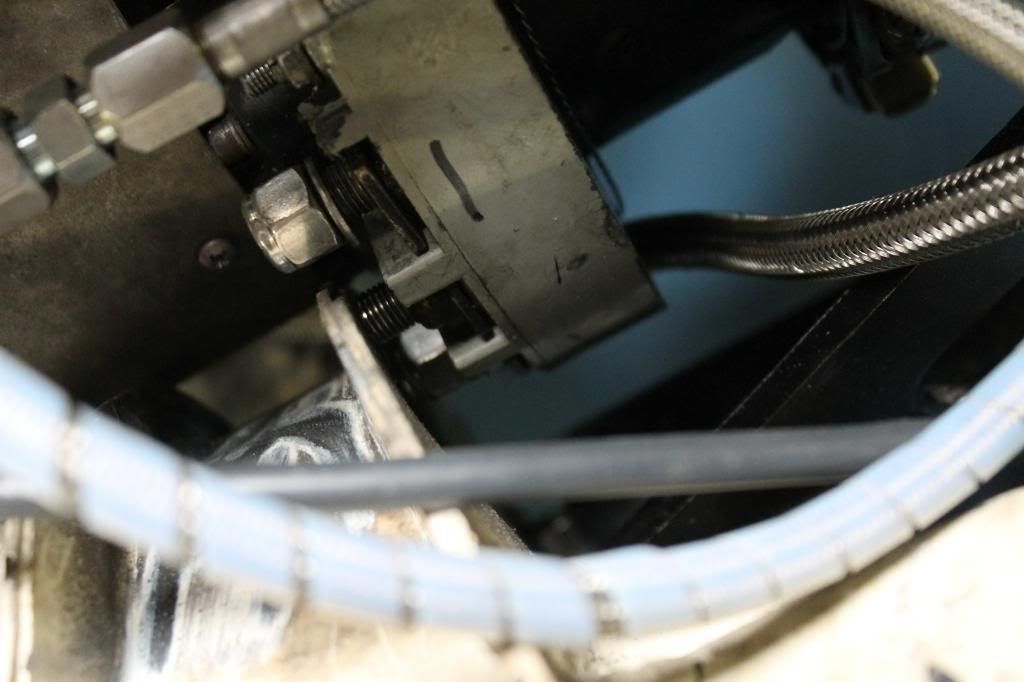

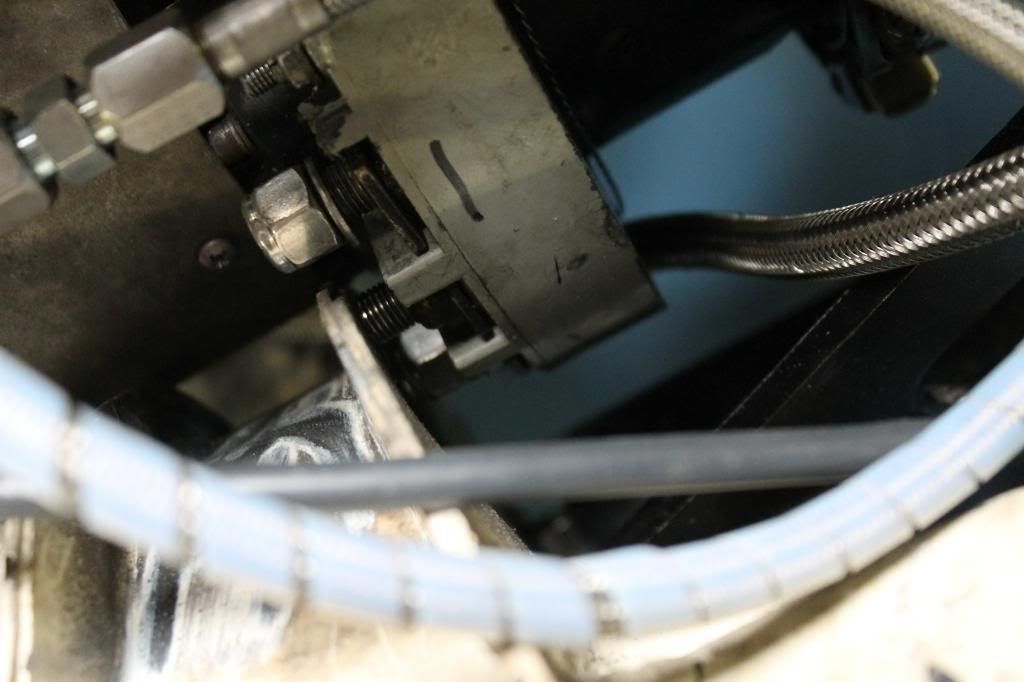

24V Helecopter starter/ generator leads a little too close for comfort. We will have to trim the a-arm mount and re-work it a bit.

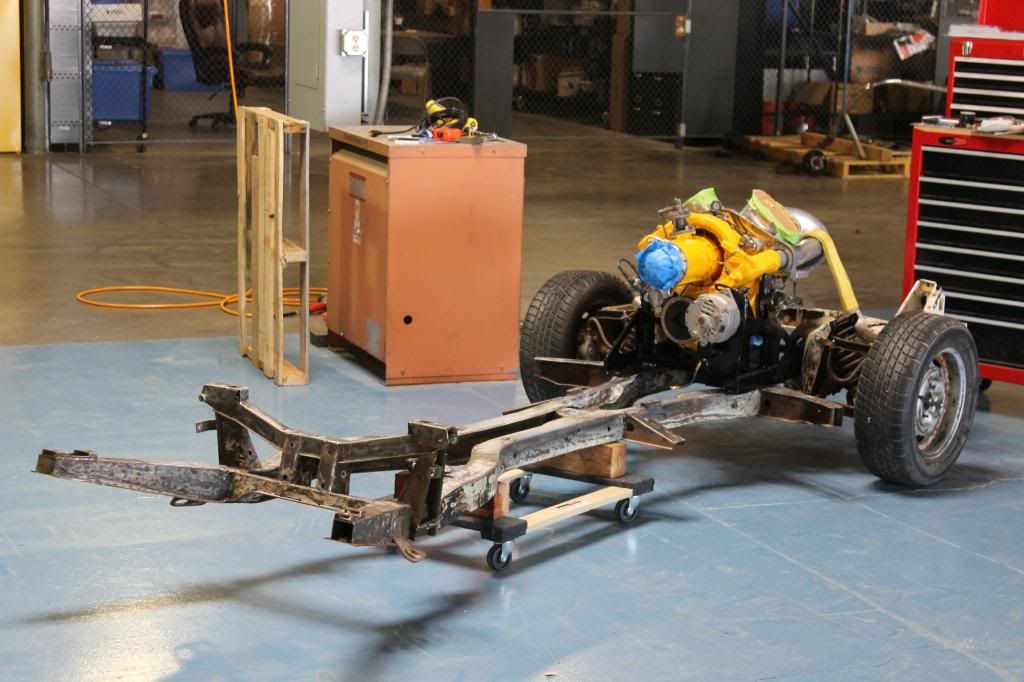

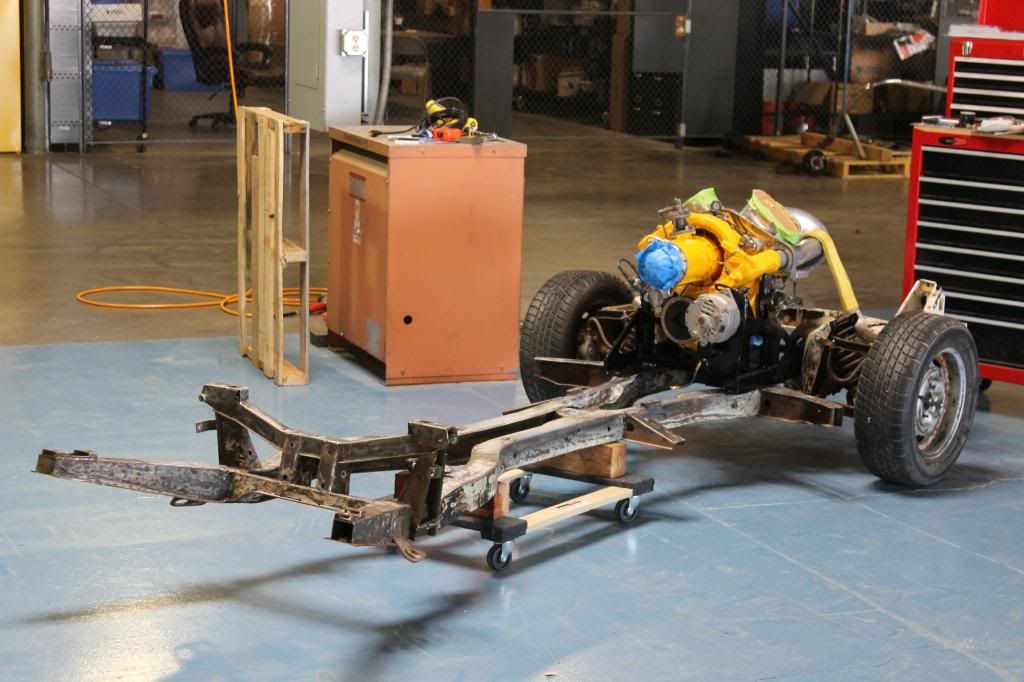

Getting ready for the first body test fit. Rear suspension and frame stripped and ready for a rebuild.

Here, you can see that the compressor housing needs to be were the firewall is. We trimmed the firewall so the turbine is about 12 inches into the "cockpit".

One of our guys massaging the firewall. We made just a simple square cut for easy fabrication of the removable aluminum plate "trans" tunnel.

A view of the space in the cockpit.

First mockup. The engine weighs about 50lbs less than the stock engine and trans, and doesn't require the cooling system, so the car sits a bit higher than stock now. We will run a 22 gal race tank, 2 12v deep cycle batteries and have a roll cage, so we will probably be back to stock weight, when its all said and done.

The turbine is fairly ubiquitous as far as turbines go, and was installed in everything from jet rangers to the Goodyear blimp. It makes around 320 hp at 53,000rpm (%100 throttle) and 425ft-lbs. It is of split-shaft design so the drive shaft and n1 turbine shaft spin independently. This lets us not need a clutch or transmission, since the viscous coupling of the n1 and n2 act like a torque converter.

We have been given a turbine with a custom output shaft with an automotive v-belt accessory drive, and a 12v ac-delco GM alternator.

I modeled the frame and turbine to design the steering and do some studies of torsional rigidity. I am also currently modelling the body to verify fitment of various parts, including the huge, 6" oval exhaust tubing.

We received the car for free from a local british sports car shop, and had quite a bit of rust. we have recently patched the rust and got some of the body in primer.

Since we only have a 3000$ budget, we will be using the stock brakes, suspension, etc., so we will never get to drive this thing in anger probably.

24V Helecopter starter/ generator leads a little too close for comfort. We will have to trim the a-arm mount and re-work it a bit.

Getting ready for the first body test fit. Rear suspension and frame stripped and ready for a rebuild.

Here, you can see that the compressor housing needs to be were the firewall is. We trimmed the firewall so the turbine is about 12 inches into the "cockpit".

One of our guys massaging the firewall. We made just a simple square cut for easy fabrication of the removable aluminum plate "trans" tunnel.

A view of the space in the cockpit.

First mockup. The engine weighs about 50lbs less than the stock engine and trans, and doesn't require the cooling system, so the car sits a bit higher than stock now. We will run a 22 gal race tank, 2 12v deep cycle batteries and have a roll cage, so we will probably be back to stock weight, when its all said and done.

Comment