Brain just leaked out of my ears. I don't know how you can keep up with so many projects, but props man, awesome work all around!

Announcement

Collapse

No announcement yet.

1969 simca 1118

Collapse

X

-

Are you using traditional blue ABS plastic to print? Hope that's just a fun project because those will melt if it is ABS. At my facility we jus picked up two carbon fiber 3D printers and I cannot stress enough how amazing they are. That and my epilog laser machine have helped me immensely with my build as well. Can't wait to see more form you, My mind is still blown due to your progress, AND casting on your own! you sir, are rad.Originally posted by godzillus View PostAlright fellas. Doin some investment casting. I bought a 3d printer to complement my CNC Router...Its the best thing ever.

Originally posted by Stupid KidI need the weed in advance i can't ride my bmx across the ocean unless im high

Comment

-

he's using the 3D prints as an positive to make the negative mould for castingOriginally posted by 190Evan View PostAre you using traditional blue ABS plastic to print? Hope that's just a fun project because those will melt if it is ABS. At my facility we jus picked up two carbon fiber 3D printers and I cannot stress enough how amazing they are. That and my epilog laser machine have helped me immensely with my build as well. Can't wait to see more form you, My mind is still blown due to your progress, AND casting on your own! you sir, are rad. Last edited by The Norwegian; 02-08-2016, 05:06 PM.

Last edited by The Norwegian; 02-08-2016, 05:06 PM.

Comment

-

Originally posted by The Norwegian View Posthe's using the 3D prints as an positive to make the negative mould for casting

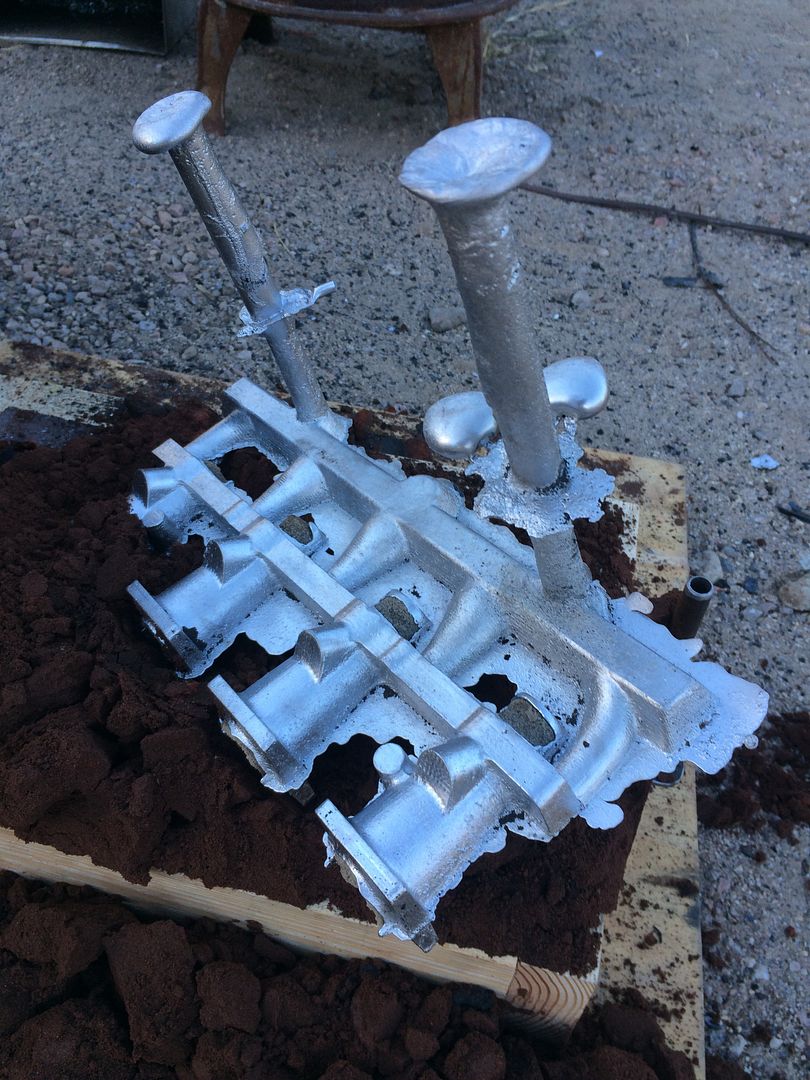

Exactly,

I sunk the PLA printed part in plaster of paris and made a couple of tunnels to the pastic before the plaster set. then I heated the cured block of plaster to melt the plastic out and drive out the remaining moisture in it. The holes allow the molten plastic to flow out and the molten alu to pour in.

No updates recently. Ive been making a little side money with my router that is subsidizing my newest tool, a 1982 HURCO KMB-1. Im upgrading this little sweethart to run on Mach3. It should be able to finish a few projects I have going on. lol

Had to build a crane to get it off the trailer. The crane itself weighs 1800lbs and should be good for 10k lbs

Needless to say, I had to have another crane to erect this crane. Whew that was a crazy dayLast edited by godzillus; 12-07-2016, 11:26 PM.

Comment

-

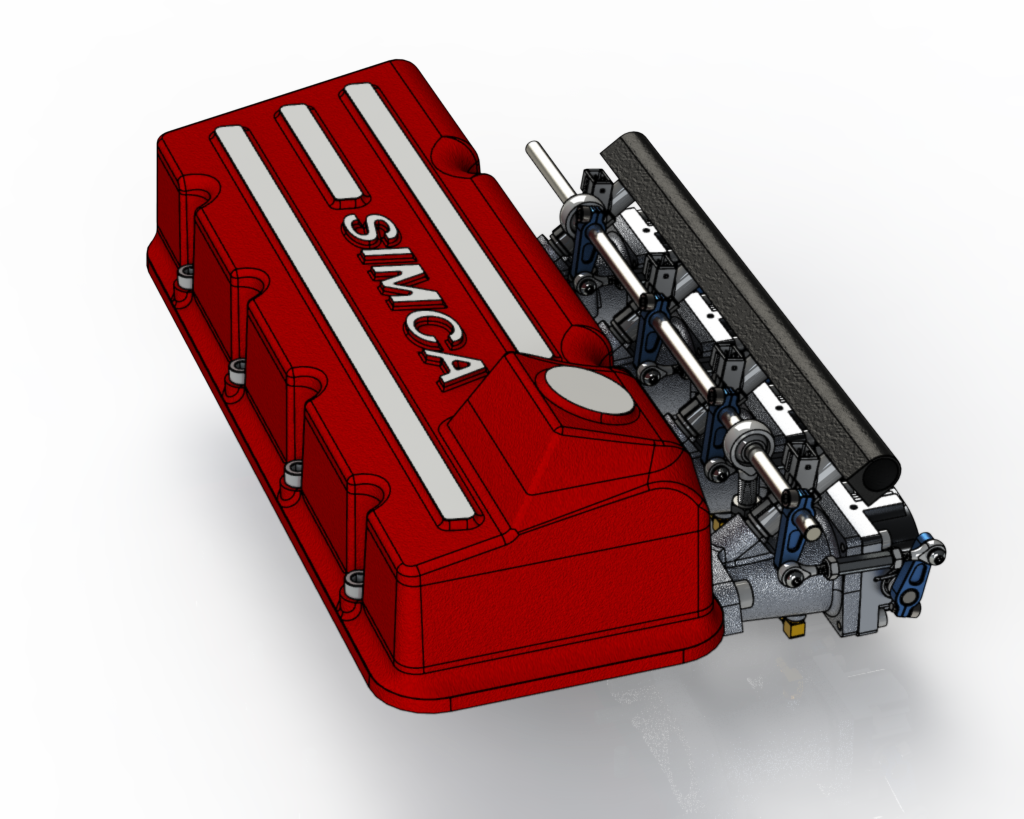

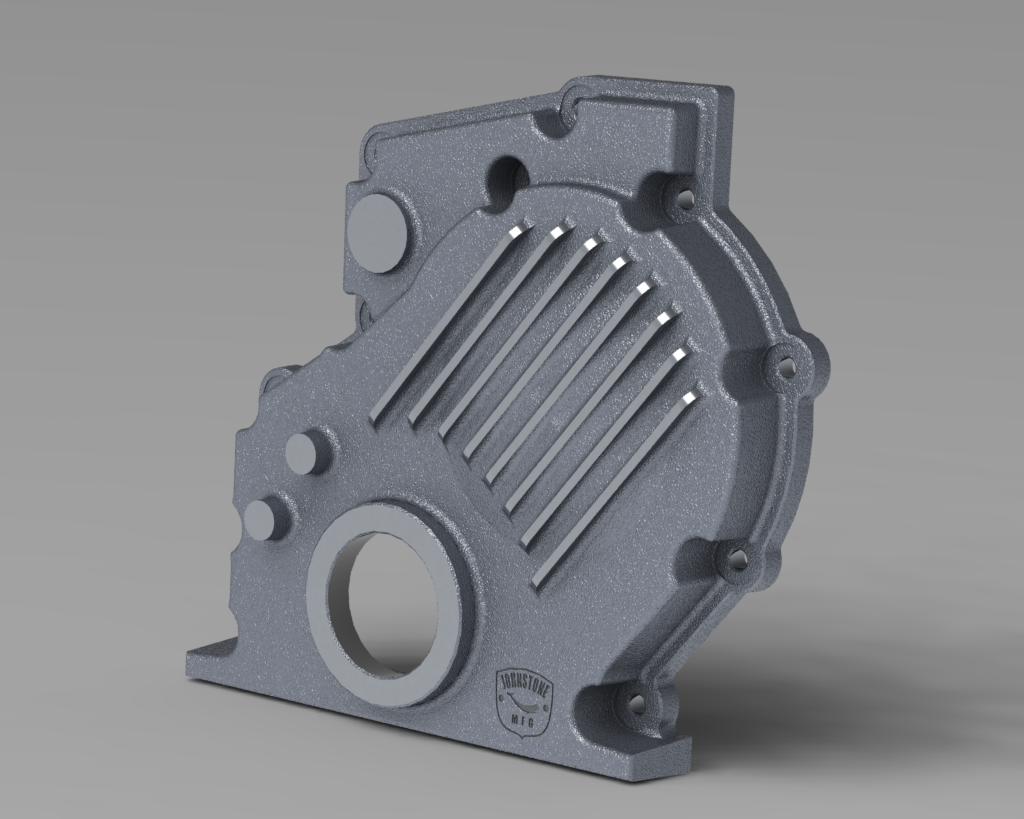

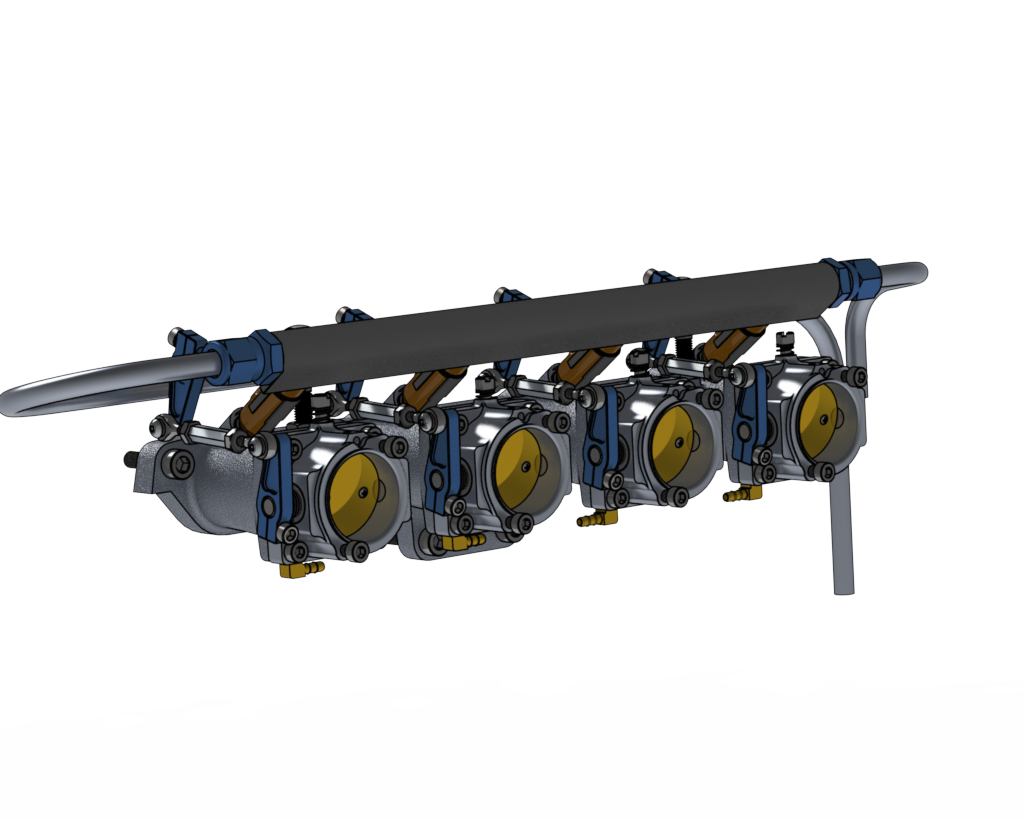

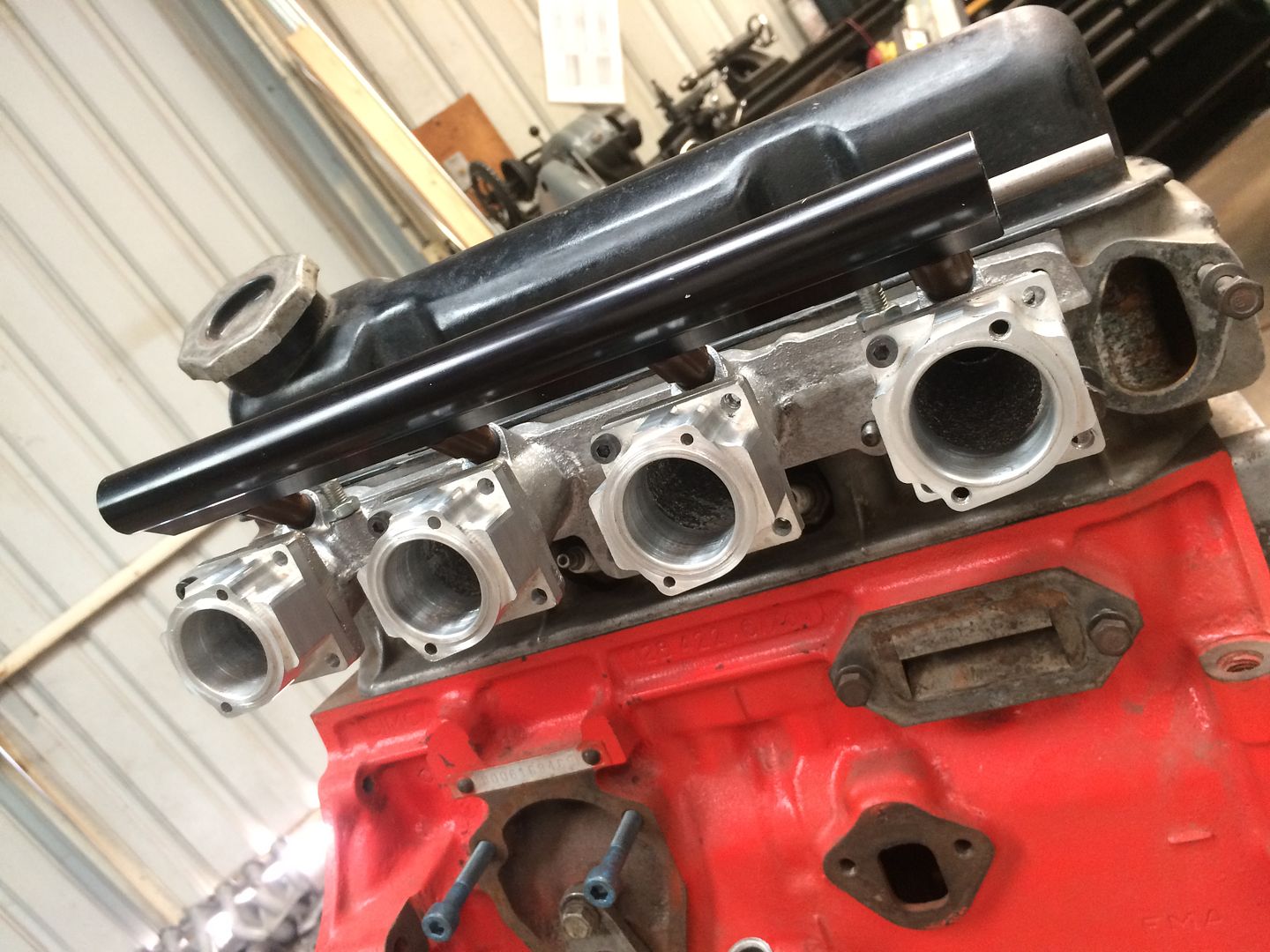

Here is the manifold, valve cover, throttle bodies, and timing chain cover I will make for the simca. Designed in SolidWorks.

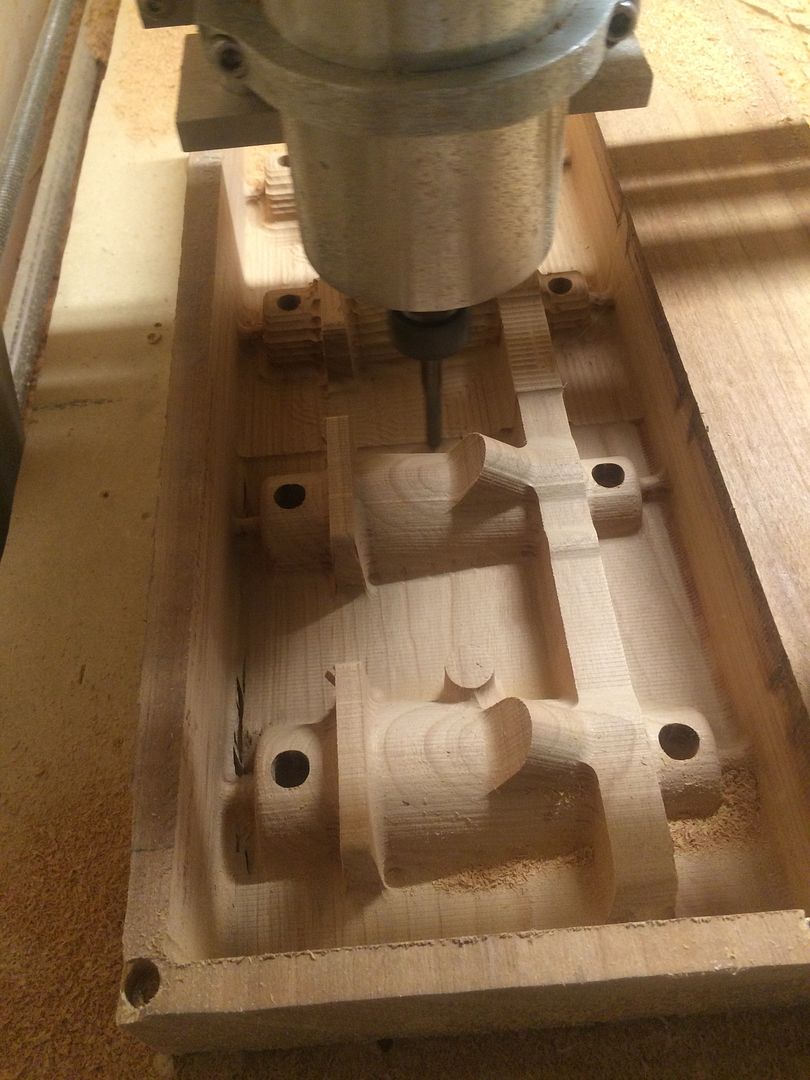

Here is the CNC Router I built to cut all of the sand casting molds.

Cutting the cope of the 2 piece mold of the manifold.

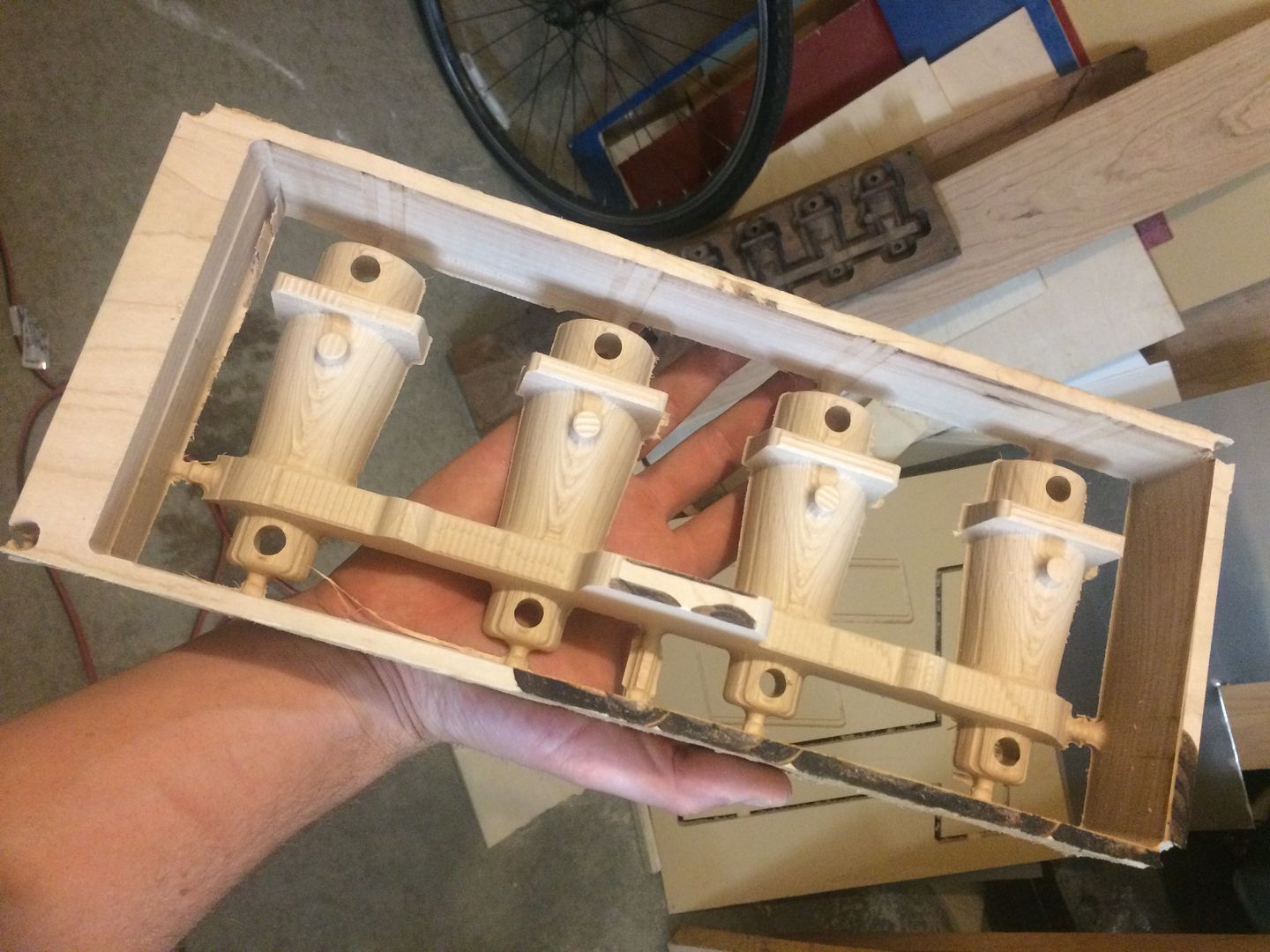

Here is the drag. Made of maple. Hardwoods machine really well, but are a bit expensive.

All 4 parts of the manifold mold. The walnut bits are the two halves of the core box.

Rammed up the sand

Installed the cores in the molds

Comment

-

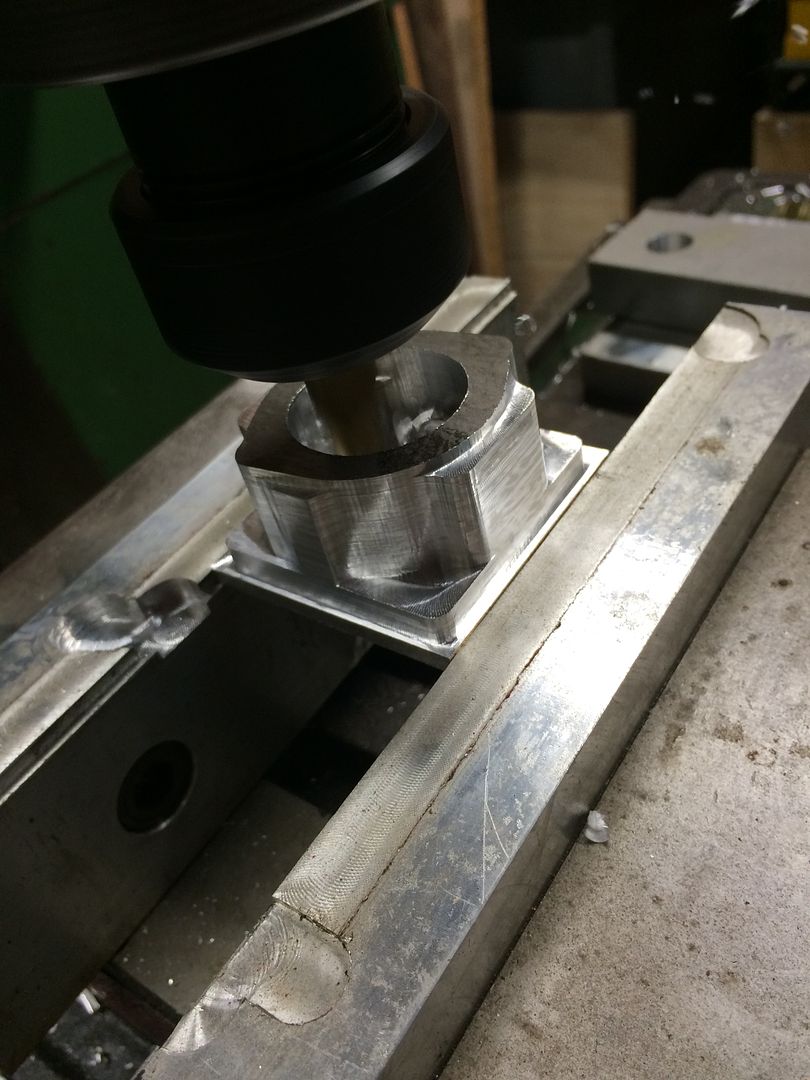

I got the Hurco CNC running on PC at this point and freshened up the display and machined up a tool holder. 21'' touchscreen display.

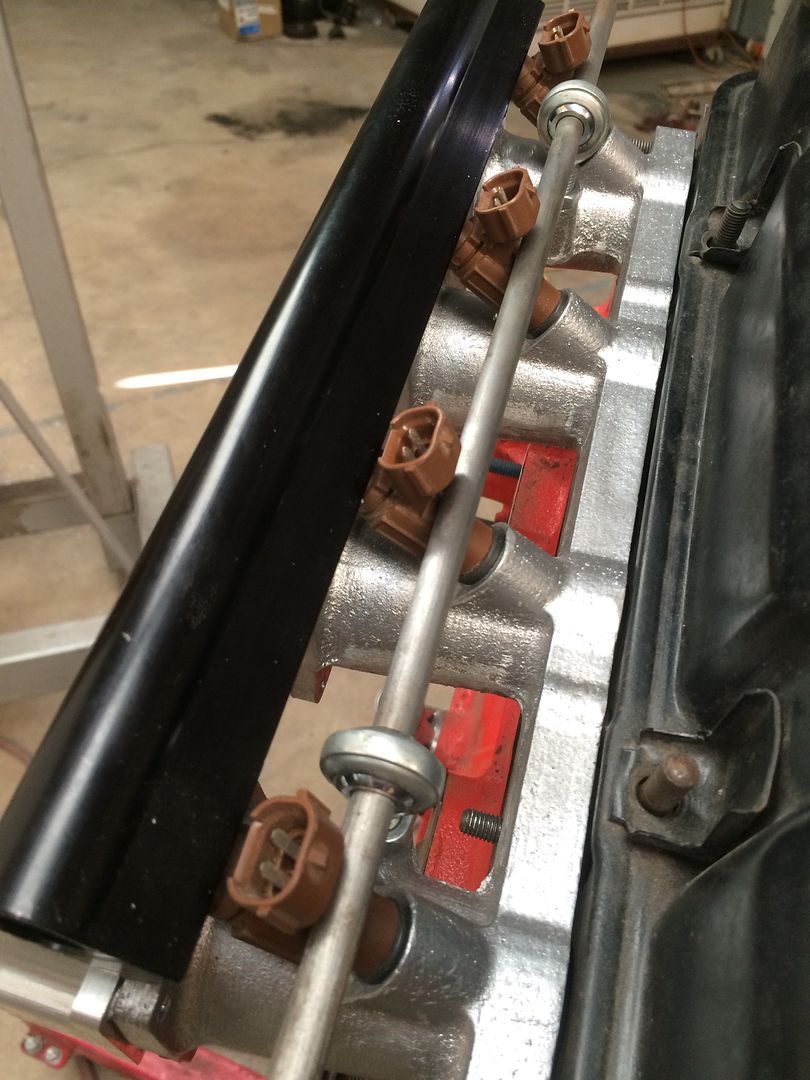

Machined up the fuel rail.

Machined the throttle bodies

The bore had a bit rough surface finish, as I wasnt running coolant. Its ok, I machined them undersized to be honed on the lathe.

Comment

-

Thanks fellas. Working on the valve cover mold this morning. Im running a paying job on the mill while I have this cut on the router. I 3d printed the text out of ABS. It sands well and will be glued in place and skimmed with bondo and high build primer

Comment

-

you sir are an incredible individual! never stop what you are doing!

Originally posted by BozoBubbleStance bug bites hard, man, you ain't gonna shake it.

Truck Build

Instagram: somestancekid

Comment

Comment