Announcement

Collapse

No announcement yet.

We can rebuild it. 91 Golf

Collapse

X

-

Guest repliedLooking good.

Guest repliedLooking good.

-

Thanks guys. Questions, comments, advice are always welcome.

In the midst of the build I picked up a MK3 rear beam off a friend. It uses the same brackets that the mk2 uses it will push out the width around half an inch on each side. Everything else is the same. The main difference is it uses 56mm dia bushings while the mk2 uses skinnier 44.5mm bushings.

VW decided to use an 8mm allen head on the carrier bolts. 3 out of 4 were stripped out before I got to them. I had to weld a nut onto the allen heads and turn them out.

Proportioning valve spring

The prop valve also uses long thin allen type bolts that have an acorn seat so they sit flush when they are tightened to the driver side beam braceket into some welded on nuts.

As usual these were seized, heads broke off. I had to cut off the welded nuts on the bracket to take off the prop valve which probably stopped functioning like it should years ago.

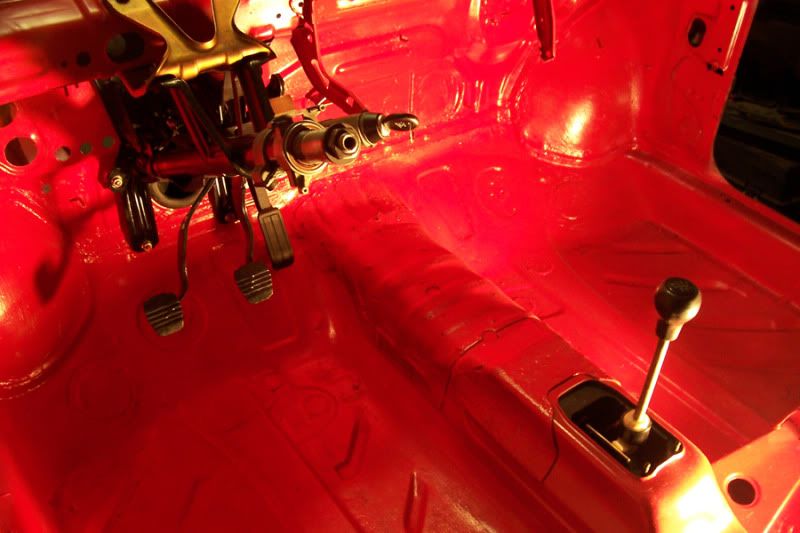

This picture is going back in time but the beam and brackets were treated to a wire wheel to get the rust off the welds. It was covered in rust bullet and painted. You can also see the shifter box here.

The the beam was really the only thing I could use out of everything that came with it. I took apart the rear calipers and found the coating on the pistons was pretty pitted so a rebuild kit was useless. They're good for cores at least. Stub axles had deep scratches in them. It looked like the bearings grenaded in the past. Rotors were also trash.

The bushings were a real treat. Chances are if your mk2 or 3 has never had these changed out the rubber is just floating around in its metal sleeve. You have to make a relief cut in the sleeve to get them to budge.

Once the beam was painted and bare I threw in a bildon motor sport style torsion bar to keep it from twisting. I will never drill one out again.

Makeshift bearing press I made.

Almost there. You want the metal collar to extend 8mm past the socket. Spec is the same for mk2 and 3.

Leave a comment:

-

amazing work! attention to every single detail = win! love this built, cant wait to see this mk2 finished!

Leave a comment:

-

im loving this. I had a 91 JEtta Coupe that was written off cause i had the infamous rot around the windshield. I should have fixed it.

Leave a comment:

-

Looking good! I totally LOVE builds where everything gets renewed and theres loads of pictures. Keep it up.

Leave a comment:

-

awesome work!!

my buddy has a 92 that he bought in pretty rough shape to and is in the process of restoring, hopefully like this.

props dude, i'm excited to see this "resurrection"

Leave a comment:

-

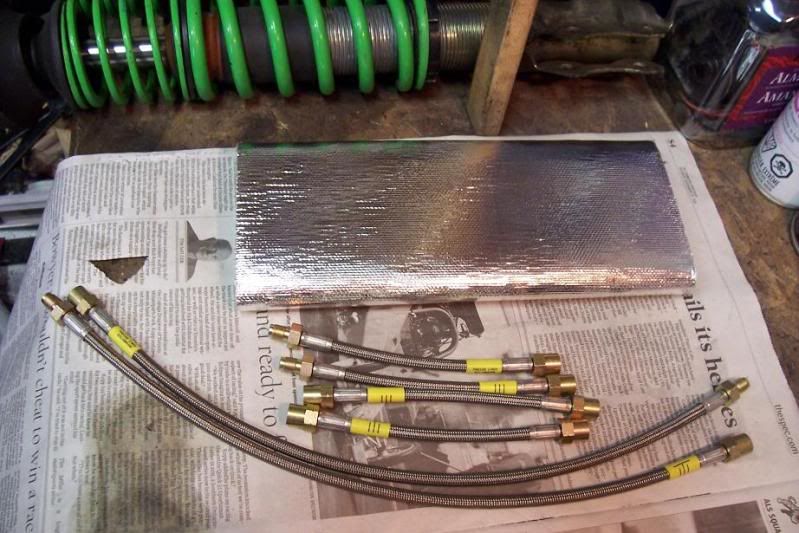

Fresh mk3 calipers and carriers. New hardware and boots.

Rotors are simple blank Brembo 10.1"

Steel braided lines from Eurosport

The coils are Weitec XS, Height/dampening.

The pads are the thick TRW 15mm's. Loved these as far as longevity is concerned.

New vr6 strut mounts,bearings are nuts were used on the front.

Leave a comment:

-

Some more pics of the progress.

I didn't get any pics of this but the exhaust tunnel heatshield was removed and the shifter box dropped disassembled with a full rebuild kit. While all that stuff was out any spots of rust were wire wheeled away, covered in rust bullet, seam sealer, a ton of rocker guard. It's a pain in the ass without a rotisserie and crawling underneath it with a grinder and painting after licks bag.

Drivers side rocker guard

Bottom of the floors. You can see just how rusted the beam is in the back along with the tank straps.

Shifter box went back in a long with the tunnel shield. Had to reuse it because it would be impossible to locate one in better shape.

With the shifter box in put up the subframe, bolted it up according to spec.

Also threw in a adhesive backed heatshield since you won't find an oem one and I didn't want to use an enormous mk3 one. The exhaust runs so close to everything there its a piece of mind.

Before throwing in the steering column I replaced the ignition switch in it. Gave it a quick spray in black and regreased the ujoints.

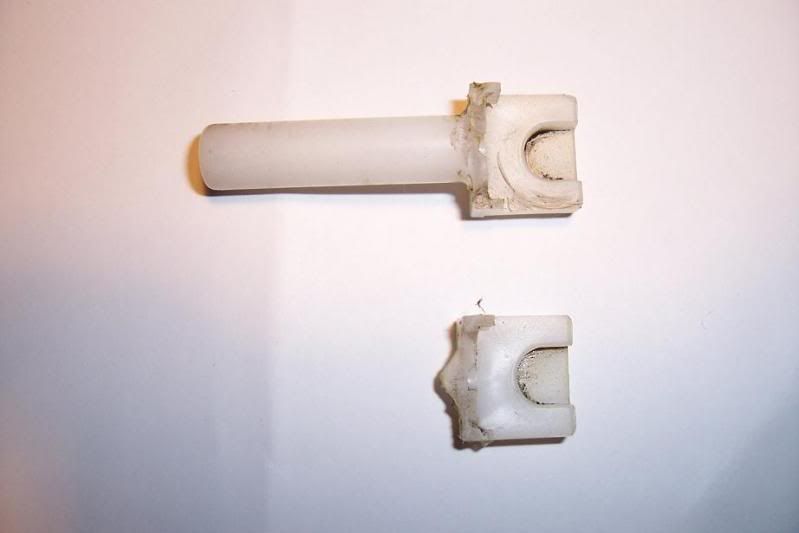

Clutch return spring piece snapped on me

I was too lazy to go to the dealer so I just fabbed up a steel one.

Mk3 22mm master cylinder, new reservoir.

Leave a comment:

-

I am backtracking posting the progress there is a good chance I might forget certain steps or details. Sorry about that.

Took a break from the body to refurbish the steering rack.

Centered and buttoned up.

Mk3 10.1" Spindles, new bearings, hubs, balljoints, rod ends.

Balljoints are coupled with PMW balljoint extenders. The spindle tie rod arm was drilled out to accept a taper sleeve allowing the running of the rod end underneath as opposed to the top to keep the bumpsteer in check.

Out with the old..in with the not as old.

Stitched the front crossmember and repainted it. Its fitted with 4 powerflex bushings and a Bahn Brenner solid front mount.

I got a mk2 subframe with control arms that was in far better shape than the original one.

It was still cleaned up, had the seams stitch welded and repainted along with the control arms. Control arms were fitted with R32 rear bushings and poly front. New balljoint hardware.

The sway is the OEM 17mm with new links/energy bushings.

The tranny mount is G60, rear engine is non-hydro TT heavy duty.

The shifter bracket was sourced from another car repainted and fitted with all new bushings. Missing Linkz UHMW relay ball.

If you're ever pressing these at home. Use your old strut top hats.

The one piece I saved of the old subframe were the sway brackets. The bolts snapped off in the nuts. I had to grind them down and weld on some new nuts.

So far all the hardware is new 10.9. Nothing better than new bolts.

Restored a crappy rad support with new latch.

Last edited by renngolf; 01-10-2011, 12:23 AM.

Last edited by renngolf; 01-10-2011, 12:23 AM.

Leave a comment:

-

Hopefully enough to satisfy interest until I can start working on it again when it warms up.Originally posted by Zic View Postmmm i like, hope you have done alot of progress. that means alot of pictures, we all like pictures you know.

Scrap

A bit more progress on the floors. Looking back I wouldn't do this again but its the I might as well's that get you. Rear portions were easily cracked and removed with a chisel. The front's were a gummy kind of tar shit that was a nightmare.

Rust Bullet

Seeing Red

Not such an eyesore anymore

Leave a comment:

Leave a comment: